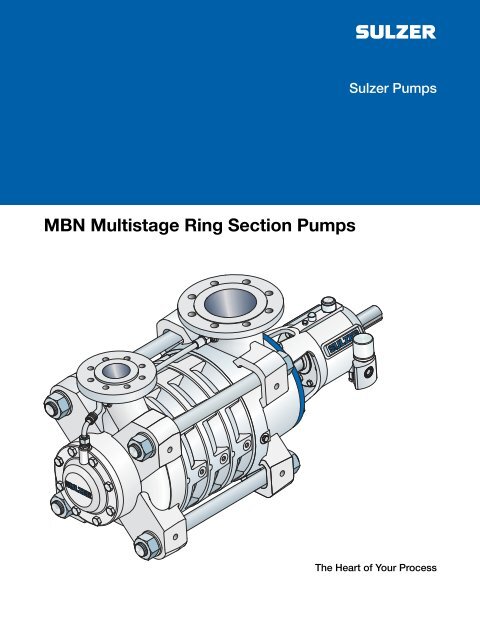

MBN Multistage Ring Section Pumps

Sulzer MBN Multistage Ring Section Pumps Brochure

Sulzer MBN Multistage Ring Section Pumps Brochure

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Sulzer <strong>Pumps</strong> – Striving to Serve You BetterSulzer <strong>Pumps</strong> is a leading globalsupplier of reliable products andinnovative pumping solutions forend users.Our active research and development,detailed process and applicationknowledge together witha comprehensive understanding ofmarket demands keeps us consistentlyat the leading edge of technicaldevelopment.Our global network of modernmanufacturing and packagingfacilities together with sales offi ces,service centers and representativeslocated close to major marketsprovide fast responses to customerneeds.Innovation, Expertise, Research & DevelopmentInnovationSulzer <strong>Pumps</strong> has a long history ofproviding innovative pumping solutionsto business partners in thefollowing industries:• Oil & Gas• Hydrocarbon Processing• Pulp and Paper• Power Generation• Food, Metals & Fertilizers• Water and WastewaterExpertiseOur expertise supports innovativetechnological solutions and equipmentfor all types of power plants- nuclear, fossil-fi red, geothermal,combined-cycle plus large andsmall industrial power plants.We offer an extensive range ofinnovative products and services.Sulzer <strong>Pumps</strong> delivers boiler feed,condensate extraction, boiler circulator,cooling water and auxiliarypumps, as well as specializedsafety related pumps for nuclearpower plants. We are leaders inboiler feed pumps for supercriticalfossil-fi red power plants.Research & DevelopmentResearch & Development hasalways been a top priority at Sulzer<strong>Pumps</strong>. Basic research focuseson hydraulics, cavitation, erosion,corrosion and mechanical design,which is then applied to advanceproduct development. Our engineerswork closely with customersall over the world on the practicalimplementation of innovative ideas.At any point, they can call uponthe diverse expertise of the manyresearch specialists working in ourlaboratories. Successful researchand development activities requirecontinuous investment. Beyondimmediate job results, this benefi tsour customers by ensuring thatthey have a stable business partnerat the leading edge of pumptechnology.

<strong>MBN</strong> <strong>Multistage</strong> <strong>Ring</strong> <strong>Section</strong> <strong>Pumps</strong><strong>MBN</strong> type pumps are horizontal,radially split, ring section pumpswith modular design.<strong>MBN</strong> pumps are suitable for pumpingclean or slightly polluted, hot orcold, chemically neutral or aggressiveliquids.The design is ideal for:• feed water supply in boiler plants• condensate supply in power stationsand industrial plants• desalination (reverse osmosis)• shower water in paper mills• high pressure pumps in variousindustriesMaterialsSuction casingStage casingDischarge casingShaft seal housingImpellersStationary wear ringsShaftShaft sleevesBearing bracketChromium steel, Duplex, SuperduplexChromium steel, Duplex, SuperduplexChromium steel, Duplex, SuperduplexDuplex, SuperduplexCast iron

Design Features and BenefitsHydraulics• special suction impeller for low NPSHr• high quality investment cast impellers andstage casings for better effi ciencyMechanical Design• keyless polygon shaft torque transmission tothe impellers• split ring fi xing for impeller stack to accommodatethermal expansion• innovative journal bearing design for betterinternal alignment and lubrication• axially fi xed shaft assembly

Bearing Unit• 4 bearing units serve 6 hydraulics• same bearing housing for both oil and grease lubrication• increased oil sump for better heat dissipation• Inpro metallic bearing isolators• constant level oiler maintains optimum oil level• grease lubrication for temperatures up to 120° C (240° F)• oil lubrication for temperatures up to 180° C (350° F)• bearing unit can be serviced without disassembling the pumpShaft Sealing• separate seal chamber enables the seal type to be changedwithout having to replace the suction casing• mechanical seal (single and double), dynamic seal and glandpacking are available• shaft sealing only required on the low pressure suction side• shaft seal can be serviced without disassembling the pumpPolygon Impeller MountingFast and easy impeller mountingon the shaft using a polygon form.Shaft straightness is guaranteed,defl ection and stress points are virtuallyeliminated and the standardkeyed design is no longer requiredthanks to the unique polygonmounted impellers.Baseplate• fabricated steel, painted or hotdipgalvanized• to be grouted at installation site

Shaft Sealing OptionsSingle Mechanical SealThe standard mechanical seal isan integrated design for increasedreliability.A large variety of other mechanicalseals with different fi ttings gives thefl exibility to choose the right sealaccording to the application andcustomer’s specifi cation.• MS 11 unfl ushed:up to 90° C (194° F)• MS 12 + Plan 11:up to 140° C (280° F)• Plan 23 with pumping ring:up to 180° C (350° F)Double Mechanical SealDouble seal minimizes the need forsealing liquid. New sealing controlequipment for double mechanicalseals can save more than 90% of the sealing liquid required byconventional equipment.• MS 21 + Plan 54:up to 180° C (350° F)Dynamic SealDynamic seals don’t need externalsealing water or sealing waterpiping thus reducing installation,operating and maintenance costs.• up to 100° C (210° F)Flange Connection Options1 2 3 4 5 6 7 8 9Different suction and discharge fl ange orientation (left-up-right) allows individualcustomer fl exibility during installation and simplifi es piping design.

Operating Data50 Hz 60 HzPump sizes 25 mm to 150 mm 1 to 6 inchesCapacities up to 700 m 3 /h up to 3,080 USgpmHeads up to 900 m up 2,950 feetPressures up to 100 bar up to 1,450 psiTemperatures up to 180° C up to 350° FPerformance Range100050 HzHead H (m)100101 10 100 10003Capacity Q (m /h)100060 HzHead H (m)100101 10 100 10003Capacity Q (m /h)

Check our worldwide offices atwww.sulzerpumps.comE00657 en (4) 6.2009 (2000), Copyright © Sulzer <strong>Pumps</strong>This brochure is a general presentation. It does not provide any warranty or guarantee of any kind. Please, contact us for a description of the warranties and guarantees offeredwith our products. Directions for use and safety will be given separately. All information herein is subject to change without notice.