download - Evides

download - Evides

download - Evides

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

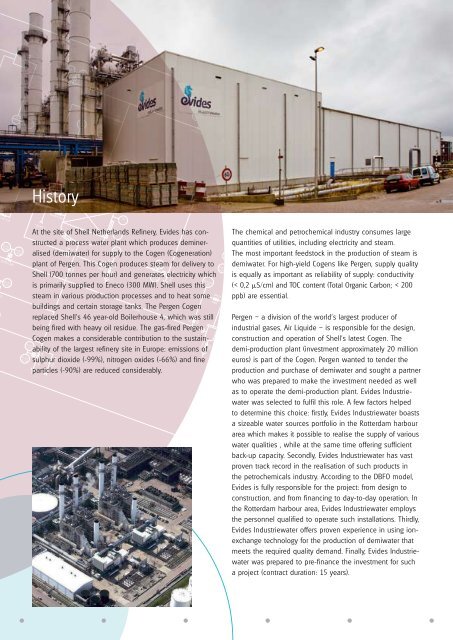

History50-V1200 At the site of Shell Netherlands Refinery, <strong>Evides</strong> has constructeda process water plant which produces demineralised(demiwater) for supply to the Cogen (Cogeneration)plant of Pergen. This Cogen produces steam for delivery toShell (700 tonnes per hour) and generates electricity whichis primarily supplied to Eneco (300 MW). Shell uses thissteam in various production processes and to heat somebuildings and certain storage tanks. The Pergen Cogenreplaced Shell’s 46 year-old Boilerhouse 4, which was stillbeing fired with heavy oil residue. The gas-fired PergenCogen makes a considerable contribution to the sustainabilityof the largest refinery site in Europe: emissions ofsulphur dioxide (-99%), nitrogen oxides (-66%) and fineparticles (-90%) are reduced considerably. The chemical and petrochemical industry consumes largequantities of utilities, including electricity and steam.The most important feedstock in the production of steam isdemiwater. For high-yield Cogens like Pergen, supply qualityis equally as important as reliability of supply: conductivity(< 0,2 mS/cm) and TOC content (Total Organic Carbon; < 200ppb) are essential.BL IX Pergen – a division of the world’s largest producer ofindustrial gases, Air Liquide – is responsible for the design,construction and operation of Shell’s latest Cogen. Thedemi-production plant (investment approximately 20 millioneuros) is part of the Cogen. Pergen wanted to tender theproduction and purchase of demiwater and sought a partnerwho was prepared to make the investment needed as wellas to operate the demi-production plant. <strong>Evides</strong> Industriewaterwas selected to fulfil this role. A few factors helpedto determine this choice: firstly, <strong>Evides</strong> Industriewater boastsa sizeable water sources portfolio in the Rotterdam harbourarea which makes it possible to realise the supply of variouswater qualities , while at the same time offering sufficientback-up capacity. Secondly, <strong>Evides</strong> Industriewater has vastproven track record in the realisation of such products inthe petrochemicals industry. According to the DBFO model,<strong>Evides</strong> is fully responsible for the project: from design toconstruction, and from financing to day-to-day operation. Inthe Rotterdam harbour area, <strong>Evides</strong> Industriewater employsthe personnel qualified to operate such installations. Thirdly,<strong>Evides</strong> Industriewater offers proven experience in using ionexchangetechnology for the production of demiwater thatmeets the required quality demand. Finally, <strong>Evides</strong> Industriewaterwas prepared to pre-finance the investment for sucha project (contract duration: 15 years).