Mini-span Bridges / technical guide - Armtec

Mini-span Bridges / technical guide - Armtec

Mini-span Bridges / technical guide - Armtec

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

_ARMTEC.COMBridge Materials / structural plate /MINI-SPAN BRIDGESTECHNICAL BROCHUREQUICKLY INSTALLEDAND ECONOMICALSHORT SPAN BRIDGESVersatileDurableRuggedReusable100% open bottom structurePre-assembled at the factoryPre-engineered structureLightweightSimple to install

mini-<strong>span</strong> bridges_<strong>Armtec</strong> <strong>Mini</strong>-Span structures are patented products developed in response to ourcustomers’ need for an economical and rapid solution for crossings ofenvironmentally sensitive streams. The features that differentiate <strong>Mini</strong>-Span fromconventional culvert structures are:NOTE• On-site <strong>technical</strong> supportavailable from <strong>Armtec</strong>• Factory-installed headwalls areavailable on all <strong>Mini</strong>-Spans100% open bottom structureThis is a bottomless structure with aclear <strong>span</strong> across the creek, and thus a“fish friendly” bridge that preserves theaquatic habitat.Pre-engineered structureThe structure is designed for acombination of <strong>span</strong>s and loadcarryingcapabilities.VersatileIdeal for use in applications such aslogging roads, secondary highways,municipal creek crossings, utilitycrossings, hiking trails and access roads.RuggedOriginally developed for the loggingindustry, <strong>Mini</strong>-Span structures aredesigned to meet the most demandinghandling and in-use requirements.Pre-assembled at the factoryStructures are pre-assembled at thefactory by skilled <strong>Armtec</strong> professionals,which means reduced installation costsand reduced installation time.Lightweight and simple to installEconomical transportation andinstallation—there is no need forspecialized or heavy equipment.Durable<strong>Mini</strong>-Spans I and II are manufacturedusing Hot Dip Galvanized components.Additional paint finish is available on<strong>Mini</strong>-Spans III.ReusableThe rugged design of <strong>Mini</strong>-Spans IIImeans that the structures may berecovered and reused many times.QUiCK FACTs<strong>Mini</strong>-<strong>span</strong>s are available in 3 models for optimum suitability<strong>Mini</strong>-Span IStandardLengthsUp to 20mMaterial68 x 13mm CorrugatedGalvanized Sheet<strong>Mini</strong>-Span IIUp to 20m<strong>Mini</strong>-Span III 7.45m152 x 51mm Hot-Dip GalvanizedCorrugated Steel Structural Plate152 x 51mm PaintedCorrugated Steel Structural Plate,in Heavy Duty 7.0mm Plate

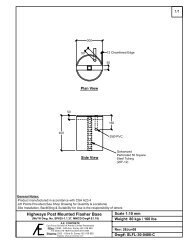

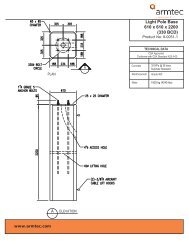

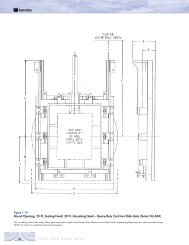

mini-<strong>span</strong> bridges<strong>Mini</strong>-Span I - 68MM x 13MM CorrugationsLoading and Cover RequirementsInsideSpanInsideRiseEndArea<strong>Mini</strong>mumSteelThicknessmm mm m 2 mmCS-600CoverMin.mL-75CoverL-100CoverL-165Cover800 400 0.25 2.8 0.3 7.4 0.3 7.4 0.4 7.4 0.4 7.3Max.mMin.mMax.mMin.mMax.mMin.mMax.m_NOTE• <strong>Mini</strong>mum soil bearing capacity = 250kPa• Footing Plate = 400mm x 12.7mm(plate to A36 minimum)1,000 500 0.39 2.8 0.3 5.9 0.3 5.9 0.4 5.8 0.5 5.71,200 600 0.57 3.5 0.4 4.8 0.4 4.8 0.4 4.8 0.6 4.6AL LENGTH OF STRUCTURE (MULTIPLE OF 609.6mm)1,400 700 0.77 3.5 0.4 4.1 0.4 4.1 0.5 4.0 0.7 3.8GALVANIZED FOOTING PLATE(TYP)GUSSET PLATE(TYP)FASTEN ARMTEC MINI-SPANARCH AT FOOTING PLATESWITH 3/8” DIA X 1 1/2” LGBOLTS c/w NUT & WASHER1,600 800 1.01 3.5 0.5 3.5 0.5 3.5 0.5 3.4 0.8 3.21,800 900 1.27 3.5 0.5 3.0 0.5 3.0 0.6 2.9 0.9 2.6FASTEN ARMTEC MINI-SPANARCH AT CIRCUMFERENTIALLAPS WITH 3/8” DIA X 1” LGBOLTS c/w NUT & WASHER(TYP)FLANGEDCSPSHELLSTIFFENER CHANNELFASTEN WITH 3/4” DIA. X 2” LG MPBOLTS c/w NUTS @ 610 CTRSCROSS STRUTCROSS STRUT610 COVERAGEFLANGED CSP SHELL(TYP)305 COVERAGEFLANGED CSP SHELL(TYP BOTH ENDS)GALVANIZEDCROSS STRUT mini-<strong>span</strong> I bridge(TYP)GUSSET PLATE(TYP)ALL HOLES IN FLANGEDCSP TO BE SLOTTEDUPSTREAM ENDINSIDE SPAN, SEE TABLE ABOVE0/0 FOOTING PLATESSECTION A-ANOMINAL LENGTH OF STRUCTURE (MULTIPLE OF 609.6mm)A3658(TYP)1219(TYP)GALVANIZED FOOTING PLATE(TYP)GUSSET PLATE(TYP)FASTEN ARMTEC MINI-SPANARCH AT FOOTING PLATESWITH 3/8” DIA X 1 1/2” LGBOLTS c/w NUT & WASHER0/0 FOOTING PLATES, SEE TABLE (PAGE 5)INSIDE SPAN, SEE TABLE (PAGE 5)CROSS STRUTCROSS STRUTCROSS STRUTFASTEN ARMTEC MINI-SPANARCH AT CIRCUMFERENTIALLAPS WITH 3/8” DIA X 1” LGBOLTS c/w NUT & WASHER(TYP)610 COVERAGEFLANGED CSP SHELL(TYP)A305 COVERAGEFLANGED CSP SHELL(TYP BOTH ENDS)DOWNSTREAM ENDGALVANIZEDFOOTING PLATE(TYP)GALVANIZEDCROSS STRUT(TYP)<strong>Mini</strong>-Span I – PLAN VIEWGUSSET PLATE(TYP)ALL HOLES IN FLANGEDCSP TO BE SLOTTEDUPSTREAM END

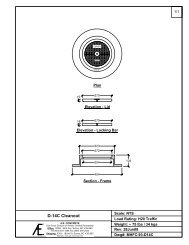

mini-<strong>span</strong> bridges<strong>Mini</strong>-Span III - 152MM x 51MM Corrugations,7MM plate thicknessLoading and Cover Requirements_InsideSpanInsideRiseEndArea<strong>Mini</strong>mumSteelThicknessmm mm m 2 mmCS-600CoverMin.mMax.mL-75CoverMin.mMax.mL-100CoverMin.mMax.mL-165CoverMin.mMax.mNOTE• <strong>Mini</strong>-Span III standard lengths = 7.45m• <strong>Mini</strong>mum soil bearing capacity = 250kPa• Footing Plate = 400mm x 12.7mm(plate to A36 minimum)2,130 1120 1.86 7.0 0.4 4.8 0.4 4.8 0.4 4.7 0.5 4.52,740 1440 3.07 7.0 0.4 3.6 0.4 3.6 0.6 3.5 0.7 3.33,660 1910 5.48 7.0 0.6 2.6 0.6 2.6 0.7 2.5 0.9 2.0mini-<strong>span</strong> III bridge

mini-<strong>span</strong> bridges_NOTE• Obtaining permits for diversionwork(s) and installation of themini-<strong>span</strong> are the responsibilityof the owner• For design of foundation/footing call<strong>Armtec</strong> for un-factored footing loads• Foundation should be investigated byqualified local geo<strong>technical</strong> engineerINSTALLATION OF mini-<strong>span</strong> bridgeINSTALLATION1. Foundation PreparationA properly prepared foundation, to support the footing plates, is essential fora successful <strong>Mini</strong>-Span installation. The elevation, grade and alignment of thefooting plates are dependant on the foundation.Foundation material of poor or non-uniform bearing capacity must beremoved to prevent differential footing settlement. Replacement foundationsoils must provide a uniform and relatively yielding support.2. Footing Design<strong>Mini</strong>-Span structures are typically designed so that the footing plates beardirectly on the foundation or bedding. If required, a concrete footing should bedesigned by a local qualified structural engineer, using available soils data,un-factored footing loads provided by <strong>Armtec</strong>, and appropriate design methods.It’s the responsibility of the owner to determine the scour line of the creek, andposition the footings and detail rock armour accordingly.3. Assembly and Installation<strong>Mini</strong>-Span structures are preassembled and lifted into place on the preparedfoundation. The total assembled weight of the structure is noted on the Bill ofMaterial. Factory installed lifting lugs are provided. Slings must be of sufficientlength such that the lifting angle is no flatter than a 1 (horizontal): 2 (vertical)slope, to prevent overstressing the lifting lugs.If concrete footings are required, the <strong>Mini</strong>-Span is lowered onto the cast-inplaceor precast footings after they are installed to the correct grade andalignment. Holes shall be drilled into the top surface of the footings, matchingthe holes pre-drilled in the footing plate. The footing plate is then bolted to thefooting using 12.5mmø x 100lg anchor bolts.4. Backfill and Footing ProtectionTo protect the critical backfill, a geotextile should be placed on the outside ofthe structure, over the granular foundation and footing plate. To protect thefootings and foundation from scour, a layer of angular armour rock/rip rapshould be placed inside the structure, above the footing plates. The owner’sengineer shall make site specific recommendations for scour protection.mini-<strong>span</strong> bridge

300 LOOSE CUSHION ARCHmini-<strong>span</strong> bridgesINSTALLATION (CONTINUED)5. Backfilling & CompactingIVE LOAD AS PROVIDED BY ENGINEEROTINGAreas close to the sides of the structure shall be compacted using vibrating ortamping equipment running parallel with the length of structure at all times.Granular fill material shall be at optimum moisture content during compaction.Each fill layer shall be compacted to at least 95% standard proctor density.PLACE AND COMPACT GRANULAR BACKFILLIN 200MM LIFTS TO 95% STANDARD PROCTORDENSITY (MIN)When the backfill reaches 3/4 of the rise, spreading and compaction over thetop STREAM arc must BED be made in a direction perpendicular to the length of the300 LOOSE CUSHION ARCHstructure (parallel to corrugations) until the finished height of the criticalSTIFFENING RIBbackfill zone is reached.300 MINRIP RAPA minimum of 300mm of backfill must exist at all times between the spreadingequipment and the structure. This layer of backfill must be built up evenly fromboth sides. The equipment used shall not be heavier than a D-4 Caterpillardozer (7,250kg) for spreading material and not heavier than a Buffalo-BomagBW-755 for compaction.If the backfill is not to be placed immediately EQUIPMENT BUT to the NOT finished elevation, aLESS THAN 600 (TYP)wearing and traveling surface is to be built over the critical backfill zone inorder to maintain a minimum allowable cover.INSIDE SPAN2 X INSIDE SPANTypical Backfill EnvelopeSTREAM BED300 MINRIP RAPSTIFFENING RIBTO SUIT COMPACTION½ SPAN MINLIVE LOAD AS PROVIDED BY ENGINEERBACKFILLING PERPENDICULARTO LENGTH OF STRUCTURE¾ RISE BACKFILLINGPARALLEL TO LENGTHOF STRUCTUREBACKFILLING PERPENDICULARTO LENGTH OF STRUCTUREARMTEC 200NON-WOVENGEOTEXTILE¾ RISE BACKFILLINGPARALLEL TO LENGTHOF STRUCTURE_NOTEAll dimensions are in millimetresunless otherwise notedBackfill and compaction parallelto arch up to 3/4 rise above topof footingBackfill and compaction perpendicularto arch from 3/4 rise above top offooting to finished gradePLACE AND COMPACT GRANULAR BACKFILLIN 200MM LIFTS TO 95% STANDARD PROCTORDENSITY (MIN)TINGINSIDE RISE COVERINSIDE SPAN2 X INSIDE SPAN300TO SUIT COMPACTIONEQUIPMENT BUT NOTLESS THAN 600 (TYP)½ SPAN MINSTREAM BED300 MINRIP RAPARMTEC 200NON-WOVENGEOTEXTILE300 LOOSE CUSHION ARCHSTIFFENING RIBBACKFILLING PERPENDICULARTO LENGTH OF STRUCTURE¾ RISE BACKFILLINGPARALLEL TO LENGTHOF STRUCTUREANCHOR BOLTS(12.5mmø x 100mm LONG)AT 1m O/CCONCRETE FOOTING(BY OTHERS)TO SUIT COMPACTIONEQUIPMENT BUT NOTLESS THAN 600 (TYP)ARMTEC 200NON-WOVENGEOTEXTILE½ SPAN MININSIDE SPAN½ SPAN MIN2 X INSIDE SPAN

Drawings and product details are for informationand/or illustrative purposes only and may vary. Please contactyour <strong>Armtec</strong> representative for the mostcurrent product information.<strong>Armtec</strong> is a leading Canadian infrastructure and construction materials company combining creativeengineered solutions, relevant advice, dedicated people, proven products and a national presence witha local focus on exceptional customer service.1-877-5-ARMTEC | ARMTEC.COMPROD-C01-G07-P02_TG-2013-06-E<strong>Armtec</strong> / Bridge Materials / Structural Plate / <strong>Mini</strong>-Span <strong>Bridges</strong> / Technical Guide | 2013–06