You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

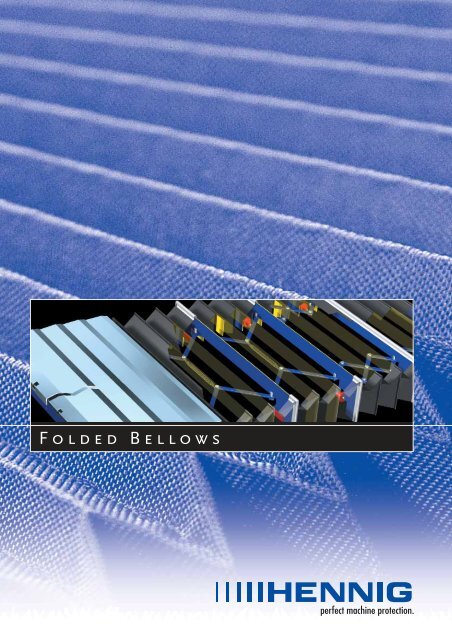

Folded Bellows

2<br />

Individually adapted protection–<br />

all bellows are made to suit customers’<br />

Perfect protection for man and machine. <strong>Hennig</strong> has designed and manufactured folded bellows for machine tools for<br />

more than 50 years. Our range includes simple dust protection, handling bellows, sophisticated designs featuring<br />

extension systems and/or lamellas, as well as special designs for laser machines. Our customers include<br />

nearly all renowned machine manufacturers. To maintain our high quality standards, all materials<br />

used are permanently checked and developed by our own R & D. <strong>Hennig</strong> offers excellent<br />

productivity and security for your machine.<br />

Advantages of <strong>Hennig</strong> bellows:<br />

• Maximum functional reliability<br />

• Tailor-made solutions<br />

• Maximum durability<br />

• Proven components<br />

• Minimum service requirements<br />

• Long-term supply of spare parts<br />

3

equirements<br />

4<br />

1<br />

5<br />

6<br />

7<br />

1<br />

2<br />

3<br />

Extension control systems<br />

(scissors, half-scissors, fold<br />

tapes)<br />

Roller<br />

End frame<br />

2<br />

4<br />

5<br />

6<br />

7<br />

1<br />

Intermediate frame<br />

Guide frame<br />

Glider<br />

Coupling rail<br />

3

4<br />

Folded Bellows<br />

High-frequency welded –<br />

remains tight for a long time<br />

Robust with a seam –<br />

a sound matter<br />

Neatly glued –<br />

can be adapted to any shape<br />

The optimum design for bellows is the high-frequency welded version.<br />

Thanks to this process developed and patented by <strong>Hennig</strong>, the<br />

cover material and guide frames made from PVC are permanently<br />

joined. The homogeneous connection of the bellows material and<br />

the guide frames ensures maximum loading capacity and absolute<br />

tightness against liquids such as cooling or grinding agents.<br />

For special requirements, e.g. resistance to temperatures of up to<br />

400 °C, stitched bellows can be used. High-frequency welded bellows<br />

can be manufactured in widths of up to 3 metres.<br />

We make bellows with round, oval or rectangular (with rounded off<br />

corners) cross-sections using a special sewing method. Bordering<br />

bands, ring fasteners or support rings will be used to meet special<br />

requirements and applications. Due to their robust design, these<br />

bellows have a reliable long service life, even under extreme mechanical<br />

and dynamic strain. The temperature resistance of these bellows<br />

can be increased to approx. 400 °C when using an aluminized glass<br />

fibre fabric.<br />

These bellows consist of up to three foils glued together in sandwich<br />

construction. Special shapes such as polygonal bellows, bellows<br />

with negative folding in the opposite direction, or bellows with<br />

small fold widths, can be easily constructed. Due to the special gluing<br />

of materials, these bellows provide maximum protection, even<br />

against liquids.

Fixed steel lamellas –<br />

a solid solution<br />

Movable steel lamellas –<br />

if space is reduced<br />

The perfect combination –<br />

to give perfect protection<br />

<strong>Hennig</strong> has developed lamella bellows to meet particularly<br />

high requirements.<br />

This type fills the gap between telescopic steel covers and<br />

conventional bellows. The lamella bellows are based on our<br />

high-frequency welded bellows. Each fold has its own guide<br />

frame which is HF-welded to the cover material.<br />

Lamellas made from stainless steel protect the bellows<br />

against red hot, sharp-edged swarf, or mechanical strain.<br />

Do you need vertically mounted bellows? Without lamella<br />

overhang? In such a case our bellows with movable lamellas<br />

are the perfect solution for you.<br />

Each lamella is flexibly fixed to the guide frame. Therefore,<br />

the lamellas can lie down flat on the machine enclosure at<br />

the bottom.<br />

These folded bellows featuring lamellas on three sides combine<br />

the advantages of telescopic steel covers and folded bellows.<br />

They are based on high-frequency welded bellows. Additionally,<br />

we have added a lamella in the shape of a telescopic element<br />

in each fold.<br />

Due to this combination of folded bellows and telescopic steel<br />

cover, these bellows are also protected on either side, especially<br />

against red hot, sharp-edged swarf or mechanical strain.<br />

Thanks to an ideal ratio between the extended and the compressed<br />

length and extremely compact dimensions – the<br />

lamella overhang equals zero – this type of bellows is perfectly<br />

suitable when space is limited.<br />

5

6<br />

Smooth running properties<br />

The dynamic properties of modern drives make heavy<br />

demands on all bellows. <strong>Hennig</strong> customers can choose<br />

between various design solutions.<br />

Hence, you can adapt every detail of the friction, exten-<br />

sion and durability properties of your bellows to your<br />

requirements.<br />

Rollers<br />

Rollers are used in large and heavy bellows with<br />

extension limits. They minimize friction and ensure<br />

excellent running properties.<br />

Scissors<br />

Scissors are used for high traversing speeds. This<br />

allows an even extension of all elements across the<br />

whole extension length. As a result, the folds are less<br />

strained and the durability of the bellows is prolonged.<br />

Half-Scissors<br />

The advantage of half-scissors is that the individual<br />

elements can be extended successively depending on<br />

the necessary extension length. Since the folds are<br />

not loaded up to the theoretically possible extension<br />

limit, the durability is also longer.

Excellent guiding properties<br />

Generally, <strong>Hennig</strong> bellows consist of a bellows cover,<br />

guide and end frames. Bellows with large extension<br />

lengths are composed of various elements which are<br />

connected by intermediate frames.<br />

Regarding the choice of material for frames and bellows,<br />

we can meet nearly all customer requirements.<br />

Guide frames<br />

The guide frames provide the bellows with the necessary<br />

stability and enable a precise operation, even at<br />

high speeds. They are made from PVC and are directly<br />

welded to the cover. The shape of the frames is<br />

adapted by <strong>Hennig</strong> to the design required.<br />

Intermediate frames<br />

Intermediate steel frames are used to connect the<br />

various elements, especially when extension limit<br />

systems are required. The intermediate frames are<br />

fastened to the bellows with a clamping rail. The<br />

intermediate frames can be guided by either plastic<br />

or brass rollers or gliders.<br />

End frames<br />

End frames, mostly made from steel or aluminium,<br />

connect the bellows with the machine. <strong>Hennig</strong> offers<br />

various fastening solutions for the adaptation to<br />

different bellows and machine interfaces.<br />

7

8<br />

Manufacturing competence<br />

The durability of <strong>Hennig</strong> folded bellows is not accidental. Meticulous<br />

production with modern joining methods and strict quality tests on<br />

our own test bench make sure that all bellows leaving our plant have<br />

the highest possible quality.<br />

High-frequency welding<br />

High-speed test bench<br />

The high-frequency welding system<br />

developed and patented for bellows<br />

by <strong>Hennig</strong> provides a homogeneous<br />

connection of bellows covers and<br />

guide frames.<br />

This method can also be used<br />

without any problem for the manufacture<br />

of up to 3 m high apron<br />

covers.<br />

As a manufacturer of high-quality<br />

machine protective systems,<br />

<strong>Hennig</strong> has its own high-speed<br />

test bench. Accelerations of up to<br />

4 g and speeds of up to 800 m/min<br />

can be tested. To simulate longterm<br />

use, we test our bellows up<br />

to the limits of physical loading.

Limitless – hennig folded bellows<br />

There is nearly no limit to the use of <strong>Hennig</strong> folded bellows.<br />

Our range of products provides an ideal solution for each<br />

application.<br />

We will assist you with pleasure in solving complicated tasks.<br />

We are in fact experts for tailor-made solutions!<br />

Horizontal cross-beam<br />

9

10<br />

Materials<br />

The covers of HENNIG folded bellows are exclusively<br />

made from high-quality plastic fabrics and foils.<br />

We select the cover material and processing<br />

according to the design ambient conditions.<br />

Decisive factors are the mechanical and thermal<br />

strain of the bellows as well as the type of swarf<br />

and aggressivity of the agents used. Exact details<br />

of the used materials may be gathered from the<br />

table of materials.<br />

Specification Coating Carrier Thick- Colour Type of bellows Resistant to<br />

number ext. int. ness wear<br />

(mm)<br />

SP 122 PUR PUR Polyester 0.35 black x x x ++<br />

SP 268 PUR PUR Polyester 0.22 black x x x 0<br />

SP 201 PUR PUR Nomex ® 0.35 black x x x 0<br />

SP 205 PVC PVC Polyester 0.23 black x x 0<br />

SP 206 PVC PVC Polyester 0.36 black x x +<br />

SP 127 PVC PVC Polyester 0.32 black x x +<br />

SP 208 ALU Glass fibre 0.35 silver x x +<br />

SP 106 PUR PUR Polyester 0.90 black/grey x ++<br />

SP 107 PUR PUR Polyester 1.00 black/grey x ++<br />

SP 109 Viton ® PUR Polyester 0.95 black/grey x ++<br />

SP 258 PVC PVC Polyester 0.40 black x +<br />

SP 259 PVC PVC Polyester 0.27 black x +<br />

SP 260 PVC PVC Polyester 0.23 black x +<br />

SP 270 PTFE PUR Polyester 0.30 black x x x x x ++<br />

– unsuitable, 0 suitable, + good, ++ very good<br />

HFwelded<br />

stitched<br />

Lamellabellows<br />

roundstitched<br />

glued<br />

special shapes

Table of Materials<br />

Most commonly used materials:<br />

POLYURETHAN (PUR): Temperature resistance up to 120°C<br />

Dickson-PTL: Aluminium-coated satin-glass fabric<br />

(Producer) Temperature resistance up to 400°C<br />

(only for stitched version)<br />

NOMEX ®<br />

: Flame-resistant material,<br />

suitable for laser applications<br />

POLYVINYLCHLORID Material does not continue burning<br />

(PVC): after energy application<br />

(self-extinguishing)<br />

TEFLON ®<br />

- Anti-adhesive, high-chemical and<br />

POLYTETRAFLUOR- thermal resilience, dirt-/water-repelling,<br />

ETHYLEN (PTFE): corrosion-proof<br />

Resistant against Surface Resistant against Self- Flame- Ratio between Note<br />

oil, greases and stability swarf, extinguishing resistant extension and<br />

coolants welding splatter compression<br />

forging scales<br />

++ ++ + +<br />

0 ++ 0 ++<br />

– + ++ x + Flame-resistant, radiant heat up to<br />

200 °C, US Standard UL94HB<br />

– 0 – – ++<br />

0 + 0 +<br />

– 0 0 x + Self-extinguishing, behaviour in fire<br />

corresponding to DIN 4102B2<br />

0 + ++ +<br />

++ ++ + 0<br />

++ ++ + 0<br />

+ ++ ++ 0 Contact temperature 400 °C<br />

0 + 0 0<br />

0 + 0 0<br />

0 + 0 0<br />

++ ++ ++ + +<br />

11

12<br />

Shapes: apron covers/folded bellows<br />

Apron cover Folded bellow<br />

Lmin.<br />

ae<br />

Fastening proposals<br />

AZ<br />

Stroke Hub<br />

Lmax.<br />

Stroke<br />

Hub<br />

Lmax.<br />

End frame (standard)<br />

• Steel, aluminium or PVC<br />

• Screwed onto the machine from<br />

inside or outside the bellows<br />

• Shape, bore holes or screw threads as per<br />

customer drawing<br />

End frame (protruding)<br />

• Steel, aluminium or PVC<br />

• Bellows screwed onto the machine from<br />

inside the bellows<br />

• Shape and bore holes as per customer<br />

drawing<br />

End frame (protruding)<br />

• Steel<br />

• Bellows fastened from inside with<br />

an auxiliary frame<br />

• Shape and bore threads as per customer<br />

drawing<br />

End frame (Velcro fastening)<br />

• Velcro band fastened with self-adhesive tape<br />

Special fixing devices and combinations are possible upon customers’ request.<br />

c<br />

AZ<br />

B<br />

a<br />

Lmin.<br />

e<br />

e<br />

cl

Shapes: apron covers/folded bellows<br />

with lamellas (fixed)<br />

Apron cover Folded bellow<br />

Guides Führungen<br />

müssen<br />

must durchgehend be<br />

continuous sein<br />

PVC PVC-Führungsrahmen<br />

Guide frame<br />

AZ<br />

Lmin. Hub Stroke<br />

Lmax.<br />

g<br />

g1<br />

a<br />

e<br />

e<br />

2 – 3<br />

2 Clearance – 3<br />

umlaufend all around<br />

4,2<br />

Fold height Extension per fold (AZ) Width of<br />

(e) Apron cover Bellow lamellas (K)<br />

24 27 33 61<br />

30 39 45 76<br />

35 49 55 81<br />

40 59 65 91<br />

45 69 75 101<br />

All dimensions in mm<br />

End frame (standard):<br />

• Steel, aluminium or PVC<br />

• Screwed onto the machine from inside<br />

or outside<br />

• Shape, bore holes or threads as per<br />

customer drawing<br />

End frame (protruding):<br />

• Steel<br />

• Screwed onto the machine from inside with<br />

an auxiliary frame<br />

• Shape and bore holes as per customer<br />

drawing<br />

End frame:<br />

• Steel, aluminium or PVC<br />

• Screwed onto the machine from inside<br />

• Shape, bore holes or threads as per<br />

customer drawing.<br />

Special fixing devices and combinations are possible up on customers’ requests.<br />

K<br />

c<br />

e<br />

AZ<br />

Stroke Hub<br />

Lmin.<br />

Lmax.<br />

g<br />

B<br />

a<br />

e<br />

e<br />

4,2<br />

K<br />

13

14<br />

Shapes: apron covers/folded bellows<br />

with lamellas (movable)<br />

Apron cover Folded bellow<br />

Guides Führungen<br />

müssen<br />

must durchgehend be<br />

continuous sein<br />

Fastening proposals<br />

g<br />

g1<br />

PVC PVC-Führungsrahmen<br />

Guide frame<br />

a<br />

AZ<br />

Lmin. Stroke Hub<br />

Lmax.<br />

e<br />

2 – 3<br />

2 Clearance – 3<br />

umlaufend all around<br />

K<br />

e<br />

Fold Extension per Fold(AZ) Width of<br />

height (e) Apron cover Bellow Lamellas(K)<br />

24 30 36 67<br />

30 42 48 82<br />

35 52 58 87<br />

40 62 68 97<br />

45 72 72 107<br />

4,2<br />

AZ<br />

Stroke Hub<br />

Lmin.<br />

Lmax.<br />

All Dimensions in mm<br />

End frame (standard):<br />

• Steel, aluminium or PVC<br />

• Screwed onto the machine from inside<br />

or outside<br />

• Shape, bore holes or threads as per<br />

customer drawing<br />

End frame (protruding):<br />

• Only suitable for movable lamellas<br />

• Steel, aluminium or PVC<br />

• Screwed onto the machine from inside<br />

• Shape, bore holes as per customer drawing<br />

End frame:<br />

• Steel, aluminium or PVC<br />

• Screwed onto the machine from inside<br />

• Shape, bore holes or threads as per<br />

customer drawing<br />

Special fixing devices and combinations are possible on customers’ requests.<br />

c<br />

e<br />

g<br />

B<br />

a<br />

K<br />

e<br />

e<br />

4,2

Shapes: round stitched bellows<br />

special glued shapes<br />

Ø G<br />

Ø G<br />

Fastening proposals<br />

Ø d<br />

e<br />

Ø D<br />

a<br />

Collar (Type 1/Type 2):<br />

Different fixing devices are possible on<br />

either side.<br />

Manschette Collar Support Stützring ring Endring End ring<br />

Manschette Collar<br />

Lmin.<br />

Lmin.<br />

Lmax.<br />

AZ<br />

Hub Stroke<br />

Stützrahmen Support frame Endrahmen End frame<br />

AZ<br />

Stroke<br />

Hub<br />

Lmax.<br />

Flange:<br />

Different fixing devices are possible on<br />

either side.<br />

Special fixing devices and combinations are possible up on customers’ request.<br />

15

1<br />

2<br />

Inquiry form for folded bellows<br />

Please copy, fill in and send to <strong>Hennig</strong> <strong>GmbH</strong> Fax No. +49 89 96096-120<br />

Company (complete address)<br />

Technical Data<br />

1. Required stroke<br />

2. Compressed length<br />

3. Extended length<br />

4. Fold height<br />

5. Length of lamellas<br />

6. Width of bellows<br />

7. Inner diameter of bellows<br />

8. Outside diameter of bellows<br />

9. Lower wrap-around<br />

10. Travel speed<br />

11. Acceleration<br />

12. Width of slideway<br />

13. Left-hand lateral height (outside)<br />

14. Right-hand lateral height (outside)<br />

15. Height of bellows above support<br />

16. Type of machine<br />

17. Axis<br />

18. Number of strokes per day<br />

19. Coolant**, lubricants<br />

20. Type of swarf<br />

21. Ambient temperature<br />

22. Linear type of slideway<br />

c 1<br />

a<br />

a<br />

d<br />

H =<br />

Lmin =<br />

Lmax =<br />

e =<br />

g =<br />

a =<br />

d =<br />

D =<br />

* see corresponding page in brochure ** no vegetable oils<br />

e<br />

c 2<br />

I =<br />

v =<br />

a =<br />

B =<br />

c1 =<br />

c2 =<br />

h =<br />

Date<br />

Contact<br />

E-Mail<br />

Phone/Facsimile<br />

mm<br />

mm<br />

mm<br />

mm<br />

mm<br />

mm<br />

mm<br />

mm<br />

mm<br />

m/min<br />

m/s 2<br />

mm<br />

X Y Z<br />

3<br />

Material of end frames<br />

Steel Stainless steel<br />

5 Mode of operation<br />

Horizontal Vertical<br />

Cross-beam Other<br />

6 Conditions of application<br />

8<br />

PVC Aluminium<br />

4 Type of fixing*<br />

Standard Protruding<br />

Velcro fastening Protruding<br />

Swarf Rust<br />

Coolant** Temperature<br />

Dust<br />

7 Standard shape*<br />

9<br />

Order quantity<br />

Sparks<br />

Drawings, sketch, photo or notes<br />

Flange<br />

Collar<br />

Wood<br />

Oil

A company of the GOELLNER Group Rockford Il./USA<br />

<strong>Hennig</strong> <strong>GmbH</strong> Postfach/PO Box 1343<br />

Überrheinerstr. 5<br />

85543 Kirchheim<br />

85551 Kirchheim<br />

Germany<br />

Germany<br />

Tel./Phone +49 89 960 96-0 info@hennig-gmbh.de<br />

Fax +49 89 960 96-120 www.hennig-gmbh.de<br />

All members of<br />

the <strong>Hennig</strong> group are<br />

DIN ISO 9001:2000 certified.<br />

www.hennigworldwide.com FTB0509/E