You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

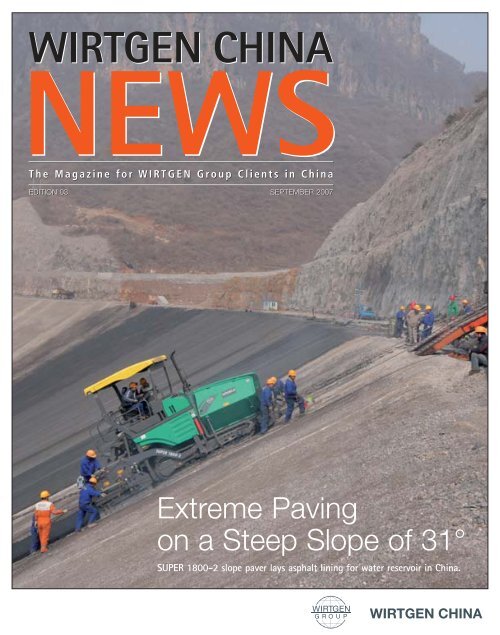

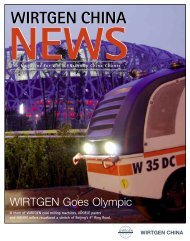

WIRTGEN CHINANEWSThe Magazine for WIRTGEN Group Clients in ChinaThe Magazine for WIRTGEN Group Clients in ChinaEDITION 03 SEPTEMBER 2007Extreme Pavingon a Steep Slope of 31°SUPER 1800-2 slope paver lays asphalt lining for water reservoir in China.

WIRTGEN CHINA NEWSEDITORIALPRODUCT PRESENTATION 20VÖGELE DEVELOP NEW MACHINETECHNOLOGY FOR “HOT ON HOT”PAVING. “INLINE PAVE”: LOWERCOSTS, HIGHER QUALITYJOB REPORT 36Dear Friends,The new 2007 WIRTGEN CHINA NEWS is covering a really unique story. The slope paver version of the VÖGELESUPER 1800-2 on a mission in Henan province. Have a look at this water reservoir job site by yourself andwitness WIRTGEN Group’s ability to adapt to even the toughest job site situations.Recycling of asphalt roads is an issue which becomes ever more popular also in China now. In this issue wewill report about the introduction of the biggest cold recycler, the WIRTGEN WR 4200, to the Chinese market.On the Jingshen expressway you can see this “giant” recycling existing asphalt layers. The province of Shaanxihas become the pioneer in this field and 6 units of WIRTGEN KMA 200 cold recycling machines on several jobsites in the Shaanxi expressway system “foamed” the existing worn out asphalt layers to a new life. WIRTGENChina does not only deliver the machines to do the job but has a dedicated team of specialists to help toexplore new horizons in road rehabilitation, help contractors to do their job faster and more profitable andsupport the relevant road authorities in setting up specifications for the different road recycling methods.Mike Yu, Luson Yu and Dr. Alan Shi come with a bundle of experience on road rehabilitation and asphalt recyclingand are ready to support you without hesitation.Thank you for sharing your time with us!Ulrich ReichertManaging DirectorWIRTGEN (China) Machinery Co., Ltd.Ulrich ReichertManaging DirectorWIRTGEN (China) Machinery Co., Ltd.Photo on Front Page: SUPER 1800 slope paver participating in new construction of a hydro power station in Henan Province.4COLDRECYCLINGWITH WR 4200IN TIANJINTECHNOLOGY 4WR 4200 LAUNCHED IN TIANJINA giant at work: The WR 4200 Cold Recyclerdoes milling, mixing and paving work andcompacts the base of the Jingshen Expressway –all that in a single pass.- - - - - - - - - - - - - - - - - - - - - - - -JOB REPORT 8WIRTGEN COLD RECYCLINGCold recycled mix is a valuable road buildingmaterial, based on RAP. With the KMA 200,this paving material can be produced quicklyand in an environmentally friendly manner –everywhere in the world.- - - - - - - - - - - - - - - - - - - - - - - -STORY 1210-YEAR EMPLOYMENTThey have been emploed in the WIRTGEN Groupfor 10 years – a good reason to take a portraitof Edwin Cai, Gary Wang und Michael Kwan.- - - - - - - - - - - - - - - - - - - - - - - -WIRTGEN GROUP WORLDWIDE 16RELIABLE, ACCURATE, FAST:WIRTGEN GROUP MACHINESCOMPLETE REHABILITATIONOF THE RUNWAY AT BELGIANAIRPORT CHARLEROI IN 6 NIGHTSPerfect logistics and top performance oflarge and small milling machines, paversand tandem rollers – based on that, buildingcontractors in Belgium got a prestigious jobdone with excellence.- - - - - - - - - - - - - - - - - - - - - - - -What do you need for placing two asphalt layersin a single pass? The InLine Pave Machines madeby VÖGELE ! Then, quality and cost-efficiencyare guaranteed.- - - - - - - - - - - - - - - - - - - - - - - -PRODUCT PRESENTATION 24CONVENTIONAL SUPER 1800-2WITH NEW SPRAYJET MODULEThe new SprayJet module turns a conventionalSUPER 1800-2 into a spray paver, which can thenbe used for a number of other road building tasks.- - - - - - - - - - - - - - - - - - - - - - - -FOCUS STORY 30SUPER 1800-2 SLOPE PAVERLAYS ASPHALT LINING FOR AWATER RESERVOIR IN CHINA:EXTREME PAVING ON A STEEPSLOPE OF 31°The reservoir holds an impressive 3 million cubicmetres of water. The reservoir’s walls with a slopeangle of 31° are being sealed with asphalt forwaterproofness. Placing the asphalt seal is acomplex challenge, taken by a special slopepaver made by VÖGELE and fulfilled impeccably.- - - - - - - - - - - - - - - - - - - - - - - -25 HAMM SINGLE DRUM ROLLERSON THE HUNAN SHAO-YONGEXPRESSWAYCompaction of the base for the expressway, some120 km long, is currently underway. An ideal jobfor the 25 HAMM rollers of contractor ShantouDaho Municipal Construction Co.- - - - - - - - - - - - - - - - - - - - - - - -PRODUCT PRESENTATION 40NEW GENERATIONOF COLD MILLING MACHINESOF THE 1-M CLASSHigher performance, higher productivity andperfect ergonomics – these are the highlightsof the new W 100 F Cold Milling Machine,successor to the successful W 1000 F model.- - - - - - - - - - - - - - - - - - - - - - - -PRACTICAL TIPS 42EACH MILLIMETRE COUNTSMaximum service life and highest qualityat the same time: In Practical Tips we showyou how to find the optimal point of timefor cutting tool change.- - - - - - - - - - - - - - - - - - - - - - - -30SPECTACULAR PICTURESOF THE VÖGELE SLOPE PAVEROPERATING IN HENAN23

WIRTGEN CHINA NEWSWR 4200 LAUNCHEDIN TIANJINOn Section K96-K98 of the Jingshen Expressway (Beijing – Shenyang), a “giant” is working withperfect efficiency; the complete process of “cold in-place recycling”, including milling, mixing,paving and pre-compaction, is all done by a single giant-sized machine, the WIRTGEN WR 4200.TECHNOLOGYThe well proven cold in-place recyclingprocess, in combination with state-ofthe-artfoamed bitumen technology, isthe key to the success of large-scalerenowned cold recycling technologythat they decided to purchase a WR 4200.a total length of 658 km. It leaves Beijingprojects with the highest qualitysince the year 2005. During this period,heading east and crosses the jurisdictionsstandards. Thanks to its large workingwidth up to 4.2 metres, the flexiblehigh-performance WIRTGEN WR 4200On Section K96-K98 of the Jinshen Expressway, after the WR 4200 Recycler, a 25-tonneHAMM roller compacts the recycled layer.they have bought several WIRTGENrecyclers and other ancillary plant such asthe WM 1000. His company was the firstThe Jingshen Expressway, which linksBeijing and Shenyang, is the only expresswayfrom Beijing to Northeast of China.of Beijing municipality, Hebei province,Tianjin municipality and Liaoningprovince. The expressway opened to therecycler is capable of recycling full trafficin China to purchase a WIRTGEN KMA 200.It comprises a very long expressway, withgeneral motoring public on Septemberlane widths in a single pass. TrafficSince purchasing the KMA 200 last year,15, 1999, after four years of work ondisruption is minimized as only one lanethey used this equipment to carry outdifferent sections. There has been ais temporarily blocked by the WR 4200.The result is a structurally rehabilitatedrehabilitation work on the Jinghu (Beijing– Shanghai) Expressway (Tianjin Section)Asphalt, 19cmdramatic increase in heavy traffic andsevere damage has been caused by theroad pavement that is precisely designedand Jincang Expressway (Tianjin – Cangzhou),overloading of vehicles transportingto carry the expected heavy traffic overusing foamed bitumen. So, when theyraw material, mostly steel and cement.its design life. In addition, it is thefastest and most economical solution forneeded to rehabilitate the JingshenExpressway this year, it is was no surpriseCement treated base, 20cmIn view of the advantages of coldthe rehabilitation of heavily traffickedrecycling with foamed bitumen in termsroads and expressways.According to Mr. Wang, Chairman ofTianjin Goldway Co. (the owner of this,the very first WR 4200 in China), theyhave investigated the possibilities of theThe WM 1000 Mixer blends cement and water into a homogenous slurry.The slurry is sprayed directly into the mixing chamber of the WR 4200.Top: New base of high bearing capacity:the existing base is cold recycled in place,adding foamed bitumen and cement, andlaid by the WR 4200.Bottom Right: The existing pavementstructure is shown below.Lime and fly ash mixture, 15cmLime stabilized soil, 15cmof cost-effectiveness, environmentalfriendliness, least disruption to traffic andshort construction time, this technologywas chosen by the project owner,Tianjin Municipal Bureau and TianjinExpressway Development Inc.45

WIRTGEN CHINA NEWSThe recycling process consists of:a single pass. Also the high rate ofproduction is very convincing: TheWR 4200 produces 400t/h. These pro-recycling with foamed bitumen, whichcovers topics that include bindingagents, relevant mixed materials, survey1. Milling off 24cm of the existing pavement structure using a WIRTGENW 2000, and transporting the milled material back to the yard.duction quantities speak for themselves.Another important point is that it canof existing roads, deflection testing,DCP testing, HVS testing, mix design,2. Cold in-place recycling 18cm of the underlying pavement structure usingthe WIRTGEN WR 4200, with 3% foamed bitumen, and 2% cement.3. After the cold in-place recycled pavement has been cured for3 days, the RAP, which has been recycled in the KMA 200 using2.3% foamed bitumen and 1.5% cement, is paved 20cm thick on topof the in-place recycled layer.4. After this layer has cured for 3 days the prime coat consisting ofbitumen emulsion is applied, followed by a temporary application ofcrusher dust as a wearing course.5. The road is then re-opened to traffic.6. After the full carriageway width has been completed a 4cm polymermodified asphalt is paved as the final wearing course.even work perfectly at night, thanks toits optimized illumination system.”Furthermore he added, “Our past experiencewith machines from WIRTGENGroup is that it is not only the machinebut also the after sales service, repair,maintenance, training and applicationsupport which is offered by WIRTGEN.”A series of high-class seminars havebeen organized by WIRTGEN, with the aimof sharing WIRTGEN’s internationallyrenowned expertise with the customersand structure design of the recycledpavements.“For us, it was vital to rely on theextensive knowledge and experience ofWIRTGEN China regarding the practicalapplications. Whenever and whereverwe are, we are assured that WIRTGENis always there to support us,” saidMr. Zhang. “Thinking about this, wehave every reason to be even moreoptimistic of the future application ofthis cold recycling technology usingin Tianjin. Invited by WIRTGEN China,foamed bitumen.”Tianjin Goldway Co., with their practicalexperience in cold recycling withimmediately after compaction. The cost oflabor is considerably reduced due to smallerProfessor Kim Jenkins from StellenboschUniversity, South Africa and ProfessorErgonomic design: from the platform of the giant Cold Recycler, the operatorhas an excellent view of the whole recycling train.foamed bitumen during the past twolabor force required” said Mr. Zhang,André A. A. Molenaar from Delft Univer-years, together with advanced machinesDeputy the General Manager of Tianjinsity, Netherlands, have given personnelfrom the WIRTGEN Group, which includeGoldway Co., when talking about thefrom Tianjin Goldway Co. as well asthe WR 4200, KMA 200, W 2000,advantages of WR 4200. “The WR 4200from the major design institutes in3625 HT, HD O 120 V and VÖGELE Pavers,can recycle complete traffic lanes inTianjin a professional training in coldare well suited as the Contractors for thisrehabilitation project.The rehabilitation project is to becarried out in several stages, Stage 1having a length of approximately 2kmwith a working width of 12.4 metres.A total area of 28,000m 2will berehabilitated.“The existing material has been 100%reused. The traffic can continue to flowalongside the traffic lane being recycled.The recycled layer is ready for useWR 4200, with optimized illumination system,works perfectly at nights.Controls to adjust the recycling depth and additional operating panels for the main functions of the machine are providedin all vital places of the WR 4200.67

WIRTGEN CHINA NEWSWIRTGEN COLDRECYCLINGplant KMA 200, new binding agent canbe added to RAP. The recycled materialcan be paved by conventional asphaltpaver to serve as new flexible base course.The shortage of raw material andresources are the problem of the world.KMA 200: Foamed bitumen and cement recycling in mobile mixing plant (Xibao, Xiyu, Xihu,Xitong expressway/Shanxi province, China)So the reuse of existing material is thefirst to be considered.In April of 2005, with the help ofBackgroundtenance of national roads, provincialShanxi Transportation Department androads and expressways.Shanxi Highway Incorporation, WIRTGENCold recycling technology is widelyGroup, Changan University and Shanxiused for road maintenance in China. InShanxi province locates in inland ofHighway Mechanization Co., Ltd conduc-1998, WIRTGEN Group introduced the firstChina; road transportation is the mainted a cold recycling project togetherJOB REPORTcold recycling machine to China. After10 years of population, cold recyclingtransportation method. Since early1980s, expressway construction ofusing foamed bitumen and locally reclaimedasphalt. Xibao expressway is one oftechnology is widely used for the main-Shanxi province was started. After 20the main expressways in China. It wasconstructed in 1992, with total lengthof 155 kilometres, 4 lanes in 2 directions,design speed of 120km/h. Now, trafficvolume per day is 15000 vehicles, amongwhich, 30% is heavy loading vehicles. Torehabilitate the failed road and increasethe safety, rebuilt of expressways wasstarted since 2004, and 2 kilometres offoamed bitumen recycled trial section wasdesigned to serve as a substitute methodfor expressway maintenance.After 2 years of opening to traffic, theThe approach ramps for filling the batchingunit can easily and quickly be put in placeon the job site.constructed, the transportation volumeis increasing fast. At the same time,large, overloading vehicles are the newtrail section is still in good condition,which totally fulfils the traffic volumerequirement. Cold recycling method haschallenge for expressways. Now, manymore advantages than conventionalroads, which were bulit many years ago,method does.years, they have been developed rapidly.need urgent maintenance. All kinds ofAdopting conventional method,With the completion of Xitong, Xibao,road maintenance produce lots of RAP,contractors would pay a lot of money toXiyu, Xitong, Tonghuang, Yujing, Xihan,which will cost a lot of time and moneyreuse the waste material. Flexible baseairport expressway and round cityof Road Administration Department tocourse recycled with foamed bitumen isexpressway, the total expressway mileageprevent the air pollution. It is necessarymore stable, which allows thinner asphaltof Shanxi province has reached 1300to find an economic method to reusesurface layer and make the expresswayThe KMA 200 Cold Recycling and Mixing Plant comes with an own diesel engine, thus being indepenent of external power supply.With the tank filled once, the plant operates up to 2 days.kilometres, and this is very importantfor economic development of Shanxiprovince. After many highways werethese RAP. With WIRTGEN foamedbitumen cold recycling technology andWIRTGEN mobile cold recycling mixinglife longer. According to relevant statistics,20% of road maintenance cost can besaved with cold recycling method.89

WIRTGEN CHINA NEWSFor preparation of the cold mix, cement can be added in precise batches from the silo.With conventional method, asphaltlayer can be paved 7 to 14 days aftercompletion of the cement stabilized basecourse. With foamed bitumen recyclingmethod, surface layer can be paved 3 daysafter the completion of the recycled layer.This greatly reduces the influence to thetransportation.In March of 2007, Shanxi HighwayGroup decided to adopt the foamedbitumen recycling in plant technologyfor the maintenance of Xiyu, Xihu, Xitongexpressway. Recycling construction areais more than 2 million m 2 . More than0.6 million tons of RAP will be reused.The construction period is from March toSeptember of 2007. 6 WIRTGEN KMA 200cold recycling plants will prepare themix before paving.Road structure designFor this recycling construction, foamedbitumen recycled materials are used intwo ways:Substitute of cement stabilized basecourse and asphalt base course; thesemi-rigid structure will be replaced byflexible course structure.The flexible course can reduce thereflecting crack from semi-rigid structure.Foamed bitumen recycled mixturedesignWith the WIRTGEN WLB 10 laboratoryfoamed bitumen design machine,Expansion (times)personnel from Changan Universitycompleted the foamed bitumen mixturedesign. The foaming device of WLB 10 isthe same as that of large cold recyclingmachine, so the design result can exactlyinstruct the construction in job site. Theperformance of foamed bitumen can beindicated by expansion ratio and halflife. The expansion ratio is the ratio ofthe maximum expansion to the unexpandedvolume. The half-life is themeasure of the time taken for thefoamed bitumen to reach half the heightof the maximum expansion (in seconds).The foaming quality is influenced byasphalt temperature, water quantityadded and so on.Proper gradation is the importantfactor for the performance of the mixture,and this is the same for foamed bitumenmixture. Lack of fine material will inducethe unevenness distribution of foamedbitumen. A minimum of 5% fines (passing0.075mm sieve) is necessary for effectivedispersion of foamed bitumen.The diagram shows the influenceof water contents upon half-life andexpansion ratio of the foamed bitumen.151413151413Expansion12111211Half-Life10987654109876541 1.5 2 2.5 3 3.5 4 4.5 5Percentage water addedHalf-Life (s)The foamed bitumen stabilised materialshall be evaluated by ITS, otherwise, theratio between the remained ITS and dryITS can evaluate the mixture performancefor water failure.Construction processThe milling of existing asphalt pavementis finished by WIRTGEN largemilling machines. The large millingmachine can mill the complete asphaltsurface in one pass, and this can savea lot of time and money. RAP is transportedto the mixing plant of KMA 200.WIRTGEN mobile mixing plant can betransported by means of standard tactorvehicle, with high performance. Theplant is assembled and disassembledeasily in next to no time at all. Specialtools are not required. Working performancecan exceed 200t/h easily. Themixed material can be transferred totruck by conveyor to transport to thejobsite.Recycled mixture, using foamedbitumen, produced by WIRTGEN mobilemixing plant KMA 200The recycled mixture can be paved byVÖGELE SUPER 2100-2 paver. VÖGELEis a member of WIRTGEN Group, withmore than 75 years of road paver manufacturinghistory. A lot of technologyinnovation, reliable quality and thecommitment to customers reinforce theleadership of VÖGELE in the world.The required compaction degree isvery important for the performanceof the road. The material with badcompaction is prone to rutting, waterOn the control panel of the KMA 200, the share of the binder by weight and thequantity of a batch prepared so far, are shown on the displays.failure and asphalt binding agent aging.To achieve the required compactiondegree (98%-102%), we choose HAMMcompactor 3625 and HD 130 tandemroller to complete the task. The compactionprocess is as follows:HAMM HD 130: compacts thestabilized material statically.HAMM 3625: 2-4 times with lowfrequency and high amplitude.HAMM HD 130: 2-4 times withhigh frequency and low amplitude.Tyred roller: 8 – 10 times.The compaction degree no less than98%; the practical compaction degree injob site is satisfying.The articulated conveyor belt allows to dump the cold mix directly into trucksfor transport to a place for intermediate storage or to the job site.1011

WIRTGEN CHINA NEWS10-YEAR EMPLOYMENTeach individual post, I’m sure I have keptone aspect unchanged, i.e. I have donemy endeavor to my own responsibilities,Edwin Cai, Gary Wang, Michael Kwan and Benjamin Feng hold different posts and work atdifferent locations – but they all have been employed in the WIRTGEN Group for 10 years now.WIRTGEN CHINA NEWS congratulates and thanks these colleagues for 10 years of pleasure intheir work, loyality with the company and passionate engagement.as well as to do the coordination for aperfect cooperation with the wholeteam.”“WIRTGEN, with its high quality machines,is undoubtedly the absolute market leaderthese past 10 years, that in this family, every10 years, what event has stirred you mostespecially in the fields of cold milling andmember is very important and indispensable.deeply?”, Edwin’s answer is:recycling etc. in China. My perspective atEverybody may have your own preferred“I couldn’t have imagined that WIRTGENpresent of WIRTGEN China 10 years laterorientation as long as you fit well in theChina, within 10 years, has become a leadingis that we should maintain ‘first-classcompany structure, you will find as big spacecompany in road construction and rehabi-construction machinery and top-rankingfor your later self-promotion as your ownlitation machinery industry in China withafter-sale service’, as well as our corporateSTORYcapacity. We are one team to work togetherto offer our customers with ‘first-classsuch a big market share.”culture – “We are one family”. Sticking tothe principle of market orientation, as aconstruction machinery and top-rankingTalking about his career in WIRTGEN,pioneer in developing leading technologiesafter-sale service’.”Edwin said, “In these years, I have beenfor road construction and road rehabilitation,Edwin Cai: To the Best of My Abilityworking in different posts. In spite of thewe shall continue to develop advancedSince April 1997, Edwin Cai’s employmentby WIRTGEN in Guangzhou has been10 years – first as a sales manager to beresponsible for spare parts sales all overWhen he was asked, “During the pastgreat changes and the responsibilities ofmachines to meet the growing marketdemands. Last but not least, I would like toexpress my hearty thanks to our dearcustomers as well as my dear colleaguesfor your backing to me as you always did,When he was asked, “What has madeyou decide to work for WIRTGEN in Chinaunder Mr. Reichert’s administration?”Like his working style, his answer is plainGary Wang has been familiar with themachinery from the WIRTGEN Group since1995. As a service engineer, he ensuresimpeccable operation of the machinesof WIRTGEN, VÖGELE and HAMM.China, and to assist the complete machineand my very best wish for your good healthbut always right to the point:sales in Guangzhou Area (namely Guang-and happiness!”“I got to know Mr. Reichert in 1995. Duedong, Guangxi, Fujian, Sichuan etc.). Now,to my poor English, our communicationEdwin Cai has become the General ManagerGary Wang: No Regret for Joiningwas very much limited, which still could beThinking about his 10-year employmentof WIRTGEN (China) Machinery Co. Ltd.,WIRTGENsufficient enough for me to realize that hein WIRTGEN China, Gary spoke feelingly ofGuangzhou Branch, responsible for all theis a real gentleman, a good boss. As everythe happy days after he joined WIRTGENbusiness operation in Guangzhou Area.Being very straightforward, superhonest,time he met me, he would shake handsFamily.and always knowing what he was doingwith me, with one simple English sentence,“When making decision to join WIRTGENand talking about, Gary Wang is always“Thank you, Gary”, the sincerity of which“For me, ‘in the same boat’ alwaysin April 1997, I was greatly encouraged bya welcome friend for all of our customers.I could always feel!means a lot more, even from the first dayits philosophy – ‘We are one family’. I wasHe has been respected by the customers asThe more machines I have commissioned,I joined WIRTGEN Family. I have beentold, as I have experienced at first hand inan experienced service engineer, alwaysthe more confidence I got in our products.working in WIRTGEN China as a serviceready to offer any possible assistance.I have always been so proud and happyengineer for more than 10 full years, mostAccording to Gary, even 2 years before hewith the reliability of our high-standardof the time I myself worked on the siteEdwin Cai, member of the WIRTGEN familysince April 1997, started his career asa Sales Manager for parts in Guangzhou.Today he is the General Manager of theWIRTGEN China branch in Guangzhou.“officially” joined WIRTGEN on July 1st,1997, he had been “working” for WIRTGENfor some commissioning job (mainlyWIRTGEN milling machines at that time).products, as I always tell our customers,“Once you choose WIRTGEN Group, we willnever let you down, because we are in thesame boat!”offering service, but I never felt being leftalone, because whenever and whereverin need, I could seek for help both fromWIRTGEN China team and even from1213

WIRTGEN CHINA NEWSWhen Michael Kwan started his career inour company, WIRTGEN Hong Kong countedno more than 16 staff. After many years asa service engineer, he now is in charge ofcustomer training throughout China.and patience. No matter when and whatproblem, simple or complicated, he hasbeen always ready to offer assistance tillthe final settlement. I have tried to be asis offering an excellent environment fortechnical training and application. The onlyregret I have sometimes is that some of ourcolleagues, for some reason, have left thewhen he met Mr. Ulrich Reichert on thesite in 1991. About 6 years late, he madedecision to join, and became a member of“WIRTGEN Family”.helpful since my transferring to Trainingcompany, but I’m sure they will alwaysDepartment 4 years ago.remember the happy laughter in WIRTGEN“Since I joined WIRTGEN 10 years ago,Family.I have been a sales engineer for sparebusiness operation in China from dealershipIn the past 10 years, I have witnessedparts. I’m very proud of having been in thisto direct sales (manufacturer – customers),the growth of service team from 3-4Benjamin Feng: Proud and happy toposition for over 10 years, as I have strongMichael was greatly impressed by the “big”engineers to over 30 engineers. Being ahave witnessed WIRTGEN's developmentconfidence on WIRTGEN and its products.capacity of this “small” team – every member,trainer, I’m very proud if I could offerin China at such a high speedI’m so proud and happy to have witnessed,in light of “We are one family”, supportsthem any assistance. Now with the openduring the past 10 years, WIRTGEN’s deve-each other in such a high efficiency.administration by Mr. Reichert, mutualUsed to be one of the WIRTGEN millinglopment in China in such a high speed.support and coordination from all depart-machine users (WIRTGEN 1900 VC) in China,Thanks to its wider and wider range ofIn WIRTGEN, Michael has been a servicements, technical promotion and training byBenjamin Feng was aware of the name ofproducts, along with the increase ofengineer, service supervisor, and now isWIRTGEN China, we can say that WIRTGENWIRTGEN and its products in the same yearits team in China, WIRTGEN Group has“Head of Training” in WIRTGEN China,become the market leader for roadresponsible for the training offered toconstruction and maintenance machinerycustomers both on the site and in theboth in the world and in China, withclassroom based in Langfang. His departmentever-growing market share and the turnoveris also responsible for the translation andof complete machine sales as well as partsupdating of all the “Operation Manual” ofsales. For Shanghai Office only, the partsthe international team based in ourWIRTGEN? Is there anything you feltthe machines.sales has increased to over RMB20 millionGerman headquarter, as “We are oneregretful?”, his answer is:“In my first days as service engineer infrom the total amount of RMB 3.6 millionfamily”. After our China headquarter hasWIRTGEN, I had chances of face-to-face10 years ago. Thinking about this, I’m evenbeen established, especially after we“I enjoyed a lot and really felt proudcommunication with the customers. All themore confident of the future of WIRTGENhave built up a spare parts service centrewhen I could manage to answer all thecolleagues, from service department inChina, in the firm belief that every WIRTGENin Langfang, we could expect evenquestions, and solve the problems for theboth Hong Kong and China Mainland, workFamily member, old or new, would do morequicker and better support. With thecustomers on the site. For the later part oftogether to solve technical problems, learncontribution to make our Family evenbacking from our professional team andyour question, my answer is absolutelyfrom each other and share the happinessbigger and stronger!”the modern facilities in WIRTGEN Chinaclear- how can I feel regret for been aof success. I learned how to build Machineheadquarter, I feel steady and sure evenmember of this big family!”Record, the processing of claim etc. underwhen I’m working alone on the site. Yearsthe instruction of Mr. Norbert Ueckerath,ago, when I received a “Happy-Birthday”Michael Kwan: WIRTGEN Offering anService Manager of WIRTGEN Asia. What isfax message with the signature of all myExcellent Environment for Technicalmore important is that from him, I came tocolleagues, I suddenly understood whatTraining and Applicationknow the real meaning of ‘service’ in‘WIRTGEN Family’ means. So, how canWIRTGEN Family. Also from him, I learnedI deny the fact that I’m working in a goodMichael Kwan remembered so clearlythat training means to share knowledge,company, among good team fellows, andwhen he started to join WIRTGEN onknow-how and your experience with others,even with a very nice boss!”Jan. 25th 1997, WIRTGEN Hong Kong waswhich you should start from self-teaching,When asked, “Is there anything you feltproud of in your 10-year employment inonly a small office with six seats, and aroundten staffs working in China mainland. Eventhough it was the transition period for itsalways be ready to help the others. I havebeen deeply touched by his sincerity, hispoliteness, personal integrity, his abilitySince Benjamin Feng joined the WIRTGENfamily 10 years ago, he has been a salesengineer for spare parts. He has a strongconfidence in WIRTGEN and its products.1415

WIRTGEN CHINA NEWSFine, large, small: the full range ofmilling operationsThe first job was carried out by aW 2100. It was equipped with a 2.10mwide microfine milling drum with over 700cutting tools and milled off the asphaltW 2200 commenced their work, one ofthem equipped with a 3.80m wide millingunit. They produced a precise edge forthe pavers to use later when commencingthe paving operation and also levelledthe peripheral areas to optimize waterdrainage. Everything had been preparedwith a working width of 35cm removedthe asphalt pavement in the peripheralareas that had not been milled by thelarge machines. Their operation wascompleted in no more than a few minutes,the two W 2200s had done an excellentjob.W 2200 with FCS: power package in XXL sizeThe standard model of the high-performance millingmachine W 2200 works with a 2.20m wide milling drum.Its powerful engine (671 kW / 900 HP) enables the machineto operate economically even at larger working widths. Ifthe machine is equipped with the Flexible Cutter System(FCS), milling drums can be exchanged to vary the millingwidth or the tool spacing. Milling widths ranging from2.20m to 4.40m can be realized using the elements of theFCS modular system. The W 2200 with an XXL-size drumunit is particularly economical when working on largeconstruction sites. Labour requirements are very low,the job is completed fairly fast due to the machine’senormous area performance, and only one machine needsto be transported to and from the site.Safe and smooth operation even at night: Bright, freely adjustable working lights ensure perfect illumination of the area in front of the drum,the discharge conveyor, the milling drum housing and the pavement behind the crawler tracks.RELIABLE, ACCURATE, FASTWIRTGEN GROUP MACHINESCOMPLETE REHABILITATION OFTHE RUNWAY AT BELGIAN AIRPORTCHARLEROI IN 6 NIGHTSIt is shortly past 10 PM, but Belgian airport Charleroi is lit as bright as day. Countless low-loaders loadedwith WIRTGEN cold milling machines, VÖGELE pavers and HAMM rollers arrive on the airport premises.Rehabilitation of the 2.5 km long runway at Charleroi Brussels South Airport is just about to commence.WIRTGEN GROUPWORLDWIDEThere were two possible options forrepairing the asphalt pavement: closingthe runway for several days or completingthe rehabilitation successively in thecourse of several nights. The decision wasmade in favour of the night operation, asthat would allow airtraffic to continuewith only minor restrictions. Consequently,the 48m wide runway was rehabilitatedin the course of six nights over a lengthof 460m per night and from 10 PM to6 AM sharp. Severe penalties had beenagreed upon in the event that the runwaywas not open to airtraffic at 6 AM. Theoperation had to be carried out undertremendous pressure of time.It demonstrated what’s in it for six long nights: The W 2200 equipped with a 3.80m wide drum assembly impressed withreliability, precision and power. Transport of the milled material from site was perfectly organized, enabling the tremendouspotential of the large machine to be utilized to full capacity.pavement of the touchdown area at adepth of 3 mm. The rubber abrasion of theaircraft tyres, which had to be disposed offseparately, was thus removed quickly andeconomically. Shortly thereafter, two highperformancemilling machine modelsvery efficiently, and transport of the milledmaterial from the site had been organizedperfectly so that the milling machineoperators never had to wait for trucks.The milling operation was completed bya W 35 DC. The small milling machinePerfectly organized asphalt pavingoperationAt midnight, when the milling machineshad completed two thirds of their work, sixpaving crews took up position to overlay1617

WIRTGEN CHINA NEWSBottom: Work in the peripheral areasis completed by the well-lit W 35 DC.The milled material was deposited on theasphalt surface via the small loadingconveyor to be disposed of by a sweeper.the runway with a new pavement. The keypositions in the paver fleet were occupiedby VÖGELE machines as maximum precisionand uniform paving speed were of theessence. One SUPER 1800-1, two SUPER2100 and one SUPER 2100-2 paved theirway ahead continuously. Thanks to theirlarge hoppers, they had sufficient mix onboard to continue the paving operationeven during truck changes. Tandem rollersfrom HAMM compacted the freshly placedasphalt layer. The roller models DV 90 andDV 70 can be identified quite easily due totheir unique lighting system. 16 halogenheadlamps illuminate the working area,offering the driver a non-dazzle view ofthe surface, the working environment, thedrums and the drum edges.Paving was completed just as smoothlyas the milling operation. A total of 52trucks supplied the pavers with sufficientquantities of mix. None of the trucks hadto put up with long waiting times despitethe fact that the stone mastic asphalt wasproduced in four different mixing plants,some 3,000 tons each night.Think forward - the extra in safety and ergonomics even at nightThe concept of the tandem rollers belonging to the DVseries offers special advantages, in particular on night sites:The main frame is open, the cabin is glazed in the area ofthe drum, and 16 halogen headlamps illuminate the drumsurface across the full width. The driver has a good view ofthe well-illuminated drum edge, the lit kerbstone and thenozzles of the drum spray system. In addition to that, theinnovative driving and operating concept HI DRIVE enablesthe roller driver to change the direction of travel quicklybut smoothly. If desired, the driver can also activate theautomatic seat rotation. When changing the direction oftravel, the driver’s seat including all operating elementsin the armrests is then turned into the new directionautomatically.All clear for take-offA breakdown of any of the machinesGrade & slope control made even more easy with NIVELTRONIC® PlusIt is very important to precisely adhere to the specifiedpaving height. All the better, therefore, if the automatic gradeand slope control system can be set correctly with minimumeffort. NIVELTRONIC® Plus, the new system from VÖGELE,offers all that is needed to do just that. Learning how tooperate it is easy thanks to its language-neutral symbols. Allimportant functions of the NIVELTRONIC® Plus system arewithin direct reach at the first menu level. The sensors canbe mounted with a few simple flicks of the wrist at thepermanently installed mounting points. The automatic sensorrecognition is a particularly convenient feature. Monitoringand actuating the sensors during the paving operation iseffected conveniently via the two ErgoPlus operating consolesat the screed.Think forward: that’s the maxim of the DV rollers made by HAMM. These tandem rollers with automatic seat rotation enablethe driver to always drive in forward direction. Advantages: perfect view at all times, a sitting position that is gentle on the back,and optimum illumination of all important machine elements.Perfection in asphalt paving: Two sonic sensors, combined with the new automatic grade and slope control systemNIVELTRONIC® Plus, ensure that the SUPER 2100-2 places the asphalt true to grade and slope.While the pavers are still underway, markings are already applied on the freshly pavedasphalt in the middle of the runway.would have incurred considerable costs butthe milling machines, pavers and rollerslived up to their good reputation, andthere was no cause for complaints. „I spentsix nights on the job site, but none ofthe machines had a malfunction“, smilesChristophe Verheyden, WIRTGEN Belgium’sservice engineer.One final remark: Meticulous planning,reliable machines and a highly professionalteam helped to make sure that the timelimit was adhered to. Airtraffic was resumedaccording to schedule at 6 AM.1819

WIRTGEN CHINA NEWSVÖGELE DEVELOP NEW MACHINE TECHNOLOGY FOR “HOT ON HOT” PAVING“INLINE PAVE”:LOWER COSTS, HIGHERQUALITY“Hot on hot” paving is in the offing! For this paving method interesting from both the economical andquality point of view, VÖGELE offer a newly developed machine technology.3SUPER 1600-2 or SUPER 1800-2for Paving Surface CourseFor paving surface course, as thethird in the trio, a SUPER 1600-2 orSUPER 1800-2 paver, both of standarddesign, can be used.2SUPER 2100-2 IPfor Paving Binder CourseThe core of the “InLine Pave” train isSUPER 2100-2 IP, a SUPER 2100-2 ofstandard design which has undergonemodification. SUPER 2100-2 IP comeswith a special transfer module forsurface course mix and an AB 600 IPExtending Screed of advanced design,with 2 pressure bars. This screedbased on the unique VÖGELE pulsedflow hydraulics is the technologicalgem of the “InLine Pave” technology.1MT 1000-1 IP Mobile FeederThe MT 1000-1 IP Mobile Feeder(IP stands for “InLine Pave”) is equippedwith a long, heated conveyor unit toalternately feed pavers with binderand surface course mixes. Red andgreen lights provided on the machinesignal to feed lorry drivers their turnto approach the feeder (green lightfor binder and red light for surfacecourse mix).PRODUCTPRESENTATIONThe VÖGELE concept named “InLinePave” allows to place binder course andsurface course “hot on hot” in a single go.Thanks to VÖGELE High CompactionTechnology, specially developed further forthis paving technique, no rollers are requiredto compact the binder course. Meanwhile,more than 500,000m 2 of area have beenpaved “hot on hot” in Germany and theNetherlands, in close co-operation withGerman building contractor Matthäi. On allprojects, excellent results were achieved.VÖGELE Machine TechnologyVÖGELE “InLine Pave” uses a paving trainfor pavement construction. The unit is madeup of a MT 1000-1 IP Mobile Feeder based ona modified VÖGELE feeder of standard design,a SUPER 2100-2 IP for placing binder courseand a paver placing wearing course. Forplacing wearing course, a SUPER 1600-2paver or SUPER 1800-2 can be used.Feed with Mix: MT 1000-1 IP Mobile FeederThe MT 1000-1 IP Mobile Feeder has aconveying capacity of 900 tonnes/h. It comeswith a powerful engine developing 106 kWand is equipped with a long conveyor unit,thus permitting to alternately feed theSUPER 2100-2 IP paver with binder andSUPER 1600-2 or SUPER 1800-2 withsurface course mix. In order to properlyreach the two pavers' material hopperslocated at different heights, the conveyorkinks hydraulically to serve the lower hopper.Professional job site logistics as a crucialfactor for successA vital condition for successful implementationof “InLine Pave” is optimal jobsite logistics, as large quantities of mixhave to be placed within a short period oftime. Utmost importance must be attachedto perfect co-ordination of the mixingplant on the one hand and haul vehiclesfor transport of the paving materials onthe other, so that sufficient mix consistentin quality is available on site at all times.On the job site itself, the feeder operator pullsthe strings. He directs the feed vehicles totheir positions by green or red lights. At thepush of a button on his console, he switchesto “green” for binder or “red” for surfacecourse mix, thus signalling to lorry driverstheir turn to approach the feeder. With thefeeder operator changing from binder toThe “InLine Pave” train in operation on a motorway. The traffic keeps flowing on theadjacent lane.2021

WIRTGEN CHINA NEWSThe operator station adjustable in height gives unobstructedvisibility.surface course mix, for instance, theconveyor automatically adjusts in heightand distance. So no need for the operator tofocus on that, he can devote his attentionto other essentials. There are further smartfunctions installed as well for ease ofoperation, thus ensuring a correct andreliable flow of operations on site.Safe and smart distance control forthe “InLine Pave” trainThe distance between the Mobile Feederand the paver for binder course is picked upby laser sensors in non-contacting operationand kept constant by automatic control. It isthe paver placing the binder mix which takesthe lead and sets the pace for the wholepaving train. Should, for instance, the distancebetween feeder and paver decrease due to thefeed lorry slowing down for some unintentionalreason, the following machines arestopped. A process-related change in distancebetween feeder and paver, however, as itoccurs when swapping between mixes, isrecognized automatically by the controlsystem and action taken.Paves Binder Course: SUPER 2100-2 IPThe core of the “InLine Pave” train isSUPER 2100-2 IP, a SUPER 2100-2 paver ofseries design which has undergone modificationto turn it into the IP version. It canbe used for conventional contracts at anytime. For application on an “InLine Pave”job, the SUPER 2100-2 IP comes with aspecial transfer module comprising anoperator station adjustable in height, areceiving bin for surface course mix and anextra conveyor unit. The operator stationadjustable in height allows a higher operatorposition for unobstructed visibility of allaction on site and eye-to-eye contact withother machine operators.The paver placing surface course comes witha water spraying system for crawler tracks toprevent the tracks from sticking to the hotbinder material.Laser sensors are installed to pick up distances between themachines for automatic speed control.Overhead transfer of mixThe extra conveyor, part of the specialtransfer module, transfers the surfacecourse mix received through the bin over theSUPER 2100-2 IP into the material hopperof the second paver following behind topave surface course. The conveyor is heatedto prevent mix from sticking. For a safeclearance between the paver placing binderand the one paving surface course, too,electronic distance control and collideprotection are installed. For the storageof binder, an extra hopper holding 20 tonnesand insulated against loss of heat isavailable to be placed into the paver’smaterial hopper should further capacity beneeded.AB 600 IP High Compaction Screedachieves highest density already at thestage of binder pavingThe crucial component and technologicalgem, when looking at the “InLine Pave”machine technology, is the High CompactionScreed’s pulsed flow hydraulics. This specialtechnology has been offered by VÖGELEexclusively since 1962. For “InLine Pave”,the AB 600 Extending Screed in TP2 versionhas been developed further to meet itsspecific requirements. As AB 600 IP, itachieves a density at the highest level,allowing the paver following behind theSUPER 2100-2 IP to pass over the bindercourse not compacted by rolling without arisk of sinking. Thanks to VÖGELE HighCompaction Technology, a density close to100% (depending on the type of mix) isachieved without a need for rolling.Thanks to high precompaction of thebinder course, final compaction of thetwo-layer asphalt package does not call forlight and heavy rollers working in echelon.Heavy rollers alone do the job. Thanks tothe High Compaction Screed, any kind ofpavement deformation, marks left in thesurface or unrolled material accumulating infront of the drum, exceeding the admissibletolerance limits, are avoided. As a result,excellent evenness of the pavement isachieved. And irregularities in the pavementcaused by incorrect rolling, too, are largelyprecluded.Paves Surface Course: SUPER 1600-2or SUPER 1800-2 with AB 500-2 TV ScreedA SUPER 1600-2 or SUPER 1800-2, thelast “InLine Pave” machine in the group ofthree, comes with an AB 500-2 TV ExtendingScreed of standard design to place surfacecourse onto the still hot binder layer. Thepaver’s crawler unit is fitted with extrawide track shoes and a water sprayingsystem is installed preventing the tracksThe 3 Advantages of “Hot on Hot” Pavingfrom sticking to the hot binder material.Large material hopper for storage of mixFor a large storage capacity, an extrahopper holding 25 tonnes is placed intothe paver’s material hopper to ensure thata sufficient quantity of surface course mixis available always. The hopper is insulatedagainst loss of heat and in part heatedelectrically to maintain a constant temperatureof the mix even for a prolongedperiod of time and to prevent the mix fromsticking. SUPER 1600-2 or SUPER 1800-2can be used for conventional paving taskswithout conversion at any time. All thatneeds to be done is removing the largeextra hopper.1. Saving of Cost Economy of expensive surface course mix in favour of low-cost binder material featuring higher stiffness and resistanceto deformation cuts cost. Cuts down on cost of machinery and labour as no compaction by rolling is required for binder course. There is no need to spray tack coat, which saves time and tack coat material. Distinctly shorter construction time compared to conventional paving methods cuts cost of contracts for new pavementsor pavement rehabilitation.2. Longer Design Lives of Road Pavements Optimal interlocking of binder and surface courses guarantees an excellent bond between layers. Furthermore, compactionof the surface course with a low but sufficient voids content is supported, thus prolonging the pavement’s life. Thanks to binder and surface courses resistant to deformation, the asphalt pavement’s design life can reach the spanof concrete pavements. In contrast to concrete, however, cost of pavement rehabilitation is much lower.3. Easy Paving in Low-Temperature Regions or During the Cold Season As the temperature in the package of binder and surface courses drops much slower compared to conventional pavingin single layers, compacting results are better and the window of time available for compaction extends. As a consequence,this method offers advangages in terms of cost-effectiveness, leads to particularly high pavement quality and is ideal forpaving in low-temperature regions or during the cold season.2223

WIRTGEN CHINA NEWS For classical road construction,with spraysystem for bitumenemulsion integrated in the paver. For paving thin layers on sprayseal or tack coat, hot on hot. Easy demounting of the SprayJetModule allows use of the paverfor conventional paving tasks, thusincreasing economic efficiency. Compact design renders thepaver ideal for inner-cityapplications, low-cost transport. Vehicles never pass over theemulsion, as emulsion isimmediately covered with asphalt.No soiling of other roads.Compact, powerful and conceived for versatile application: SUPER 1800-2 can be used with the SprayJet Module as a spray paver, or withoutSprayJet as a conventional paver for jobs as usual. The paver is powered by a PERKINS engine type 1106D – E66 TA rated at 129.6kW.Very low and constant spraying pressure (3 bar) reduces spray mist to a minimumand achieves uniform spraying.The Conventional VÖGELE Paver with Spraying Capability. Rehabilitating roads by replacing wearingcourse is very popular in numerous countries. No wonder contractors prefer this technique as itfulfils in an excellent manner the requirements of high cost-effectiveness and eco-friendliness.PRODUCTPRESENTATIONCONVENTIONALSUPER 1800-2 WITH NEWSPRAYJET MODULEVÖGELE now present the SUPER 1800-2with SprayJet Module, a cutting-edgemachine ideal not only for pavingthinlayers on spray seal or tack coat, hoton hot, but also highly interesting formany non-specialized road buildingcompanies. The VÖGELE SprayJet Moduleoffers an economical and clean alternativewherever spaying bitumen emulsion andsubsequent paving are required.SprayJet technology meets higheststandards in terms of eco-friendlinessThe concept of the “Paver withSprayJet” is based on a SUPER 1800-2of standard design which, after minormodification and addition of a newlydeveloped spray module, can be used asa spray paver. The motif behind thisconcept was development of a machinewhich, in a very short time, can beconverted back to a standard paver forconventional paving as usual. This goalhas been excellently achieved and theeconomic efficiency of the SprayJetModule is outstanding.The SprayJet Module offers a host oftechnological advantages. For instance,the rate of spread can be set from0.2kg/m 2 , allowing the bitumen emulsionto be finely metered and applied in smallvolumes at slow pave speeds. Thanks toan extremely low and constant sprayingpressure of just 3 bar prevailing inthe system, the spraying work can beperformed with a minimum of spray mistTop Left: The emulsion tank holds2,000 litres.Bottom Left: The display of the colourtouch screen supplies all vital informationto the operator. The desired rate of spreadcan be entered very easily.and pollution. As this was not possiblewith previous systems, the SprayJetModule is a trailblazer in both economicaland ecological terms.Use as a spray paver or conventionalpaver boosts productive utilizationWhen it comes to new developments,VÖGELE always focus on designingmachines featuring economical andversatile utilization. SUPER 1800-2 withSprayJet Module is a brilliant example.The machine is suited to use both as aconventional paver or as a spray paver.The spray module can be fitted or removedin just a short time. Easy for contractorsto make money out of this advantage:if there are currently no jobs requiring theuse of the SprayJet Module, contractors canemploy their SUPER 1800-2 for conventionalpaving tasks at any time, thus boostingthe machine’s productive utilization.2425

WIRTGEN CHINA NEWSSUPER 1800-2 as a Conventional Paverwithout SprayJet ModuleThe SprayJet ModuleThe SprayJet Module includes an emulsiontank holding 2,000 litres. Handling theThe spray system comes with a total of 5spray bars (red) and 20 spray nozzles. Maximum pave width 10mSprayJet system is very easy. All the operatorneeds to do is enter the desired rate ofErgoPlus on board, the user-friendly Laydown rate up to 700 tonnes/h Maximum layer thickness 30cmspread on his touch screen. No other inputis required for standard spraying operation.As a matter of principle, the tank should beconcept for paver handlingLike all “dash 2” generation pavers, Transport width 2.55m Pave speed up to 24m/min. Travel speed up to 4.5km/h Powerful PERKINS engine rated at 129.6 kW ErgoPlus, the concept for easy paver handling Hardtop with wide sunshadesfilled with hot emulsion. But of course, thetank nevertheless comes with an integratedheating unit (2 x 7 kW) to keep the emulsionat the desired temperature. Temperaturesensors are fitted in order to prevent theemulsion from burning and automaticallyswitch off the heating process if theemulsion level becomes too low. Theheating limit can be set via controller toSUPER 1800-2 too comes with the VÖGELEErgoPlus operating concept, whichsubstantially facilitates handling of thepaver for the paving team. For use with theSprayJet Module, an additional menue forspraying is integrated in the display of thepaver operator’s ErgoPlus console. Inaddition to the functions for activatingand deactivating the automatic spraya value between 0 and 80 °C.The SUPER 1800-2 is fitted with fivespray quantities, SprayJet allows to selectsystem, this menue also provides two otherIn order to maintain the bitumen emulsionspray bars with a total of 20 self-sealinga spray volume from 0.2kg to 1.0kg pervery useful features that allow the “StartSUPER 1800-2 as a Spray Paverwith SprayJet Modulein a highly homogenous state, the SprayJetModule comes with a heated emulsion pumpdriven by a hydraulic motor with rpm sensor.This pump ensures that the emulsion isspray nozzles. The spray bars are so positionedon the paver that the emulsion film spreadon the base cannot be damaged by thepaver’s tracks.square meter. This allows working even atslow pave speeds without applying moreemulsion than specified. Paving at speedsof between 2 and 20m per minute isof job” and “End of job” to be selected atthe press of a button. The “Start of job”function ensures that the various spraybars located around the paver are activated Uniform rate of spread across the entire pave widthup to 5m. Spray volume from 0.2kg/m 2 allows smallest quantitiesto be applied highly economically.kept in constant circulation. The SprayJetModule is controlled with the help of anon-board computer. A control panel, easilyaccessible, is provided on the spray module.Just like the ErgoPlus operating concept forThe special technical design of thenozzles and the constant sprayingpressure of 3 bar allow absolutelyuniform spraying. Spraying does nottake place continuously but in pulsedpossible without any problems.selectively, so that the spraying process Very low and constant spraying pressure (3 bar) reducesspray mist to a minimum and achieves uniform spraying. Rate of spread can be selected between 0.2 and 1.0kg/m 2 ,independent of the pave speed (2m/min. to 15m/min.).the paver, handling is extremely easy asself-explanatory symbols are provided. Thespecified rate of spread or desired emulsiontemperature, for example, can thus be configuredvery easily and without any problems.operation. The formation of spray mist isalso reduced substantially by the newVÖGELE system, as the spraying pressureis very low and the spray droplets arelarger. VÖGELE SprayJet thus represents Optimal spray pattern due to double-slotted spray nozzles. Easy handling.The spray technologya major advantage for the job site team,too, as emulsion fumes are reduced toa minimum. The accurate technique makes Practical automatic function to set “Start” and “Stop”of spraying. Closed circuit for constant circulation of the emulsion,no splitting, no foam.In the paver’s engine compartment,compressed air tanks with a total capacityof 60 litres are installed for supplying thepneumatically operated spray nozzles withcompressed air. In the system a pressure of8 bar pevails.it possible to even spray along road curbswithout getting emulsion on the curb.A very important technical innovationof the VÖGELE SprayJet Module refers tothe rate of spread. While previoussystems were only able to apply largeA heated pump circulates the emulsion in the tank, thus guaranteeing an alwayshomogeneous state of the bitumen emulsion.2627

WIRTGEN CHINA NEWSThe Highlights of the SprayJet Module Emulsion tank holding 2,000 litres,heated electrically and insulatedagainst loss of heat. Sensor controlled safety shutdownof heating unit to prevent theemulsion from burning. Emulsion tank filled by internalpump at up to 120 litres/min.or, alternatively, via externalpump (e.g. tanker). Cleaning of pump system and spraybars by compressed air and rinsing. Control panel on the SprayJet Moduleto select operating mode of theemulsion pump and activate/deactivate single spray nozzles. SprayJet Module can be tiltedthough 15° for easy access toperform maintenance services.As a technical innovation, the Spray Module allows very small emulsion quantities to be applied. The rate of spread can be selectedbetween 0.2 and 1.0kg/m 2 , independent of the pave speed (2 - 15m/min.).having to heat the screed. An additionalgas heating system can be used to quicklylayers, but also for conventional pavingjobs wherever emulsion spraying is desired.design, asphalt is paved immediately afterspreading tack coat. As a result, vehiclesheat up cold emulsion.With the emulsion tank installed on thenever pass over the emulsion, so thatover the entire pave width starts preciselyOn the two ErgoPlus operating consolespaver, sufficient emulsion is available at allpollution and soiling of surrounding roadsat the specified point. When activating thefor the screwmen, all vital informationtimes. This allows job site times to be reducedis effectively avoided.“End of job” function, spraying stopsconcerning the AB 500-2 is displayed.substantially. Due to the equipment’saccordingly.Thanks to self-explanatory symbols, set-upand adjustments can easily be made.AB 500-2 Extending Screed for perfectpavement qualityWide field of applications forSUPER 1800-2 with SprayJet ModuleSUPER 1800-2 with SprayJet Modulecombines with the AB 500-2 ExtendingThe SUPER 1800-2 with SprayJet ModuleScreed. The screed allows pave widths up tois a sophisticated piece of equipment5m. AB 500-2 is available in the versionsperfectly suited not only to placing thinTV (with tamper and vibrators) or TP1(with tamper and 1 pressure bar) for highcompaction.Like all VÖGELE screeds, AB 500-2 featureselectric heating. Screed and emulsion tankare heated independently, so that heatingof the emulsion can take place withoutBottom Left: Clearly arranged - the ErgoPlusoperating console.Bottom Right: On the ErgoPlus display,the practical functions of "Start" and"Stop" of spraying can be selected.2829

WIRTGEN CHINA NEWSSUPER 1800-2 SLOPE PAVER LAYS ASPHALTLINING FOR WATER RESERVOIR IN CHINAelectricity in Henan Province is concerned,home to 96 million people and oneof China’s most populated regions, theBaoquan Power Station Project is anthese turbines generates 306MW ofelectricity, satisfying the region’s needsprimarily during the day and at times ofpeak usage. At night when less power isResearch), headed by Dr. Hao Jutao, reliedon the know-how of WIRTGEN China.WIRTGEN China together with VÖGELEand IWHR modified a SUPER 1800-2 toEXTREME PAVING ONA STEEP SLOPE OF 31°important investment.Reservoirs hold 3 million cubic metresof waterThe upper reservoir, with a holdingneeded across the province, water ispumped back up from the lower reservoirto the higher one to let the cycle beginanew on the next day. This way, theregion will overcome bottlenecks inenergy supply.meet the project’s particular requirements.After undergoing technical modification,the slope paver was up to itstask of laying asphalt on the huge area.For the wall of the reservoire alone,166,000 square metres need to be linedThe project of a hydro power station in the Chinese province of Henan is extreme from every pointof view: a giant 3 million cubic metres of water will turn turbine generators achieving a combinedoutput of 1,200MW of electricity. Two water reservoirs are needed to operate the pumped storagepower facility, one of them located in the valley and one in the mountains. They are surrounded byretaining walls 31° steep. The main reservoir lying higher up needs lining with an asphalt seal.capacity of 3 million cubic metres, will beflooded with water from sources in thesurrounding mountains during the rainyseason between July and August. Thewater flows downhill in massive pipes toturn four powerful turbines and is thencollected in the lower reservoir. Each of166,000 m 2 of asphalt seal to be pavedFor sealing the water reservoir, asphaltis paved. When selecting machinery forthe job, contractor IWHR (China Instituteof Water Resources and Hydropowerwith asphalt to provide a waterproof seal.Job Site DetailsPaving asphalt seal on the wallof a water reservoir (gradientof slope 31°) for the BaoquanHydro Power Station in HenanProvince, China.Area to be sealed:166,000 m 2Gradient of slope:31°FOCUS STORYPave width:2.5m to 4mThis challenge is taken by a modifiedSUPER 1800-2 paver. In close co-operationwith the contractor, WIRTGEN China andVÖGELE got the paver ready to face thesteep uphill task.After undergoing modification into aslope paver, the SUPER 1800-2 is on thescene in Henan Province situated some750km from Beijing, to tackle the hugejob. Work on site is progressing steadilyand will be completed by the end of 2007.Even for the booming Chinese buildingindustry, this project is a kind of specialchallenge. And as far as local supply ofFeed with mix under difficult conditions: the shuttlevehicle is anchored to a winch by safety cable.Pave speed:1.5m/min.Screed Assist:25 barLayers paved:- 10cm binder course of asphalt(0/19) with 4% of bitumen- 10cm surface course of asphalt(0/12) with 7% of bitumenEquipment:- SUPER 1800-2 Slope Paver withAB 500-2 Extending Screed inTP2 Version- HAMM HD 13 Roller- Transfer Station with Rope Winch3031

WIRTGEN CHINA NEWSThe Chinese Province of HenanDr. Hao Jutao (left) of the China Institute ofWater Resources and Hydropower Researchthanks Andy Klingels from the WIRTGENChina Sales Team for the excellent support.With roughly 96 million inhabitants, Henan isChina’s most populated province situated in theEastern part of the Central Kingdom. The capitalof Zhenzhou alone, a booming industrial city, ishome to more than 6.8 million people. HenanProvince is regarded as the cradle of the Chinesenation and culture. 19 dynasties had their imperialresidences there. Furthermore, the region is thehome of many historical personalities and renownedwriters, among them Laotsi, a famous philosopher,generally better known under* the name of Lao-Tse.On the Baoquan Hydro Power StationProject, an articulated HAMM tandemroller type HD, linked to a cable winch forsafety, handles the compacting job.Paving is carried out in two layers withcompletion, a liquid seal 2cm thick willunder these extreme conditions is due toA transfer station positions the pavera thickness of 10cm each. For the binderbe sprayed on the finished lining.a number of technical modifications.in placecourse, asphalt (0/19) is used with aCombined with an AB 500-2 Extendingbitumen content of 4% and for theHigh Compaction Technology performsScreed in TP2 version, the SUPER 1800-2The conditions on site are extreme notsurface course asphalt (0/12) with 7%great on the slope of 31°paves vertical strips varying in widthonly from the engineering point of viewof bitumen. The relatively high contentbetween 2.5m and 4m. On the slope,of bitumen is required to achieve waterproofness.The SUPER 1800-2 paves 80mIt is the steep slope angle of 31° thatposes a particular challenge on site. Thethe machine operates at a speed of 1.5mper minute. A small roller is sufficient toThe Best Seller Among VÖGELE Paverswide strips, from bottom to top. AfterSUPER 1800-2‘s capability of actingbring about the pavement’s final density.SUPER 1800-2 is the best seller among theVÖGELE road pavers. The powerful machineof the upper mid range comes with a hostof features construction companies value onthe machines made by VÖGELE. SUPER 1800-2is unrivalled especially in terms of versatility.Configured with an Extending Screed or Fixed-Width Screed, the paver handles jobs in conventionalroad construction. When combined withthe SprayJet Module, SUPER 1800-2 does anexcellent job as a spray paver and is ideal primarilyfor placing thin layers.Another example of the SUPER 1800-2’s highversatility is its latest appearance on the stageas a slope paver. In this version, the machine iscapable of paving asphalt in vertical strips onslopes with gradients up to 32°. Challenges likethis are found on landfill projects, canals, damsor, as shown in China, for water reservoirs.TRACKED PAVER SUPER 1800-2User-Friendly ErgoPlus Operating ConceptEngine:powerful PERKINS engine rated at 129.6kW,Hardtop of Glass-Fibre Reinforced Polymer Materialcomplies with exhaust standards COM 3aMaximum Pave Width:10mand EPALaydown Rate:up to 700 tonnes/hScreeds:AB 500-2 and AB 600-2 Extending ScreedsMaximum Layer Thickness:30cmand SB 250 Fixed-Width Screed, each ofTransport Width: 2.55mthem in TV, TP1 and TP2 VersionsPave Speed:up to 24 m/min.The paving team does a great job on the steep slope.Travel speed:up to 4.5km/h3233

WIRTGEN CHINA NEWSTechnical Features of the VÖGELE SUPER 1800-2 Slope Paverof the paver operator to his platform, thefootboard attached to the rear of the screedis fitted at an angle of 30 degrees, and soare the extra step on the screed and thesteps on the rear of the tractor unit.Perfect conveyance of mix under difficultconditionsA flow gate, hydraulically adjustable inheight, is installed inside the machinebehind the material hopper’s rear wall. Thegate serves to reduce the conveyor tunnel’scross section in order to control the flow ofmix on the conveyors while working on theslope. The flow gate prevents mix in theconveyor tunnel from slipping rearwardsto the screed. In addition, the materialhopper’s rear wall is higher to avoid spillsof mix on the engine cowling during feed ofthe paver with mix.ErgoPlus masters every situationThe SUPER 1800-2 slope paver, too,comes with ErgoPlus, the concept focussedon easy paver operation and perfect ergonomics.This way, handling the machine islight work for the paving team. In contrastto the standard version of ErgoPlus, the oneinstalled in the slope paver has two extrabuttons to operate the flow gate. In orderto offer ergonomic working conditions forthe paver operator also when working onthe slope, his two seats are adjustable ininclination to four different positions. Thisallows a horizontal seated posture at alltimes, also on the job in Henan, for relaxedand safe working.Adapted to job site requirements:the operator’s seat inclined forth by31 degrees allows ergonomical working.but also for the paving team headed byDr. Hao Jutao. The team paves asphalt,strip after strip, from bottom to top.When arrived at the top, a transfer stationpositions the paver in place for the nextstrip. Attached to safety cables, the pavermoves back down the slope to get readythere for its new climb. Safety first is themotto for feed of the paver with mix, too.A special shuttle vehicle driven electricallyand provided with a sheeted, insulateddump body supplies the paver with hotmix on the steep slope, several times foreach strip.Extra weights fitted to the front of the paver’schassis relocate its centre of gravity to preventthe paver from tilting over when working onthe incline.This method of construction made highdemands on machine technology, whicha conventional paver would not havebeen able to meet. Therefore, a team ofengineers at the VÖGELE headquartersin Mannheim, Germany, subjected theSUPER 1800-2 to a number of modificationsin order to allow paving under the extremeconditions to the usual, high standards ofquality.The paver on the slopeSeveral components of the SUPER 1800-2needed modifying for use on the slope fromtwo points of view: operational safety ofthe machine on the one hand and safety ofthe paving team on the other. It began withextra weights fitted to the front of thepaver’s chassis for relocating its centre ofgravity, a measure which prevents thepaver from tilting over when working onthe incline. The extra weights are providedwith two cable anchor points 3m apartfrom each other. To these points, pullcables can be attached to support thepaver’s climb. In order to ensure safe accessLeft: The operator’s ErgoPlus console withseparate push-buttons for the flow gate.Above: Infinitely variable control of the flow gateto adjust the conveyor tunnel’s cross section.34 35

WIRTGEN CHINA NEWS25 HAMM SINGLE DRUM ROLLERSON THE HUNAN SHAO-YONGEXPRESSWAYHunan Province, located in the heart of central China is one of the strong developing Provinces besidethe well known Regions in the East and South. With a size of 210.000 km 2 and a population of 67 Mioresidents, it is to become a signification position in the economy of central China.plants, 800 kinds of medicinal plants andIn 2004 Hunan squashed into the top60 varieties of rare plants protected byten longest road mileage lists of Chinathe State. Among more than 160 knownwith a road mileage of 1218KM. This net-mineral resources, 141 can be found inwork is going to be extended year by yearHunan, especially the Stibium, tungstenand of the new project is the new Hunanand manganese which recoverable depositsShao-Yong Expressway from Shaoyang toJOB REPORToccupy the first five positions in China.After more than 20 year’s opening up,Yongzhou.For the construction of this importantHunan is rich in materials and products,the economy in Hunan has harvestedbrilliant achievements. In 2004, GDP was4.5 Billion RMB investment, Shantou DahoMunicipal Construction Co. was awarded.The compactor’s pads can be removed, so that it can also be used as smooth compactor.well known as “a land flowing with milkRMB 561.226 billion, increasing byWith his long experience and excellentand honey”, and also famous for its “non12.0%. The achievements are based on anwork force Shantou Daho is able to com-After Shantou Daho Municipal ConstructionWIRTGEN (China) Machinery Co. Ltd.cylinder engine with 147 kW. The flagship,ferrous metal” and “non metal” andongoing growth of investments, whichplete this fastidious task. The ExpresswayCo. was awarded for this contract, theThis job requires unique and reliableHAMM 3625 HT has a max weight of“tourist attraction” etc. It is endowedneeds as well an ongoing improvement ofwill have a total length of 111.8km. andcompanies General Manager for Machinery,technology says Mr. Xia, Vice Project25.000 kg, a drum width of 2.22m and iswith more than 2,000 species of woodythe infrastructure, in transportation ina widths of 26m with 4 lanes for eachMr. Luo Gan Lai, started to contact all wellManager. To fulfil all requirements incl.powered by a water cooled DEUTZ 6 cylinderplants, 1,000 species of economic usefulparticular.direction. The construction starts in Mayknow manufacturer. Beside of Excavators,economical and environmental friendlyengine with 174 kW. Both machines have a2006 and is scheduled for completion tillDozers and Wheel Loaders, Mr. Luo wasaspects, so we decided to make deep inve-compaction drum with a 1.600mm in dia-End of 2008.looking of course for Single Drum Rollers.stigations and also several test. At the end,meter and a steel thickness of 45mm.As high quality standards for ExpresswaysShantou Daho Municipal Construction Co.To build this Expressway, almost 30 Mioare requested and the quality of anto the decision for 13 units 20t HAMMTo use the machines for differentm 3 have to be moved and till April 2007,Expressway starts from the foundation3520 with Hammtronic and 12 units 25tapplications, Shantou Daho Municipal50 % of the earthmoving work was finished.and the base course, it was clear, thatHAMM 3625 with Hammtronic. This wasConstruction Co. Choose also the uniqueonly the best equipment is good enough.the biggest single order from a customerHAMM pad foot shells which allow usingFor this huge job of earth moving andAfter the evaluation of different brands,for HAMM single drum rollers in China,the machine also for heavy soil compactioncompaction, heavy equipment was needed.3 major manufactures have been invitedand we are very proud about it says Andyincl. the effect to de-hydrate the soil. Thefor the first talks. One of this manufac-Klingels, Sales Director for VÖGELE andadvantage of these shells is that they aretures was the well known HAMM AG,HAMM Products of WIRTGEN (China)easy to assemble and disassemble. All overIn the comfortable cabin of the HAMMcompactor, the operator can adjust hisseat and the steering column to meet hispersonal needs. This way, an optimal viewof the job site is guaranteed.a member of the world leading WIRTGENGroup. The project was handled withGuangzhou based Estrong Trading CoLtd., which is a long term partner ofMachinery Co.Ltd.The HAMM 3520 HT has a max weightof 22.500 kg, a drum width of 2.22m andis powered by a water cooled DEUTZ 6all it means, two different applicationswith one machine.The innovative Hammtronic design is a36 37

WIRTGEN CHINA NEWSShaoyang, the gateway of the southwest, situatedin the centre of Hunan province, consists of eightcounties, one county-level city and three urbandistricts, with an area of 21000 square kilometresranking the second in Hunan and with a populationof 7.3 million ranking the first in Hunan. It hasalways been the important city of Hunan forThe Province of Hunan and Shaoyang2500 years. Yongzhou is in the south of HunanProvince on the upper reaches of the XiangjiangRiver, where it meets Xiaoshui River. Therefore,Yongzhou is sometimes called Xiaoxiang. It is afamous historical and cultural city of HunanProvince, attracting many distinguished personssince the Tang and Song dynasties.The highly efficient coolingsystem with optimized airrouting provides for excellentcooling of all compactors ofthe series 3000.unique system for construction machineoperation. The system supports the driverand improves the working quality and performanceof the machine. As a result, unitoperating costs drop significantly and jobprofit increases. The system is a network offour modules. The drive control commandsthe starting, braking and driving speedwhile the engine is protected by the loadlimit control. The antislip control guaranteesan excellent slope climbing ability of thecompactor and an exceptional drivingperformance on difficult terrain.The vibration control regulates thehydrostatic vibration drive and optimizes thecompaction performance and compactionquality. The intelligent electronic systemadjusts the engine speed to the performancedemands of different terrains, and achievessignificant fuel economy. Working on fullpower with low cost and low noise themachine is just perfect for this kind of jobs.Mr. Luo , GM of the machinery Dept. ofShantou Daho Municipal Construction Coexplains why he also count on a WIRTGENGroup Product like the HAMM Compactors,It is not the machine only but also the aftersales service, repair, training and applicationsupport which is offered by WIRTGEN.With the assembling, repair and servicecentre in Langfang (Hebei) and additionalservice centres in Guangzhou, Shanghaiand Xian, WIRTGEN is always close to us.As usual WIRTGEN supported this job withtheir 24h service. Parts and ServiceEngineers how are on site, gives us thegreat confidence which we are used tohave from WIRTGEN.Easy maintenance and longintervals between servicingkept downtime of the HAMMcompactors short on the HunanShao-Yong Expressway.Hammtronic controls all major machinefunctions and adjusts performance to meetthe requirements. This enhances economicaloperating efficiency while reducing fuelconsumption.3839