LAKESIDE EfW

WELCOME TO LAKESIDE EfW - Ricardo-AEA

WELCOME TO LAKESIDE EfW - Ricardo-AEA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

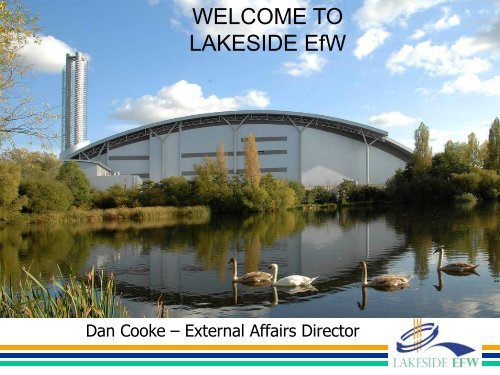

WELCOME TO<strong>LAKESIDE</strong> <strong>EfW</strong>Dan Cooke – External Affairs Director

December 2005

May 2007

Lakeside <strong>EfW</strong> Overview• Lakeside <strong>EfW</strong> Ltd is a joint venture with Grundon andViridor – leading UK recycling, renewable power andwaste players• Cost to build the plant: £160M• Design life: 25 years• Capable of treating 410,000 tonnes of waste per year• 37 MW capacity - equates to generating 250,000 MWhof electricity annually to the national grid• Lakeside <strong>EfW</strong> is privately funded and therefore thecost to the tax payer is nothing.• Created 46 new jobs

The Waste Hierarchy and ResourceEfficiency• Waste Hierarchy: Reduce, Re-Use, Recycle,Recover, Dispose• Grundon and Viridor – recycling-led service providers• Facility inputs from local authorities and businessesacross SE England – delivering landfill diversion andimproved resource efficiency• Lakeside recovers energy from non-hazardousresidual (post-recycling) waste only• New generation plant – safe, robust and efficient• CHP-ready

•Two process streams - throughput of 27 tonnes of waste per houreach.•Each stream will produce approximately 5.5 tonnes of bottom ash,and 1 tonne metals - re-useable commodities•Ash from the Flue Gas Treatment (FGT) system is approximately 0.9tonnes per hour (c.24 tpd) - classed as hazardous waste - taken fromsite, neutralised and landfilled.•95% of input produces energy or is recycled•

Environment• State-of-the–art engineering, monitoring and environmentalcontrol systems• Emissions controlled and monitored by Lakeside <strong>EfW</strong>• Also monitored and regulated by the Environmental Agency.• Emissions from all <strong>EfW</strong> plants must comply with the WasteIncineration Directive (WID) – do not compromise local airquality standards.

Monitoring Lakeside <strong>EfW</strong>The plant is designed to meet the requirements of the WasteIncineration Directive (WID) as a minimum for release.Abatement equipment is designed to reduce emissions:-– Lime to remove acidic gases such as HCl, SO 2 and HF– Activated Carbon to reduce dioxins, PCB's, PAH's,mercury vapour and heavy metal salts.– The final stage is a bag filter to remove particulates– NO x removal is by ammonia injection into the furnaceto reduce the NO x to N 2

Monitoring Lakeside <strong>EfW</strong>The plant will not continue to operate if:• emission limit values are exceeded for a period ofmore than 4 hours• Continuous monitoring equipment is out of servicefor more than 4 hours• Cumulative duration of abnormal operation exceeds60 hours in either of the above cases, calculatedover one calendar year.• Total particulates shall not exceed 150 mg/m 3• Total particulates half hourly limit 30 mg/m 3 or 10mg/m 3 daily average

Tonnes emitted per yearHow do We Compare – 58 mile Stretch?Annual emissions from the Lakeside <strong>EfW</strong> facility and the Surreysection of the M253,000.002,500.002,000.001,500.00Annual ActualEmissions to air fromLakeside <strong>EfW</strong>1,000.00Annual ActualEmissions to air fromthe Surrey Section ofthe M25500.000.00Oxides of nitrogen Carbon monoxide Fine ParticulateMatterVolatile OrganicCompounds

Annual Emissions – Lakeside vs Surrey M25SubstanceActual Emissionsfrom Lakeside<strong>EfW</strong> (tonnes perannum)Permitted Emissionsfrom Lakeside <strong>EfW</strong>(tonnes per annum)Surrey Section ofthe M25 (tonnes perannum)Actual <strong>EfW</strong> emissionsas a percentage ofthe Surrey Section ofthe M25Oxides of Nitrogen (NOx) 306 416 2,987 10.3%Carbon Monoxide (CO) 24 104 2,330 1.0%Fine Particulate Matter(PM10)2.73 21 78 3.5%VolatileOrganicCompounds (VOCs)4 21 366 1.0%Carbon Dioxide 355,614 n/a 696,818 51.0%

Lakeside - Summary• Award winning facility• Converts up to 410,000 tonnes residual waste into37MW of power• By-products (bottom ash and metals) recycled• Safe, robust and reliable technology• <strong>EfW</strong> – potential significant contribution to base-loadpower for UK• Value for money treatment option• Complements high levels of recycling, delivers landfilldiversion and improved resource efficiency.