StoMachine Technology Revolutionizing EIFS Application - Sto Corp.

StoMachine Technology Revolutionizing EIFS Application - Sto Corp.

StoMachine Technology Revolutionizing EIFS Application - Sto Corp.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

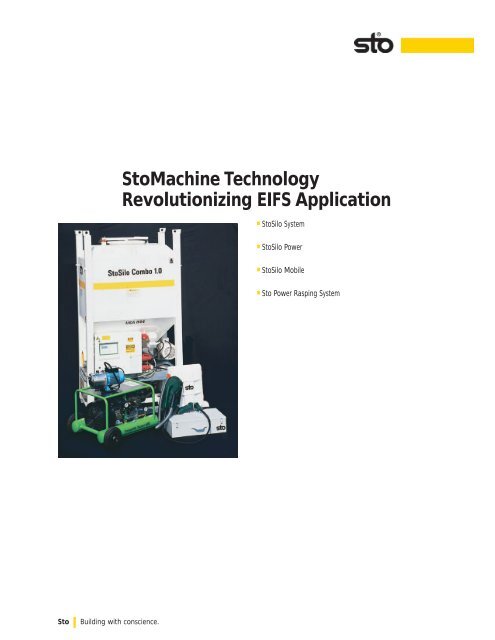

<strong><strong>Sto</strong>Machine</strong> <strong>Technology</strong><strong>Revolutionizing</strong> <strong>EIFS</strong> <strong>Application</strong>. <strong>Sto</strong>Silo System. <strong>Sto</strong>Silo Power. <strong>Sto</strong>Silo Mobile. <strong>Sto</strong> Power Rasping System<strong>Sto</strong>Building with conscience.

<strong>Sto</strong>SiloThe <strong>Sto</strong>Silo System was introduced in Europe in the mid 1990’s. In that shorttime, it has redefined the application of <strong>EIFS</strong> adhesives and base coats. Nowthe <strong><strong>Sto</strong>Machine</strong> <strong>Technology</strong> program is bringing this unique technology to NorthAmerica, giving customers a competitive edge by shortening the length of timeon jobs and reducing labor costs.The <strong><strong>Sto</strong>Machine</strong> <strong>Technology</strong> Program features the <strong>Sto</strong>Silo Combo. This uniquesystem provides storage, mixing and pumping all in one self-contained unit. The<strong>Sto</strong>Silo Combo has many advantages over the traditional application of <strong>EIFS</strong>. Thissystem is totally automated and can be remote controlled at the point of delivery,adding convenience, enhancing productivity and reducing waste.Three <strong>Sto</strong>Silo packages areavailable:The <strong><strong>Sto</strong>Machine</strong> <strong>Technology</strong> Program offersshort-term and long-term leases on threedifferent <strong>Sto</strong>Silo packages to fit your specificjob site needs.<strong>Sto</strong> offers various package options for the <strong>Sto</strong>Silo Combo to fit your specific needs.<strong>Sto</strong> will also upgrade equipment and provide technical support so you can restassured you will have the latest technology available.What is the <strong>Sto</strong>Silo Combo?The <strong>Sto</strong>Silo Combo consists of a dry material hopper, an integral continuous mixer,and variable speed pump. The remote control pump allows the person at the spraynozzle to be in full control of the machine from up to 210 feet away. No one isneeded to attend the machine or hand mix pails of material. The <strong>Sto</strong>Silo Combocomes in two sizes: 1.0m 3 and 3.0m 3 . The 1.0m 3 <strong>Sto</strong>Silo holds approximately 40,60 lb (27kg) bags of <strong>Sto</strong> BTS-Silo material. The 3.0m 3 <strong>Sto</strong>Silo holds approximately120, 60 lb. (27kg) bags of material. The <strong>Sto</strong> BTS-Silo material is a speciallyengineered material developed for use with the <strong>Sto</strong>Silo System. The <strong>Sto</strong> BTS-Silomaterial is loaded into the <strong>Sto</strong>Silo through a hatch with a customized bag-breakeron the top of the hopper. The dry storage container is weathertight, providingprotection of the material on the job site.<strong>Sto</strong>Silo System:includes the <strong>Sto</strong>SiloCombo, air compressorand water pump<strong>Sto</strong>Silo SystemFEATURESOne self-contained systemLarge dry storage capacityWeathertight, secure storage containerTotally automated systemSpray application of adhesive and base coatAdhesive/base coat formulated and tested for<strong><strong>Sto</strong>Machine</strong> <strong>Technology</strong>Remote control material mixing and deliveryReversible pumpVariable speed settingsContinuously controlled water additionDiagnostic center on machineSingle source supply for equipmentFactory upgrade of equipmentQuick change componentsVarious equipment packages availableBENEFITSEasy to handle, saves time and space loadingReduces need to handle or move bagsReduces material losses due to weather conditions or theftReduces labor costs; enhances quality controlIncreases productivityOptimum material consistency for sprayingMixes only material neededReduces pressure in hose safely when neededProvides flexibility for specific job conditionsConsistent mix every timeMachine troubleshoots itself quicklyStreamlines setup and production; no need to deal withmultiple organizationsNo cost to upgrade; no outdated equipmentReduces down time for part changesChoose the package that meets your needs

<strong>Sto</strong>Silo Power: Includes the <strong>Sto</strong>SiloSystem components with a portablegenerator<strong>Sto</strong> Power Rasping System<strong>EIFS</strong> applicators know the tedious process of manually rasping EPS insulation boardcan be time consuming and labor intensive. <strong>Sto</strong> has introduced a revolutionarysystem that may increase productivity up to three times over conventional rasping –decreasing time spent on jobs and worker fatigue. With the applicator professionalin mind, <strong>Sto</strong> <strong>Corp</strong>., introduces the <strong>Sto</strong> Power Rasping System.The <strong>Sto</strong> Power Rasping System consists of twocomponents: the <strong>Sto</strong> Power Rasp and the <strong>Sto</strong>Vac.The <strong>Sto</strong> Power Rasp is an electric rasp, whichfeatures variable speed selection and counter rotatingrasping discs with replaceable sanding discs. Itsclean cutting action produces smoother walls thanmanual rasping, reducing critical sunlight effects. The<strong>Sto</strong> Power Rasp has an adjustable cutting depth forconsistently smoother walls, and unlike other rasps,which pull out full beads from boards, the <strong>Sto</strong> PowerRasp cuts beads in half providing the advantage ofbetter adhesion.<strong>Sto</strong>Silo Mobile: includes the <strong>Sto</strong>SiloCombo, air compressor, water pump andgenerator mounted on a 24’ (7.3m) trailerthat can be attached to any truck withone ton (907kg) of towing capacity.The <strong>Sto</strong>Vac is a vacuum backpack attachment,which features a reusable cloth vacuum bag that eliminates the costly replacementand disposal of paper bags. It has a built-in power outlet for the <strong>Sto</strong> Power Raspso that both units can operate from one extension cord. The vacuum removes looserasping residue for better adhesion. It also provides active environmental protectionby taking EPS particles out of the air. This is vital on projects where EPSparticulates may impose a hazard, such as hospitals, restaurants and retail centers.<strong>Sto</strong> Power RaspFEATURESVariable speedCounter rotating rasping discsLightweight and efficient systemBENEFITSAllows user to vary working speedsProvides clean cutting action; Compared to manually rasped walls,<strong>Sto</strong> Power Rasp rasps walls smoother, reducing critical sunlight effectsDecreases user fatigue and increases productivity up tothree times compared to manual rasps<strong>Sto</strong>VacFEATURESVacuum attachmentReusable cloth vacuum bag110V power requirement with plugfor <strong>Sto</strong> Rasp on <strong>Sto</strong>VacBENEFITSRemoves all loose rasping residue for better adhesion and keying;Active environmental protection – No airborne EPS particulatesEliminates costly disposal of paper bagsBoth units require only one extension cord with standard 110V power

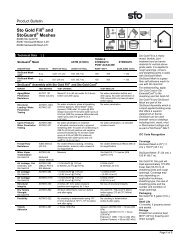

<strong>Sto</strong>Silo Comparative Job DataProject #1Project #2Project #3Project #4Compare YOUR numbersProject Type:Church BuildingHotelMall/Cinema ExpansionOutlet Shopping MallProject Description:Project Location:Project Size (SF):L-shaped two-story churchbuilding with partialone-story elevation.Medallions aroundwindows and doors.Shawnee, Kansas20,000 (SF)28' tall L-shaped hotelwith windows andseven 150 sq ft gablesChicago, Illinois27,500 (SF)Cinema structure in a mallwith 50' walls in back and35' high walls in front withdetails and buildoutsSherwood Park,Alberta, CN40,000 (SF)Large Outlet ShoppingMall with two 35,000towers, flat walls, bull nosedetails and cornice detailsOrlando, Florida253,000 (SF)Conventional <strong>Application</strong>Conventional<strong>Application</strong><strong>Sto</strong>Silo System<strong>Technology</strong>Conventional<strong>Application</strong><strong>Sto</strong>Silo System<strong>Technology</strong>Conventional<strong>Application</strong><strong>Sto</strong>Silo System<strong>Technology</strong>Conventional<strong>Application</strong><strong>Sto</strong>Silo System<strong>Technology</strong>Conventional<strong>Application</strong><strong>Sto</strong>Silo System<strong>Technology</strong>Crew Size:6 54 46 612 10AdhesiveSquare feet (SF) per man per day450 1,000400 1,000400 1,000400 620Production per day(crew size * SF/man/day)Number of production days(project size / daily prod)2,700 5,0007 41,600 4,00017 72,400 6,00017 74,800 6,20053 41Base CoatSquare feet (SF) per man per dayProduction per day (SF)(crew size * SF/man/day)450 1,0002,700 5,000400 1,0001,600 4,000500 1,0003,000 6,000400 6204,800 6,200Number of production days(project size/daily production)7 417 714 753 41Adhesive + Basecoat TotalsAdhesive Production DaysBase Coat Production DaysTotal BC + ADH Production Days7 47 414 817 717 734 1417 714 731 1453 4153 41106 82Total BC + ADH Man Hours(crew size * prod days * 8 hrs)672 3201,088 4481,488 67210,176 6,560Average Man Cost Per Hour(wages, benefits, comp, etc)$35 $35$48 $48$28 $28$30 $30Total Labor Costs(Total Man Hours * Man Cost Per Hour)$23,520 $11,200$52,224 $21,504$41,664 $18,816$305,280 $196,800LABOR SAVINGS$12,320$33,720$22,848*This is an example givenin Canadian dollars$108,480*Costs may vary depending on location, labor market and other economic conditions.<strong>Sto</strong> <strong>Corp</strong>.3800 Camp Creek ParkwayBuilding 1400, Suite 120,Atlanta, GA. 30331Tel: 404-346-3666Toll Free: 1-800-221-2397Fax: 404-346-3119www.stocorp.comContact <strong>Sto</strong> <strong>Corp</strong>.For more information on how <strong><strong>Sto</strong>Machine</strong> <strong>Technology</strong> can help reduce job time and increase labor savings withthe <strong>Sto</strong>Silo System and <strong>Sto</strong> Power Rasping System, contact <strong>Sto</strong> <strong>Corp</strong>., toll free at 1-800-221-2397 or your local<strong>Sto</strong> distributor. If you have operational or technical questions on any of the <strong><strong>Sto</strong>Machine</strong> <strong>Technology</strong> programs orequipment, please call the helpline at 1-888-522-0184, available 8:00 AM – 5:00 PM EST.For more information about <strong>Sto</strong> <strong>Corp</strong>., the innovative world leader in cladding, coating and restoration systems,visit us on-line at www.stocorp.com.S555 04/04 rev01 2000 VEN5609