BoxCooler brochure-6pgFA.qxd - Duramax Marine

BoxCooler brochure-6pgFA.qxd - Duramax Marine

BoxCooler brochure-6pgFA.qxd - Duramax Marine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

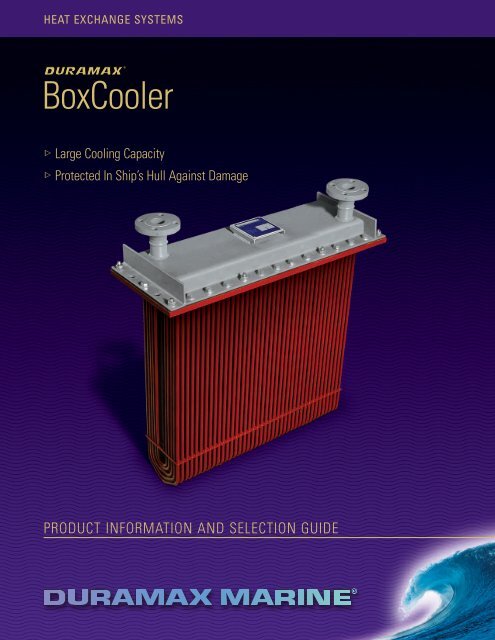

HEAT EXCHANGE SYSTEMS<strong>BoxCooler</strong> Large Cooling Capacity Protected In Ship’s Hull Against DamagePRODUCT INFORMATION AND SELECTION GUIDE

Design and maintenance flexibility Larger cooling capacity than external cooling systems Can cool engines from 0-10,000+ HP No spare parts required Maintenance and repairs can be made without dry-docking. No need to overhaul raw waterpumps and piping every 5 yearsCan be engineered to coolmultiple heat sources on one coolerSingle heat source =single circuit2 heat sources =2 circuits on one <strong>BoxCooler</strong>Ideal for most vessel typesType of vesselTug boatsSupply vesselsIce breakersDredgersFishing vesselsCargo shipsBargesFerriesHeat sourcesMain enginesAuxiliary enginesBow thrustersAir-conditioningsystemsHydraulic systemsSecondary raw water cooling system unnecessary Raw water pump is not required - this meansraw sea water is not being pumped into the vessel Eliminates the need for sea water strainers or filtersNautical classification<strong>Duramax</strong> <strong>BoxCooler</strong>s meet or exceed specificationrequirements of the following classification societies:ABSBVCCSDNVGLAmerican Bureau of ShippingBureau VeritasChinese Classification SocietyDet Norske VeritasGermanischer LloydLRS Lloyds Register of ShippingMROS Maritime Registerof ShippingPRS Polski Rejestr StatkowRINA Registro Italiano NavaleUncoated 90/10 Copper-Nickel <strong>BoxCooler</strong>In freshwater applications and upon request, we canmanufacture units with tube bundles constructed with a bare90/10 copper-nickel alloy – and without our protective coating.WE DO NOT RECOMMEND the use of an uncoated 90/10copper-nickel <strong>BoxCooler</strong> in seawater applications.This is due to the significant potential for galvanic corrosion.This situation, unique to <strong>BoxCooler</strong> applications, is created byplacing a significant amount of uncoated 90/10 copper-nickel tubesin a sea chest which is in close proximity to the ships hull.

The Advantages of<strong>Duramax</strong> <strong>Marine</strong>® <strong>BoxCooler</strong>s.<strong>Duramax</strong> <strong>Marine</strong> ® <strong>BoxCooler</strong>s provide you with superior protection, design flexibility and large cooling capacity.How? The <strong>BoxCooler</strong> operates in a sea chest within your vessel’s hull - so it is completely protectedagainst damage from underwater hazards. And, it’s compact design and large cooling capacityallow for flexibility in sizing. This means that the <strong>BoxCooler</strong> can easily meet the specificcooling needs of your engine - as well as the cooling needs of multipleheat sources - while using less space in your vessel.The working principle of the <strong>BoxCooler</strong>s.The <strong>BoxCooler</strong> works on the principle of Thermal Siphoning.This is the movement of heated water due to convectivecurrents. The fact that hot water will rise and cold (denser)water will fall, results in a natural movement of water orcirculation through the sea chest.In a <strong>BoxCooler</strong>, the engine’s cooling water is pumped througha highly efficient aluminum brass (CuZn20Al) tube bundlewhich is suspended in a sea chest. Openings at the top andbottom of the sea chest permit thecreation of a convection current(thermal siphoning effect) whichflows over the tube bundle andtransfers heat into the sea andaway from the vessels’ engine.The Ultimate <strong>BoxCooler</strong> SystemWith this unique <strong>Duramax</strong> <strong>Marine</strong> ® <strong>BoxCooler</strong>, you get all thedesign advantages of standard <strong>BoxCooler</strong>s; in-hull protection,design flexibility, large cooling capacity and anti-foulingprevention systems. The cooler tubes are coated with aheat-cured synthetic coating which protects the unit fromgalvanic corrosion. This coating is also resistant to saltwater,polluted water, floating debris and chemicals.These added features provide unmatched protection foryour vessel and significantly extend the service life of your<strong>BoxCooler</strong> - making it the ultimate <strong>BoxCooler</strong>.

The Ultimate <strong>BoxCooler</strong> Construction<strong>Duramax</strong> ® <strong>BoxCooler</strong>s are constructed from aluminum brass alloy (CuZn20Al) as standard. The tube bundle and parts that areexposed to raw water are protected by our proprietary heat-cured synthetic coating. The coating is resistant to chemicals, saltwater and polluted water and protects the unit and your vessel from galvanic corrosion. We further extend service life with anImpressed Current Anti-Fouling (ICAF) System to prevent marine growth on the <strong>BoxCooler</strong>.Inlet & Outletmounting flangeWater CoverCoverbolts, nuts& washersCover gasketCollarboltsMounting frame gasketMounting frameBaked-on GalvanicCorrosion Preventive SystemCoated cooler tubes offer increasedprotection against galvanic corrosionin seawater environments.The baked-on coating is notsensitive to stray electrical currents.Connects to PowerSupply/Monitoring SystemSea chestOutlet slotsInlet slotsImpressed Current Anti-Fouling System (ICAF)helps protect the <strong>BoxCooler</strong> and sea chest from foulingAn ICAF System is mounted beneath the <strong>BoxCooler</strong> to prevent marinegrowth. This highly effective anti-fouling system is based on theprinciple of creating an environment inside the sea chest whichprevents the accumulation of biological marine growth and maintainsthe cooling capacity of the <strong>BoxCooler</strong> at full efficiency.

Impressed CurrentAnti-Fouling System (ICAF) *While <strong>Duramax</strong> ® <strong>BoxCooler</strong>s require very little maintenance,the tube bundle is exposed to seawater and can potentiallybecome fouled from algae, mussels, barnacles and othershellfish. The rate of heat transfer can be adversely affectedby this build-up of biological marine growth. The ICAF systemworks to prevent fouling caused by biological sea growth.<strong>Duramax</strong> ®<strong>BoxCooler</strong>Installation andPositioningTHE BOXCOOLER CAN BE INSTALLED IN2 DIFFERENT WAYS*Sometimes referred to as a MGPS (marine growth prevention system).How the ICAF System works.The system uses an artificiallyICAF SYSTEM INSTALLEDtriggered voltage differentialbetween the copper anodesand the cathodes. A smallelectrical current causes thecopper anodes to dissolve.CopperThe copper ions that areAnodeSteelformed in this way mix withCathodethe seawater in the sea chest,creating an environment thatprevents the build up of marinegrowth. The size of the copper anodes are based on the drydocking cycle of the vessel. Anodes typically are sized for 3 to5 year dry docking cycles.The steel frame carrying the copper anodes and the cathodeplates is welded in place inside the sea chest, while thecables from each anode are connected to the power supply unit.System can be monitored during operation.The ICAF System is equipped with a control panel that canbe monitored to ensure the system’s operation.POWER SUPPLY UNIT/CONTROL PANELThis control and powersupply unit will: Monitor the life ofcopper anodes Log data that can be downloadedfor diagnostics Sound an alarm in theevent of a malfunctionTRANSVERSELY:This is the most common way to install a <strong>BoxCooler</strong>.The <strong>BoxCooler</strong> is installed between the existing framesof the vessel.LONGITUDINALLY:This method of installation is less popular as the framesof the vessel must be cut open to allow the sea chestto be installed.Sea Chest OpeningsRegardless of installation method, the sea chest requiresinlet and outlet slots to allow uninterupted water flow overthe cooler tubes.The inlet slots are situated in the base of the sea chestand positioned transversly. The outlet slots are situated inthe outer wall of the hull and positioned longitudinallydirectly under the top surface of the sea chest and mustremain below the water line when the vessel is empty.

INNOVATION.EXPERIENCE.RESULTS.<strong>Duramax</strong> <strong>Marine</strong> ® is committed to providing excellence in every productwe manufacture. Our Johnson Cutless ® marine and industrial bearings,heat exchangers, impact protection systems and sealing systems are knownworldwide for their engineered quality and dependable performance. Please contactthe factory for information on any of the following <strong>Duramax</strong> <strong>Marine</strong> ® products:JOHNSON CUTLESS ®WATER-LUBRICATED BEARING SYSTEMSJohnson Cutless ® Sleeve and Flanged BearingsDX 490 Rudder BushingsDURAMAX ®DURAMAX ®DuraCooler ® Keel Coolers<strong>Duramax</strong> ® Demountable Keel Coolers<strong>Duramax</strong> ® <strong>BoxCooler</strong>sADVANCED WATER-LUBRICATED BEARING SYSTEMSJohnson ® Demountable Stave BearingsROMOR ® I Stave Bearings and Segmental HousingsROMOR ® C- Partial Arc BearingsDMX ® Polymer Alloy BearingsIndustrial Pump Bearing SystemsHEAT EXCHANGE SYSTEMSDURAMAX ®IMPACT PROTECTION SYSTEMSJohnson ® Commercial Dock Bumpers, Fenders & Tow KneesWeatherstrip Door Gaskets, Window Channel and Hatch Cover GasketsLINERITE ® Composite Batterboard SystemsDURAMAX ®SHAFT SEALING SYSTEMS<strong>Duramax</strong> ® Shaft Seal SystemsJohnson ® Heavy-Duty Air Seal Stuffing Boxes<strong>Duramax</strong> ® Ultra-X High Performance Compression PackingJohnson ® Strong Boy Stern Castings and Stuffing Boxes© 2007 <strong>Duramax</strong> <strong>Marine</strong> ®17990 Great Lakes ParkwayHiram, Ohio 44234 U.S.A.PHONE 440.834.5400FAX 800.497.9283 USA & Canadaor 440.834.4950info@<strong>Duramax</strong><strong>Marine</strong>.comwww.<strong>Duramax</strong><strong>Marine</strong>.com