Aracruz Uses a Dynamic Simulator for Control System ... - Andritz

Aracruz Uses a Dynamic Simulator for Control System ... - Andritz

Aracruz Uses a Dynamic Simulator for Control System ... - Andritz

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

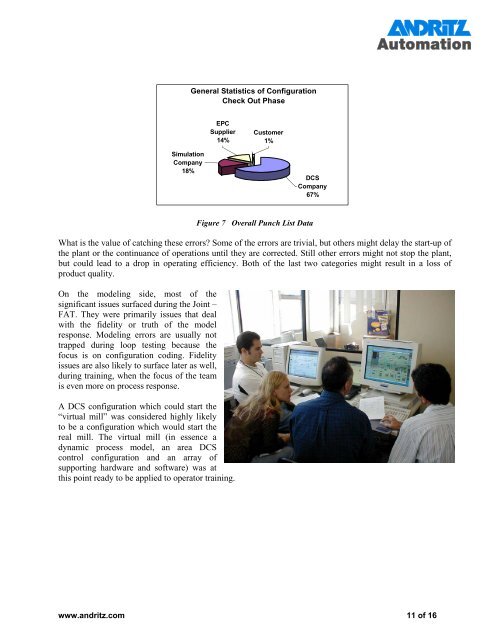

Simulation<br />

Company<br />

18%<br />

Figure 7 Overall Punch List Data<br />

What is the value of catching these errors? Some of the errors are trivial, but others might delay the start-up of<br />

the plant or the continuance of operations until they are corrected. Still other errors might not stop the plant,<br />

but could lead to a drop in operating efficiency. Both of the last two categories might result in a loss of<br />

product quality.<br />

On the modeling side, most of the<br />

significant issues surfaced during the Joint –<br />

FAT. They were primarily issues that deal<br />

with the fidelity or truth of the model<br />

response. Modeling errors are usually not<br />

trapped during loop testing because the<br />

focus is on configuration coding. Fidelity<br />

issues are also likely to surface later as well,<br />

during training, when the focus of the team<br />

is even more on process response.<br />

A DCS configuration which could start the<br />

“virtual mill” was considered highly likely<br />

to be a configuration which would start the<br />

real mill. The virtual mill (in essence a<br />

dynamic process model, an area DCS<br />

control configuration and an array of<br />

supporting hardware and software) was at<br />

this point ready to be applied to operator training.<br />

General Statistics of Configuration<br />

Check Out Phase<br />

EPC<br />

Supplier<br />

14%<br />

Customer<br />

1%<br />

DCS<br />

Company<br />

67%<br />

www.andritz.com 11 of 16