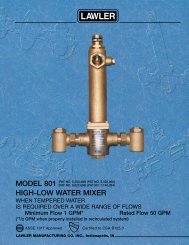

MODEL 802 HIGH-LOW WATER MIXER

HIGH-LOW WATER MIXER - Lawler Thermostatic Mixing Valves

HIGH-LOW WATER MIXER - Lawler Thermostatic Mixing Valves

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

BDIMENSIONS:Valve A BNumber N.P.T. N.P.T. C D E<strong>802</strong> 1″ 1 1 /4″ 11″ 12″ 10 1 /2″DECAPACITIES – <strong>MODEL</strong> <strong>802</strong>HCPressure Drop PSI 5 10 20 30 45 60 80Valve NumberCapacityACELIMINATES SELECTION CONCERNSLawler’s Model <strong>802</strong> simplifies your choice toone valve which is the proper selection over anextremely wide flow range.The <strong>802</strong> is sized correctly for any pressure drop/flow condition which falls in the shaded area ofthe graph to the right.Higher maximum flows may be achieved byinstalling two <strong>802</strong> valves in parallel. Such aninstallation will double the maximum and minimumflows.APRESSURE DROP (PSI)10090807060504030201098765<strong>802</strong>-GPM 28 39 54 66 80 91 103<strong>802</strong>-LPM 106 148 208 247 303 341 388MINIMUM FlOW <strong>802</strong>*MAXIMUM FlOW <strong>802</strong>TYPICAL SPECIFICATIONMaster water mixing valve shall be of the thermostatictype with liquid filled thermal motor. It shallhave bronze body construction with replacablecorrosion resistant components. Valve constructionshall employ a sliding piston controlmechanism. Sliding piston and liner shall be ofstainless steel material. Valve shall come equippedwith union end stop and check inlets with removablestainless steel strainers. Valve shall controltemperature from a low flow of 2 GPM* up to amaximum flow rate for a given pressure differential.Valve shall provide protection against hot or coldsupply line failure and thermostat failure.4321 2 3 4 51020 30 40 50 60 70 80 90100AllOWABlE FlOWSMAXMINFlOW (gPM)<strong>MODEL</strong> <strong>802</strong> FEATURES• Built with a powerful liquid thermal motor.• Compensates for supply line temperature andpressure changes.• Outlet flow is greatly reduced upon supply lineor liquid motor failure.• Inlets are fully rotatable through 360° and outletis rotatable through 360° in 90° increments.Full flexibility is provided for roughing in thevalve.• Tamper-resistant control adjustment.• Rugged design equipped with stainless steelpiston and liner.*1/ 2 gpm when properly installed in recirculated system.• Easy maintenance valve can be completelyrepaired without being removed from the system.