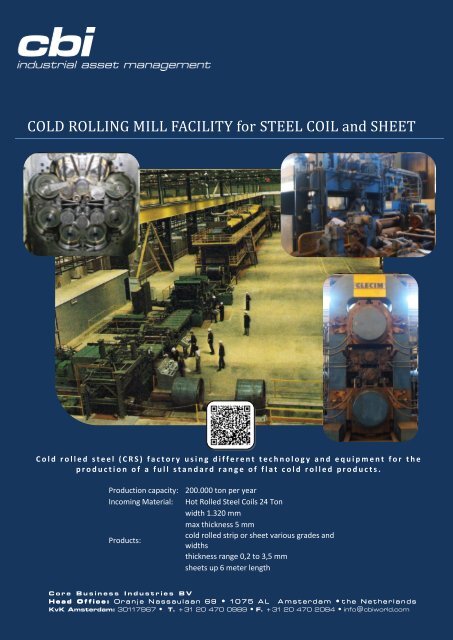

COLD ROLLING MILL FACILITY for STEEL COIL and SHEET

COLD ROLLING MILL FACILITY for STEEL COIL and SHEET

COLD ROLLING MILL FACILITY for STEEL COIL and SHEET

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

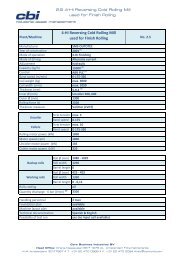

PayoffTWENTY ROLLS REVERSIBLE SENDZIMIR <strong>COLD</strong> <strong>ROLLING</strong> <strong>MILL</strong>Mill’s Motor (General Electric)Strip <strong>and</strong> work rolls cooling <strong>and</strong>lubricationMax. coil weightCoil inside diameterCoil outside diameterPayoff motor(only <strong>for</strong> first rolling pass)Mill winder motor (left)Mill winder motor (right)Mill driven rolls motorWater-Oil emulsion capacityEmulsion storage capacityBearings lubricationHydraulic System24 t610 mm1.950 mm1 x 500 kW, 400 V, 200/600 r/Min.2 x 1.840 kW, 200/600 r/Min.2 x 1.840 kW, 200/600 r/Min.2 x 1.840 kW, 0/1000/2500 r/Min.5.680 l/Min.114.500 lOil/fog12,55 kW2 M-Pumps á 74 bar; 75,7 l/Min.Hydraulic ControlScrew Down Device13.154 kg (during operation)<strong>for</strong> thicknesses up to 2 mm 2 LFE non-contact measuring unitsAutomatic strip thickness control <strong>for</strong> thicknesses over 2 mm 2 ESP contact measuring units(ESP)<strong>for</strong> strip speed measuring 2 TachometersProcess digital computer PDP 8MNominal Mill Capacity125.000 t/aNote: In case of lower average reduction, bigger coils (24t), thinner thicknesses <strong>and</strong> strong managementthis mill can produce 200.000t/a of low carbon CRS.All data have been prepared to the best of our knowledge, however we can not be held liable <strong>for</strong> any errors <strong>and</strong> or omissions.3 C o r e B u s i n e s s I n d u s t r i e s B VH e a d O f f i c e : O r a n j e N a s s a u l a a n 6 9 • 1 0 7 5 A L A m s t e r d a m • t h e N e t h e r l a n d sKvK Amsterdam: 30117967 • T. +31 20 470 0989 • F. +31 20 470 2084 • info@cbiworld.com

LINE IVFOUR HIGH TEMPER <strong>MILL</strong>non-reversible – direction left to rightManufacturerWaterbury Farrel (USA)YoM 1978ModelSerial number 50305Mill motor power373 kWControlsGE Siltrol PlusCoil weightmax. 12 tCold Rolled Strip (CRS)Strip widthmax. 660 mmStrip thicknessmax. 4 mmNote: up to 5% of strip thickness reductionRolls width762 mm254 mmRollsWork rolls diameter- 4 rolls with chocks- 8 rolls no chocksBack-up rolls diameter508 mm- 4 rolls with chocksNote: Hydraulic Screw-Down from the BottomAll data have been prepared to the best of our knowledge, however we can not be held liable <strong>for</strong> any errors <strong>and</strong> or omissions.4 C o r e B u s i n e s s I n d u s t r i e s B VH e a d O f f i c e : O r a n j e N a s s a u l a a n 6 9 • 1 0 7 5 A L A m s t e r d a m • t h e N e t h e r l a n d sKvK Amsterdam: 30117967 • T. +31 20 470 0989 • F. +31 20 470 2084 • info@cbiworld.com

LINE VCOMBINED TEMPERING AND TENSIONLEVELING LINEIntended <strong>for</strong> cold rolled strip, annealed cold rolled strip <strong>and</strong> hot deep galvanized stripManufacturerSiemens VAI ClecimYoM 1989Note: this line consists of two independent units: one temper mill <strong>and</strong> one tension leveler.Strip width600 – 1.300 mmStrip thickness0,2 – 1,5 mmMaterial Yield Point200 – 500 N/mm²Strip/MaterialMaterial Tension Strength300 – 700 N/mm²Leveler Tensionmax. 15.000 daNStrip elongation (two high D-Mill) max. 5%Strip elongation (tension leveler) max. 2%Four High Temper Mill Hydraulic pressure max. 1.000 tNote: This line is constructed <strong>for</strong> continuous strip tempering <strong>and</strong> leveling. These two basic line units maybe used together or separately, depending on the characteristics of material needed.Included is the perpendicular cutting <strong>and</strong> strip edge slitting as well as the electro-static strip oiling.All data have been prepared to the best of our knowledge, however we can not be held liable <strong>for</strong> any errors <strong>and</strong> or omissions.5 C o r e B u s i n e s s I n d u s t r i e s B VH e a d O f f i c e : O r a n j e N a s s a u l a a n 6 9 • 1 0 7 5 A L A m s t e r d a m • t h e N e t h e r l a n d sKvK Amsterdam: 30117967 • T. +31 20 470 0989 • F. +31 20 470 2084 • info@cbiworld.com

LINE VIMEDIUM GAUGE SLITTING LINEintended <strong>for</strong> pickled hot rolled <strong>and</strong> cold rolled stripManufacturerFATA Hunter - Production MachineryYoM 1978TypePull-through lineCoilCutting LineSlitting HeadKnivesWinder motorCoil weightStrip widthStrip thicknessEntry/exit coil inside diameterMin. slit strip widthLine speedShaft diameterThreading motorNote: spare slit head availableDiam. 355 mm x 12 mm200 hp DCmax. 24 tmax. 1.320 mmmax. 5 mm610 mm25 mmmax. 150m/Min.200 mm15 hpAll data have been prepared to the best of our knowledge, however we can not be held liable <strong>for</strong> any errors <strong>and</strong> or omissions.6 C o r e B u s i n e s s I n d u s t r i e s B VH e a d O f f i c e : O r a n j e N a s s a u l a a n 6 9 • 1 0 7 5 A L A m s t e r d a m • t h e N e t h e r l a n d sKvK Amsterdam: 30117967 • T. +31 20 470 0989 • F. +31 20 470 2084 • info@cbiworld.com

LINE VIILIGHT GAUGE SLITTING LINEManufacturerFATA Hunter - Production MachineryYoM 1978TypePull-through slitterCoilCutting LineSlitting HeadWinder MotorCoil weightStrip widthStrip thicknessEntry/exit coil inside diameterMin. slit strip widthLine speedShaft diameterThreading motorNote: spare slit head available150 Hpmax. 24 tmax. 1.320 mmmax. 2 mm610 mm25 mmmax. 200m/Min.200 mm15 hpNote: This line includes cut strip bending, packaging <strong>and</strong> transport equipmentLINE VIIICOMBINED LIGHT SLITTING LINE <strong>and</strong>CUT-to-LENGTH LINEintended mainly <strong>for</strong> cut-to-length of cold rolled strip (CRS) <strong>for</strong> drum production (920 x 1650 mm)ManufacturerSchleicher (Germany)YoM 1982TypePull-through slitterStripStrip widthStrip lengthStrip thicknessmax. 1.000 mmmax. 3.000 mmmax. 1,5 mmAll data have been prepared to the best of our knowledge, however we can not be held liable <strong>for</strong> any errors <strong>and</strong> or omissions.7 C o r e B u s i n e s s I n d u s t r i e s B VH e a d O f f i c e : O r a n j e N a s s a u l a a n 6 9 • 1 0 7 5 A L A m s t e r d a m • t h e N e t h e r l a n d sKvK Amsterdam: 30117967 • T. +31 20 470 0989 • F. +31 20 470 2084 • info@cbiworld.com

LINE IXMEDIUM CUT-TO-LENGTH LINEintended <strong>for</strong> pickled hot rolled <strong>and</strong> cold rolled stripManufacturerFATA Hunter - Production MachineryYoM 1978Strip (HRS <strong>and</strong> CRS)Coil weightStrip widthStrip thicknessmax. 24 tmax. 1.320 mmmax. 3 mm1’’ diameter rolls 17 rollsStrip Precision Leveling UnitFlights back up rolls (top)Flights motorized adjustable back up rollsMotor driveCutting size5 rolls3 rolls75 HP Dc600 – 6.000 mmCutting Lineincl. cut table stacking unit with 2 package desksLine speedmax. 60m/Min.Note: with heavy <strong>and</strong> light levelerROLLS PREPARATION WORKSHOPThe Rolls Preparation Workshop consists of: Roll Grinder Coil Lifter (<strong>for</strong> coils with vertical axe) Coil Car <strong>for</strong> Perpendicular Transport Coil ‘C’ Hook2 OFF3 OFF4 OFF3 OFFAll data have been prepared to the best of our knowledge, however we can not be held liable <strong>for</strong> any errors <strong>and</strong> or omissions.8 C o r e B u s i n e s s I n d u s t r i e s B VH e a d O f f i c e : O r a n j e N a s s a u l a a n 6 9 • 1 0 7 5 A L A m s t e r d a m • t h e N e t h e r l a n d sKvK Amsterdam: 30117967 • T. +31 20 470 0989 • F. +31 20 470 2084 • info@cbiworld.com