Semi-Finished - Engineering Plastic Products - Ensinger-online.com

Semi-Finished - Engineering Plastic Products - Ensinger-online.com

Semi-Finished - Engineering Plastic Products - Ensinger-online.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

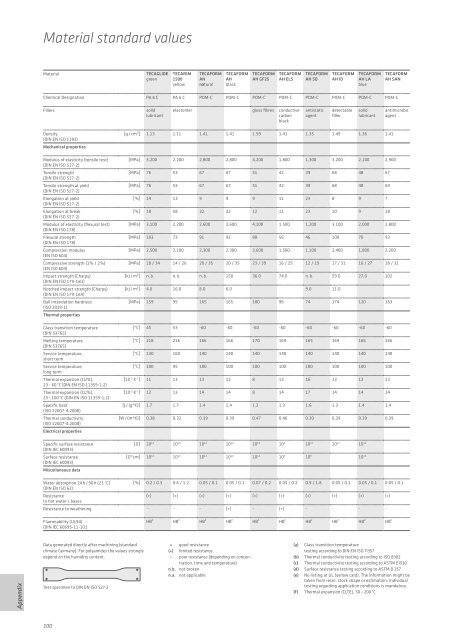

Material standard values<br />

Material<br />

TECAGLIDE<br />

green<br />

TECARIM<br />

1500<br />

yellow<br />

TECAFORM<br />

AH<br />

natural<br />

TECAFORM<br />

AH<br />

black<br />

TECAFORM<br />

AH GF25<br />

TECAFORM<br />

AH ELS<br />

TECAFORM<br />

AH SD<br />

TECAFORM<br />

AH ID<br />

TECAFORM<br />

AH LA<br />

blue<br />

TECAFORM<br />

AH SAN<br />

Chemical Designation<br />

PA 6 C PA 6 C POM-C POM-C POM-C POM-C POM-C POM-C POM-C POM-C<br />

Fillers<br />

solid<br />

lubricant<br />

elastomer glass fibres conductive<br />

carbon<br />

black<br />

antistatic<br />

agent<br />

detectable<br />

filler<br />

solid<br />

lubricant<br />

antimicrobic<br />

agent<br />

Density<br />

(DIN EN ISO 1183)<br />

Mechanical properties<br />

Modulus of elasticity (tensile test)<br />

(DIN EN ISO 527-2)<br />

Tensile strength<br />

(DIN EN ISO 527-2)<br />

Tensile strength at yield<br />

(DIN EN ISO 527-2)<br />

Elongation at yield<br />

(DIN EN ISO 527-2)<br />

Elongation at break<br />

(DIN EN ISO 527-2)<br />

Modulus of elasticity (flexural test)<br />

(DIN EN ISO 178)<br />

Flexural strength<br />

(DIN EN ISO 178)<br />

Compression modulus<br />

(EN ISO 604)<br />

Compressive strength (1% / 2 %)<br />

(EN ISO 604)<br />

Impact strength (Charpy)<br />

(DIN EN ISO 179-1eU)<br />

Notched impact strength (Charpy)<br />

(DIN EN ISO 179-1eA)<br />

Ball intendation hardness<br />

(ISO 2039-1)<br />

Thermal properties<br />

Glass transition temperature<br />

(DIN 53765)<br />

Melting temperature<br />

(DIN 53765)<br />

Service temperature,<br />

short term<br />

Service temperature,<br />

long term<br />

Thermal expansion (CLTE),<br />

23 – 60 °C (DIN EN ISO 11359-1;2)<br />

Thermal expansion (CLTE),<br />

23 – 100 °C (DIN EN ISO 11359-1;2)<br />

Specific heat<br />

(ISO 22007-4:2008)<br />

Thermal conductivity<br />

(ISO 22007-4:2008)<br />

Electrical properties<br />

Specific surface resistance<br />

(DIN IEC 60093)<br />

Surface resistance<br />

(DIN IEC 60093)<br />

Miscellaneous data<br />

Water absorption 24 h / 96 h (23 °C)<br />

(DIN EN ISO 62)<br />

Resistance<br />

to hot water / bases<br />

Resistance to weathering<br />

Flammability (UL94)<br />

(DIN IEC 60695-11-10;)<br />

[ g / cm³ ]<br />

[ MPa ]<br />

[ MPa ]<br />

[ MPa ]<br />

[%]<br />

[%]<br />

[ MPa ]<br />

[ MPa ]<br />

[ MPa ]<br />

[ MPa ]<br />

[ kJ / m² ]<br />

[ kJ / m² ]<br />

[ MPa ]<br />

[ °C ]<br />

[ °C ]<br />

[ °C ]<br />

[ °C ]<br />

[ 10 -5 K -1 ]<br />

[ 10 -5 K -1 ]<br />

[ J / (g*K)]<br />

[ W /(m*K)]<br />

[ Ω ]<br />

[ Ω*cm ]<br />

[%]<br />

1.13 1.11 1.41 1.41 1.59 1.41 1.35 1.49 1.36 1.41<br />

3,200 2,200 2,800 2,800 4,200 1,800 1,300 3,200 2,100 2,900<br />

76 53 67 67 51 42 39 68 48 67<br />

76 53 67 67 51 42 39 68 48 69<br />

14 13 9 9 9 11 23 8 9 7<br />

18 58 32 32 12 11 23 10 9 18<br />

3,100 2,200 2,600 2,600 4,100 1,500 1,200 3,100 2,000 2,800<br />

103 73 91 91 88 56 46 100 70 93<br />

2,500 2,100 2,300 2,300 3,600 1,500 1,100 2,400 1,800 2,200<br />

18 / 34 14 / 26 20 / 35 20 / 35 23 / 39 16 / 25 12 / 19 17 / 31 16 / 27 18 / 31<br />

n. b. n. b. n. b. 150 36.0 74.0 n. b. 59.0 27.0 102<br />

4.0 16.0 8.0 6.0 9.0 11.0<br />

159 95 165 165 180 96 74 174 120 163<br />

45 53 -60 -60 -60 -60 -60 -60 -60 -60<br />

218 216 166 166 170 169 165 169 166 166<br />

130 160 140 140 140 140 140 140 140 140<br />

100 95 100 100 100 100 100 100 100 100<br />

11 13 13 13 8 13 16 13 13 13<br />

12 13 14 14 8 14 17 14 14 14<br />

1.7 1.7 1.4 1.4 1.2 1.3 1.6 1.3 1.4 1.4<br />

0.38 0.32 0.39 0.39 0.47 0.46 0.30 0.39 0.39 0.39<br />

10 14 10 14 10 14 10 14 10 14 10 4 10 11 10 13 10 14<br />

10 14 10 14 10 13 10 14 10 14 10 5 10 9 10 14<br />

0.2 / 0.3 0.6 / 1.2 0.05 / 0.1 0.05 / 0.1 0.07 / 0.2 0.05 / 0.2 0.9 / 1.8 0.05 / 0.1 0.05 / 0.1 0.05 / 0.1<br />

(+) (+) (+) (+) (+) (+) (+) (+) (+) (+)<br />

- - - (+) - (+) - - - -<br />

HB e HB e HB e HB e HB e HB e HB e HB e HB e HB e<br />

Appendix<br />

Data generated directly after machining (standard<br />

climate Germany). For polyamides the values strongly<br />

depend on the humidity content.<br />

Test specimen to DIN EN ISO 527-2<br />

+ good resistance<br />

(+) limited resistance<br />

– poor resistance (depending on concen -<br />

tration, time and temperature)<br />

n.b. not broken<br />

n.a. not applicable<br />

(a) Glass transition temperature<br />

testing according to DIN EN ISO 11357<br />

(b) Thermal conductivity testing according to ISO 8302<br />

(c) Thermal conductivity testing according to ASTM E1530<br />

(d) Surface resistance testing according to ASTM D 257<br />

(e) No listing at UL (yellow card). The information might be<br />

taken from resin, stock shape or estimation. Individual<br />

testing regarding application conditions is mandatory.<br />

(f) Thermal expansion (CLTE), 50 – 200 °C<br />

100