Worksheet Specifications - Concrete Batch Plants

Worksheet Specifications - Concrete Batch Plants

Worksheet Specifications - Concrete Batch Plants

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

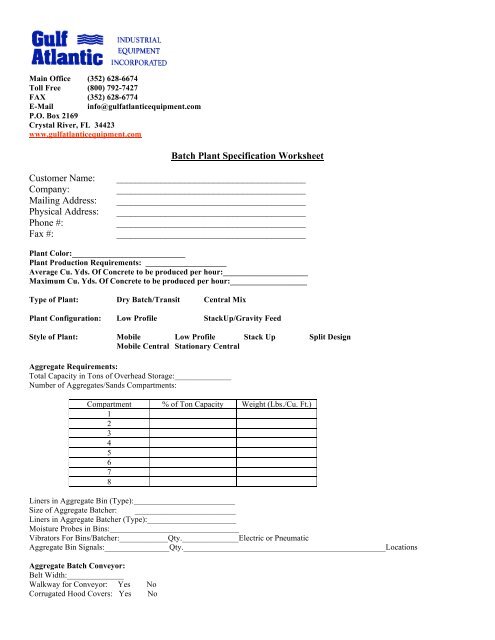

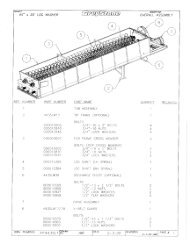

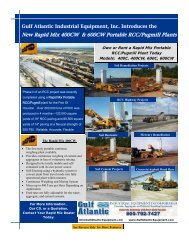

Main Office (352) 628-6674Toll Free (800) 792-7427FAX (352) 628-6774E-Mail info@gulfatlanticequipment.comP.O. Box 2169Crystal River, FL 34423www.gulfatlanticequipment.com<strong>Batch</strong> Plant Specification <strong>Worksheet</strong>Customer Name:Company:Mailing Address:Physical Address:Phone #:Fax #:__________________________________________________________________________________________________________________________________________________________________________________________________________________________________________Plant Color:____________________________Plant Production Requirements: ____________________Average Cu. Yds. Of <strong>Concrete</strong> to be produced per hour:_____________________Maximum Cu. Yds. Of <strong>Concrete</strong> to be produced per hour:___________________Type of Plant: Dry <strong>Batch</strong>/Transit Central MixPlant Configuration: Low Profile StackUp/Gravity FeedStyle of Plant: Mobile Low Profile Stack Up Split DesignMobile Central Stationary CentralAggregate Requirements:Total Capacity in Tons of Overhead Storage:______________Number of Aggregates/Sands Compartments:Compartment % of Ton Capacity Weight (Lbs./Cu. Ft.)12345678Liners in Aggregate Bin (Type):_________________________Size of Aggregate <strong>Batch</strong>er: _________________________Liners in Aggregate <strong>Batch</strong>er (Type):______________________Moisture Probes in Bins:________________________________Vibrators For Bins/<strong>Batch</strong>er:____________Qty.______________Electric or PneumaticAggregate Bin Signals:________________Qty.__________________________________________________LocationsAggregate <strong>Batch</strong> Conveyor:Belt Width:______________Walkway for Conveyor: Yes NoCorrugated Hood Covers: Yes No

Cement Requirements:Total Capacity in Tons or Barrels/Cu. Ft.Type of Cement# of CompartmentsSplit? 50/50, 60/40, etc.Size of Cement <strong>Batch</strong>erNumber of Bin SignalsPneumatic or Blower System AerationOverfill Protection Kit?Cement 1 Cement 2 Cement 3 Cement 4Water and Air Requirements:Metered or Weighed Water ___________________ Water Meter Size: ___________________Weighed Water <strong>Batch</strong>er Size ___________________ Air Compressor HP: ___________________Electrical Requirements:Voltage of Plant: Volts:_______ Phase:________ Hz:_________Motor Starters at each motor:________________Motor Starters in a single panel location:_________________Wiring by Customer to be: SO Cord ConduitPlant Controls:Manual Push Button: Brand Preference:_______________________Semi-Automatic Control: Brand Preference:_______________________Fully Automatic Control: Brand Preference:_______________________Also complete control data sheetDust Collection:Silo Roof Top Dust Collectors:_______________________________________Cement <strong>Batch</strong>er Dust Collectors:______________________________________Centralized Pick-up Dust Collector:____________________________________Ready Mix Truck Pickup Point:_______________________________________Dust Control:_______________Types of Trucks:_________________________Drive Thru:________________ Back In Lanes:___________________________Aggregate Feed System:Radial Stacking Conveyor Feeding Plant:________________________________Stationary Conveyor Feeding Plant:_____________________________________Front End Loader Hopper:_____________________________________________Back Dump Hopper:_________________________________________________Drive Over Hopper:__________________________________________________Belt Width:________________Walkway for Conveyor:_______________________Corrugated Hood Covers:______________________Safety Equipment:Safety Pull Cord Switches:_____________________________________________Ladders and Cages:___________________________________________________Erection Requirements:Installation by: Owner Gulf-AtlanticInstallation Supervision Required: Yes NoPlant Start-Up Supervision Required: Yes NoMixer Requirements:Drum Mixer Size: 10 Cu. Yd. 12 Cu. Yd. 15 Cu. Yd.Pan Mixer Capacity: (C.F.): 50 60 80 100 120 160Twin Shaft Capacity: (Cu. Meter) 2.25 3.0 3.5 4.5 6.0