NCB shaft liner installation-guide - Marine Office

NCB shaft liner installation-guide - Marine Office

NCB shaft liner installation-guide - Marine Office

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

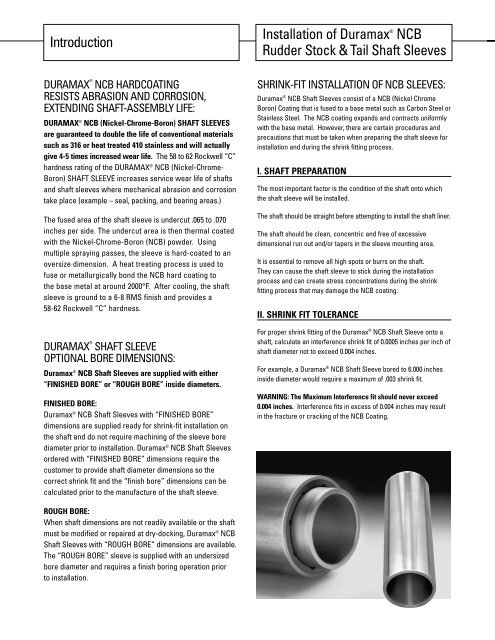

IntroductionInstallation of Duramax ® <strong>NCB</strong>Rudder Stock & Tail Shaft SleevesDURAMAX ® <strong>NCB</strong> HARDCOATINGRESISTS ABRASION AND CORROSION,EXTENDING SHAFT-ASSEMBLY LIFE:DURAMAX ® <strong>NCB</strong> (Nickel-Chrome-Boron) SHAFT SLEEVESare guaranteed to double the life of conventional materialssuch as 316 or heat treated 410 stainless and will actuallygive 4-5 times increased wear life. The 58 to 62 Rockwell “C”hardness rating of the DURAMAX ® <strong>NCB</strong> (Nickel-Chrome-Boron) SHAFT SLEEVE increases service wear life of <strong>shaft</strong>sand <strong>shaft</strong> sleeves where mechanical abrasion and corrosiontake place (example – seal, packing, and bearing areas.)The fused area of the <strong>shaft</strong> sleeve is undercut .065 to .070inches per side. The undercut area is then thermal coatedwith the Nickel-Chrome-Boron (<strong>NCB</strong>) powder. Usingmultiple spraying passes, the sleeve is hard-coated to anoversize dimension. A heat treating process is used tofuse or metallurgically bond the <strong>NCB</strong> hard coating tothe base metal at around 2000°F. After cooling, the <strong>shaft</strong>sleeve is ground to a 6-8 RMS finish and provides a58-62 Rockwell “C” hardness.DURAMAX ® SHAFT SLEEVEOPTIONAL BORE DIMENSIONS:Duramax ® <strong>NCB</strong> Shaft Sleeves are supplied with either“FINISHED BORE” or “ROUGH BORE” inside diameters.FINISHED BORE:Duramax ® <strong>NCB</strong> Shaft Sleeves with “FINISHED BORE”dimensions are supplied ready for shrink-fit <strong>installation</strong> onthe <strong>shaft</strong> and do not require machining of the sleeve borediameter prior to <strong>installation</strong>. Duramax ® <strong>NCB</strong> Shaft Sleevesordered with “FINISHED BORE” dimensions require thecustomer to provide <strong>shaft</strong> diameter dimensions so thecorrect shrink fit and the “finish bore” dimensions can becalculated prior to the manufacture of the <strong>shaft</strong> sleeve.SHRINK-FIT INSTALLATION OF <strong>NCB</strong> SLEEVES:Duramax ® <strong>NCB</strong> Shaft Sleeves consist of a <strong>NCB</strong> (Nickel ChromeBoron) Coating that is fused to a base metal such as Carbon Steel orStainless Steel. The <strong>NCB</strong> coating expands and contracts uniformlywith the base metal. However, there are certain procedures andprecautions that must be taken when preparing the <strong>shaft</strong> sleeve for<strong>installation</strong> and during the shrink fitting process.I. SHAFT PREPARATIONThe most important factor is the condition of the <strong>shaft</strong> onto whichthe <strong>shaft</strong> sleeve will be installed.The <strong>shaft</strong> should be straight before attempting to install the <strong>shaft</strong> <strong>liner</strong>.The <strong>shaft</strong> should be clean, concentric and free of excessivedimensional run out and/or tapers in the sleeve mounting area.It is essential to remove all high spots or burrs on the <strong>shaft</strong>.They can cause the <strong>shaft</strong> sleeve to stick during the <strong>installation</strong>process and can create stress concentrations during the shrinkfitting process that may damage the <strong>NCB</strong> coating.II. SHRINK FIT TOLERANCEFor proper shrink fitting of the Duramax ® <strong>NCB</strong> Shaft Sleeve onto a<strong>shaft</strong>, calculate an interference shrink fit of 0.0005 inches per inch of<strong>shaft</strong> diameter not to exceed 0.004 inches.For example, a Duramax ® <strong>NCB</strong> Shaft Sleeve bored to 6.000 inchesinside diameter would require a maximum of .003 shrink fit.WARNING: The Maximum Interference fit should never exceed0.004 inches. Interference fits in excess of 0.004 inches may resultin the fracture or cracking of the <strong>NCB</strong> Coating.ROUGH BORE:When <strong>shaft</strong> dimensions are not readily available or the <strong>shaft</strong>must be modified or repaired at dry-docking, Duramax ® <strong>NCB</strong>Shaft Sleeves with “ROUGH BORE” dimensions are available.The “ROUGH BORE” sleeve is supplied with an undersizedbore diameter and requires a finish boring operation priorto <strong>installation</strong>.