You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

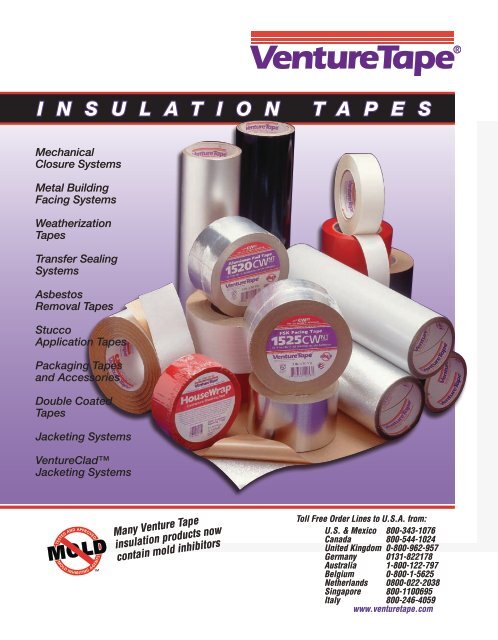

I N S U L A T I O N T A P E SMechanicalClosure SystemsMetal BuildingFacing SystemsWeatherization<strong>Tape</strong>sTransfer SealingSystemsAsbestosRemoval <strong>Tape</strong>sStuccoApplication <strong>Tape</strong>sPackaging <strong>Tape</strong>sand AccessoriesDouble Coated<strong>Tape</strong>sJacketing Systems<strong>Venture</strong>CladJacketing SystemsMany <strong>Venture</strong> <strong>Tape</strong><strong>insulation</strong> products nowcontain mold inhibitorsToll Free Order Lines to U.S.A. from:U.S. & Mexico 800-343-1076Canada 800-544-1024United Kingdom 0-800-962-957Germany 0131-822178Australia 1-800-122-797Belgium 0-800-1-5625Netherlands 0800-022-2038Singapore 800-1100695Italy 800-246-4059www.venturetape.com

The headquarters of <strong>Venture</strong> <strong>Tape</strong> Corp. houses research and development, product testing laboratories, sales,customer service and product training. Expanded to 234,000 square feet, it contains our specially designed,state-of-the-art manufacturing facility. Planned for peak efficiency, this plant features the industry’s latestdevelopments in process equipment and controls, as well as custom machinery available to no other tapemanufacturer.is a team of highly qualified professionalsworking together to provide our customerswith the highest quality products and the greatest economic value. Our mission is to seekcontinuous improvement in everything that we do. We are operating our business in a waythat safeguards the well-being of our people, our customers and our neighbors.We strive to give you, our customers, the latest, best and most innovativetechnology which will allow you to stay in the forefront in your industry at a cost that givesyou maximum economic value.Most <strong>Venture</strong> <strong>Tape</strong> products are shipped fromstock, from warehouses in:Rockland, MAAtlanta, GAHouston, TXCity of Industry, CAChicago, ILMilwaukee, WIPortland, ORCanadaAustraliaUnited KingdomSingaporeNetherlandsItaly<strong>Venture</strong> <strong>Tape</strong> Corp.30 Commerce RoadRockland, Massachusetts 02370 U.S.A.Tel 781-331-5900800-343-1076 (U.S.A.)Fax: 781-871-0065www.venturetape.com<strong>Venture</strong> <strong>Tape</strong> ® and C.W. ® are registered trademarks, and the “NoMold”symbol, <strong>Venture</strong>Clad and <strong>Venture</strong>Guard are trademarks of <strong>Venture</strong><strong>Tape</strong> Corp. Other trademarks are acknowledged to their respective owners.*U.S. Patent Nos. 4,606,957 & 4,595,615. Patented Canada 1987 1,218,923.Product specifications are subject to change without notice.©2008 <strong>Venture</strong> <strong>Tape</strong> Corp. Printed in U.S.A. 5/08

About <strong>Venture</strong> Quality…ISO9001: 2000 Status<strong>Venture</strong> <strong>Tape</strong> is committed to providingthe highest level of customer service. We strive tokeep our customers up to date on order status, productavailability, quotations, new products, quality, andother issues. Honesty and integrity are the hallmarksof <strong>Venture</strong> <strong>Tape</strong> and the cornerstones of our permanentcustomer satisfaction commitment.This commitment to our customers has allowed<strong>Venture</strong> <strong>Tape</strong> to achieve ISO9001: 2000 status at itsglobal facilities and ensures product consistencyworldwide. Beginning with product development,carrying through materials procurement, manufacturing,and delivery, we strive to match our productsexactly to customers needs and meet our customersexpectations every time. Our goal is always clear:Supply products which help solve problems.In addition to our extensive internal capabilities, <strong>Venture</strong>welcomes customer input in fulfilling this goal.Providing samples, application specific testing, andon-site consultation allows us to see our products inuse and gives us understanding of field performance,assuring that our products meet the most importantspecification of all: they work.Products described in this <strong>catalog</strong> are standard; contact<strong>Venture</strong> <strong>Tape</strong> about roll configurations or caselot information. Consult <strong>Venture</strong> <strong>Tape</strong> specialists forrecommendations on product selection, specializeddevelopment and testing, and innovative answersto engineering, packaging, marking, or materialhandling problems and let us demonstrate our commitmentto you.About <strong>Venture</strong> Adhesives...Rubber-Based Adhesives<strong>Venture</strong> <strong>Tape</strong>s indicating the use of rubber-basedadhesives are fabricated with a premium formulationcharacterized by extreme aggressiveness,high-peel and high shear strengths. They showexceptionally good adhesion to low surface energysubstrates such as polyethylene and polypropylene.They are generally recommended for interior usedue to inherently low UV resistance. They are notrecommended for use where temperatures mayexceed 200°F (93°C).Although rubber-based adhesives form a superiorbond, caution should be taken where resistance totemperatures above 180°F (82°C), UV exposure,solvents and weathering are required. <strong>Venture</strong>acrylic formulations perform better in these circumstances.Acrylic Adhesives<strong>Venture</strong> products specifying Acrylic Adhesives areuniformly manufactured with a specially developedformulation which combines exceptionallyhigh shear strength with both high tack and coldstick properties, so important in working underless-than-ideal conditions. The bond strength ofthe products in this aggressive, high temperatureadhesive family actually increases after application,through self cross-linking of its acrylic polymers.Cold Weather (CW ® ) Acrylics<strong>Venture</strong> <strong>Tape</strong>s constructed with Cold Weather AcrylicAdhesives are formulated specially for handlingin adverse conditions. A breakthrough in adhesivetechnology, these tapes retain their superior tackin cold, humid, even damp conditions, yet are heatstable up to 250°F (121°C). They are field testedand recommended for application in conditions aslow as –10°F (–23°C). As with our other acrylicformulae, bond strength increases after adhesion,due to self cross-linking properties.Revolutionary New CW ® Plus!In 1990, <strong>Venture</strong> introduced new CW ® Plus, anacrylic adhesive formula with 50% greater adhesion.It also features the amazing capability of beingapplied effectively at temperatures as low as –25°F(–32°C). CW ® Plus is currently limited in use toseveral ASJ products.Proprietary CW ®NT<strong>Venture</strong> <strong>Tape</strong> CW ®NT adhesives are specially formulatedfor the most extreme conditions. A variationof our standard CW ® adhesives, CW ®NT extendsthe application temperature range to -35°F/+260°F(37°C/+127°C); a range unmatched in the tapeindustry. Additionally, CW ®NT has 80% higherquick-stick with aggressive tack values which areactually higher than most rubber based products.Higher quick-stick is the technical characteristicthat actually saves you time/money. CW ®NT tapes godown and stay down, with no back-tracking to reseal.CW ®NT tapes also afford the superior resistance toUV and aging of our other CW ® acrylics, as well astheir phenomenal ability to perform in damp andotherwise adverse conditions.Super High BondA series of double coated tapes utilizing a variety ofhigh performance acrylic adhesives which exhibitextremely high peel, shear, heat and/or plasticizerresistance. Each adhesive type has slightly differentperformance properties but all show exceptionallyhigh bonding properties to a wide variety of substrates.Extra heavy coating weights allow for superadhesion to rough, uneven or textured surfaces. Theultimate in double sided tapes.Limited WarrantyProducts sold by <strong>Venture</strong> <strong>Tape</strong> Corp. are warranted upon deliveryto be of the quality set forth in the specifications. <strong>Venture</strong> <strong>Tape</strong>Corp. makes no other representations or warranties, expressedor implied, including but not limited to, the implied warrantiesof merchantability and fitness for a particular purpose. Should aproduct sold by <strong>Venture</strong> <strong>Tape</strong> Corp. not be as warranted, <strong>Venture</strong><strong>Tape</strong> Corp.’s sole obligation shall be, at its sole option, to repair,correct or replace the products, or, at <strong>Venture</strong> <strong>Tape</strong> Corp.’s solediscretion,to refund amounts paid for such product upon itsreturn to a location designated by <strong>Venture</strong> <strong>Tape</strong> Corp. No productmay be returned to <strong>Venture</strong> <strong>Tape</strong> Corp. without prior written approval.Any return must be shipped within 14 days of delivery.<strong>Venture</strong> <strong>Tape</strong> Corp. shall in no event have any responsibility forany damages beyond the cost of the product, either for labor,expense or other damages of any sort including special, incidentalor consequential damages incurred by the buyer or user.Determination of the suitability of the product to its applicationand product installation are solely the responsibility of the buyer.VENTURE TAPE CORP. MAKES NO OTHER REPRESENTATIONSOR WARRANTIES, EXPRESSED OR IMPLIED, INCLUDINGBUT NOT LIMITED TO, THE IMPLIED WARRANTIES OFMERCHANTABILITY AND FITNESS FOR A PARTICULARPURPOSE. SHOULD A PRODUCT SOLD BY VENTURE TAPECORP. NOT BE AS WARRANTED, VENTURE TAPE CORP.’S SOLEOBLIGATION SHALL BE, AT ITS SOLE OPTION, TO REPAIR,CORRECT OR REPLACE THE PRODUCTS, OR, AT VENTURETAPE CORP.’S SOLE DISCRETION, TO REFUND AMOUNTS PAIDFOR SUCH PRODUCT UPON ITS RETURN TO A LOCATIONDESIGNATED BY VENTURE TAPE CORP. NO PRODUCT MAYBE RETURNED TO VENTURE TAPE CORP. WITHOUT PRIORWRITTEN APPROVAL. ANY RETURN MUST BE SHIPPEDWITHIN 14 DAYS OF DELIVERY. VENTURE TAPE CORP. SHALLIN NO EVENT HAVE ANY RESPONSIBILITY FOR ANY DAMAGESBEYOND THE COST OF THE PRODUCT, EITHER FOR LABOR,EXPENSE OR OTHER DAMAGES OF ANY SORT INCLUD-ING SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGESINCURRED BY THE BUYER OR USER. DETERMINATION OFTHE SUITABILITY OF THE PRODUCT TO ITS APPLICATION ANDPRODUCT INSTALLATION ARE SOLELY THE RESPONSIBILITYOF THE BUYER.

Mechanical Closure Systems2 mil Aluminum FoilHigh Temperature<strong>Tape</strong>3243A 2 mil (50 micron) aluminum foil coated with a highshear, high heat resistant acrylic adhesive system.Dead soft foil conforms well to irregular surfaces.Primary use: Can be used in most flue pipe andchimney pipe applications in temperatures up to450°F.Thickness: 3.8 mils (96.5 µ) (exclusive of liner)Adhesion: 85 oz./inch width (24.1 N/2.5 cm)Elongation: 4.4%Tensile: 27 lbs./inch width (122 N/2.5 cm)Widths: 3 inches (7.6 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) core2 mil (50 micron)Aluminum Foil <strong>Tape</strong>1520CW ®NTA 2 mil (50 µ) high strength aluminum foil coatedwith special cold weather acrylic adhesive systemthat combines superior quick stick at normaltemperatures with superior low temperatureperformance at freezing (32°F or 0°C). The ultimatein cold weather tapes. Recommended for use atnormal and high temperatures also.Primary use: Improved vapor sealing of fiberglassductboard, ductwrap and FSK systems.Thickness: 3.5 mils (88 µ) (exclusive of liner)Adhesion: 96 oz./inch width (27.1 N/2.5 cm)Elongation: 4.4%Tensile: 27 lbs./inch width (122 N/2.5 cm)Widths: 2, 2½, 3, 4 inches (5.1, 6.4, 7.6, 1<strong>0.</strong>2 cm)Lengths: 50, 100 yards (46, 91 m) on 3 inch (7.6 cm) coreU.S. Coast Guard Approval No: 164.112/63/0for interior finish.Conforms to British Standard BS 476:Part 7, Class 1; Part 6, Class <strong>0.</strong>High Tack 1.5 mil(38 micron)Aluminum Foil <strong>Tape</strong>1521CW ®A special 1.5 mil (38 µ) high strength aluminum foiltape with a higher tack, special CW ® cold weatheracrylic adhesive system. This formulation combinesextremely high quick stick at normal temperatureswith superior performance at low temperatures andhigh humidity.Primary use: Thinner material allows for superiorconformability in vapor sealing of fiberglassductboard and FSK systems.Thickness: 3.0 mils (75 µ) (exclusive of liner)Adhesion: 98 oz./inch width (27.7 N/2.5 cm)Elongation: 4.4%Tensile: 21 lbs./inch width (95 N/2.5 cm)Widths: 2, 2½, 3, 4 inches (5.1, 6.4, 7.6, 1<strong>0.</strong>2 cm)Lengths: 50, 100 yards (46, 91 m) on 3 inch (7.6 cm) coreU.S. Coast Guard Approval No: 164.112/63/0for interior finish.2 mil (50 micron)Aluminum Foil <strong>Tape</strong>Self-Wound2520CW ®A 2 mil (50 µ) high strength aluminum foil coatedwith an aggressive, high temperature acrylicadhesive. 2520CW ® is release coated and selfwound, with no release liner for ease of use. Superiorquick stick at normal temperatures; superior highand low temperature performance.Primary use: Masking material on acrylic and polycarbonateaircraft windows. Also used as a sealingsystem in refrigerated appliances and microwaveovens as well as a variety of other industrial applications.Thickness: 3.5 mils (88 µ)Adhesion: 85 oz./inch width (24.1 N/2.5 cm)Elongation: 4.4%Tensile: 27 lbs./inch width (122 N/2.5 cm)Widths: 2, 2½, 3, 4 inches (5.1, 6.4, 7.6, 1<strong>0.</strong>2 cm)Length: 60 yards (55 m) on 3 inch (7.6 cm) core1.5 mil (38 micron)Rubber BasedAluminum Foil3531A 1.5 mil (38 µ) high strength aluminum foil coatedwith an aggressive, high tack rubber based adhesivesystem. The foil conforms well to both fibrous andsheet metal ducts, providing an excellent vaporseal. Conforms well around corners and to irregularsurfaces.Primary use: Used for vapor sealing of FSK facedthermal <strong>insulation</strong> systems.Thickness: 3.0 mils (75 µ)Adhesion: 150 oz./inch width (42.5 N/2.5 cm)Elongation: 4.4%Tensile: 21 lbs./inch width (95 N/2.5 cm)Widths: 2, 2½, 3 inches (5.1, 6.4, 7.6 cm)Length: 50 yards (46 m) on a 3 inch (7.6 cm) coreConforms to British Standard BS 476: Parts 6 & 72 mil (50 micron)Aluminum Foil <strong>Tape</strong>Self-Wound6520A 2 mil (50 µ) high strength, non-silicone releasecoated,self-wound aluminum foil, coated withan aggressive, high temperature acrylic adhesivesystem. The foil conforms well to both fibrous andsheet metal ducts, providing an excellent vapor seal.The malleable foil also conforms well around cornersand to irregular surfaces. The acrylic adhesivesystem performs excellently at low temperatures.Primary use: Masking material on acrylic and polycarbonateaircraft windows. Also, used as a sealingsystem in refrigerated appliances and microwaveovens as well as a variety of other industrial applications.Thickness: 4 mils (102 µ)Adhesion: 80 oz./inch width (22.7 N/2.5 cm)Elongation: 4.4%Tensile: 27 lbs./inch width (113 N/2.5 cm)Widths: 2, 2½, 3, 4 inches (5.1, 6.4, 7.6, 1<strong>0.</strong>2 cm)Length: 60 yards (55 m) on 3 inch (7.6 cm) coreHigh Tack 1.5 mil38 Micron AluminumFoil <strong>Tape</strong> Self Wound2521CW ®A special 1.5 mil (38 µ) high strength aluminumfoil tape with a high tack CW ® cold weatheracrylic adhesive. 2521CW ® is release coated andself wound, with no release liner for ease of use.Extremely high quick stick at normal temperatures;superior performance at low temperatures and highhumidity.Primary use: Masking material on acrylic andpolycarbonate aircraft windows. Also used asa sealing system in refrigerated appliances andmicrowave ovens as well as a variety of otherindustrial applications.2 mil (50 micron)HVAC Aluminum Foil<strong>Tape</strong>3520CW ®High strength, 2 mil (50 µ) foil coated with anaggressive, high temperature acrylic adhesivesystem. Bonds well to both fibrous and metal ducts,providing an excellent vapor seal. Malleable foilconforms well on corners and to irregular surfaces.The special cold weather adhesive combines superiorquick stick at normal temperatures with superiorlow temperature performance down to freezing. Theultimate for cold weather, with excellent at normaland high temperatures.Primary use: Vapor sealing fiberglass ductboard andsheet metal ducts. Also used on FSK systems.Thickness: 3.0 mils (75 µ)Adhesion: 85 oz./inch width (24.1 N/2.5 cm)Elongation: 4.4%Tensile: 21 lbs./inch width (95 N/2.5 cm)Widths: 2, 2½, 3, 4 inches (5.1, 6.4, 7.6, 1<strong>0.</strong>2 cm)Length: 60 yards (55 m) on 3 inch (7.6 cm) coreThickness: 3.7 mils (90 µ)Adhesion: 100 oz./inch width (28.3 N/2.5 cm)Elongation: 5%Tensile: 34 lbs./inch width (154 N/2.5 cm)Widths: 2, 2½, 3, 4 inches (5.1, 6.4, 7.6, 1<strong>0.</strong>2 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) core6

Mechanical Closure Systems2 mil (50 micron)Rubber BasedAluminum Foil3530A 2.0 mil, high strength aluminum foil coated with anaggressive, high tack rubber based adhesive system.The foil conforms well to both fibrous and sheetmetal ducts, providing an excellent vapor seal. Themalleable foil also conforms well around corners andto irregular surfaces.Primary use: Vapor sealing sheet metal ducts; generalpurpose, heavy duty service. Can also be usedon all FSK <strong>insulation</strong> systems3 mil (75 micron)Aluminum FoilDuct <strong>Tape</strong>1519CW ®High strength, 3 mil (75 µ) aluminum foil tape coatedwith 2 mils (50 µ) of an aggressive, high temperatureacrylic adhesive system. Conforms well to cornersand irregular surfaces. Superior adhesion to bothfibrous and metal ducts, providing an excellent vaporseal. Meets Mil-T-23397B.Primary use: Moisture and vapor barrier for ductsystems. For roofing applications, flashing, jointsand <strong>insulation</strong>. Used as a protective layer duringwelding.Thickness: 3.7 mils (90 µ)Adhesion: 150 oz./inch width (42.5 N/2.5 cm)Elongation: 5%Tensile: 34 lbs./inch width (154 N/2.5 cm)Widths: 2, 2½, 3 inches (5.1, 6.4, 7.6, 1<strong>0.</strong>2 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreConforms to British Standard BS 476:Parts 6 & 7Thickness: 5.0 mils (125 µ) (exclusive of liner)Adhesion: 96 oz./inch width (27.1 N/2.5 cm)Elongation: 5%Tensile: 27.8 lbs./inch width (125.9 N/2.5 cm)Widths: 2, 2½, 3, 4 inches (5.1, 6.4, 7.6, 1<strong>0.</strong>2 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreUL-181B-FX ListedDuct Joint Sealing<strong>Tape</strong>1580 & 1580PHeavy duty, high strength aluminum foil with speciallyformulated adhesive system. Performance andmaterials guaranteed to meet or exceed UL-181B-FXquality standards, and assures against this tape beinga conductor of any flame.Also available unprintedPrimary use: Superior vapor sealing of metal duct.Thickness: 17.0 mils (177.8 µ) (exclusive of liner)Adhesion: 160 oz./inch width (45.3 N/2.5 cm)Elongation: 5%Tensile: 20 lbs./inch width (62.8 N/2.5 cm)Widths: 2, 3 inches (5.1, 7.6 cm)Length: 100’ on 3 inch (7.6 cm) core3 mil (75 micron)Aluminum Foil Duct<strong>Tape</strong> Self Wound2519CW ®High strength, 3 mil (75 µ) aluminum foil tape coatedwith 2 mils (50 µ) of an aggressive, high temperatureacrylic adhesive system. 2519CW ® is release coatedand self wound, with no release liner for ease ofuse. Conforms well, with superior adhesion to bothfibrous and metal ducts. Provides an excellent vaporseal. Meets L-T-80B and Mil-T-23397B.Primary use: Masking material on acrylic and polycarbonateaircraft windows. Also used as a sealingsystem in refrigerated appliances and microwaveovens as well as a variety of other industrial applications.Thickness: 5.0 mils (125 µ)Adhesion: 85 oz./inch width (24.1 N/2.5 cm)Elongation: 5%Tensile: 27.8 lbs./inch width (125.9 N/2.5 cm)Widths: 2, 2½, 3, 4 inches (5.1, 6.4, 7.6, 1<strong>0.</strong>2 cm)Length: 60 yards (55 m) on 3 inch (7.6 cm) coreUL-181A Printed 2 mil(50 micron) AluminumFoil Ductboard <strong>Tape</strong>1581A-CW ®Heavy duty, high strength aluminum foil withspecially formulated acrylic adhesive system.Performance and materials guaranteed to meetor exceed UL-181A-P and UL-181B-FX qualitystandards, and assures against this tape being aconductor of any flame. Superior adhesion andconformance for fibrous ductboard systems.Primary use: Vapor sealing sheet metal ducts; tapingfiberglass ductboard & flexible duct.Thickness: 4.0 mils (100 µ) (exclusive of liner)Adhesion: 85 oz./inch width (24.2 N/2.5 cm)Shear Adhesion:5 lb. weight–24 hours+ 40°F/6 hours10 lb. weight–>120 hours+ 73.4°F/120 hours1 lb. weight–>6 hours+ 150°F/6 hoursElongation: 4.3%Tensile: 25 lbs./inch width (113.2 N/2.5 cm)Widths: 2½, 3 inches (6.4, 7.6 cm)Length: 60 yards (55 m) on 3 inch (7.6 cm) core3 mil (75 micron)Aluminum Foil <strong>Tape</strong>Self Wound6519CW ®A 3 mil (75 micron) high strength, non-siliconerelease-coated, self-wound aluminum foil, coatedwith an aggressive, high temperature acrylicadhesive system. The foil conforms well to bothfibrous and sheet metal ducts, providing an excellentvapor seal. The malleable foil also conforms wellaround corners and to irregular surfaces.Primary use: Masking material on acrylic and polycarbonateaircraft windows. Also, used as a sealingsystem in refrigerated appliances and microwaveovens as well as a variety of other industrial applications.Thickness: 5.0 mils (125 µ) totalAdhesion: 80 oz./inch width (22.7 N/2.5 cm)Elongation: 5%Tensile: 27.8 lbs./inch width (133.4 N/2.5 cm)Widths: 2, 3 inches (5.1, 7.6 cm)Length: 60 yards (55 m) on 3 inch (7.6 cm) coreWhite AluminumFoil <strong>Tape</strong>1511CW ®A 1.5 mil (38 µ) white aluminum foil coated with anaggressive cold weather acrylic adhesive systemwhich offers superior quick stick at below zeroand elevated temperatures. Zero temper, deadsoft aluminum foil conforms well to smooth andembossed surfaces.Primary use: Matching lap joint and vapor seal for bothsmooth and satin foil faced board. For use on Thermax ®and Atlas ® products.Conforms to: British Standards Class 1, BS 47776: Part 7 &U.S. Coast Guard Approval No: 164.112/63/0for interior finish.Thickness: 3.5 mils (88 µ) (exclusive of liner)Adhesion: 100 oz./inch width (28.3 N/2.5 cm)Elongation: 5%Tensile: 34 lbs./inch width (154 N/2.5 cm)Widths: 2, 3, 4, 5 inches (5.1, 7.6, 1<strong>0.</strong>2, 12.7 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreFSKFacing <strong>Tape</strong>1525CW ®NTTridirectionally reinforced with 2 x 3/sq.in. (2.5 x2.5 cm) fiberglass scrim, U.L. listed Foil/Scrim/Kraftlamination. Coated with a special cold weatheracrylic adhesive system which combines very highquick stick at normal temperatures with superior lowtemperature performance. Recommended for usedown to 10°F (–12°C). Conforms well to both fibrousductboard and blankets. The ultimate in cold weathertapes. Meets ASTM C1136.Primary use: Vapor seal on FSK faced fiberglassductboard and blanket systems.Thickness: 6.5 mils (165 µ) (exclusive of liner)Adhesion: 92 oz./inch width (26.0 N/2.5 cm)Elongation: 2%Tensile: 40 lbs./inch width (178 N/2.5 cm)Widths: 2, 3, 4, 5 inches (5.1, 7.6, 1<strong>0.</strong>2, 12.7 cm)Length: 50, 100 yards (46, 91 m) on 3 inch (7.6 cm) coreConforms to British Standard Class 1BS 476: Part 7Toll free lines to U.S.A. from U.S. and Mexico 800-343-1076, from Canada 800-544-1024, from United Kingdom 0-800-962-957, from Australia 1-800-122-797,from Germany 0131-822178, from Belgium 0-800-1-5625, from Netherlands 0800-022-2038, from Singapore 800-1100695, from Italy 800-246-40597

FSK Rubber BasedFacing <strong>Tape</strong>3525Tridirectionally reinforced with 2 x 3/sq.in. fiberglassscrim, U.L. listed foil/scrim/kraft lamination. Thistape conforms well to both fiberglass board andblankets. Coated with an aggressive, high tack rubberbased adhesive system.Primary use: Used as a vapor seal on FSK facedfiberglass <strong>insulation</strong>.Mechanical Closure SystemsUL-181B-FX 3 mil (75micron) Printed FlexibleDuct Closure <strong>Tape</strong>1599BFSKVapor SealDisks & Squares1528CW ® & SQPolyethyleneReinforced Foil <strong>Tape</strong>1529CW ®PolyethyleneReinforced Foil <strong>Tape</strong>3529HTThickness: 6.5 mils (165 µ)Adhesion: 125 oz./inch width (35.4 N/2.5 cm)Elongation: 2%Tensile: 40 lbs./inch width (178 N/2.5 cm)Widths: 2, 3, 4, 5 inches (5.1, 7.6, 1<strong>0.</strong>2, 12.7 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreA polypropylene film with an acrylic, CW ® coldweather adhesive system. Will perform well in eithersub-zero cold or abnormally warm temperatures.UL listed. Meets or exceeds all state building codesrequiring UL181B-FX.Colors: Silver, Black, ClearPrimary use: Sealing flexible air ducts and airconnectors.Thickness: 3.0 mils (1<strong>0.</strong>0762 mm)Adhesion:To stainless steel: 41 oz./inch width (11.4 N/2.5 cm)To backing: 31 oz./inch width (8.6 N/2.5 cm)Elongation: 150%Tensile: 22 lbs./inch width (99.4 N/2.5 cm)Width: 2, 3 inches (5.1, 7.6 cm)Length: 120 yards (110 m) on3 inch (7.6 cm) coreDie cut disks and squares, on release paper linerfor ease of application. Same U.L. listed material asNo. 1525, with 2 x 3/sq.in. (2.5 x 2.5 cm) diagonalreinforced Foil/Scrim/ Kraft lamination. 500 per roll.Cold weather adhesive formula.Primary use: Provides vapor seal over washersand pins used in mounting <strong>insulation</strong>. seals smallpunctures and tears.Tremendous labor savings overhand cut tape sections.1528CW ® Kiss-Cut Disks2 ½ inch (6.4 cm) diameter1528CW ® /SQ Kiss-Cut Squares3 x 3 inch (2.5 x 2.5 cm) squareThickness: 6.5 mils (165 µ) (exclusive of liner)Adhesion: 92 oz./inch width (26.0 N/2.5 cm)Elongation: 2%Tensile: 45 lbs./inch width (203.8 N/2.5 cm)Quantity: 500 disks/squares on 3 inch (7.6 cm) coreA tridirectionally reinforced, hand tearable, expandedpolyethylene foil tape coated with acrylic adhesivewhich exhibits superior quick stick at high andlow temperatures. Resistant to moisture, it isrecommended for use in conditions of high humidity.Meets AS 1530 -Part 3.Primary use: Vapor seal for reinforced aluminumfaced fiberglass or mineral wool thermal <strong>insulation</strong>.Thickness: 5 mils (<strong>0.</strong>127mm)Adhesion: 72 oz./inch width (2<strong>0.</strong>3 N/2.5 cm)Elongation: 21.3%Tensile: 16.1 lbs./inch width (71.6 N/2.5 cm)Width: 2, 3 inches (5.1, 7.6 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreA tri-directionally reinforced expanded polyethylenefoil tape coated with a high performance rubberpressure sensitive adhesive. Hand tearable withsuperior resistance to moisture, and is recommendedfor use in high humidity applications. Provides easyapplication and superior performance and durabilityover a wide range of temperatures and environmentalconditions.Primary use: Primarily used as a vapor seal forreinforced aluminum faced fiberglass or mineral woolthermal <strong>insulation</strong>.Thickness: 5 mils (<strong>0.</strong>127mm)Adhesion: 100 oz./inch width (27.8 N/2.5 cm)Elongation: 21.3%Tensile: 24 lbs./inch width (106.8 N/2.5 cm)Width: 2, 3 inches (5.1, 7.6 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreWMP-DW ReinforcedBlack PolypropyleneFacing <strong>Tape</strong>1538CW ®ASJFacing <strong>Tape</strong>1540CW ® PlusASJ Vapor SealDisks & Squares1542CW ®Plus & SQCryogenic VaporBarrier <strong>Tape</strong><strong>Venture</strong>Wrap1555CW ®A tridirectionally reinforced, black, polypropylene/skrim /kraft lamination coated with a special CW ®cold weather acrylic adhesive which exhibitssuperior quick stick at high and low; 10°F(-12°C) temperatures. Resistant to moisture, it isrecommended for use in conditions of high humidity.Colors: Black, GrayPrimary use: Vapor seal and closure system onLamtec WMP-DW faced thermal <strong>insulation</strong>.Thickness: 7.5 mils (<strong>0.</strong>191 mm)Adhesion: 68 oz./inch width (19.2 N/2.5 cm)Tensile: 40 lbs./inch width (181 N/2.5 cm)Width: 3 inches (7.6 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreAll Service Jacket <strong>Tape</strong>. White Kraft/Scrim/Foillamination with 4 x 4/sq.in. (2.5 x 2.5 cm)tridirectional scrim reinforcement. Special coldweather acrylic adhesive system that combinessuperior quick stick at normal temperatures withsuperior low temperature performance downto –25°F (–32°C). Excellent at normal and hightemperatures also.Primary use: Closure system and vapor seal on AllService Jacket faced duct and piping systems.Thickness: 11.5 mils (287 µ) (exclusive of liner)*Adhesion: 92 oz./inch width (26.0 N/2.5 cm)Elongation: 2%Tensile: 40 lbs./inch width (181 N/2.5 cm)Widths: 2, 3, 4, 5 inches(5.1, 7.6, 1<strong>0.</strong>2, 12.7 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) corePre-cut disks and squares on release paper liner.Same U.L. listed material as No. 1540 with 4 x 4/sq.in. (2.5 x 2.5 cm) diagonally reinforced WhiteKraft/Scrim/Foil lamination. 500 per roll. With specialCW ® cold weather adhesive system.Primary use: Vapor seal over washers and pins usedin mounting <strong>insulation</strong>. Easily handled, preparedproduct saves time in application.1542CW ® Kiss-Cut Disks2 ½ inch (6.4 cm) diameter1542CW ® /SQ Kiss-Cut Squares3 x 3 inch (2.5 x 2.5 cm) squareThickness: 11.5 mils (287 µ) (exclusive of liner)*Adhesion: 92 oz./inch width (26.0 N/2.5 cm)Elongation: 2%Tensile: 40 lbs./inch width (181 N/2.5 cm)Quantity: 500 disks/ squares on 3 inch (7.6 cm) coreA three ply laminate made with a 1 mil aluminumfoil with <strong>0.</strong>5 mil polyester film on both sides andcoated with a special cold weather acrylic pressuresensitive adhesive system which combines superiorquick stick at normal temperatures with superior lowtemperature performance below freezing.Colors: Silver and WhitePrimary use: This tape is primarily used a lowtemperature vapor barrier joint closure system.Thickness: 4 mils (102 µ)Adhesion: 60 oz./inch width (17 N/2.5 cm)Elongation: 50%Tensile: 15 lbs./inch width (68 N/2.5 cm)Widths: 2, 3 inch (5.1, 7.6 cm)Length: 50 yards (46m) on 3 inch (7.6 cm) coreToll free lines to U.S.A. from U.S. and Mexico 800-343-1076, from Canada 800-544-1024, from United Kingdom 0-800-962-957, from Australia 1-800-122-797,from Germany 0131-822178, from Belgium 0-800-1-5625, from Netherlands 0800-022-2038, from Singapore 800-1100695, from Italy 800-246-40599

Mechanical Closure SystemsSheathing<strong>Tape</strong>1585CW ® -2A thin, strong, polypropylene film tape coated with<strong>Venture</strong>’s aggressive CW ® cold weather acrylicadhesive system. Excellent performance characteristicsat elevated temperatures and down to 10°F (–12°C).Colors: Red, White, Pink, ClearPrimary use: Closure system and vapor seal on allexterior sheathing; plywood, OSB, Dens Glass Gold®and other house wrap products, including Tyvek®and Typar®. Also used as an interior barrier repairtape, and for air tightness on door and windowflanges, sill plates, corners and joints. Seam tape onpolyethylene.Thickness: 3 mils (76 µ)Adhesion (Tyvek): 28 oz./inch width (7.95 N/2.5 cm)Elongation: 136%Tensile: 20 lbs./inch width (9<strong>0.</strong>6 N/2.5 cm)Widths: 1 7 ∕8, 2½, 3 inches (4.8, 6.4, 7.6 cm)Lengths: 55, 72 yards (50, 66 m) on 3 inch (7.6 cm) corePolypropyleneLine Set <strong>Tape</strong>;Black, Metalized & White1507A polypropylene film with an acrylic adhesive system.<strong>Venture</strong>’s special adhesive formula will perform wellfrom sub-zero to tropical temperatures. Waterproofweatherproof and UV resistant, it is ideal for outdooruse in any climate.Colors: Black, Metalized (Silver) & WhitePrimary use: For taping line sets. Works well onblack foam pipe used in line sets. Metalized usedfor reflective <strong>insulation</strong>. White used on white foam<strong>insulation</strong> or line set.Thickness: 3 mils (75 µ)Adhesion: 31 oz./inch width (8.6 N/2.5 cm)Elongation: 150%Tensile: 22 lbs./inch width (99.4 N/2.5 cm)Widths: 2 inches (5.1 cm)Length: 60 yards (55 m) on 3 inch (7.6 cm) corePrintedSheathing <strong>Tape</strong>1585CW ® -P2Same product as No. 1585CW ® -2, but imprinted withcopy reading, “No. 1585CW ® -P2 Sheathing <strong>Tape</strong>, SeeCCMC Evaluation Report No. 11362-R,” <strong>Venture</strong>’slogo and address listed.Color: RedPrimary use: Closure system and vapor seal onTyvek® faced thermal <strong>insulation</strong> requiring notice ofspecification, and other housewraps. Repairs ripsand tears in the facing. Polyethylene seaming.Thickness: 3.1 mils (78 µ)Adhesion: 43 oz./inch width (12.0 N/2.5 cm)Elongation: 136%Tensile: 20 lbs./inch width (9<strong>0.</strong>6 N/2.5 cm)Width: 2 1 ∕3 inches (60 mm)Length: 72 yards (66 m) on 3 inch (7.6 cm) corePolyfoam<strong>Tape</strong>1509A high density cross linked polyethylene foam tapecoated on one side with rubber based adhesive,which allows for excellent quick stick sealing andhigh shear properties. Good resistance to humidity,mild acids, oil and grease. Adheres well to texturedand irregular surfaces.Colors: Black, WhitePrimary use: Used for condensation control onplumbing pipes and as lap tape on pipe <strong>insulation</strong>:also sound vibration dampening.Thickness: 1/8 inch (3.2 mm) (exclusive of liner)Peel Adhesion: 100 oz./inch width (28.3 N/2.5 cm)Elongation: 300%Tensile: 6 lbs./inch width (27.2 N/2.5 cm)Width: 2 inches (5.1 cm)Length: 10 yards (9.1 m) on 3 inch (7.6 cm) core5 mil (125 micron)Vinyl Seal <strong>Tape</strong>1506RThin, strong and conformable vinyl film tape coatedwith <strong>Venture</strong>’s special rubber based adhesivedesigned to adhere well to PVC fittings.Colors: Black, WhitePrimary use: Sealing longitudinal and circumferentialjoints in pipe coverings and vessels. Seals 45°, 90°joints, T’s and valves in PVC materials.10 mil (250 micron)Vinyl Seal <strong>Tape</strong>1510RA tough, conformable, specially formulated vinylfilm tape coated with <strong>Venture</strong>’s special rubber basedadhesive which is designed to adhere well to PVCfittings. This tape is particularly resistant to moisture,acids, alkalis, and oils, and is highly abrasionresistant as well.Color: WhitePrimary use: Application of premolded high impactPVC <strong>insulation</strong> fitting covers.Thickness: 5 mils (125 µ)Adhesion: Peel—29 oz./inch width (8.0 N/2.5 cm)Elongation: 150%Tensile: 15 lbs./inch width (67.9 N/2.5 cm)Widths: 1, 1½, 2 inches (2.5, 3.8, 5.1 cm)Length: 36 yards (33 m) on 11/2 inch (3.8 cm) core*Not recommended for outdoor use.Thickness: 10 mils (250 µ)Adhesion: 29 oz./inch width (8.0 N/2.5 cm)Elongation: 325%Tensile: 31 lbs./inch width (14<strong>0.</strong>4 N/2.5 cm)Widths: 1, 1½, 2 inches (2.5, 3.8, 5.1 cm)Length: 33.33 yards (3<strong>0.</strong>4 m) on 11/2 inch (3.8 cm) core6 mil (150 micron)Vinyl Seal <strong>Tape</strong>1506CW ®Thin, strong and conformable copolymer film tapecoated with <strong>Venture</strong>’s special, high grade, U.V.resistant CW ® cold weather acrylic adhesive system.Also resistant to solvents.Color: WhitePrimary use: Sealing longitudinal and circumferentialjoints in PVC pipe coverings and vessels. Seals 45°,90° joints, T’s and valves in PVC materials.Thickness: 6 mils (150 µ)Adhesion: Peel—64 oz./inch width (18.1 N/2.5 cm)Elongation: 500%Tensile: 18 lbs./inch width (81.5 N/2.5 cm)Widths: 1, 1 ½, 2 inches (2.5, 3.8, 5.1 cm)Length: 36 yards (33 m) on 11/2 inch (3.8 cm) coreTedlar ®Facing <strong>Tape</strong>1570CW ® (White)1571CW ® (Gray)A thin, strong Tedlar® (polyvinyl fluoride) film tape.<strong>Venture</strong>’s special cold weather acrylic adhesivesystem together with this facing tape make for anexceptional product for high performance belowfreezing.Colors: White, GrayPrimary use: Closure system and vapor seal forTedlar ® / fiberglass lamination faced thermal <strong>insulation</strong>,rigid foam <strong>insulation</strong> board, and rigid foam orfiberglass pipe <strong>insulation</strong>. Extremely high resistanceto U.V. rays, weathering and most chemicals, makesthis an outstanding tape for solar or chemical plantapplication.Thickness: 3 mils (75 µ)Adhesion: 68 oz./inch width (19.2 N/2.5 cm)Elongation: 130%Tensile: 11 lbs./inch width (49.8 N/2.5 cm)Widths: 2, 3 inches (5.1, 7.6 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) core10

Asbestos Removal/ Weatherization ProductsWaterproofCloth Duct <strong>Tape</strong>Ruggedly structured cotton fabric tape withpolyethylene coated face. Aggressive, high tacknatural rubber adhesive conforms and bonds tonearly any surface. Unwinds flat, tears readily.Colors: Silver, Black, White1500Primary use: Vapor sealing sheet metal ducts;general purpose, heavy duty service.Thickness: 10 mils (254 µ)Adhesion: 50 oz./inch width (5.47 N/2.5 cm)Elongation: 18%Tensile: 23 lbs./inch width (4<strong>0.</strong>3 N/2.5 cm)Widths: Silver – 2, 3 inches (5.1, 7.6 cm)Black – 2 inches (5.1 cm)White – 2 inches (5.1 cm)Length: 60 yards (55m) on 3 inch (7.6 cm) coreClear PolyethyleneRemovable <strong>Tape</strong>923A 5 mil (125 µ) clear polyethylene film coatedwith a specially formulated, high tack, removableacrylic adhesive system. The adhesive will adhere topolyethylene and remove cleanly, in most instances,from drywall and painted surfaces. Reduces mostcostly repainting and repair of damage often incurredwhen using permanent adhesive tapes.Color: ClearPrimary use: Hanging poly sheeting, especially duringasbestos removal projects in finished areas.Thickness: 6.2 mils (157 µ)Adhesion: 24 oz./inch width (6.8 N/2.5 cm)Elongation: 250%Tensile: 12.5 lbs./inch width (56.6 N/2.5 cm)Widths: 1, 1½, 2, 3, 4 inches (2.5, 3.8, 5.1, 7.6, 1<strong>0.</strong>2 cm)Length: 36 yards (33 m) on 3 inch (7.6 cm) coreUtility GradeCoated ClothDuct <strong>Tape</strong>1501An economical, polyethylene coated cotton clothduct tape with a natural rubber, pressure sensitiveadhesive system. High tack, adheres well to metalsurfaces, conforms well to corners and irregularsurfaces.Color: SilverPrimary use: Sealing sheet metal ducts and generalpurpose industrial applications.Thickness: 9 mils (229 µ)Adhesion: 45 oz./inch width (4.9 N/2.5 cm)Elongation: 16%Tensile: 24 lbs./inch width (42 N/2.5 cm)Widths: 2 inches (5.1 cm)Length: 60 yards (55 m) on 3 inch (7.6 cm) coreRemovable DoubleCoated 1 mil (25 micron)Polyester <strong>Tape</strong>523Controlled high/low tack acrylic adhesives set onpolyester film. Removes cleanly without residue.Resists U.V., moisture, solvents, mild acids, oil andgrease.Color: ClearPrimary use: Where removability without damage isrequired, such as hanging poly barrier sheeting onasbestos removal projects. Removes cleanly fromdrywall.Thickness: 3.75 mils (93 µ) (exclusive of liner)Adhesion: 24 hrs. (to polyester)High Tack—80 oz./inch width (22.5 N/2.5 cm)Low Tack—16 oz./inch width (3.4 N/2.5 cm)Elongation: 100%Tensile: 16 lbs./inch width (72.5 N/2.5 cm)Widths: 1, 1½, 2, 3 inches (2.5, 3.8, 5.1, 7.6 cm)Lengths: 36, 60 yards (33, 55 m) on 3 inch (7.6 cm) coreBlackPolyethylene<strong>Tape</strong>912A black polyethylene surface protection tape coatedwith a specially formulated removable acrylicpressure sensitive adhesive (PSA).Color: BlackPrimary use: Weatherseal for poly sheeting andsealing ink containersThickness: 5.8 mils (147.3 µ)Adhesion: 24 oz./inch width (6.8 N/2.5 cm)Elongation: 250%Tensile: 13 lbs./inch width (58.8 N/2.5 cm)Widths: 2, 3 inches (5.1, 7.6 cm)Length: 36 yards (33 m) on 3 inch (7.6 cm) coreDouble CoatedCloth <strong>Tape</strong>581A tightly woven cotton/polyester blend fabric coatedon both sides with an extremely aggressive, premiumgrade rubber-based adhesive system. Flexibilityand thickness enhance sealing ability to rough andtextured surfaces.Color: WhitePrimary use: Mounting poly sheet to materials suchas brick and cinder block. Splicing sheet for pressurizedenvironments.Thickness: 11 mils (275 µ) (exclusive of liner)Adhesion: 190 oz./inch width (53.7 N/2.5 cm)Elongation: 29%Tensile: 12 lbs./inch width (54.3 N/2.5 cm)Widths: 1½, 1¾, 2, 3, 4 inches (3.8, 4.4, 5.1, 7.6, 1<strong>0.</strong>2cm)Lengths: 25, 36 yards (23, 33 m) on 3 inch (7.6 cm) corePolyethyleneSplicing <strong>Tape</strong>919A thick, strong polyethylene tape coated with anaggressive, premium quality, synthetic rubber basedadhesive system.Colors: Clear, BlackPrimary use: Poly film splicing and sealing.Thickness: 8.3 mils (208 µ)Adhesion: 40 oz./inch width (11.3 N/2.5 cm)Elongation: 400%Tensile: 19 lbs./inch width (85.9 N/2.5 cm)Widths: 2, 3 inches (5.1, 7.6 cm)Length: 36 yards (33 m) on 3 inch (7.6 cm) coreClearPolyethylene<strong>Tape</strong>921CW ®A 5 mil (125 µ) thin, strong and conformabletransparent polyethylene film tape with a very highshear, UV resistant cold weather acrylic adhesivewith excellent holding properties and cold stick.Excellent resistance to moisture, acids, chemicals,alkalis, oils, abrasion and weathering.Color: ClearPrimary use: Weather seal for applying plastic stormwindows, door jams, window casings in low temperatureenvironment. Also used for film can sealing,ink container sealing and splicing polyethylene film.Thickness: 6.2 mils (157 µ)Adhesion: 75 oz./inch width (21.2 N/2.5 cm)Elongation: 250%Tensile: 12.5 lbs./inch width (56.6 N/2.5 cm)Sizes: 1” x 45 feet, 2” x 25 feet, 2” x 108 feet(2.5 cm x 13.7 m, 5.1 cm x 7.6 m, 5.1 cm x 33 m)Toll free lines to U.S.A. from U.S. and Mexico 800-343-1076, from Canada 800-544-1024, from United Kingdom 0-800-962-957, from Australia 1-800-122-797,from Germany 0131-822178, from Belgium 0-800-1-5625, from Netherlands 0800-022-2038, from Singapore 800-1100695, from Italy 800-246-405911

Jacketing SystemsNon-Adhesive FSKFacing1527Uncoated flame resistant Aluminum Foil/FiberglassScrim/Kraft lamination used for facing thermal<strong>insulation</strong>.Scrim: 2 x 3/sq.in. (2,5 x 2.5 cm) tridirectional pattern.Primary use: Vapor barrier paper over plain fiberglassand other <strong>insulation</strong> products.Thickness: 3.5 mils (88 µ)Elongation: 2%Tensile: 40 lbs./inch width (181 N/2.5 cm)Widths: 42, 48, 50, 54, 71 inches(107, 122, 127, 137, 180 cm)Lengths: 200, 600, 900 feet(61, 183, 274 m) on 3 inch (7.6 cm) core<strong>Venture</strong>GuardHypalon ® Cladding& Jacketing System1574CW ® -HA self adhesive, chemical resistant vapor barrier,performance alternative to stainless steel for<strong>insulation</strong> and jacketing applications. Installsquickly and easily with no special tools, resultingin significant time, labor and material cost savings.<strong>Venture</strong>Guard exceeds most building coderequirements, can be used for new construction orrepair. Hypalon ® exhibits superior strength, flexibility,elasticity and resistance to chemicals, UV and ozone.Apply from 10° to 302°F (-12° to 150°C).Primary use: Alternative to metal jacketing on pipingand <strong>insulation</strong> in chemical, oil & gas refining andprocessing, transportation and marine industries.Thickness: 26.6 mils (675 µ) (exclusive of liner)Adhesion: 50 oz./inch width (14.3 N/2.5 cm)Elongation: 1000%Tensile: 1075 lbs./inch width (7427 N/2.5 cm)Width: 20, 35½ inches (50, 90 cm)Length: 25 yards (23 m) on 3 inch (7.6 cm) coreWhite Polypropylene/Kraft2537Uncoated PSK barrier material. Scrim: 5 x 5/sq.in.(2,5 x 2.5 cm) Meets ASTM C1136.Primary use: Vapor barrier PSK to go over all typesof <strong>insulation</strong> materials.Widths: 42, 54, 78 inchLengths: 150, 200, 300 feet(46, 61, 91 m) on 3 inch (7.6 cm) core<strong>Venture</strong>Clad5-Ply LaminatedFoil/Film Facing1577CW ®A five-ply laminate; three layers of aluminum foil (coreand outer layers), and two layers of polyester film,coated with a special cold weather acrylic adhesivesystem. High quick stick at normal temperaturescoupled with superior performance below freezing.Highly puncture and tear resistant, flame retardant.Zero permeability, low weight, fast, clean safeinstallation. Apply at –10 to 248°F (–23 to 120°C).Colors: White, Natural Aluminum, Black, StuccoEmbossed, White Stucco Embossed, Black Embossedand TedlarPrimary use: Facing system and vapor seal on foamglass, mineral fiber, nitrile rubber, and foam <strong>insulation</strong>,on interior/exterior piping & duct.Thickness: 6 mils ( 152.4 µ) (exclusive of liner)Adhesion: 55 oz./inch width (15.6 N/2.5 cm)Tensile: 68 lbs./inch width (306 N/2.5 cm)Width: 23½, 35½, 46, 60 inches (60, 120, 152 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreNon-Adhesive ASJFacing1541Uncoated All Service Jacketing barrier materialconsisting of flame resistant, high intensity whitekraft paper, fiberglass yarn reinforcement andaluminum foil lamination.Scrim: 5 x 5/sq.in. (2,5 x2.5 cm) tridirectional pattern. Meets ASTM C1136.Primary use: Vapor barrier paper for all types of<strong>insulation</strong> materials.<strong>Venture</strong>Clad 3-PlyLaminated Foil/FilmFacing <strong>Tape</strong>1578CW ®A three-ply laminate; two layers of aluminum foil(outer layers), and a layer of polyester film, coatedwith a special cold weather acrylic adhesive system.High quick stick at normal temperatures coupledwith superior performance below freezing. Highlypuncture and tear resistant, flame retardant. Zeropermeability, low weight, fast, clean safe installation.Apply at –10 to 248°F (–23 to 120°C).Primary use: Adjunct to #1577CW to facilitate sealingbends. Also used as a low temperature vapor barrierjoint closure system.Thickness: 3.3 mils (83 µ) (exclusive of liner)Adhesion: 60 oz./inch width (17 N/2.5 cm)Tensile: 34 lbs./inch width (153 N/2.5 cm)Width: 2, 3 inches (5.1, 7.6 cm)Length: 55 yards (5<strong>0.</strong>6 m) on 3 inch (7.6 cm) coreWidths: 3, 23½, 35½, 48, 71 inches(7.6, 59.7, 9<strong>0.</strong>2, 122, 180 cm)Lengths: 200, 600, 900 feet(61, 183, 274 m) on 3 inch (7.6 cm) coreNon-Adhesive ASJFacing Sheets w/Self Sealing Lap <strong>Tape</strong>1541SPrecut ASJ sheets with SSL applied. Jacketing meetsASTM C1136.Primary use: Applied over all types of pipe <strong>insulation</strong>as a vapor retarder.Thickness: .009 inchTensile: 50 lbs./inch width (113 N/2.5 cm)Sizes: All pipe sizes available.<strong>Venture</strong>Clad Plus13-Ply LaminatedFoil/Film Facing1579CW ®A thirteen-ply laminate (six aluminum foil, fourpolyester film on scrim reinforced core), with specialCW cold weather acrylic adhesive system allowingsuperior performance to10°F (–12°C). Highly punctureand tear resistant, as well as flame retardant. Zeropermeability, low weight, fast, clean safe installation.Maximum continuous use to 300°F (149°C). Alsoavailable without adhesive (NA).Colors: White, Natural Aluminum, Stucco EmbossedPrimary use: Facing system and vapor seal on foamglass, mineral fiber, nitrile rubber, rigid and semirigidfoam <strong>insulation</strong>, interior or exterior.Total Thickness: 15.5 mils (380 µ) (exclusive of liner)Adhesion: 100 oz./inch width (28.4 N/2.5 cm)Tensile: 160 lbs./inch width (720 N/2.5 cm)Puncture ASTM D-1000): 80 lbs (360n)Elongation: 35%Widths: 2, 4, 23½, 35½ inches (5, 10, 58, 90 cm)Length: 25 yards (23 m) on 3 inch (7.6 cm) core12

Metal Building Facing SystemsWMP ® -10PolypropyleneFacing <strong>Tape</strong>1531CW ®White metalized polypropylene/scrim/kraft laminatedfacing tape. 4 x 4/sq.in. (2.5 x 2.5 cm) Tridirectionalscrim reinforcement. C.W. acrylic adhesive.Colors: Black, WhitePrimary use: Closure system and vapor seal onLamtec WMP ® -10 faced thermal <strong>insulation</strong>.Thickness: 7.0 mils (175 µ) (exclusive of liner)Adhesion: 68 oz./inch width (19.2 N/2.5 cm)Tensile: 40 lbs./inch width (181 N/2.5 cm)Widths: 3, 5 inches (7.6, 12.7 cm)Lengths: 50, 100 yards (46, 91 m) on 3 inch (7.6 cm) coreVRP ® -3 VinylFacing <strong>Tape</strong>1545CW ®White vinyl/scrim/metalized polyester lamination.4 x 4/sq.in. (2.5 x 2.5 cm) Bidirectional scrimreinforcement. C.W. cold weather acrylic adhesivesystem.Primary use: Closure system and vapor seal onAlpha Associates VRP-3 faced thermal <strong>insulation</strong>.Thickness: 1<strong>0.</strong>5 mils (262 µ) (exclusive of liner)Adhesion: 60 oz./inch width (16.9 N/2.5 cm)Tensile: 40 lbs./inch width (181 N/2.5 cm)Width: 3 inches (7.6 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreVSF-HD ReinforcedVinyl Facing <strong>Tape</strong>1532CW ®A 4x4 bidirectionally reinforced, UL listed, whitevinyl/scrim/ aluminum foil lamination coated witha special cold weather acrylic, pressure sensitiveadhesive system. The ultimate in cold weathertapes, this product combines superior quick stickat normal temperatures with superior performancedown to 10°F. Also recommended for use at elevatedtemperatures.Primary use: Vapor seal and closure system onLamtec VSF-HD ® facing.WMP ® -VR-R PlusPolypropyleneFacing <strong>Tape</strong>1547CW ®A triple ply laminate of white polypropylene film witha metalized polyester film backing, and fiberglassscrim reinforcement.Colors: Silver, Black, WhitePrimary use: Closure system and vapor seal onLamtec WMP ® -VR-R Plus metal building facings.Thickness: 11.5 mils (287 µ) (exclusive of liner)Adhesion: 60 oz./inch width (16.6 N/2.5 cm)Tensile: 45 lbs./inch width (200 N/2.5 cm)Width: 3 inches (7.6 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreThickness: 8.6 mils (218 µ) (exclusive of liner)Adhesion: 68 oz./inch width (19.2 N/2.5 cm)Tensile: 30 lbs./inch width (5.25 N/2.5 cm)Width: 3 inches (7.6 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreWCF ® -50Facing <strong>Tape</strong>1535CW ®A scrim reinforced, white aluminum foil/kraftlamination coated with a special pressure sensitive,cold weather acrylic, adhesive system. Thisproduct combines superior quick stick at normaltemperatures with superior low temperatureperformance (–10°F/–23°C). Superior resistanceto moisture; recommended for conditions of highhumidity.Primary use: Vapor seal on reinforced aluminumfaced fiberglass or mineral wool thermal <strong>insulation</strong>.Matches Lamtec WCF-30 and WCF-50 facings.Thickness: 9.6 mils (243 µ) (exclusive of liner)Adhesion: 65 oz./inch width (18.9 N/2.5 cm)Tensile: 55 lbs./inch width (248.6 N/2.5 cm)Width: 3 inches (7.6 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreHeavy DutyFSK Facing <strong>Tape</strong>1549CW ®Heavy duty aluminum foil/scrim/kraft laminationconstructed with fiberglass and polyester yarnreinforcement. Special vapor barrier coatingmaintains <strong>0.</strong>02 perm WVTR. Highly abuse resistant.Flame resistant adhesive bond. CW cold weatheradhesive system allows application at 10°F (–12°C).Primary use: Closure system and vapor seal on FSKfaced metal building <strong>insulation</strong>.Thickness: 6.5 mils (165 µ) (exclusive of liner)Adhesion: 92 oz./inch width (26.0 N/2.5 cm)Tensile: 45 lbs./inch width (203.8 N/2.5 cm)Width: 3 inches (7.6 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreWMP ® -VRPolypropyleneFacing <strong>Tape</strong>1537CW ®Tridirectionally reinforced U.L. listed whitepolypropylene/ scrim/kraft lamination. Coatedwith <strong>Venture</strong>’s C.W. cold weather acrylic adhesivesystem for superior quick stick at temperatures aslow as 10°F (–12°C). Better in humid as well as hotconditions.Colors: Black, WhitePrimary use: Closure system and vapor seal onLamtec WMP ® -VR <strong>insulation</strong>.Thickness: 7.5 mils (187 µ) (exclusive of liner)Adhesion: 68 oz./inch width (19.2 N/2.5 cm)Tensile: 40 lbs./inch width (181 N/2.5 cm)Widths: 3, 5 inches (7.6, 12.7 cm)Lengths: 50, 100 yards (46, 91 m) on 3 inch (7.6 cm) coreWMP ® -50PolypropyleneFacing <strong>Tape</strong>1551CW ®A tri-directionally reinforced, UL listed, whitepolypropylene/ scrim/metallized polyester facing tapecoated with a specialty acrylic pressure sensitiveadhesive system. Combining superior quick stick atnormal temperatures with superior low temperatureperformance down to 10oF, this is the ultimatein cold weather tapes. Recommended for use atelevated temperatures also.Primary use: Primarily used as a closure systemand vapor seal on Lamtec WMP-50 faced thermal<strong>insulation</strong>.Thickness: 11.85 mils (301 µ)Adhesion: 75 oz./inch width (21.2 N/2.5 cm)Tensile: 65 lbs./inch width (294 N/2.5 cm)Width: 3 inches (7.6 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreToll free lines to U.S.A. from U.S. and Mexico 800-343-1076, from Canada 800-544-1024, from United Kingdom 0-800-962-957, from Australia 1-800-122-797,from Germany 0131-822178, from Belgium 0-800-1-5625, from Netherlands 0800-022-2038, from Singapore 800-1100695, from Italy 800-246-405915

Metal Building Facing Systems2 mil (50 micron)White AluminumFoil <strong>Tape</strong>1558HTA 2.0 mil (50 µ) white aluminum foil coated with anaggressive cold weather acrylic adhesive systemwhich offers superior quick stick at below zeroand elevated temperatures. Zero temper, dead softaluminum foil conforms well to smooth surfaces.Primary use: Lap joint and vapor seal for bothsmooth and satin foil faced board. For use onThermax ® and Atlas ® products.Thickness: 3.5 mils (88 µ) (exclusive of liner)Adhesion: 100 oz./inch width (28.3 N/2.5 cm)Tensile: 34 lbs./inch width (154 N/2.5 cm)Width: 3 inches (7.6 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreVR-R PlusMetal BuildingFacing <strong>Tape</strong>1568CW ®A triple ply laminate of a white polypropylene filmwith a metalized polyester film backing and fiberglassscrim.Primary use: Closure system and vapor seal on AlphaVR-R Plus.Thickness: 8.6 mils (<strong>0.</strong>218 mm)Adhesion: 68 oz./inch width (19.2 N/2.5 cm)Tensile: 30 lbs./inch width (5.25 kN/m) - machine directionWidth: 3 inches (7.6 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreWMP-FFacing <strong>Tape</strong>1562CW ®A 4 x 4/sq.in. (2.5 x 2.5 cm) bidirectionally reinforcedwhite polypropylene/scrim/foil lamination coatedwith CW ® cold weather acrylic adhesive.Primary use: Closure system and vapor seal onLamtec WMP ® -F.Thickness: 1<strong>0.</strong>5 mils (262 µ)Adhesion: 68 oz./inch width (19.2 N/2.5 cm)Tensile: 40 lbs./inch width (181 N/2.5 cm)Width: 3 inches (7.6 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreArenashield1582CW ®Aluminum foil reinforced with a fiberglass/polyesterblend fabric coated with <strong>Venture</strong>’s C.W. cold weatheracrylic adhesive system. Specifically designed as apatch tape for high impact applications, i.e., hockeyarenas, gymnasiums, tennis courts, etc. Excellentstrength and tear resistance.Primary use: Matches Lamtec ® Arenashield forapplications where low emissivity is a requirement.Creates a continuous vapor barrier.Thickness: 6 mils (150 µ) (exclusive of liner)Adhesion: 85 oz./inch width (24.1 N/2.5 cm)Tensile: 195 lbs./inch width (883.1 N/2.5 cm) machinedirection;150 lbs./inch width (679.3 N/2.5 cm) transverseWidth: 3 inches (7.6 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreVR-RHDMetal BuildingFacing <strong>Tape</strong>1565CW ®A triple ply laminate of white vinyl/scrim/metalizedpolyester coated with a high tack acrylic adhesivesystem.Primary use: Vapor seal and closure system on AlphaAssociates VRP-3T facing.Thickness: 1<strong>0.</strong>5 mils (262 µ) (exclusive of liner)Adhesion: 60 oz./inch width (16.9 N/2.5 cm)Tensile: 18 lbs./inch width (81.5 N/2.5 cm)Width: 3 inches (7.6 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreGymguard1583CW ®Metalized white polypropylene reinforced witha fiberglass/polyester blend fabric coated with<strong>Venture</strong>’s C.W. cold weather acrylic adhesive system.Specifically designed as a patch tape for high impactapplications, i.e., hockey arenas, gymnasiums, tenniscourts, etc. Excellent strength and tear resistance.Primary use: Matches Lamtec ® Gymguard for walland ceiling applications offering a smooth, brightwhite finish and a continuous vapor barrier.Thickness: 6.5 mils (165 µ) (exclusive of liner)Adhesion: 65 oz./inch width (18.4 N/2.5 cm)Tensile: 195 lbs./inch width (883.1 N/2.5 cm) machinedirection;150 lbs./inch width (679.3 N/2.5 cm) transverseWidth: 3 inches (7.6 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreVRR-50Metal BuildingFacing <strong>Tape</strong>1567CW ®A triple ply laminate of a white polypropylene filmwith a metalized polyester film backing and fiberglassscrim.Primary use: Closure system and vapor seal on AlphaVRR-50 facing.Thickness: 10 mils (<strong>0.</strong>254 mm)Adhesion: 68 oz./inch width (19.2 N/2.5 cm)Tensile: 30 lbs./inch width (5.25 kN/m) - machine directionWidth: 3 inches (7.6 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreWoven CopolymerPatch <strong>Tape</strong>442W442BUnique composite of copolymer film, laminatedto bi-directional woven copolymer alloy providingextremely high tensile strength. Special self-curing,-crosslinking acrylic adhesive gives high initial tack,even under humid conditions.Colors: White or BlackPrimary use: Used for taping PE and PP cotton bales,bags, tarps, silage covers, lumber wraps, seaming ofagricurtural films, greenhouse patching.Thickness: 8.3 mils (XX mm OR XXµ)Peel Adhesion: 40 oz./inch width (11.3 N/2.5 cm)Width: 4 inches (1<strong>0.</strong>2 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) core16

Metal Building Facing SystemsWoven CopolymerPatch <strong>Tape</strong>442BLLUnique composite of copolymer film, laminatedto bi-directional woven copolymer alloy providingextremely high tensile strength. Special self-curing,-crosslinking acrylic adhesive gives high initial tack,even under humid conditions.Colors: White or BlackPrimary use: Used for taping PE and PP cottob bales,bags, tarps, silage covers, lumber wraps, seaming ofagricurtural films, greenhouse patching.Thickness: 8.3 mils (XX mm OR XXµ)Peel Adhesion: 40 oz./inch width (11.3 N/2.5 cm)Width: 4 inches (1<strong>0.</strong>2 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreDouble CoatedPolyfoam <strong>Tape</strong>700 Series<strong>Venture</strong>’s 700 Series of double coated polyfoamtapes is constructed from high density, crosslinked,polyethylene foam. They are coated with a high tack,extremely high shear, heat and weather resistantacrylic adhesive system.Colors: Black or WhitePrimary use: Vapor seal and lap joint seal in corrugatedmetal building panels, or prefabricated wallpanels. Mounts mirrors, plastic signs, etc.Thickness: (exclusive of liner)708: 1/8 inch (3.2 mm)716: 1/16 inch (1.6 mm)732: 1/32 inch (.83 mm)Peel Adhesion: 90 oz./inch width (25.5 N/2.5 cm)Tensile: 5 lbs./inch width (22.6 N/2.5 cm)Widths: 1/2, 3/4, 1, 1½, 2 inches (1.3, 1.9, 2.5, 3.8, 5.1 cm)Lengths: 18, 36, 72 yards (16, 33, 66 m) on 3 inch (7.6 cm) coreWoven PolyethyleneSealing <strong>Tape</strong>450An extremely strong and durable woven polyethylenefabric coated with a high tack, pressure sensitiveacrylic adhesive system. This adhesive is speciallyformulated to bond polyethylene, polypropyleneand other low surface energy materials. Resistantto moisture, acids, chemicals, oils, weathering andabrasion. Temperature range: –25°F (–32°C) to+225°F (107°C).Colors: White, Black, ClearPrimary use: Sealing tape for <strong>insulation</strong> facings,especially effective for poultry house use.Thickness: 8.6 mils (215 µ) (exclusive of liner)Adhesion: 55 oz./inch width (15.6 N/2.5 cm)Shear Adhesion: 2.2 psi–48 hours+Tensile: 44 lbs./inch width (199.3 N/2.5 cm)Widths: 2, 3, 4 inches (5.1, 7.6, 1<strong>0.</strong>2 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreVinyl FoamSealant <strong>Tape</strong>1718Specially formulated, closed cell vinyl foam tapeswith 10 lb. per cubic foot density. Gray in color. Veryflexible, with a specially formulated acrylic adhesivesystem.Primary use: Vapor seal where large spaces occur,and as a lap joint seal in corrugated metal buildingpanels or prefabricated wall panels. Thermal breaktape.Thickness (exclusive of liner) Length1718: 1/8 inch (3.2 mm) 75 feet (22.8 m)Adhesion: 20 oz./inch width (5.5 N/2.5 cm)Widths: 1/4, 3/8, 1/2, 5/8, 3/4, 7/8, 1, 1¼, 1½, 2, 3 inches(.63, .95, 1.3, 1.6, 1.9, 2.2, 2.5, 3.2, 3.8, 5.1, 7.6 cm)EmbossedVinyl <strong>Tape</strong>Thin, strong, conformable, premium vinyl tape withan aggressive acrylic adhesive system. Shrink andplasticizer resistant.Colors: White, Gray, BlackVinyl FoamSealant <strong>Tape</strong>Specially formulated, closed cell vinyl foam tapeswith 10 lb. per cubic foot density. Gray in color. Veryflexible, with a specially formulated acrylic adhesivesystem.460 SeriesPrimary use: Seaming vinyl faced fiberglass <strong>insulation</strong>in metal buildings and for water heater blanket<strong>insulation</strong>.Thickness: 5 mils (125 µ) (exclusive of liner)Adhesion: Peel—57 oz./inch width (15.9 N/2.5 cm)Hold—Minimum 4 hours @ 2 psi load1716Primary use: Vapor seal where large spaces occur,and as a lap joint seal in corrugated metal buildingpanels or prefabricated wall panels. Thermal breaktape.Thickness (exclusive of liner) Length1716: 1/16 inch (1.6 mm) 100 feet (3<strong>0.</strong>5 m)Tensile: 6.31 lbs./inch width (28.5 N/2.5 cm) machinedirection8.8 lbs./inch width (26.3 N/2.5 cm) transverseWidths: White—3, 5 inches (7.6, 12.7 cm)Black—3 inches (7.6 cm)Gray—3 inches (7.6 cm)Length: 50 yards (46 m) on 3 inch (7.6 cm) coreAdhesion: 20 oz./inch width (5.5 N/2.5 cm)Widths: 1/4, 3/8, 1/2, 5/8, 3/4, 7/8, 1, 1¼, 1½, 2, 3 inches(.63, .95, 1.3, 1.6, 1.9, 2.2, 2.5, 3.2, 3.8, 5.1, 7.6 cm)Double CoatedPolyfoam <strong>Tape</strong>600 SeriesA high density cross linked polyethylene foam tapecoated on both sides with rubber based adhesive,which allows for excellent quick stick sealing andhigh shear properties. Good resistance to humidity,mild acids, oil and grease. Adheres well to texturedand irregular surfaces.Colors: Black, WhitePrimary use: Mounting name plates, signs, small diecast parts, mirrors, maps, etc. Used for sound andvibration dampening in electronic equipment, glassand metal mounts, seal gaskets, etc.Thickness: (exclusive of liner)632: 1/32 inch (.83 mm)616: 1/16 inch (1.6 mm)608: 1/8 inch (3.2 mm)Peel Adhesion: 100 oz./inch width (28.3 N/2.5 cm)Elongation: 300%Tensile: 6 lbs./inch width (27.2 N/2.5 cm)Widths: 1/2, 3/4, 1, 1½, 2 inches (1.2, 1.9, 2.5, 3.8, 5.1 cm)Lengths: 18, 36, 72 yards (16, 33, 66 m) on 3 inch (7.6 cm) coreVinyl FoamSealant <strong>Tape</strong>1714Specially formulated, closed cell vinyl foam tapeswith 10 lb. per cubic foot density. Gray in color. Veryflexible, with a specially formulated acrylic adhesivesystem.Primary use: Vapor seal where large spaces occur,and as a lap joint seal in corrugated metal buildingpanels or prefabricated wall panels. Thermal breaktape.Thickness (exclusive of liner) Length1714: 1/4 inch (6.3 mm) 50 feet (15.2 m)\Adhesion: 20 oz./inch width (5.5 N/2.5 cm)Widths: 1/4, 3/8, 1/2, 5/8, 3/4, 7/8, 1, 1¼, 1½, 2, 3 inches(.63, .95, 1.3, 1.6, 1.9, 2.2, 2.5, 3.2, 3.8, 5.1, 7.6 cm)Toll free lines to U.S.A. from U.S. and Mexico 800-343-1076, from Canada 800-544-1024, from United Kingdom 0-800-962-957, from Australia 1-800-122-797,from Germany 0131-822178, from Belgium 0-800-1-5625, from Netherlands 0800-022-2038, from Singapore 800-1100695, from Italy 800-246-405917

Stucco <strong>Tape</strong>sRed Stucco Mask<strong>Tape</strong>1499A strong and conformable, red polyethylene filmtape coated with a specially formulated, high tack,removable, acrylic, non-curing adhesive system.Excellent UV resistance, and resistance to moisture,acids, alkalis, oils, abrasion and weathering.Primary use: A masking tape for stucco application,but also used as a weather seal for plastic stormwindows, container sealing and applying poly sheetingwhere clean removability is important. Used forgeneral protection of glazing.Thickness: 4.75 mils (120 µ)Adhesion: 24 oz./inch width (6.8 N/2.5 cm)Elongation: 250%Tensile: 12.5 lbs./inch width (55.6 N/2.5 cm)Width: 2 inches ( 5.1 cm)Length: 60 yards (55 m) on 3 inch (7.6 cm) coreStucco SealDrywall ContractorsEIFS <strong>Tape</strong>1592CW ®A thin, strong, UV resistant white polypropylene filmcoated with an aggressive, cold weather acrylicadhesive system. Adhesive specially formulated forexcellent performance at sub-freezing temperatures,along with good quick stick for ease of application.Primary use: VA closure system and vapor sealon all EIFS (Exterior Insulation Finishing Systems)materials such as plywood, OSB, Dens Glass Gold ® ,thermal <strong>insulation</strong> and vapor barriers includingTyvek ® and Typar ® housewraps, prior to stuccoapplication. Provides seal on window and doorflanges, sills and joints.Thickness: 3 mils (76 µ)Adhesion (Tyvek ® ): 28 oz./inch width (8 N/2.5 cm)Elongation: 136%Tensile: 20 lbs./inch width (91 N/2.5 cm)Width: 1 7 ∕8 inches ( 5.1 cm)Length: 72 yards (66 m) on 3 inch (7.6 cm) corePackaging and Accessory <strong>Tape</strong>sGeneral PurposeMasking <strong>Tape</strong>A conformable, natural colored crepe paper, coatedwith a high grade, pressure sensitive, syntheticrubber based adhesive system. Excellent as an allpurpose masking tape.2 Inch (5.1 cm)<strong>Tape</strong> ApplicatorVery heavy duty steel framed tape dispenser withfine, resharpenable 13 pitch fluted cutter. For 3 inch(7.6 cm) cores.100Primary use: Bundling <strong>insulation</strong>, sealing small packages,paint masking, etc.Thickness: 6 mils (150 µ)Adhesion: 40 oz./inch width (11.3 N/2.5 cm)Elongation: 10%Tensile: 20 lbs./inch width (9<strong>0.</strong>6 N/2.5 cm)Widths: 3/4, 1, 2, 3 inches (1.9, 2.5, 5.1, 7.6 cm)Length: 60 yards (55 m) on 3 inch (7.6 cm) core201Primary use: Recommended for applying cartonsealing tape. Useful for dispensing nearly any tapeof 2 inch (5.1 cm) width or less, including linedproducts.CartonSealing <strong>Tape</strong>200An extremely thin, strong, clear polypropylene filmtape with an exceptionally aggressive rubber basedadhesive. Excellent resistance to heat, cold andwater.Primary use: Sealing cartons, wrapping <strong>insulation</strong>rolls.Thickness: 2.3 mils (58 µ)Adhesion: 33 oz./inch width (9.0 N/2.5 cm)Elongation: 142%Tensile: 25 psi (172.5 kPa)Widths: 2, 3 inches (5.1, 7.6 cm)Length: 55 yards (50 m) on 3 inch (7.6 cm) core3 Inch (7.6 cm)<strong>Tape</strong> Applicator203Very heavy duty steel framed tape dispenser withfine, resharpenable 13 pitch fluted cutter. For 3 inch(7.6 cm) cores.Primary use: Recommended for applying No.1585CW-2 Sheathing <strong>Tape</strong>. Useful for dispensingnearly any tape of 2½ or 3 inch (6.4 or 7.6 cm)width.Printed Carton Sealing& Packaging <strong>Tape</strong>200PAn extremely thin, strong, clear polypropylene filmtape with an exceptionally aggressive rubber basedadhesive. Excellent resistance to heat, cold andwater.Printed:ROOF (Red), SIDEWALL (Green), ENDWALL (Blue).Primary use: Sealing cartons, wrapping, binding,bundling.Thickness: 2.3 mils (58 µ)Adhesion: 33 oz./inch width (9.0 N/2.5 cm)Elongation: 142%Tensile: 25 psi (172.5 kPa)Widths: 2, 3 inches (5.1, 7.6 cm)Length: 55 yards (50 m) on 3 inch (7.6 cm) coreStrapping<strong>Tape</strong>205A high strength fiberglass reinforced strapping tapewith split resistant polyester backing.Primary use: Heavy bundling and wrapping <strong>insulation</strong>rolls.Thickness: 6.5 mils (165 µ)Adhesion: 47 oz./inch width (13.5 N/2.5 cm)Elongation: 11%Tensile: 140 lbs./inch width (634 N/2.5 cm)Widths: 1/2, 3/4, 1 inches (1.3, 1.9, 2.5 cm)Lengths: 60 yards (55 m) on 3 inch (7.6 cm) core18

Double Coated & Transfer Sealing SystemsDouble CoatedPolyester <strong>Tape</strong>510Self-sealing lap tape of polyester film, coated onboth faces with an extremely aggressive, high peel,high shear premium quality rubber based adhesivesystem.Primary use: High performance <strong>insulation</strong> mounting,splicing and joining the lapped seams of pipingjackets.Thickness: 3.5 mils (88 µ)Adhesion: Peel—96 oz./inch width (27.1 N/2.5 cm)Hold—96+ hours @ 2.2 psi (27.1 kPa)Elongation: 100%Tensile: 7.5 lbs./inch width (33.9 N/2.5 cm)Widths: 1, 1½, 2 inches (2.5, 3.8, 5.1 cm)Lengths: 36, 150, 250 yards (33, 137, 229 m) on3 inch (7.6 cm) coreSSL 2 mil (50 micron)Acrylic Transfer <strong>Tape</strong>592CW ®A 2 mil (50 µ), unsupported clear acrylic, pressuresensitive transfer adhesive. <strong>Venture</strong>’s cold weatheradhesive system on easy release, specially treatedsilicone liner. Adheres well to a wide varietyof surfaces. Excellent oxidation and ultravioletresistance.Primary use: High performance self sealing lap forjoining seams on ASJ faced or PVC faced pipingjackets. High performance mounting of <strong>insulation</strong>.Thickness: 2 mils (50 µ)Adhesion: 100 oz./inch width (28.3 N/2.5 cm) -ultimateWidths: 1, 1½, 2 inches (2.5, 3.8, 5.1 cm)Lengths: 60, 180, 360 yards (55, 165, 329 m) on3 inch (7.6 cm) coreDouble CoatedPolyester <strong>Tape</strong>512/60Self-sealing lap of polyester film coated on bothsides with an extremely aggressive, high tack rubberbased adhesive system. Good balance of peel andshear, good heat resistance.Primary use: Securing fiberglass <strong>insulation</strong> topurlins, joists, walls, etc. in metal buildings.Thickness: 3.5 mils (88 µ) (exclusive of liner)Adhesion: 96 oz./inch width (27.1 N/2.5 cm)Elongation: 100%Tensile: 7.5 lbs./inch width (33.9 N/2.5 cm)Widths: 1, 1½, 2 inches (2.5, 3.8, 5.1 cm)Lengths: 60, 250 yards (55, 229 m) on 3 inch (7.6 cm) coreSST 4 mil (100 micron)Acrylic Transfer <strong>Tape</strong>594CW ®Unsupported clear acrylic, pressure sensitive transferadhesive utilizing <strong>Venture</strong>’s special, cold weatheracrylic adhesive system on a specially treated,silicone coated easy-release liner. Superior quickstick at normal temperatures, superior performancebelow freezing down to 10°F (–12°C).Primary use: Self-sealing tab for joining the lapsof metal building <strong>insulation</strong>. Cuts installation time,eliminates stapling, pinning, gives a complete vaporseal. Excellent under adverse conditions.Thickness: 4 mils (100 µ)Adhesion: 120 oz./inch width (34.0 N/2.5 cm)Widths: 1, 1½, 2 inches (2.5, 3.8, 5.1 cm)Lengths: 60, 180, 336 yards (55, 165, 307 m) on3 inch (7.6 cm) coreDouble CoatedPolyester <strong>Tape</strong>514CW ®A self-sealing lap tape for use in temperatureextremes. Coated on both faces with <strong>Venture</strong>’sC.W. cold weather acrylic adhesive formulationcombining superior quick stick with excellentadhesionperformance down to –17°F (–27°C).Primary use: High performance <strong>insulation</strong> mountingin high and low temperature extremes.Thickness: 3.75 mils (93 µ)Adhesion: 83 oz./inch width (23.5 N/2.5 cm)Elongation: 100%Tensile: 7.5 lbs./inch width (33.9 N/2.5 cm)Widths: 1, 1½, 2 inches (2.5, 3.8, 5.1 cm)Lengths: 60, 180, 360 yards (55, 165, 329 m) on3 inch (7.6 cm) core<strong>0.</strong>5 mil (12 micron)Double CoatedPolyester <strong>Tape</strong>5170A <strong>0.</strong>5 mil (12 micron), hand tearable polyester filmcoated on both sides with 3 mils of ultra high peelacrylic adhesive. The heavy adhesive depositionallows for superior bonding and conformability toirregular surfaces as well as flat surfaces. Bonds wellto most substrates, including low energy plastics.Excellent UV and heat resistance.Primary use: Used for securing metal building<strong>insulation</strong>. Also, for bonding irregular surfaces,plastics and metal profile extrusions, decorative trim.A universal, all purpose double coated tape with ahoney-colored liner. Used extensively for seamingvinyl banners.Thickness: 6.5 mils (165 µ)Peel Adhesion: 170 oz./inch width (48.1 N/2.5 cm)Elongation: 100%Tensile: 7.5 lbs./inch width (33.9 N/2.5 cm)Width: 1 inch (2.5 cm)Lengths: 36, 60 yards (33, 55 m) on 3 inch (7.6 cm) coreDouble CoatedPolyester <strong>Tape</strong>518A self-sealing lap of polyester film, coated on bothfaces with an extremely aggressive acrylic adhesivesystem. High temperature and U.V. resistance.Primary use: High performance <strong>insulation</strong> mounting,and splicing of wide width <strong>insulation</strong> facings duringlamination.Double Coated <strong>0.</strong>5 mil(12 micron) Ultra HighPeel Polyester <strong>Tape</strong>1163/MS74A .5 mil hand-tearable polyester film coated onboth sides with 3 mils of an ultra high peel acrylicadhesive system. The heavy adhesive depositionallows for superior bonding and conformabilityto irregular as well as flat surfaces. Thespecial acrylic adhesive bonds well to mostsubstrates including most low surface energyplastics. Excellent U.V. and heat resistance.Primary use: Superior bonding of rough, smooth anddifficult materials. Also, securing of fiberglass <strong>insulation</strong>to purlins, joists, walls, etc. in metal buildings.Thickness: 3.75 mils (93 µ)Adhesion: 85 oz./inch width (24.1 N/2.5 cm)Elongation: 100%Tensile: 7.5 lbs./inch width (33.9 N/2.5 cm)Widths: 1, 1½, 2 inches (2.5, 3.8, 5.1 cm)Lengths: 60, 180, 360 yards (55, 165, 329 m) on3 inch (7.6 cm) coreThickness: 6.5 mils (165 µ) (exclusive of liner)Adhesion: 170 oz./inch width (48.1 N/2.5 cm)Elongation: 100%Tensile: 7.5 lbs./inch width (33.9 N/2.5 cm)Widths: 1, 1½, 2 inches (2.5, 3.8, 5.1 cm)Lengths: 36, 60, 150 yards (33, 55, 137 m) on 3 inch(7.6 cm) coreToll free lines to U.S.A. from U.S. and Mexico 800-343-1076, from Canada 800-544-1024, from United Kingdom 0-800-962-957, from Australia 1-800-122-797,from Germany 0131-822178, from Belgium 0-800-1-5625, from Netherlands 0800-022-2038, from Singapore 800-1100695, from Italy 800-246-405919

Pipe jacketing -made easy!Pre-cut <strong>Venture</strong>Clad Jacketing Sheetsapplied in your shop, quickly and efficientlywrapped and sealed on the job.Nothing less than revolutionary.<strong>Venture</strong>Clad • Pre-cut jacketing sheets with 3” scored liner forease of application• Available for all types and sizes of pipe <strong>insulation</strong>• Zero Permeability• UL Classified• Indoor/Outdoor jacketing in one step®• CW Adhesive - can be applied as lowas -10°F (-23°C)• Matching Butt Strip <strong>Tape</strong> for sealing joints• Major Labor SavingsEmbossed Natural Aluminum Sheets1577CW ® -ES <strong>Venture</strong>CladAttractive, Tough, Easy ApplicationEmbossed white Aluminum Sheets1577CW ® -WES <strong>Venture</strong>CladHigh Aesthetic AppealMeets FSIS for USDA, FDA and Food Facilities800-343-1076www.venturetape.com

Double Coated & Transfer Sealing SystemsDouble CoatedPolyester <strong>Tape</strong>A 1/2 mil (12 micron) polyester film coated on bothsides with a highly aggressive acrylic adhesivesystem that delivers high tack, high peel, and highshear strength. Excellent adhesion to glass, metals,paper, and films. Excellent cold weather resistanceand a built-in ultra violet stabilizer system.Primary use: High performance splicing tape for3604flying splice application for corrugated paper, paper,plastics, and other continuous web processes;mounting of metal and polycarbonate nameplates;laminating dissimilar metals. Used for fasteningmetal building <strong>insulation</strong>.Thickness: 3.1 mils (78 µ)Peel Adhesion: 70 oz./inch width (19.8 N/2.5 cm)Elongation: 100%Tensile: 7.5 lbs./inch width (33.97 N/2.5 cm)Width: 11/2, inches (3.8 cm)Length: 60 yards (55 m) on 3 inch (7.6 cm) coreFire Retardant DoubleCoated Film <strong>Tape</strong> w/Finger Lift Edge3694FLE FRA thin, conformable, fire retardant film coated onthe liner side with our extremely aggressive coldweather acrylic adhesive system. The exposed sideis coated with our ultra aggressive cold weatheracrylic adhesive system. Excellent bonding strengthin a wide temperature range. Excellent adhesion tolow surface energy plastics as well as treated papers,metals, etc. A finger lift edge is supplied for easyrelease liner removal.Primary use: Self adhesive closure system on thelongitudinal lap of jacketed pipe <strong>insulation</strong>(SSL-self seal lap.)Thickness: 3.6 mils (89 µ) (exclusive of liner)Adhesion: Liner side: 70 oz./inch width (19.8 N/2.5 cm)Exposed side: 100 oz./inch width (28.3 N/2.5 cm)Elongation: 52%Tensile: 12.7 lbs./inch width (56.5 N/2.5 cm)Widths: 1, 1¼, 1½ inches (2.5, 3.2, 3.8 cm)Length: 60 yards (55 m) on 3 inch (7.6 cm) coreFire RetardantDouble CoatedTissue <strong>Tape</strong>3683FRA thin, conformable non-woven tissue coated onboth sides with our extremely aggressive coldweather acrylic fire retardant adhesive system.Excellent bonding strength in a wide temperaturerange. Excellent adhesion to low surface energyplastics as well as treated papers, metals, etc.Primary use: Self adhesive closure system on thelongitudinal lap of jacketed pipe <strong>insulation</strong> (SSL–selfseal lap).Thickness: 4.2 mils (107 µ) (exclusive of liner)Adhesion: 70 oz./inch width (19.8 N/2.5 cm)Elongation: 5%Tensile: 7 lbs./inch width (31.7 N/2.5 cm)Widths: 1, 1½, 2, 3 inches (2.5, 3.8, 5.1, 7.6 cm)Lengths: 60, 180 yards (55, 165 m)on 3 inch (7.6 cm) coreDouble Coated,Fire RetardantFilm <strong>Tape</strong>3697FLE FRA double coated, fire retardant film tape coated witha differential acrylic adhesive. The exposed sidedesigned to bond to low surface energy plastics.Primary use: Designed a closure system for foilfaced pipe <strong>insulation</strong> with a polyethylene interlayer.Also used as a bonding and laminating tape for difficultsurfaces and materials.Thickness: 3.5 mils (88 µ)Adhesion: Exposed Side—87 oz. (24.6 N/2.5 cm)Liner Side—80 oz. (22.6 N/2.5 cm)Elongation: 100%Tensile: 7.5 lbs./inch width (33.9 N/2.5 cm)Widths: 1, 1¼, 1½ inches (2.5, 3.2, 3.8 cm)Length: 60 yards (55 m) on a 3 inch (7.6 cm) coreFire Retardant DoubleCoated Film <strong>Tape</strong>w/ Finger Lift Edge3693FLE FRA thin, conformable, fire retardant film coated onboth sides with our extremely aggressive coldweather acrylic adhesive system. Excellent bondingstrength in a wide temperature range. Excellentadhesion to low surface energy plastics as wellas treated papers, metals, etc. A finger lift edge issupplied for easy release liner removal.Primary use: Self adhesive closure system on thelongitudinal lap of jacketed pipe <strong>insulation</strong> (SSL-selfseal lap.)Thickness: 3.6 mils (89 µ) (exclusive of liner)Adhesion: 70 oz./inch width (19.8 N/2.5 cm)Elongation: 52%Tensile: 12.7 lbs./inch width (56.5 N/2.5 cm)Widths: 1, 1¼, 1½inches (2.5, 3.2, 3.8 cm)Length: 60 yards (55 m) on 3 inch (7.6 cm) coreHigh PerformanceTransfer <strong>Tape</strong>3802 (3802R)A 2 mil (50 micron) glass reinforced transfer tapewith aggressive acrylic adhesive; excellent oxidationand ultraviolet light resistance; good quick stickand high shear; wets out to metals, high surfaceenergy plastics, most elastomers, treated olefins andcoated plain papers. Red available for visible spliceidentification.Colors: Clear, RedPrimary use: High performance splicing tape forflying splices of light weight papers to heavy weightboard. For nameplates, decals, aluminum, polyester,vinyls, polycarbonates, and papers.Thickness: 2 mils (50 µ)Peel Adhesion: 55 oz./inch width (15.6 N/2.5 cm)Widths: Available to 54 inches (137 cm)Length: 60 yards (55 m) on 3 inch (7.6 cm) coreHigh PerformanceScrim Transfer <strong>Tape</strong>1153A 3 mil (75 micron) high performance, scrimreinforced acrylic transfer film tape. A versatile,cost effective, pressure sensitive adhesive (PSA)tape, specially designed for high stress bondingapplications. <strong>Venture</strong> <strong>Tape</strong> 1153 provides apermanent bond on foams, plastics, metals andcomposite materials subjected to a broad range ofenvironmental conditions.Primary use: Bonding and laminating to <strong>insulation</strong>materials, foam laminating and general bonding forapplications requiring transfer film performance withdimensional stability. Bonds well to most metals,plastics, composites and other building materials.Thickness: 3 mils (76.2 µ)Peel Adhesion: 116 oz./inch width (32.2 N/2.5 cm)Widths: Available to 60 inches (152 cm)Length: Available to 250 yards (229 m) on 3 inch(7.6 cm) coreToll free lines to U.S.A. from U.S. and Mexico 800-343-1076, from Canada 800-544-1024, from United Kingdom 0-800-962-957, from Australia 1-800-122-797,from Germany 0131-822178, from Belgium 0-800-1-5625, from Netherlands 0800-022-2038, from Singapore 800-1100695, from Italy 800-246-405921