MODEL 911 THERMOSTATIC MIXING VALVE FOR EMERGENCY SHOWER FIXTURES

Model 911 - Lawler Thermostatic Mixing Valves

Model 911 - Lawler Thermostatic Mixing Valves

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

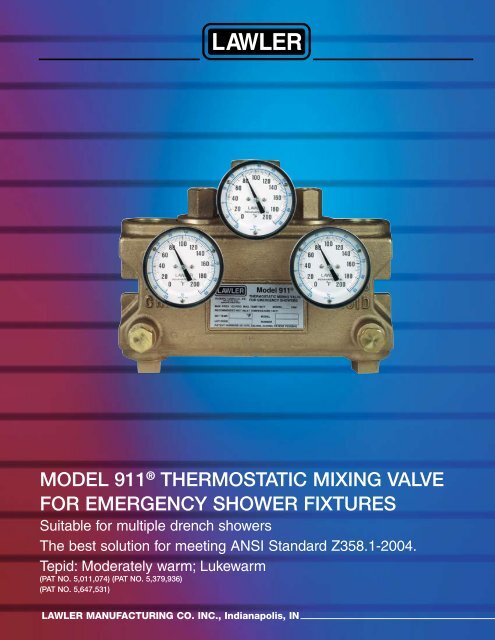

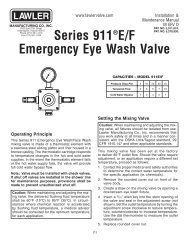

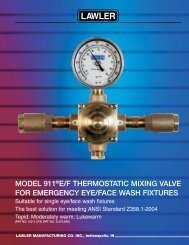

<strong>MODEL</strong> <strong>911</strong> ® <strong>THERMOSTATIC</strong> <strong>MIXING</strong> <strong>VALVE</strong><strong>FOR</strong> <strong>EMERGENCY</strong> <strong>SHOWER</strong> <strong>FIXTURES</strong>Suitable for multiple drench showersThe best solution for meeting ANSI Standard Z358.1-2004.Tepid: Moderately warm; Lukewarm(PAT NO. 5,011,074) (PAT NO. 5,379,936)(PAT NO. 5,647,531)Lawler Manufacturing Co. Inc., Indianapolis, IN

Lawler <strong>MODEL</strong> <strong>911</strong> ®Thermostatic Water ControllerThe SolutionComplies with ANSI Standard Z358.1-2004 of20 gpm of tepid water for emergency showers.The Lawler Model <strong>911</strong> Water Controller thermostaticallymixes large quantities of hot and coldwater for emergency drench shower applicationsand eye wash units.Dual ProtectionThe Model <strong>911</strong>’s twin thermostatic elementsrespond independently to incoming hot andcold water temperatures and provide backupprotection against element failure. In the eventone of the thermostatic elements should fail,the Model <strong>911</strong> will continue to deliver temperedwater to the emergency fixtures.Positive Hot Water Shut-offShould the cold water supply to the valve fail, theModel <strong>911</strong> will shut-off all incoming hot water.Integral Cold Water BypassIn the event the thermostatic element fails, orthe hot water supply is interrupted, the <strong>911</strong> willstill deliver enough cold water to the emergencyeye/face wash equipment to satisfy ANSI’s minimumflow rate safety standard of 40 gpm for twodrench showers.High-Low Flow CapabilityThe Model <strong>911</strong> can temper water to a wide rangeof flows to meet your needs. High-low flowcapability allows the valve to deliver safe, temperedwater to a variety of emergency fixturessupplied by the same water line. This meansmultiple shower and emergency fixtures can beinstalled on the same supply line.FlexibilityThe Model <strong>911</strong> is available in a variety of finishes,piping configurations and cabinet designs tomeet your requirements. Bronze, brass, copper,and stainless steel construction assures yearsof dependable service.Note: Gallon per minute ratings may varydependent upon incoming water temperaturesand pressures. Hot and cold waterinlet pressures must be equal.Ambient Water Temperature ChartCAPACITY OF TYPE <strong>911</strong><strong>THERMOSTATIC</strong> <strong>MIXING</strong> <strong>VALVE</strong><strong>FOR</strong> <strong>EMERGENCY</strong> <strong>SHOWER</strong>SPRESSURE DROP - POUNDS PER SQUARE INCH70605045403530252015109876510 20 30 40 50 60 70 100FLOW OF WATER - GALLONS PER MINUTECAPACITIES – <strong>MODEL</strong> <strong>911</strong>Pressure Drop PSI 5 10 20 30 45Tempered Flow GPM 25 35 50 60 72Tempered Flow LPM 94 132 189 227 275BYPASS CAPACITIES - <strong>MODEL</strong> <strong>911</strong>Pressure Drop PSI 5 10 20 30 45Cold Bypass GPM 14 20 28 40 45Cold Bypass LPM 53 75 106 151 170

C1″14 N.P.T.HOTINLET70 806050403070 8060504030Dimensions: ValveNumber A B C<strong>911</strong> 11″ 9″ 8″Typical SpecificationThe Emergency Shower Mixing Valve shall employtwo fully independent control mechanisms whichsplit the flow in half, blend each half to the designtemperature and then integrate each stream at theoutlet. The valve shall control outlet temperatureover a wide range of flow and shall be suitablefor deluge shower or eyewash applications.The valve shall include three thermometers tomeasure the temperature of each stream andthe merged flow. Temperature adjustment shallbe vandal resistant.Each independent control mechanism shallemploy a liquid-filled thermostatic motor to drivethe valve without additional power requirements.Each control mechanism shall employ a stainlesssteel sliding piston control device with reverseseat closure and both fixed and variable coldwater bypass.In the event of interruption of the cold watersupply, each control mechanism closes off thehot water port, stopping all flow.In the event of interruption of the hot water supply,each control mechanism shall allow cold flowthrough both the fixed and variable by-pass.In the event that one liquid motor fails, the controlmechanism closes off the hot water port with thereverse seat and fully opens the internal variablebypass to allow cold water flow. The other controlmechanism will be unaffected by the failure andwill maintain design temperature.Maximum Inlet Pressure: 125 PSIRecommended Inlet Temperature: 120°F.*Recommended Operating Pressure: 65 PSIConnections: 1 1/4″ NPTCapacity: 60 GPM at 30 PSI9011012013070 8090601105012040130 30BA1″14N.P.T. TEMPEREDOUTLET901101201301″14N.P.T.COLDINLETLawler Model <strong>911</strong> ThermostaticMixing ValvesBenefits:• Comfortable, tempered water for emergencyfixtures encourages proper usage.• Twin thermostatic elements providebackup protection against element failure.• High-Low flow capability.• Installs into existing plumbing lines.• Easy to replace thermostatic cartridges.• Triple thermometers allow hands-offtesting.Features:• Built with two powerful liquid thermal motors.• Compensates for supply line temperatureand pressure changes.• Internal cold water bypass upon thermostatfailure or hot water failure.• Single valve can supply three emergencydrench showers and/or eyewashes.• Tamper-resistant control adjustment.• Rugged design equipped with stainlesssteel piston and liner.• Valve can recirculate both hot and coldwater supply.• Easy-maintenance valve can be completelyrepaired without being removed from thesystem.• Lockout plate and mounting bracket available.PerformanceThe Model <strong>911</strong> controllers will maintain outlettemp-erature to within 5°F. under any of the followingconditions, providing the recommendedminimum flow and minimum supply temperaturedifferentials are met:• reduction to 3 gpm**• 30°F change in hot water temperature• 30°F change in cold water temperature• 20% drop in inlet supply pressureCaution: When maintaining and adjustingthe mixing valve. The delivered flushing fluidtemperature shall be 60°F (15 C) to 95°F (35 C).In circumstances where chemical reaction isaccelerated by flushing fluid temperature, amedical advisor should be consulted for theoptimum temperature for each application.*When supplying 140°F or greater, additional outletcontrols should be used.**Extreme cold water may affect minimum flow rate.

5040603070 8090110120504050406030603070 8070 809013090110120130 30Indianapolis, Indiana 462021101205040605040603070 8070 8090130110120130 3090130110120Indianapolis, Indiana 4620250406070 8090130110120Typical InstallationAfter installing the mixing valve, be sure toflush the system thoroughly. Lawler recommendsisolation and check valves for propermaintenance.Typical Installation #1 (Figure 1)When installed at or near the water heaterand without a recirculation system.Install the valve as shown in Figure 1 with themixing valve positioned below the hot watertank or heater. If this is not possible, pipe ina heat trap as shown.Typical Installation #2 (Figure 2)When installed away from the water heaterwith recirculating pump on the hot watersupply line.Design Consideration: When installed 20feet or more from the water heater, it is importantto recirculate the hot water supply tothe mixing valve.When installing the mixing valve as shown inFigure 1 or 2. The dead leg should be limitedto 10 feet. In order to circulate stagnant wateron a "dead leg" piping run, it may be necessaryto install a timer and solenoid switchat the farthest point to flush the system ona weekly basis.Figure 1Typical installation. Valve must be installedwith check valves.Check Valve (TYP.)waterHeateraFigure 2CWBHeat Trap27" DropCStorageTankLawLerMANUFACTURING CO., INC.600 East Ohio StreetSeries <strong>911</strong>ESV Single Temp SystemTo LowTemperatureFixturesTypical recirculating installation. Valve must beinstalled with check valves.Caution: The cold water line must be installedso that it is not effected by excessively hot ambienttemperatures. Provisions shall be madeto thermally isolate the valve. Cold water pipeinstalled in the ceilings of boiler rooms or roomsthat increase ambient temperature require a recirculatingpump.Caution: When maintaining and adjustingthe mixing valve, all fixtures should be isolatedfrom use. Lawler Manufacturing Co., Inc.recommends that you work safely at all timesand in a manner consistent with the OSHALock/Tagout standard, 29 CFR 1910.147 andother applicable standards.Check Valve (TYP.)aCWBHeat Trap27" DropCLawLerMANUFACTURING CO., INC.600 East Ohio StreetSeries <strong>911</strong>To LowTemperatureFixtureswaterHeaterStorageTankRecirculating Pump5330 East 25th StreetIndianapolis, Indiana 46218Phone (317) 261-1212Fax (317) 261-1208www.lawlervalve.com