Cold milling machine W 50 - Wirtgen GmbH

Cold milling machine W 50 - Wirtgen GmbH

Cold milling machine W 50 - Wirtgen GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

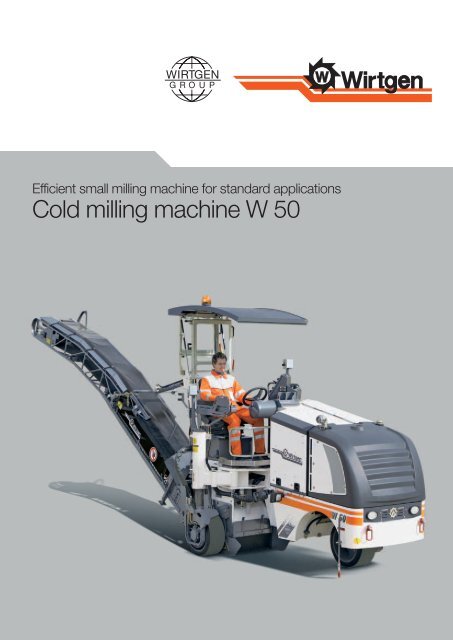

Efficient small <strong>milling</strong> <strong>machine</strong> for standard applications<strong>Cold</strong> <strong>milling</strong> <strong>machine</strong> W <strong>50</strong>

The economically efficient alternativefor countless small <strong>milling</strong> jobsEfficiency is the W <strong>50</strong>’s hallmarkThe W <strong>50</strong> is the perfect intermediate-size <strong>machine</strong>between the tried-and-tested small <strong>milling</strong> <strong>machine</strong>models W 35 DC and W <strong>50</strong> DC, and fully meets the requirementsof standard users. Whether <strong>milling</strong> on small to mediumsizedroads, carrying out small repairs or <strong>milling</strong> tie-ins,<strong>milling</strong> around manhole covers or removing asphalt strips:The W <strong>50</strong> performs all the jobs that are typical of a small<strong>milling</strong> <strong>machine</strong> with tremendous economic efficiency. Easeof operation, low fuel consumption and the <strong>machine</strong>’s soliddesign do their bit to guarantee surprisingly low operatingcosts. It goes without saying that many different customerexpectations are also taken into account, for the W <strong>50</strong>’sequipment concept offers a tremendous variety of individualoptions.

The W <strong>50</strong> is distinctive for itstried-and-tested equipment featuresand extremely easy handlingCompact,dependable andeconomicallyefficientIn accordance with thecustomer’s specification:<strong>machine</strong> without loadingconveyorThe W <strong>50</strong>’s intuitive control interface and ergonomicallyoptimized operator’s platform considerably increasecomfort for the <strong>machine</strong> operator.Additional options, such as different conveyor choices,canopy, three-wheel or four-wheel design, or FCSextend the range of applications and ease of operation.Highly precise <strong>milling</strong> results of top quality can beachieved with the optional LEVEL PRO levelling system,which has been specially developed for use in <strong>milling</strong><strong>machine</strong>s.The W <strong>50</strong>’s compact design guarantees ease oftransport, exceptional manoeuvrability, and goodoverall view.2// 3

Large surfaces are no problemfor small <strong>machine</strong>sA class of its own in practical operationThe W <strong>50</strong> impresses not only when swiftly removingsurface courses at depths of up to 4 cm. It cuts a finefigure also when <strong>milling</strong> off several layers or even entireasphalt packages at depths of up to 16 cm. The performancediagram is proof that the small <strong>milling</strong> <strong>machine</strong> iscapable of achieving high daily production rates.The schematic diagram on the opposite page can be usedfor a rough calculation of the practical <strong>milling</strong> performanceto be expected. An allowance factor takes account of influencingfactors that may reduce the performance, such ashindrances to the work resulting from traffic, waiting timesfor trucks, non-contiguous <strong>milling</strong> areas or road fixtures.

Milling depth (cm)161412Hard asphaltSoft asphalt108Most frequent operating area64200 <strong>50</strong> 100 1<strong>50</strong> 200 2<strong>50</strong> 300 3<strong>50</strong> 400 4<strong>50</strong> <strong>50</strong>0Theoretical areaperformance(m 2 /h)Economically efficient<strong>milling</strong> of surfacesFree motorway section(allowance factor: 0.7)0 <strong>50</strong> 100 1<strong>50</strong> 200 2<strong>50</strong> 300 3<strong>50</strong>Practical areaperformance(m 2 /h)Country road with road fixtures(allowance factor: 0.5)0 <strong>50</strong> 100 1<strong>50</strong> 200 2<strong>50</strong>Practical areaperformance(m 2 /h)An allowance factor of 0.3 isused where space is limitedHeavily trafficked inner-city road(allowance factor: 0.3)0 <strong>50</strong> 100 1<strong>50</strong>Practical areaperformance(m 2 /h)Calculation of the area performance,taking account of different job siteconditionsThe modern engine and direct mechanical <strong>milling</strong> drumdrive guarantee full performance up to a <strong>milling</strong> depthof 160 mm.The <strong>machine</strong>'s powerful, flexible conveyor system canbe depended on to preclude performance losses duringloading of the milled material.The allowance factor is between 0.7 for free sectionsof road and 0.3 for heavy urban traffic.4// 5

Mature engineering guarantees highdaily production ratesReliable high-tech works the ground<strong>Wirtgen</strong> has been the leader in cutting technology formany years, guaranteeing high-quality <strong>milling</strong> results.An optimized arrangement of the toolholders on the <strong>milling</strong>drum and clever tooling of the drum edges ensure a clean<strong>milling</strong> texture and quiet operation of the <strong>machine</strong>. The<strong>milling</strong> drum is fitted with welded toolholders and worksagainst the direction of travel in an effectively sealed <strong>milling</strong>chamber. Clean loading of the milled material is ensuredby the hydraulically height-adjustable scraper blade:Depending on its position, all or just part of the milledmaterial is loaded on trucks, while the remainder is left inthe milled cut.

Cutting tools per cubic metre2,52,01,51,00,5Perfect <strong>milling</strong>results0,025 <strong>50</strong> 75 100 125 1<strong>50</strong> 175Milling depth in mmCutting tools per m 3 at high wear and tear Cutting tools per m 3 at low wear and tearCutting tools per m 3 at medium wear and tearCutting tool wear as a function of the <strong>milling</strong> depth and the properties of thepavement to be milledThe scraper blade islocked when in raisedposition to allow convenientreplacement of cutting toolsLow cutting tool wearcuts operating costsWhen in floating position,the scraper blade permits fullloading of the milled materialThe scraper blade can be opened hydraulically toprovide the <strong>machine</strong> operator with ample room forthe replacement of cutting tools.To ensure the safety of the <strong>machine</strong> operator, the <strong>milling</strong>drum is switched off automatically when opening thescraper blade.Cutting tools are replaced quickly and easily usingstandard tools.The rotating point-attack tools from <strong>Wirtgen</strong> aresynonymous with tried-and-tested, highly durablecutting-edge technology.6// 7

Making child’s play of workon the job siteFCS fine <strong>milling</strong> drumMilling width:Milling depth:Tool spacing:<strong>50</strong>0 mm0 – <strong>50</strong> mm6 mmFCS micro fine <strong>milling</strong> drumMilling width: 300 + 2 x 25 mmMilling depth:0 – 30 mmTool spacing:3 mmFCS micro fine <strong>milling</strong> drumMilling width:<strong>50</strong>0 mmMilling depth:0 – 30 mmTool spacing:3 mmFCS makes the W <strong>50</strong> an all-rounder on the job siteThe small <strong>milling</strong> <strong>machine</strong> W <strong>50</strong> is fully equippedfor meeting the daily challenges on the job site.A mechanically driven <strong>milling</strong> drum guarantees maximumefficiency and top performance. The power belts of the<strong>milling</strong> drum drive ensure optimum transmission of power,while successfully absorbing peak loads. The optional FCSoffers an even larger range of applications – the patentedquick-change system for <strong>milling</strong> drums turns the W <strong>50</strong> intoan all-rounder, guaranteeing full utilization of the small <strong>milling</strong><strong>machine</strong> at all times. The system enables the W <strong>50</strong> to befitted with <strong>milling</strong> drums of different working widths and toolspacings easily and in an extremely short period of time.

Changing the<strong>milling</strong> drum in afew swift movesRaise the side plates whentravelling over obstacles, orpress down on the ground asand when requiredThe <strong>milling</strong> drum is easily pulledoff the shaft after unscrewingThe hydraulically pressurizedside plates reliably sealoff the drum housingThe <strong>machine</strong>’s electrically operated water spraysystem reduces cutting tool wear and tear, as well asthe development of dust during the <strong>milling</strong> operation.The side plates on both sides of the <strong>milling</strong> drum canbe raised, preventing them from digging into unpavedshoulders.The nozzles of the water spray system can beremoved and cleaned in no time at all.Special <strong>milling</strong> drums for different applications areavailable upon request.8// 9

Fast and flexible loading of materialThe loading conveyor canbe adjusted in height …… and slewed by 25° to the leftand 20° to the right, permittingloading to be effected to the sideEconomically efficient material loading is most importantReliable loading of the milled material is of crucialimportance when it comes to ensuring the smoothcompletion of a <strong>milling</strong> site. That’s where our W <strong>50</strong> makesa strong showing. Customers can choose from as many asfour different loading conveyor options. Whether the milledmaterial is loaded on trucks or into the bucket of a wheelloader, deposited as a windrow next to the <strong>machine</strong>, or leftin the milled cut – efficient removal is guaranteed at alltimes. The conveyor belts are fitted with robust, sturdy cleatsto ensure powerful transport of the milled material. All conveyorsare adjustable in height and can be slewed to eitherside. The conveyor belt speed is continuously adjustable toenable even large trucks to be filled right to the top.

The W <strong>50</strong>’s optional foldingconveyor facilitates transportAlways on thesafe side with fourloading optionsThe short conveyor permitsloading into the bucket of a wheelloader or onto a mini dumperThe W <strong>50</strong> leaves the milledmaterial in the cut when workingwithout loading conveyorThe W <strong>50</strong> is available with the following conveyoroptions: without conveyor, with one-stage short conveyor,one-stage long conveyor, or long folding conveyor.A special coupling device enables the loading conveyorto be attached or removed in a few swift moves by oneperson only.The optionally available folding conveyor shortens thetransport length by approx. 2 m, enabling the small<strong>milling</strong> <strong>machine</strong> to be transported on smaller trailers.The conveyor’s hydraulic power take-off can optionallybe used for ancillary equipment like, for instance,a hydraulic hammer.10 // 11

Effective <strong>milling</strong> when space is limitedThe W <strong>50</strong> can turn nearly on thespot when the front wheel issteered to maximum lockFour instead of three wheelsfor even better tractionA steering angle indicator on theengine cowling shows the position ofthe front wheel (3-wheeled model only)Unmatched in terms of manoeuvrabilityA compact, manoeuvrable cold <strong>milling</strong> <strong>machine</strong> onthree (optionally four) individually driven wheels – that’sthe W <strong>50</strong> from <strong>Wirtgen</strong>. The <strong>machine</strong>’s superior manoeuvrabilityin space-restricted conditions enables many jobs ona <strong>milling</strong> site to be completed with much more ease andspeed. An extremely large locking angle of the front axle ispart and parcel of the entirely coherent <strong>machine</strong> concept,enabling extremely tight <strong>milling</strong> radii when <strong>milling</strong> aroundmanhole covers or gas valves. The rear right support wheelcan additionally be folded in or out quickly to improve the<strong>machine</strong>’s side clearance. This practical feature permitshighly precise <strong>milling</strong> along obstacles like, for instance, wallsor traffic islands.

Permanent all-wheel drive withengageable differential lock is astandard featureManoeuvrabilityoffers significant timeadvantagesThe support wheel is folded inquickly in a few swift movesThe W <strong>50</strong> is capable of <strong>milling</strong> flushto kerb with the support wheelfolded in front of the drumThe W <strong>50</strong>’s hydraulic, finger-light steering supports the<strong>machine</strong> operator when working in narrow sections.The travel speed can be infinitely varied from zero tomaximum speed in both <strong>milling</strong> gears and in travel gear.A hydraulic flow divider acts as differential lock,guaranteeing permanent and uniform traction all thetime regardless of ground conditions.The <strong>machine</strong>’s large ground clearance protects thelower part of the chassis from being damaged by, forinstance, high kerbstones.12 // 13

Ergonomics and operator comfortRelaxed working for extended periods of timeErgonomics boost performance! For precisely thatreason, the development of the W <strong>50</strong> has produceda role model of user-friendliness and maximum customerbenefit. The control elements are arranged clearly, withineasy reach and within the operator’s immediate field ofvision. The optional driver’s seat, which can be movedbeyond the right edge of the <strong>machine</strong>, and comfortableworking in both standing and sitting positions ensure anexcellent view of the <strong>milling</strong> edge and the working environment.It goes without saying that the steering wheel can betilted to adapt to each operator’s personal preferences.Altogether, the intelligent workplace design prevents fatigueand ensures relaxed working for extended periods of time.

In line with practical requirements –the clearly structured main controlpanel is within easy reachFeelingcomfortablehelps to do afaster jobLockable covers protect thecontrol elements from damageSimple handling,single-handedlyThe tilting steering wheel andample legroom increase theoperator’s comfort when workingin standing positionThe <strong>machine</strong> operator has a full view of the <strong>milling</strong> edge,which guarantees maximum safety.A multi-functional display at the control panel keeps theoperator informed of all relevant operating states.The spring-mounted driver’s seat can be adjusted in thedirection of travel, in height and lengthwise, offering amaximum degree of individual comfort.The W <strong>50</strong>’s main functions are easily operated via thecontrol elements integrated in the right-hand armrest.14 // 15

The <strong>Wirtgen</strong> levelling systemguarantees precise work resultsConvenient levellingwith LEVEL PROScales installed on bothsides indicate the <strong>milling</strong> depthwith pin-point accuracyConvenient and simple operation isa mark in favour of the LEVEL PROcontrol systemFull control of <strong>milling</strong> depth and slopeA unique feature in this <strong>machine</strong> class, the innovativeLEVEL PRO automatic levelling system (optional) enablesthe performance capacity of small <strong>milling</strong> <strong>machine</strong>s tobe increased even further. Wire-rope and cross slope sensorsintegrated in the LEVEL PRO levelling system ensureprecise, automatic control of <strong>milling</strong> depth and slope. Theuser-friendly LEVEL PRO control panel is arranged on theoperator’s platform and within the <strong>machine</strong> driver’s immediatefield of vision. Its clearly structured, intuitive designmakes operation of the W <strong>50</strong> simple and significantlyincreases operator comfort. Target and actual values of the<strong>milling</strong> depths left and right are displayed on easy-to-read<strong>milling</strong> depth indicators all the time. Target values are easilypre-programmed, saved and called up as required.

Power under the bonnet –yet low in fuel consumptionP (kW)M [Nm]Economicallyefficient travel drive60260<strong>50</strong>240402203020020180101600100011001200130014001<strong>50</strong>0160017001800190020002100 2200 2300 24001402<strong>50</strong>0 [1/min]Characteristic curve of engineoutput and torqueExhaust fumes are conductedaway from the operator’s platformin the front part of the <strong>machine</strong>Power is supplied by astate-of-the-art diesel engineThe major hallmarks of the tried-and-tested 4-cylinderdiesel engine are high power combined with economicaloperation.Thanks to low noise levels, the soundproofed enginecompartment protects both the <strong>machine</strong> operator andthe environment from noise pollution.The highly efficient <strong>milling</strong> drum drive in the W <strong>50</strong> paysfor itself through low fuel consumption.16 // 17

An ingenious maintenance conceptpays for itself dailyLittle effort is needed to keep the W <strong>50</strong> in top shapeThe W <strong>50</strong> impresses with a simple maintenance concept.The small amount of maintenance work has beenreduced to a small number of individual inspection points.Wide opening doors on both sides enable maintenance tobe carried out quickly and easily from the ground. Engine,service points and filters are all located within easy reach.Water or fuel are refilled just as quickly via the easily accessiblefilling ports. The surprisingly simple maintenanceconcept will ultimately give the <strong>machine</strong> user a lucrativelead, allowing rapid completion of the construction work.

Clearly arrangedmaintenance pointsFast maintenancewins preciousoperating timeThe W <strong>50</strong> offers sufficientspace for storage, includingthe storage compartmentunder the driver’s seatWide opening wing doorsprovide optimum access tothe engine compartmentAll maintenance points are within easy reach thanksto the wide opening engine cowling.The W <strong>50</strong> is equipped with a spacious, lockablestorage compartment for tool containers or tools.A comprehensive tool kit is part of the standardscope of delivery.18 // 19

Working under controlled conditionsday and nightMilling regardless ofthe time of dayFlexible spotlights are attached tothe <strong>machine</strong> in no time at allSafe and convenient access atthe rear side of the <strong>machine</strong>When switched on, the<strong>machine</strong>’s lighting systemilluminates the entire working areaEffective lighting system ensures safe operationAn excellent range of vision by day and night, as wellas controlled working even in difficult conditions – theW <strong>50</strong> is a role model when it comes to meeting these vitalcriteria. The advantages are obvious: In addition to ensuringthe safety of the <strong>machine</strong> driver and producing a clean workresult, undisturbed working at night also increases the<strong>machine</strong>’s overall utilization. Optimum illumination is ensuredby two headlights at the front, as well as several additionallamps that can be attached in any position on the <strong>machine</strong>.The safety package is completed by quickly accessibleemergency stop buttons, exterior mirrors, a clearly audiblereversing horn and illuminated control panel.

Loaded in no time at all andoff to the next job siteDriving the <strong>machine</strong> onto a trailer iseasy, posing no problem at allMachine transport theshort way aroundA large number of lashing lugsenable the <strong>machine</strong> to besecurely lashed onto the traileror loaded by craneThe W <strong>50</strong> reduces its sizefor transport purposesSafe and fast loading permits the cold <strong>milling</strong> <strong>machine</strong>to be transported to the next job location as quickly aspossible.The W <strong>50</strong> has the ideal size not only for low-loaders butalso for small, low-cost trailers.The optional canopy can be folded down convenientlyvia gas-filled springs to save space during transport.<strong>Wirtgen</strong>’s product portfolio offers made-to-measuretrailers for transport of the W <strong>50</strong>.20 // 21

The dependable W <strong>50</strong>in versatile operationA good view of the <strong>milling</strong> edgepermits precise <strong>milling</strong> flush to kerbMilling along road fixturesis no problem at allThe W <strong>50</strong> masters its range of applications with superior easeA normal working day for the W <strong>50</strong> can sometimes bequite multi-faceted: In the morning, a trailer transportsthe <strong>machine</strong> to the job site, where it is quickly unloaded.Work commences immediately, consisting of the many jobsthat are typical of a small <strong>milling</strong> <strong>machine</strong>: On this day, theW <strong>50</strong> will carry out work that the large <strong>milling</strong> <strong>machine</strong>working on the same job is not capable of performing.The pavement around some manhole covers needs to bemilled off first, followed by pavement strips in difficult bends.At around lunchtime, the rear right wheel is folded in withoutfurther ado to mill off any remaining pavement strips flush tokerb. Just before the working day ends, the W <strong>50</strong> quicklymills two wedge-shaped tie-ins. That’s it for today! All thatremains to be done is load the <strong>machine</strong> because the nextjob site is waiting on the next day.

Milling tie-ins in acrossroad areaThe W <strong>50</strong> is masterof many tradesMilling larger surfaces isno problem at all for the W <strong>50</strong>Milling around a manholecover is child’s play, indeedOn <strong>milling</strong> sites, the W <strong>50</strong> is an ideal companion of large<strong>milling</strong> <strong>machine</strong>s which are responsible for <strong>milling</strong> off thelarge surfaces.The compact small <strong>milling</strong> <strong>machine</strong>’s exceptionalmanoeuvrability makes it the ideal candidate in particularfor jobs in space-restricted conditions.A broad variety of special <strong>milling</strong> drums are available,including a slot cutting ring for cutting butt joints, or a<strong>milling</strong> drum for producing water gutters.Three different loading conveyor options broaden the<strong>machine</strong>’s spectrum of applications, while ensuringoptimum completion of jobs at the same time.22 // 23

Illustrations are non-binding and may include customized fittings. Subject to technical changes.Performance data depend on operational conditions. No. 03-10 EN-04/08 © by <strong>Wirtgen</strong> <strong>GmbH</strong> 2008. Printed in Germany<strong>Wirtgen</strong> <strong>GmbH</strong>Reinhard-<strong>Wirtgen</strong>-Straße 2 · 53578 Windhagen · GermanyPhone: +49 (0) 26 45 / 131-0 · Fax: +49 (0) 26 45 / 131-242Internet: www.wirtgen.com · E-Mail: info@wirtgen.com