DS05 Dial Set Pressure Regulating Valves - Wolseley Express

DS05 Dial Set Pressure Regulating Valves - Wolseley Express

DS05 Dial Set Pressure Regulating Valves - Wolseley Express

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

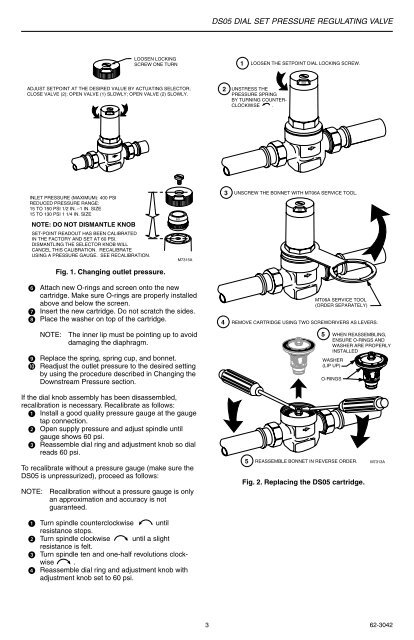

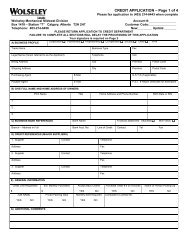

<strong>DS05</strong> DIAL SET PRESSURE REGULATING VALVELOOSEN LOCKINGSCREW ONE TURN1LOOSEN THE SETPOINT DIAL LOCKING SCREW.ADJUST SETPOINT AT THE DESIRED VALUE BY ACTUATING SELECTOR;CLOSE VALVE (2); OPEN VALVE (1) SLOWLY; OPEN VALVE (2) SLOWLY.2UNSTRESS THEPRESSURE SPRINGBY TURNING COUNTER-CLOCKWISE .6060INLET PRESSURE (MAXIMUM): 400 PSIREDUCED PRESSURE RANGE:15 TO 150 PSI 1/2 IN. –1 IN. SIZE15 TO 130 PSI 1 1/4 IN. SIZENOTE: DO NOT DISMANTLE KNOBSET-POINT READOUT HAS BEEN CALIBRATEDIN THE FACTORY AND SET AT 60 PSI.DISMANTLING THE SELECTOR KNOB WILLCANCEL THIS CALIBRATION. RECALIBRATEUSING A PRESSURE GAUGE. SEE RECALIBRATION.60M7315A3UNSCREW THE BONNET WITH MT06A SERVICE TOOL.60Fig. 1. Changing outlet pressure. Attach new O-rings and screen onto the newcartridge. Make sure O-rings are properly installedabove and below the screen. Insert the new cartridge. Do not scratch the sides. Place the washer on top of the cartridge.NOTE:The inner lip must be pointing up to avoiddamaging the diaphragm. Replace the spring, spring cup, and bonnet. Readjust the outlet pressure to the desired settingby using the procedure described in Changing theDownstream <strong>Pressure</strong> section.4MT06A SERVICE TOOL(ORDER SEPARATELY)REMOVE CARTRIDGE USING TWO SCREWDRIVERS AS LEVERS.5 WHEN REASSEMBLING,ENSURE O-RINGS ANDWASHER ARE PROPERLYINSTALLEDWASHER(LIP UP)O-RINGSIf the dial knob assembly has been disassembled,recalibration is necessary. Recalibrate as follows: Install a good quality pressure gauge at the gaugetap connection. Open supply pressure and adjust spindle untilgauge shows 60 psi. Reassemble dial ring and adjustment knob so dialreads 60 psi.To recalibrate without a pressure gauge (make sure the<strong>DS05</strong> is unpressurized), proceed as follows:NOTE:Recalibration without a pressure gauge is onlyan approximation and accuracy is notguaranteed. Turn spindle counterclockwise untilresistance stops. Turn spindle clockwise until a slightresistance is felt. Turn spindle ten and one-half revolutions clockwise. Reassemble dial ring and adjustment knob withadjustment knob set to 60 psi.5REASSEMBLE BONNET IN REVERSE ORDER.Fig. 2. Replacing the <strong>DS05</strong> cartridge.M7313A362-3042