Instructions for Use: SonoCheck - Support

Instructions for Use: SonoCheck - Support

Instructions for Use: SonoCheck - Support

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

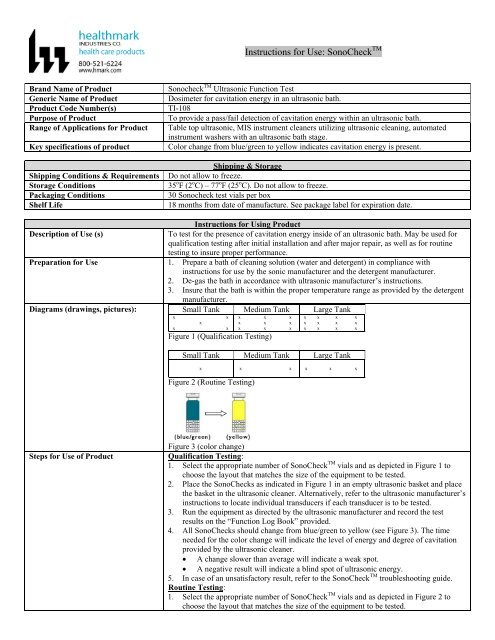

2. Place the <strong>SonoCheck</strong>s as indicated in Figure 2 in an empty ultrasonic basket and placethe basket in the ultrasonic cleaner.3. Run the equipment as directed by the ultrasonic manufacturer and record the testresults on the “Routine Log Book” provided.4. All <strong>SonoCheck</strong>s should change from blue/green to yellow (see Figure 3). The timeneeded <strong>for</strong> the color change will indicate the level of energy and degree of cavitationprovided by the ultrasonic cleaner. A change slower than average will indicate a weak spot. A negative result will indicate a blind spot of ultrasonic energy.5. In case of an unsatisfactory result, refer to the <strong>SonoCheck</strong> TM troubleshooting guide.Interpretation of Results: Color change from blue/green to yellow indicates presence of cavitation energy. Time <strong>for</strong> color change indicates the strength of cavitation energy. Failure <strong>for</strong> color change to yellow indicates a failure to achieve sufficient cavitationenergy to clean. Ultrasonic energy is localized and failure to achieve color change may indicate one ormore sonic transducers is failing.Contraindications of Test Results: In the presence of very powerful cavitation energy, color of Sonocheck TM liquid may gocompletely clear (no color). This can be interpreted as a passed test.Documentation If conducting Qualification Testing, use the Functional Log BookIf conducting Routine Testing the Routine Log Book to record your results.Report any unsatisfactory results to the proper management <strong>for</strong> corrective actionaccording to the policy of your facility.Point of use:Preparation <strong>for</strong> decontamination:Disassembly <strong>Instructions</strong>:Cleaning – Manual:Cleaning – Automated:Disinfection:Drying:Maintenance, inspection, and testing:Reassembly <strong>Instructions</strong>:Packaging:Sterilization:Storage:Additional In<strong>for</strong>mation:Related Healthmark Product(s)Other Product <strong>Support</strong> DocumentsReference DocumentsCustomer service contact:2012-05-07 Ralph J BasileReprocessing <strong>Instructions</strong>35 o F (2 o C) – 77 o F (25 o C). Do not allow to freeze.USTK-1L (weekly ultrasonic test kit), TWTL-1L (weekly tunnel washer test kit)Pro<strong>for</strong>mance Product BrochurePro<strong>for</strong>mance Price ListFunctionality Testing Log SheetRoutine Testing Log SheetSonocheck Trouble Shooting GuideSonocheck Weekly Log SheetPB-Automated Washer TestsPB-Ultrasonic Lumen TestsValidation of <strong>SonoCheck</strong> <strong>for</strong> the Monitoring of Ultrasonic Energy of Ultrasonic Cleaner,Martin PfeiferHealthmark Industries Company, Inc33671 DorekaFraser, MI 480261-586-774-7600healthmark@hmark.com, hmark.comManufacturer:PEREG GmbHPorsche Str. 12D-84478 Waldkraiburgwww.pereg.de