StoMachine Technology Revolutionizing EIFS Application - Sto Corp.

StoMachine Technology Revolutionizing EIFS Application - Sto Corp.

StoMachine Technology Revolutionizing EIFS Application - Sto Corp.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

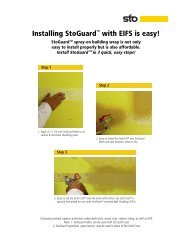

<strong>Sto</strong>SiloThe <strong>Sto</strong>Silo System was introduced in Europe in the mid 1990’s. In that shorttime, it has redefined the application of <strong>EIFS</strong> adhesives and base coats. Nowthe <strong><strong>Sto</strong>Machine</strong> <strong>Technology</strong> program is bringing this unique technology to NorthAmerica, giving customers a competitive edge by shortening the length of timeon jobs and reducing labor costs.The <strong><strong>Sto</strong>Machine</strong> <strong>Technology</strong> Program features the <strong>Sto</strong>Silo Combo. This uniquesystem provides storage, mixing and pumping all in one self-contained unit. The<strong>Sto</strong>Silo Combo has many advantages over the traditional application of <strong>EIFS</strong>. Thissystem is totally automated and can be remote controlled at the point of delivery,adding convenience, enhancing productivity and reducing waste.Three <strong>Sto</strong>Silo packages areavailable:The <strong><strong>Sto</strong>Machine</strong> <strong>Technology</strong> Program offersshort-term and long-term leases on threedifferent <strong>Sto</strong>Silo packages to fit your specificjob site needs.<strong>Sto</strong> offers various package options for the <strong>Sto</strong>Silo Combo to fit your specific needs.<strong>Sto</strong> will also upgrade equipment and provide technical support so you can restassured you will have the latest technology available.What is the <strong>Sto</strong>Silo Combo?The <strong>Sto</strong>Silo Combo consists of a dry material hopper, an integral continuous mixer,and variable speed pump. The remote control pump allows the person at the spraynozzle to be in full control of the machine from up to 210 feet away. No one isneeded to attend the machine or hand mix pails of material. The <strong>Sto</strong>Silo Combocomes in two sizes: 1.0m 3 and 3.0m 3 . The 1.0m 3 <strong>Sto</strong>Silo holds approximately 40,60 lb (27kg) bags of <strong>Sto</strong> BTS-Silo material. The 3.0m 3 <strong>Sto</strong>Silo holds approximately120, 60 lb. (27kg) bags of material. The <strong>Sto</strong> BTS-Silo material is a speciallyengineered material developed for use with the <strong>Sto</strong>Silo System. The <strong>Sto</strong> BTS-Silomaterial is loaded into the <strong>Sto</strong>Silo through a hatch with a customized bag-breakeron the top of the hopper. The dry storage container is weathertight, providingprotection of the material on the job site.<strong>Sto</strong>Silo System:includes the <strong>Sto</strong>SiloCombo, air compressorand water pump<strong>Sto</strong>Silo SystemFEATURESOne self-contained systemLarge dry storage capacityWeathertight, secure storage containerTotally automated systemSpray application of adhesive and base coatAdhesive/base coat formulated and tested for<strong><strong>Sto</strong>Machine</strong> <strong>Technology</strong>Remote control material mixing and deliveryReversible pumpVariable speed settingsContinuously controlled water additionDiagnostic center on machineSingle source supply for equipmentFactory upgrade of equipmentQuick change componentsVarious equipment packages availableBENEFITSEasy to handle, saves time and space loadingReduces need to handle or move bagsReduces material losses due to weather conditions or theftReduces labor costs; enhances quality controlIncreases productivityOptimum material consistency for sprayingMixes only material neededReduces pressure in hose safely when neededProvides flexibility for specific job conditionsConsistent mix every timeMachine troubleshoots itself quicklyStreamlines setup and production; no need to deal withmultiple organizationsNo cost to upgrade; no outdated equipmentReduces down time for part changesChoose the package that meets your needs