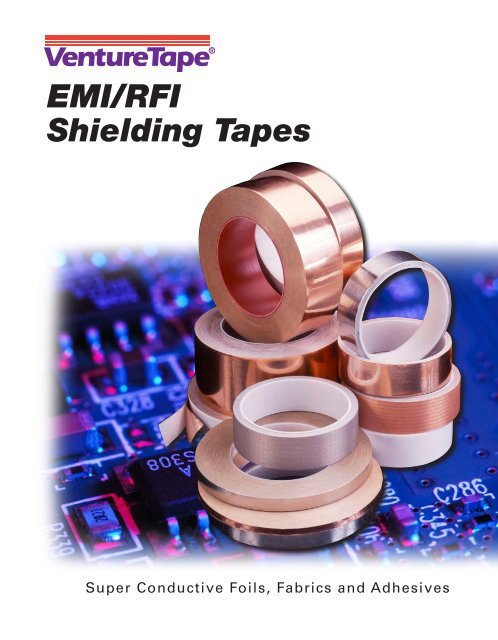

EMI/RFI Shielding Tapes - Venture Tape

EMI/RFI Shielding Tapes - Venture Tape

EMI/RFI Shielding Tapes - Venture Tape

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ProductDescriptionFeaturesSuper ConductiveFoil <strong><strong>Tape</strong>s</strong>1688 2 mil (50 micron)Super Electrically ConductiveAluminum Foil <strong>Shielding</strong> <strong>Tape</strong>Premium dead soft, high strength aluminum foil. Superior adhesion, malleabilityand adhesive conductivity. Extremely low resistance.169116971697AT1.5 mil (38 micron)Super Electrically Conductive,Tin Clad Copper Foil <strong>Shielding</strong> <strong>Tape</strong>1.4 mil (36 micron)Super Electrically ConductiveCopper Foil <strong>Shielding</strong> <strong>Tape</strong>1.4 mil (36 micron)Super Electrically Conductive,Tarnish Resistant Copper Foil <strong>Tape</strong>Electrolytic grade of a dead soft, zero temper copper foil, tin clad on bothsides for corrosion resistance. Superior adhesion, malleability and adhesiveconductivity. Extremely low resistance. Excellent shielding tape.Premium dead soft, zero temper, high tensile copper foil. Superioradhesion, malleability and adhesive conductivity. Extremely low resistance.Excellent shielding tape.Premium dead soft, zero temper, high tensile copper foil. Designed to resistsurface oxidation. Superior adhesion, malleability and adhesive conductivity.Extremely low resistance. Excellent shielding tape.1699 1.4 mil (36 micron)Super Electrically ConductiveDouble Coated Copper Foil <strong>Shielding</strong>Premium dead soft, zero temper, high tensile copper foil, adhesivecoated on both sides for superior adhesion and adhesive conductivity.Extremely low resistance. Excellent shielding tape.1694HT1694M3 mil (75 micron)Super Electrically Conductive2 oz. Tin Plated Copper Foil <strong>Tape</strong>3 mil (75 micron)Super Conductive Powder PaintingFoil Masking <strong>Tape</strong>A tin plated copper foil tape coated with an aggressive, high temperatureresistant, conductive, pressure sensitive adhesive.High temperature resistant, masked, tin plated copper foil. Recessed, removablepaint mask is a 2 mil, heat stabilized film adhesive designed for easyand clean removability.Super ConductiveTransfer AdhesivesFoil <strong><strong>Tape</strong>s</strong>1642 2 mil (50 micron)Super Electrically ConductiveUnsupported Transfer Adhesive1643 3 mil (75 micron)Super Electrically ConductiveUnsupported Transfer Adhesive1692 2 mil (50 micron)Super Electrically ConductiveUnsupported Transfer Adhesive1692FR16501650AT2 mil (50 micron) Flame RetardantSuper Electrically ConductiveUnsupported Transfer Adhesive1.5 mil (38 micron)Copper Foil <strong>Tape</strong>1.5 mil (38 micron)Anti-TarnishCopper Foil <strong>Tape</strong>Pressure sensitive acrylic adhesive that conducts electricity in the X, Y and Zdirection. Good quick stick and shear properties; extremely low electricalresistance. This adhesive is flexible and offers excellent conformability.Pressure sensitive acrylic adhesive that conducts electricity in the X, Y and Zdirection. Good quick stick and shear properties; extremely low electricalresistance. This adhesive is flexible and offers excellent conformability.Pressure sensitive acrylic adhesive that conducts electricity anisotropicallythrough the adhesive thickness. Good quick stick and shear properties;extremely low electrical resistance. This adhesive is flexible and offersexcellent conformability.Flame-retardant pressure sensitive acrylic adhesive that conducts electricityanisotropically through the adhesive thickness.Good quick stick and shearproperties; extremely low electrical resistance. This adhesive is flexible andoffers excellent conformability.Special electrolytic grade, zero temper, high tensile copper foil.Aggressive acrylic adhesive system. Foil readily accepts solder and isextremely malleable.Special electrolytic grade, zero temper, high tensile anti-tarnish copper foil.Aggressive acrylic adhesive system. Foil readily accepts solder and isextremely malleable.16901.5 mil (38 micron)Copper Foil <strong>Tape</strong>Special electrolytic grade copper foil, pressure clad on both surfaceswith tin foil for superior corrosion resistance. Accepts solder readily.Aggressive acrylic adhesive; high quick stick; excellent temperature range.Super ConductiveFabric <strong><strong>Tape</strong>s</strong>Heat Activated<strong><strong>Tape</strong>s</strong>3520CW ®1689 6 mil (150 micron)Super Electrically ConductiveMetalized Fabric <strong>Tape</strong>1689ROHS2 mil (50 micron)Cold WeatherAluminum Foil <strong>Tape</strong>6 mil (150 micron)Super Electrically ConductiveMetalized Fabric <strong>Tape</strong>5964 7.5 mil (190 micron)Heat ActivatedLaminating <strong>Tape</strong>6964 7.5 mil (190 micron)Heat ActivatedLaminating <strong>Tape</strong>Zero temper aluminum foil with aggressive, low out-gassing, acrylicadhesive system. Malleable; conforms to irregular surfaces. Superior quickstick at both low and elevated temperatures.Silver metalized ripstop nylon cloth, overcoated with nickel for superiorcorrosion resistance and conductivity. Aggressive flame retardent acrylic,conductive adhesive. Good balance of peel and shear strength properties.Silver metalized ripstop nylon cloth, overcoated with nickel for superiorcorrosion resistance and conductivity. Aggressive acrylic, conductiveadhesive. Good balance of peel and shear strength properties. ROHS compliant.Flexible thermoplastic adhesive tape which has excellent adhesion to avariety of materials. The construction consists of a nonwoven core coatedboth sides with the same heat activated adhesive.Flexible thermosetting adhesive tape which has excellent adhesion to avariety of materials. The construction consists of a nonwoven core coatedboth sides with the same heat activated adhesive.

Primary ApplicationsPeel AdhesionShearStrengthElongationTensile StrengthTemp. RangeElec. Resistance<strong>Shielding</strong> EffectivenessFrequency Attenuation<strong>EMI</strong>/<strong>RFI</strong> shielding. Printed circuit manufactureand repair.36 oz/in width(10.2 N/2.5 cm)2.2 psi 72+ hours(15.2 kPa)4.4%27 lb/in width(123 N/2.5 cm)–40°F to 250°F(–40°C to 121°C)0.009 ohms/sq in100 mhz 60 db400 mhz 69 db1 Ghz 70 db<strong>EMI</strong>/<strong>RFI</strong> shielding. Printed circuit manufactureand repair. Exceptional solderability and corrosionresistance.36 oz/in width(10.2 N/2.5 cm1.1 psi indefinite(7.6 kPa)6%36 lb/in width(163 N/2.5 cm)–51°F to 275°F(–46°C to 135°C)0.002 ohms/sq in100 mhz 101.5 db400 mhz 102 db1 Ghz >116 db<strong>EMI</strong>/<strong>RFI</strong> shielding. Printed circuit manufactureand repair. Foil accepts solder readily.36 oz/in width(10.2 N/2.5 cm1.1 psi indefinite(7.6 kPa)6%36 lb/in width(163 N/2.5 cm)–40°F to 250°F(–40°C to 121°C)0.002 ohms/sq in100 mhz 101.5 db400 mhz 102 db1 Ghz >116 db<strong>EMI</strong>/<strong>RFI</strong> shielding. Printed circuit manufactureand repair. Foil accepts solder readily. Highlyresistant to tarnish/oxidation.36 oz/in width(10.2 N/2.5 cm1.1 psi indefinite(7.6 kPa)6%36 lb/in width(163 N/2.5 cm)10°F to 400°F(–12°C to 206°C)0.002 ohms/sq in100 mhz 141.5 db400 mhz 102 db1 Ghz >116 dbSplicing flexible circuits and LCD mounting.<strong>EMI</strong>/<strong>RFI</strong> shielding. Printed circuit manufactureand repair.36 oz/in width(10.2 N/2.5 cm1.1 psi indefinite(7.6 kPa)6%36 lb/in width(163 N/2.5 cm)–40°F to 250°F(–40°C to 121°C)0.002 ohms/sq in100 mhz 101.5 db400 mhz 102 db1 Ghz >116 db<strong>EMI</strong>/<strong>RFI</strong> shielding. Offers exceptional solderability,corrosion resistance and high temperatureresistance.70 oz/in width(20 N/2.5 cm)2.2 psi indefinite(15.2 kPa)6%70 lb/in width(317 N/2.5 cm)10°F to 400°F(–12°C to 206°C)0.002 ohms/sq in100 mhz 141 db400 mhz 102 db1 Ghz >116 dbDesigned to meet rigorous powder paint processby providing a non-corrosive, conductivesurface for shielded sheet metal enclosures.Foil: 70 oz/in width(20 N/2.5 cm)Mask: 20 oz/in width2.2 psi(15.2 kPa)6%70 lb/in width(317 N/2.5 cm)–50°F to 400°F(–46°C to 205°C)0.002 ohms/sq in100 mhz 101.5 db400 mhz 102 db1 Ghz >116 dbMounting <strong>EMI</strong>/<strong>RFI</strong> shields and gaskets, ESDpads and flexible circuit splicing and attachment.40 oz/in width (ult.)(11.3 N/2.5 cm)2.2 psi Indefinite(15.2 kPa)NANA–30°F to 225°F(–34°C to 107°C)0.005 ohms/sq inNAMounting <strong>EMI</strong>/<strong>RFI</strong> shields and gaskets, ESDpads and flexible circuit splicing and attachment.35 oz/in width(9.9 N/2.5 cm)2.2 psi indefinite(15.2 kPa)NANA–30°F to 225°F(–34°C to 107°C)0.005 ohms/sq inNAMounting <strong>EMI</strong>/<strong>RFI</strong> shields and gaskets, ESDpads and flexible circuit splicing and attachment.70 oz/in width (ult.)(19.8 N/2.5 cm)2.2 psi indefinite(15.2 kPa)NANA–30°F to 225°F(–34°C to 107°C)0.005 ohms/sq inNAMounting <strong>EMI</strong>/<strong>RFI</strong> shields and gaskets, ESDpads and flexible circuit splicing and attachment.71.8 oz/in width (ult.)(20.3 N/2.5 cm)1.1 psi indefinite(7.6 kPa)NANA–40°F to 400°F(4°C to 205°C)0.005 ohms/sq inNADiverse industrial and electrical applications suchas printed circuit manufacture and repair, flexibleflat conductor, electrostatic and RF <strong>Shielding</strong>.60 oz/in width(17.3 N/2.5 cm)2 psi indefinite(13.8 kPa)6%36 lb/in width(163 N/2.5 cm)–40°F to 250°F(–40°C to 121°C)NA100 mhz 54 db400 mhz 61 db1 Ghz 67 dbDiverse industrial and electrical applications suchas printed circuit manufacture and repair, flexibleflat conductor, electrostatic and RF <strong>Shielding</strong>.60 oz/in width(17.3 N/2.5 cm)2 psi indefinite(13.8 kPa)6%36 lb/in width(163 N/2.5 cm)–40°F to 250°F(–40°C to 121°C)NA100 mhz 54 db400 mhz 61 db1 Ghz 67 dbIndustrial and electrical applications andlow level <strong>EMI</strong>/<strong>RFI</strong> shielding. Exceptionalsolderability and corrosion resistance.103 oz/in width(27.9 N/2.5 cm)2.2 psi(15.2 kPa)6%30 lb/in width(135.8 N/2.5 cm)10°F to 250°F(–12°C to 121°C)NA100 mhz 54 db400 mhz 61 db1 Ghz 67 dbIndustrial use for laminating, die-cutting, andlow level <strong>EMI</strong>/<strong>RFI</strong> shielding96 oz/in width(27.1 N/2.5 cm)2.2 psi(15.2 kPa)4.4%27 lb/in width(123 N/2.5 cm)–25°F to 260°F(–32°C to 127°C)NANASuperior adhesion, flexibility and conductivity makethis an excellent <strong>EMI</strong>/<strong>RFI</strong> shielding tape. Used forcable end and cable assembly shielding.71.8 oz/in width (ult.)(20.3 N/2.5 cm)1.1 psi indefinite(7.6 kPa)27%43 lb/in width(195 N/2.5 cm)7°F to 300°F(14°C to 149°C)0.009 ohms/sq in100 mhz 69 db400 mhz 70 db1 Ghz 75 dbSuperior adhesion, flexibility and conductivity makethis an excellent <strong>EMI</strong>/<strong>RFI</strong> shielding tape. Used forcable end and cable assembly shielding.71.8 oz/in width (ult.)(20.3 N/2.5 cm)1.1 psi indefinite(7.6 kPa)27%43 lb/in width(195 N/2.5 cm)7°F to 300°F(14°C to 149°C)0.009 ohms/sq in100 mhz 69 db400 mhz 70 db1 Ghz 75 dbUsed as a heat applied laminating adhesive for avariety of plastics films, foams, metal, papers, andetc. Specifically designed for the mobile telephone market.Destructive bondDestructive bond>15%>8 lb/in width(>39.8 N/2.5 cm)Activation 275°F(135°C)NAUsed as a heat applied laminating adhesive for avariety of plastics films, foams, metal, papers, andetc. Specifically designed for the mobile telephone market.Destructive bondDestructive bond>15%>8 lb/in width(>39.8 N/2.5 cm)Activation 275°F(135°C)NA

R&D Customer-responsive product development keeps<strong>Venture</strong> at the forefront in solutions to sealing, mountingand assembly problems. At <strong>Venture</strong> <strong>Tape</strong> we strive forcontinuous improvement through process control andtechnical innovation.Coating A new, state-of-the-art coating line providessubstantially increased capacity, through both speedand web width, with precise response to our computercontrol systems.Control The continuously advanced process controlsystems at <strong>Venture</strong> <strong>Tape</strong> are unrivaled in the industry.Computer-controlled from start to finish, the manufactureof our tapes is managed in a way never before possible.Converting Fully automated systems introduce aflexibility, speed and improved consistency to the conversionprocess which facilitates custom cuts, reduces wasteand provides better value to our customers.QA To better serve your needs, we maintain a programof continuous in-house testing and batch-tracking; thebackbone of the <strong>Venture</strong> <strong>Tape</strong> quality assurance system,aimed at providing consistent, predictable performance.Service Special order-handling capabilities, fastreaction service, high inventory levels and warehousesworldwide, get <strong>Venture</strong> products on their way to meetyour most challenging schedules.Limited WarrantyProducts sold by <strong>Venture</strong> <strong>Tape</strong> Corp. are warranted upon deliveryto be of the quality set forth in the specifications. <strong>Venture</strong> <strong>Tape</strong>Corp. makes no other representations or warranties, expressedor implied, including but not limited to, the implied warrantiesof merchantability and fitness for a particular purpose. Should aproduct sold by <strong>Venture</strong> <strong>Tape</strong> Corp. not be as warranted, <strong>Venture</strong><strong>Tape</strong> Corp.’s sole obligation shall be, at its sole option, to repair,correct or replace the products, or, at <strong>Venture</strong> <strong>Tape</strong> Corp.’s solediscretion,to refund amounts paid for such product upon itsreturn to a location designated by <strong>Venture</strong> <strong>Tape</strong> Corp. No productmay be returned to <strong>Venture</strong> <strong>Tape</strong> Corp. without prior written approval.Any return must be shipped within 14 days of delivery.<strong>Venture</strong> <strong>Tape</strong> Corp. shall in no event have any responsibility forany damages beyond the cost of the product, either for labor,expense or other damages of any sort including special, incidentalor consequential damages incurred by the buyer or user.Determination of the suitability of the product to its applicationand product installation are solely the responsibility of the buyer.<strong>Venture</strong> <strong>Tape</strong> Corp.30 Commerce RoadRockland, Massachusetts 02370 U.S.A.Tel: 781-331-5900 800-343-1076 (U.S.A.)800-544-1024 (Canada) Fax: 781-871-0065<strong>Venture</strong> <strong>Tape</strong> Europe Corp.Units 5/6, Faraday Close, Drayton FieldsDaventry, Northants, England NN11 5RDTel +44 (0) 1327 876555 Fax +44 (0) 1327 876444Toll Free from United Kingdom: 0-800-962-957<strong>Venture</strong> <strong>Tape</strong> Australasia, PTY, Ltd.11B Production Drive, Campbellfield 3061Victoria, AustraliaTel: 61 3 9357 6025 Fax: 61 3 9357 6045Toll Free from Australia: 1-800-122-797