You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

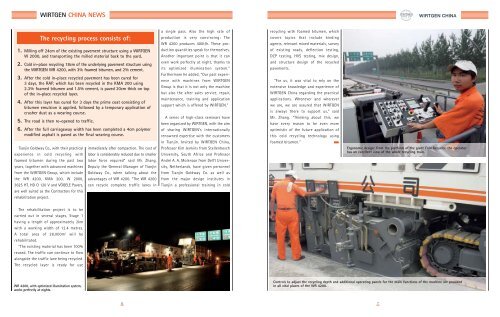

WIRTGEN CHINA NEWSWR 4200 LAUNCHEDIN TIANJINOn Section K96-K98 of the Jingshen Expressway (Beijing – Shenyang), a “giant” is working withperfect efficiency; the complete process of “cold in-place recycling”, including milling, mixing,paving and pre-compaction, is all done by a single giant-sized machine, the WIRTGEN WR 4200.TECHNOLOGYThe well proven cold in-place recyclingprocess, in combination with state-ofthe-artfoamed bitumen technology, isthe key to the success of large-scalerenowned cold recycling technologythat they decided to purchase a WR 4200.a total length of 658 km. It leaves Beijingprojects with the highest qualitysince the year 2005. During this period,heading east and crosses the jurisdictionsstandards. Thanks to its large workingwidth up to 4.2 metres, the flexiblehigh-performance WIRTGEN WR 4200On Section K96-K98 of the Jinshen Expressway, after the WR 4200 Recycler, a 25-tonneHAMM roller compacts the recycled layer.they have bought several WIRTGENrecyclers and other ancillary plant such asthe WM 1000. His company was the firstThe Jingshen Expressway, which linksBeijing and Shenyang, is the only expresswayfrom Beijing to Northeast of China.of Beijing municipality, Hebei province,Tianjin municipality and Liaoningprovince. The expressway opened to therecycler is capable of recycling full trafficin China to purchase a WIRTGEN KMA 200.It comprises a very long expressway, withgeneral motoring public on Septemberlane widths in a single pass. TrafficSince purchasing the KMA 200 last year,15, 1999, after four years of work ondisruption is minimized as only one lanethey used this equipment to carry outdifferent sections. There has been ais temporarily blocked by the WR 4200.The result is a structurally rehabilitatedrehabilitation work on the Jinghu (Beijing– Shanghai) Expressway (Tianjin Section)Asphalt, 19cmdramatic increase in heavy traffic andsevere damage has been caused by theroad pavement that is precisely designedand Jincang Expressway (Tianjin – Cangzhou),overloading of vehicles transportingto carry the expected heavy traffic overusing foamed bitumen. So, when theyraw material, mostly steel and cement.its design life. In addition, it is thefastest and most economical solution forneeded to rehabilitate the JingshenExpressway this year, it is was no surpriseCement treated base, 20cmIn view of the advantages of coldthe rehabilitation of heavily traffickedrecycling with foamed bitumen in termsroads and expressways.According to Mr. Wang, Chairman ofTianjin Goldway Co. (the owner of this,the very first WR 4200 in China), theyhave investigated the possibilities of theThe WM 1000 Mixer blends cement and water into a homogenous slurry.The slurry is sprayed directly into the mixing chamber of the WR 4200.Top: New base of high bearing capacity:the existing base is cold recycled in place,adding foamed bitumen and cement, andlaid by the WR 4200.Bottom Right: The existing pavementstructure is shown below.Lime and fly ash mixture, 15cmLime stabilized soil, 15cmof cost-effectiveness, environmentalfriendliness, least disruption to traffic andshort construction time, this technologywas chosen by the project owner,Tianjin Municipal Bureau and TianjinExpressway Development Inc.45