PRIMARY IMPACT BULLETIN - Concrete Batch Plants

PRIMARY IMPACT BULLETIN - Concrete Batch Plants

PRIMARY IMPACT BULLETIN - Concrete Batch Plants

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

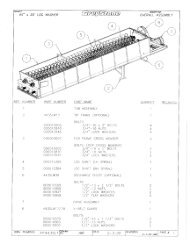

UNIVERSAL MAXCAP<strong>PRIMARY</strong> <strong>IMPACT</strong> CRUSHERThe Universal MaxCap Primary Impact Crusher features thebest of both the Andreas and New Holland style primarycrushers. The MaxCap features a large expansion area abovethe rotor “like the New Holland Style” while using thetechnology of the “Andreas Style” for the ease of operationand maintenance. The primary stage impact chamber utilizesinterchangeable fixed impact plates to deflect the material asit vertically expands and promote controlled re-entry into theimpact zone for maximum reduction. The secondary impactchamber with adjustable breaker plate and cast wear plates,controls product top-size as the chamber is adjusted tocompensate for changes in product requirements. TheUniversal MaxCap provides maximum capacity of a highquality,cubical product at a lower cost-per-ton.The crusher housing is fabricated of Heavy-duty plate steelconstruction with interchangeable sideliners and large inspection doors for ease of maintenanceand routine inspections. Reversible and interchangeable cast manganese wear plates protectthe feed plate and the lower breaker plate. The crusher hood opens hydraulically to provideeasy access to the interior. The solid rotor, constructed of steel plate is machined and balanced,accommodating three (3) cast manganese full-width reversible hammers with a quick-changewedge system. The hammers are vertically installed with a protruding leading edge for optimumcapacity and greater utilization, optional high chrome steel hammers are available for certainapplications. For additional sizing control a third stage reduction plate with replaceable linersis available that can be added at the factory or in the field. Asingle electric hydraulic package provides the power for thehydraulic hood opening, the hydraulic feed plate (shim adjustable),and the hydraulic adjustment of the lower breaker plate withautomatic reset. The MaxCap advantage is unmatched productcontrol at the touch of a button.The Universal MaxCap is the result of years of impact crushingexperience, and advanced design concepts in metallurgy andprocesses. Compare the Universal MaxCap with other primarycrushers, and you will see that it is one of the most technologicallyadvanced line of crushers available!

UNIVERSAL ANDREAS<strong>PRIMARY</strong> <strong>IMPACT</strong> CRUSHERThe Universal Andreas Primary Impact Crushers arethe most advanced line of Andreas style crushersavailable in today’s industry. These crushers are highlyimproved, productive crushers designed for low costoperation. A high reduction ratio and cubical productare key benefits of the Universal Andreas PrimaryImpact design.The Universal Andreas Impact Primary Crushers aretrue impact type crushers and are ideal for a variety ofapplications.What separates Universal’s Andreas Primary ImpactCrusher from other designs is an unique, largediameter rotor. Universal has developed a rotor thatoperates at a reduced speed, decreasing wear and consuming less energy while delivering asuperior high-inertia impact force. The rotor is supported by self-aligning, grease lubricatedspherical roller bearings contained in a maintenance-free housing with labyrinth seals. Theunique “S” design of the hammer provides a sharp leading edge for a longer period as thehammer wears. This sharp leading edge enables the crusher to sustain greater capacitieslonger with consistent product gradation. The hammers are reversible and are vertically liftedfrom the rotor for reversing or replacement, resulting in less downtime. Both the primary andsecondary curtains are lined with interchangeable abrasion resistant liners and come equippedwith a hydraulic assisted adjustment system. Thecrusher housing is fabricated of heavy-duty steel plateand lined with interchangeable abrasion resistantliners. Incorporating numerous inspection doors in thehousing enhances maintenance efficiency. For a moredetailed inspection and routine maintenance, the hoodhydraulically opens providing clear access to theinterior of the crusher.Compare the benefits of the Universal Andreas PrimaryImpact Crusher with any other Andreas primary impactcrusher on the market today, and you will find that youcan rely on the experience and expertise of UniversalEngineering, a proven industry leader.

UNIVERSAL NEW HOLLAND<strong>PRIMARY</strong> <strong>IMPACT</strong> CRUSHERNo other impact crusher can match the versatility and capacity ofthe Universal New Holland Primary Impact Crusher. A reductionratio up to 20 to 1 reduces even the largest pieces of quarry run todesired product size in seconds.The Universal New Holland Primary Impact Crusher’s unique “freeflow”design combines superior engineering with top quality, ruggedconstruction. “Free-flow” combines a large expansion crushingchamber, a massive fabricated rotor, upper deflector screen gratewith vertical openings, upper and lower breaker bars; all adding upto precise product control with maximum output.The fabricated steel rotor is precision machined andbalanced, and provides tremendous impact power withless horsepower. Shallow hammer wells provide strengthand no two wells are located directly across from oneanother to weaken the rotor. The Universal threehammer design has been field proven for years!Weldable rotor hammers are made of cast manganesesteel and are reversible on most models for extendedlife.A heavy chain and rubber curtain helps prevent materialfrom rebounding out of the crushing chamber. Thecurtain also helps keep dust to a minimum.Replaceable abrasion resistant steel liners are securedin place by an unique bolting arrangement. This provides50% longer liner life and eliminates the danger ofretaining bolts wearing and dropping into the crushingchamber.Compare the benefits of the Universal New HollandPrimary Impact Crusher with any other New Holland style impact crusher on the market today,and you will find that you can rely on the experience and expertise of a proven industry leader.

UNIVERSAL RCPRECYCLE <strong>IMPACT</strong> CRUSHERUniversal Engineering has supplied crushing,screening and associated equipment for recyclingapplications since 1966. Over the years continuousdesign refinements have been incorporated intoour crushers for enhanced performance andefficiency.The RCP Recycle Impact Crusher has beenspecifically designed to meet the need of the growing market for recycled concrete andasphalt materials. These Universal crushers feature an extra-wide feed opening toaccommodate large slabby material more efficiently. Two independent curtains form theprimary and secondary crushing chambers. The curtain liners are interchangeable and castof a chromium alloy for extended wear life. The curtainweldments are heavily reinforced providing sufficientweight to negate any need for spring bridges. The “S”shaped hammers are high chrome steel alloy for lowwear and low high durability to better tolerate reinforcedconcrete with heavy re-bar.The heart of the RCP Recycle Impact Crusher is the heavyduty large diameter rotor. The rotor consists of discs thatare made from high yield strength steel, and includereplaceable face plates. The one-piece rotor incorporatesa keyless shaft and is designed to handle rebar and wire mesh cleaning efficiently. Thiscrusher is available as standard with a 4-bar rotorto allow for maximum range of rotor tip speed. Anextra heavy duty 3-bar rotor is available as anoption and is particularly well suited for a variety ofapplications.Compare the Universal RCP Recycle ImpactCrusher feature by feature and see why it issuperior in performance and operating efficiency.Contact one of Universal’s application specialistsfor assistance in selecting the “right” plant for yournext project.

PORTABILITY MEANS PROFITUniversal’s portable plants provide an efficient flow ofmaterial throughout each transition point. Design emphasisis placed on optimum control of the material flow for flexibility,safety, and efficiency. This makes Universal’s plants easyto set up on the job site and reduces downtime betweenproduction runs.Your crushing profits begin with a Universal EngineeringPrimary Impact Portable Plant. Based on our expertiseand field experience, combined with the advice and inputfrom our valued customers, Universal Engineering hasdesigned rugged portable crushing plants with featuresthat put extra dollars in your pocket. The Primary ImpactPortable <strong>Plants</strong> are available with various high qualitycustom engineered Universal feed and dischargesystems, that are always designed to meet or exceedyour specifications.Universal Engineering’s portable recycling plants are designed to take you from job to job,handling large slabs of concrete and asphalt profitably. Universal Engineering can furnishboth single and two-stage recycle plants that utilize either an impact crusher alone or acombination of crushers.A typical single-stage portable recycling plant startswith a portable RCP Recycle Impact Crusher with avibrating grizzly feeder.A typical two-stage recycling application includes aprimary and secondary crusher and is used whenhigher production and greater flexibility are desired.Two stage crushing is ideal for multifunctional systemsthat may be called upon to crush reinforced concreteone day and tough quarry-shot dolomite the next day.Several different configurations of primary and secondary crushers can be utilized in a twostagerecycling operation.Universal Engineering has a broad range of equipment, the experience and the know-how todesign the perfect portable plant for your individual specifications and capacity requirements.Contact a Universal application specialist for assistance in selecting the “right” plant for yournext project.

COMMITMENT TO QUALITYCrushing equipment is only as good as the quality assurance programs ofthe manufacturer. Universal Engineering takes every step to make sure yourequipment is built with superior workmanship. From engineering and designto manufacturing and shipping, Universal Engineering employees give eachorder the conscientious care that has made us leaders in the aggregateindustry!Our parts specialists are dedicated to providing our customerswith prompt, efficient service and high quality parts to reducedowntime. Efficient inventory controls assure competitive pricesand quality parts to keep equipment and plants running. Formore information about Universal Engineering’s replacement parts,contact your local Universal Engineering distributor or give one ofour parts specialists a call.CONTINUOUS PRODUCT IMPROVEMENTUniversal Engineering Corp.’s reputation as an innovator in theindustry is due in part to our process of continuous improvement. Asproduct enhancements are developed, Universal engineers makeevery effort to allow retrofits wherever possible. This practice ensuresthat Universal’s equipment users have the opportunity to upgradetheir equipment to take advantage of the latest technology and costsavingfeatures.These enhancements may provide you the opportunity to increaseoverall production, improve gradation control, and provide timesavingmaintenance procedures. In most cases, an upgrade will allowcontinued use of the same components currently in your inventory.Give us a call, Universal Engineering’s team of specialists would liketo discuss your current application and various means to enhanceyour operations.The information contained herein is general in nature and is not intended for specific construction, installation or application purposes. Predictions of actual performance of a given piece of equipmentshould take into account the many variable field factors, no warranty of any kind, expressed or implied, is extended by presenting the generalized data herein. We reserve the right to make changes inspecifications shown herein or add improvements at any time without notice or obligation. Where drive mechanism guards are not shown, they have been removed for illustration purposes only; in actualworking conditions these protective devices should never be removed.

Printed in USA. Bulletin Number: B-PRIM-04-03-Rev. 0