Refrigeration, air-conditioning and cooling technology - 2007.pdf

Refrigeration, air-conditioning and cooling technology - 2007.pdf

Refrigeration, air-conditioning and cooling technology - 2007.pdf

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

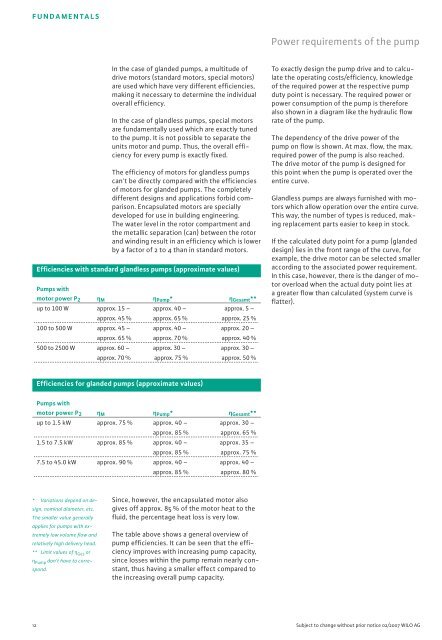

PLH_KKK_U2_31.QXP 25.05.2007 11:01 Uhr Seite 12FUNDAMENTALSPower requirements of the pumpIn the case of gl<strong>and</strong>ed pumps, a multitude ofdrive motors (st<strong>and</strong>ard motors, special motors)are used which have very different efficiencies,making it necessary to determine the individualoverall efficiency.In the case of gl<strong>and</strong>less pumps, special motorsare fundamentally used which are exactly tunedto the pump. It is not possible to separate theunits motor <strong>and</strong> pump. Thus, the overall efficiencyfor every pump is exactly fixed.The efficiency of motors for gl<strong>and</strong>less pumpscan't be directly compared with the efficienciesof motors for gl<strong>and</strong>ed pumps. The completelydifferent designs <strong>and</strong> applications forbid comparison.Encapsulated motors are speciallydeveloped for use in building engineering.The water level in the rotor compartment <strong>and</strong>the metallic separation (can) between the rotor<strong>and</strong> winding result in an efficiency which is lowerby a factor of 2 to 4 than in st<strong>and</strong>ard motors.Efficiencies with st<strong>and</strong>ard gl<strong>and</strong>less pumps (approximate values)Pumps withmotor power P 2 η M η Pump * η Gesamt **up to 100 W approx. 15 – approx. 40 – approx. 5 –approx. 45 % approx. 65 % approx. 25 %100 to 500 W approx. 45 – approx. 40 – approx. 20 –approx. 65 % approx. 70 % approx. 40 %500 to 2500 W approx. 60 – approx. 30 – approx. 30 –approx. 70 % approx. 75 % approx. 50 %To exactly design the pump drive <strong>and</strong> to calculatethe operating costs/efficiency, knowledgeof the required power at the respective pumpduty point is necessary. The required power orpower consumption of the pump is thereforealso shown in a diagram like the hydraulic flowrate of the pump.The dependency of the drive power of thepump on flow is shown. At max. flow, the max.required power of the pump is also reached.The drive motor of the pump is designed forthis point when the pump is operated over theentire curve.Gl<strong>and</strong>less pumps are always furnished with motorswhich allow operation over the entire curve.This way, the number of types is reduced, makingreplacement parts easier to keep in stock.If the calculated duty point for a pump (gl<strong>and</strong>eddesign) lies in the front range of the curve, forexample, the drive motor can be selected smalleraccording to the associated power requirement.In this case, however, there is the danger of motoroverload when the actual duty point lies ata greater flow than calculated (system curve isflatter).Efficiencies for gl<strong>and</strong>ed pumps (approximate values)Pumps withmotor power P 2 η M η Pump * η Gesamt **up to 1.5 kW approx. 75 % approx. 40 – approx. 30 –approx. 85 % approx. 65 %1.5 to 7.5 kW approx. 85 % approx. 40 – approx. 35 –approx. 85 % approx. 75 %7.5 to 45.0 kW approx. 90 % approx. 40 – approx. 40 –approx. 85 % approx. 80 %* Variations depend on design,nominal diameter, etc.The smaller value generallyapplies for pumps with extremelylow volume flow <strong>and</strong>relatively high delivery head.** Limit values of η Ges orη Pump don't have to correspond.Since, however, the encapsulated motor alsogives off approx. 85 % of the motor heat to thefluid, the percentage heat loss is very low.The table above shows a general overview ofpump efficiencies. It can be seen that the efficiencyimproves with increasing pump capacity,since losses within the pump remain nearly constant,thus having a smaller effect compared tothe increasing overall pump capacity.12 Subject to change without prior notice 02/2007 WILO AG