Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

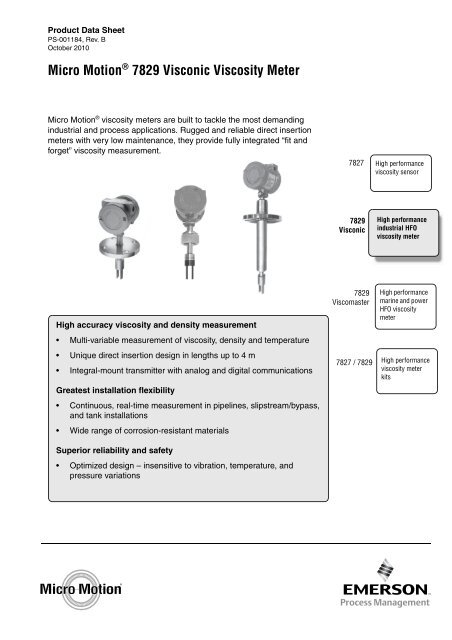

Low Maintenance RequiredBecause the <strong>7829</strong> viscosity meters have nomoving parts, minimal maintenance is required,leading to lower overall operating costs.The vibrating forks are available with PFA coatingto assist self-cleaning. PFA is ideal for hydrocarbonapplications. Care should be taken if the PFAcoating is to be used in a corrosive application.Please consult your local <strong>Micro</strong> Motion sales office.ADView Software Tool FeaturesADView is a PC-based configuration anddiagnostics tool that runs on a <strong>Micro</strong>soft ®Windows ® platform, communicates with the <strong>7829</strong>meter through a standard serial port, and providesthe following functionality:ProLink II Software Tool FeaturesThe ProLink II software tool (v2,9 or later) can beused with the <strong>7829</strong> viscosity meter. ProLink II runson a <strong>Micro</strong>soft Windows platform, communicateswith the <strong>7829</strong> meter through a standard serial portor USB port, and provides the followingfunctionality:• Configuring the <strong>7829</strong> transmitter• Viewing and logging process parameters• Viewing meter diagnostics• Setting up a serial link to communicate with the<strong>7829</strong> transmitter• Configuring the <strong>7829</strong> transmitter• Displaying data real-time or as a graph• Logging data to a file• Verifying correct operation of the system anddiagnosing faults• Loading or storing Modbus register values• Read/write to individual Modbus registers<strong>Micro</strong> Motion <strong>7829</strong> <strong>Visconic</strong> <strong>Viscosity</strong> <strong>Meter</strong> 5

Pressure ratingsMaximum operatingpressure (1)Test pressureShort-stem versionLong-stem versionTested to 1,5 x the maximum operating pressure207 bar100 barPED complianceOutside the scope of European directive 97/23/EC on Pressure Equipment.(1) Actual maximum operating pressures are limited by the process connection rating.Hazardous area classificationsATEXATEX-approved: Certification for use in EuropeATEX II2G Ex d IIC, T4CSACSA-approved: Certification for use in Canada and USAClass I, Division 1 Groups C & D, T4General classificationsElectromagnetic compatibilityAll versions conform to the latest international standards for EMC, and are compliant withEN 61326/IEC 61326.Environment• Weather rating: IP66<strong>Micro</strong> Motion <strong>7829</strong> <strong>Visconic</strong> <strong>Viscosity</strong> <strong>Meter</strong> 7

<strong>7829</strong> Long StemOpen-tank connection (cast housing)Dimensions in mm146Mounting hardware is customer specific, and is not supplied.External EarthconnectorLower nodal massLong-stem 1,5″ SCH 80 tube(1,9″ external diameter)Vibrating elementElectronic housing∅109Pipe must be securelyclamped in at least twoplaces along this length.145115∅35Stem lengths up to 4 m are available as an ETOpurchase.500Open-tank connection (stainless steel housing)Dimensions in mmCover lock screwM4 x 5 ST.STL -Kept captive bydata label175Mounting hardware is customer specific, and is not supplied.External EarthscrewUpper nodal massLower nodal massAmplifier housingLong-stem 1,5″ SCH 80 tube(1,9″ external diameter)Vibrating element∅120Pipe must be securelyclamped in at least twoplaces along this length.145128NPT∅35Stem lengths up to 4 m are available as an ETOpurchase.50010 <strong>Micro</strong> Motion <strong>7829</strong> <strong>Visconic</strong> <strong>Viscosity</strong> <strong>Meter</strong>

<strong>7829</strong> Long Stem continuedClosed-tank connection (cast housing)Dimensions in mmExternal Earthconnector290140Lower nodal massLong-stem 1,5″ SCH 80 tube(1,9″ external diameter)Vibrating element∅109Electronic housingConnection to pipeline (Zone 0 area) by meansof a standardized industry flange (for example,DIN, ANSI, BS, or JIS Limit ANSI 1500equivalent)115NPT∅35145Stem lengths up to 4 m are available asan ETO purchase.500Closed-tank connection (stainless steel housing)Dimensions in mmCover lock screwM4 x 5 ST.STL -Kept captive bydata label290External Earthscrew140Lower nodal mass∅120Amplifier housingUpper nodal massLong-stem 1,5″ SCH 80 tube(1,9″ external diameter)Vibrating elementConnection to pipeline (Zone 0 area) by meansof a standardized industry flange (for example,DIN, ANSI, BS, or JIS Limit ANSI 1500equivalent)128NPT∅35500145Stem lengths up to 4 m are available asan ETO purchase.<strong>Micro</strong> Motion <strong>7829</strong> <strong>Visconic</strong> <strong>Viscosity</strong> <strong>Meter</strong> 11

Installation<strong>7829</strong> Short StemA variety of installation accessories can be provided, such as weldolets, for direct pipeline insertion orflow-through chambers, which provide the optimum environment for the short-stemmed <strong>7829</strong> meters.<strong>7829</strong> Long StemOpen-tank installation exampleFor open-tank installations, the long-stemmed <strong>7829</strong><strong>Visconic</strong> is clamped to a structure.The position of the clamp determines the insertion depth.Closed-tank installation exampleFor closed-tank installations, the long-stemmed<strong>7829</strong> <strong>Visconic</strong> needs a factory fitted flangeattachment.To vary the insertion depth, a standoff section withflange (not supplied) can then be used.12 <strong>Micro</strong> Motion <strong>7829</strong> <strong>Visconic</strong> <strong>Viscosity</strong> <strong>Meter</strong>

Ordering Information continuedCode Default software configuration of 4–20 mA output 1 (1)Available with all amplifier system codes:H0 to 25 cStJ0 to 50 cStE0 to 100 cStZETO custom configurationAvailable with amplifier system codes C, D, W, K, or L:M0 to 200 cStK0 to 500 cStF0 to 1000 cStAvailable only with amplifier system codes W, K, or L:G100 to 12500 cPCode Calibration rangeAvailable with all amplifier system codes:B0,5 to 100 cPZETO calibration rangeAvailable only with amplifier system codes C, D, W, K, or L:F10 to 1000 cPAvailable only with amplifier system codes W, K, or L:G (2)Code100 to 12500 cPCalibration typeAvailable only with amplifier system codes C, D, W, K, or L:AFree streamD (3)2” schedule 80 boundary (200 cP limit)Available only with amplifier system codes C, D, E or F:B (3)EH (3)2” schedule 40 boundary (200 cP limit)3" schedule 80 boundary2-1/2” schedule 40 boundaryAvailable with all amplifier system codes:ZETO calibration typeCode Factory SetBReserved for future useCode TraceabilityANoneXCertificates of material traceability (per single order)Typical model number: <strong>7829</strong>ADAAAEBABA(1) 4–20 mA output 2 default setting is temperature.(2) Available with calibration type A only.(3) Available with default software configuration of 4–20 mA output type E, H, J, or M only.14 <strong>Micro</strong> Motion <strong>7829</strong> <strong>Visconic</strong> <strong>Viscosity</strong> <strong>Meter</strong>

<strong>Micro</strong> Motion <strong>7829</strong> <strong>Visconic</strong> <strong>Viscosity</strong> <strong>Meter</strong> 15

<strong>Micro</strong> Motion—The undisputed leader in flow and density measurementWorld-leading <strong>Micro</strong> Motion measurement solutions from EmersonProcess Management deliver what you need most:Technology leadership<strong>Micro</strong> Motion introduced the first reliable Coriolis meter in 1977.Since that time, our ongoing product development has enabled usto provide the highest performing measurement devices available.Product breadthFrom compact, drainable process control to high flow rate fiscaltransfer—look no further than <strong>Micro</strong> Motion for the widest range ofmeasurement solutions.Unparalleled valueBenefit from expert phone, field, and application service andsupport made possible by more than 600000 meters installedworldwide and over 30 years of flow and density measurementexperience.WWW.micromotion.com© 2010 <strong>Micro</strong> Motion, Inc. All rights reserved.The <strong>Micro</strong> Motion and Emerson logos are trademarks and service marks of Emerson Electric Co. <strong>Micro</strong> Motion, ELITE, MVD, ProLink, MVD DirectConnect, and PlantWeb are marks of one of the Emerson Process Management family of companies. All other trademarks are property of theirrespective owners.<strong>Micro</strong> Motion supplies this publication for informational purposes only. While every effort has been made to ensure accuracy, this publication is notintended to make performance claims or process recommendations. <strong>Micro</strong> Motion does not warrant, guarantee, or assume any legal liability forthe accuracy, completeness, timeliness, reliability, or usefulness of any information, product, or process described herein. We reserve the right tomodify or improve the designs or specifications of our products at any time without notice. For actual product information and recommendations,please contact your local <strong>Micro</strong> Motion representative. For a complete list of contact information and websites, please visit: www.emersonprocess.com/home/contacts/global.