INTEGRATED MISSION SOLUTIONS DD(X ... - Raytheon

INTEGRATED MISSION SOLUTIONS DD(X ... - Raytheon

INTEGRATED MISSION SOLUTIONS DD(X ... - Raytheon

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CHIP TECHNOLOGY (continued)<br />

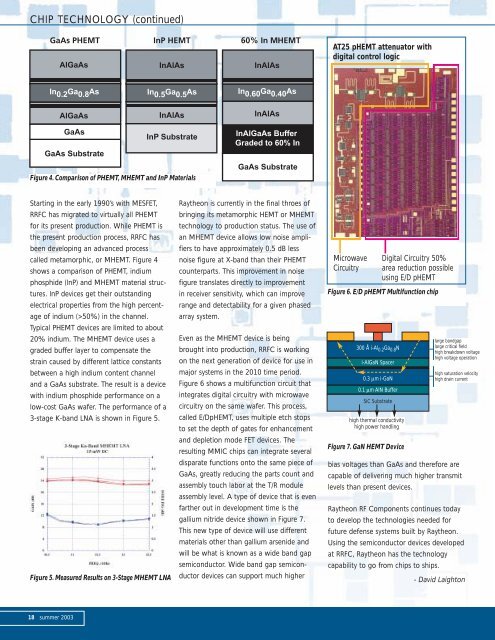

Figure 4. Comparison of PHEMT, MHEMT and InP Materials<br />

Starting in the early 1990’s with MESFET,<br />

RRFC has migrated to virtually all PHEMT<br />

for its present production. While PHEMT is<br />

the present production process, RRFC has<br />

been developing an advanced process<br />

called metamorphic, or MHEMT. Figure 4<br />

shows a comparison of PHEMT, indium<br />

phosphide (InP) and MHEMT material structures.<br />

InP devices get their outstanding<br />

electrical properties from the high percentage<br />

of indium (>50%) in the channel.<br />

Typical PHEMT devices are limited to about<br />

20% indium. The MHEMT device uses a<br />

graded buffer layer to compensate the<br />

strain caused by different lattice constants<br />

between a high indium content channel<br />

and a GaAs substrate. The result is a device<br />

with indium phosphide performance on a<br />

low-cost GaAs wafer. The performance of a<br />

3-stage K-band LNA is shown in Figure 5.<br />

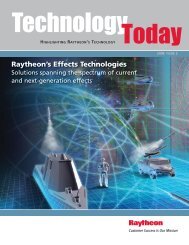

Figure 5. Measured Results on 3-Stage MHEMT LNA<br />

18 summer 2003<br />

<strong>Raytheon</strong> is currently in the final throes of<br />

bringing its metamorphic HEMT or MHEMT<br />

technology to production status. The use of<br />

an MHEMT device allows low noise amplifiers<br />

to have approximately 0.5 dB less<br />

noise figure at X-band than their PHEMT<br />

counterparts. This improvement in noise<br />

figure translates directly to improvement<br />

in receiver sensitivity, which can improve<br />

range and detectability for a given phased<br />

array system.<br />

Even as the MHEMT device is being<br />

brought into production, RRFC is working<br />

on the next generation of device for use in<br />

major systems in the 2010 time period.<br />

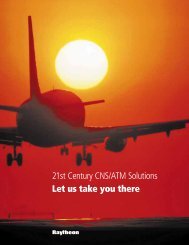

Figure 6 shows a multifunction circuit that<br />

integrates digital circuitry with microwave<br />

circuitry on the same wafer. This process,<br />

called E/DpHEMT, uses multiple etch stops<br />

to set the depth of gates for enhancement<br />

and depletion mode FET devices. The<br />

resulting MMIC chips can integrate several<br />

disparate functions onto the same piece of<br />

GaAs, greatly reducing the parts count and<br />

assembly touch labor at the T/R module<br />

assembly level. A type of device that is even<br />

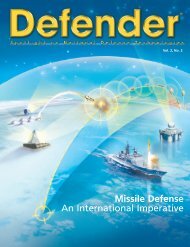

farther out in development time is the<br />

gallium nitride device shown in Figure 7.<br />

This new type of device will use different<br />

materials other than gallium arsenide and<br />

will be what is known as a wide band gap<br />

semiconductor. Wide band gap semiconductor<br />

devices can support much higher<br />

AT25 pHEMT attenuator with<br />

digital control logic<br />

Microwave<br />

Circuitry<br />

Digital Circuitry 50%<br />

area reduction possible<br />

using E/D pHEMT<br />

Figure 6. E/D pHEMT Multifunction chip<br />

300 Å i-Al 0.2 Ga 0.8 N<br />

i-AlGaN Spacer<br />

0.3 µm i-GaN<br />

0.1 µm AlN Buffer<br />

SiC Substrate<br />

high thermal conductivity<br />

high power handling<br />

Figure 7. GaN HEMT Device<br />

large bandgap<br />

large critical field<br />

high breakdown voltage<br />

high voltage operation<br />

high saturation velocity<br />

high drain current<br />

bias voltages than GaAs and therefore are<br />

capable of delivering much higher transmit<br />

levels than present devices.<br />

<strong>Raytheon</strong> RF Components continues today<br />

to develop the technologies needed for<br />

future defense systems built by <strong>Raytheon</strong>.<br />

Using the semiconductor devices developed<br />

at RRFC, <strong>Raytheon</strong> has the technology<br />

capability to go from chips to ships.<br />

- David Laighton