- Page 1 and 2:

GENERAL CATALOGUE

- Page 3 and 4:

18 Trapezoidal screw jacks 86 Aleph

- Page 5 and 6:

BEVEL GEAR BOXES 156 Production lin

- Page 8 and 9:

In times of recent globalisation UN

- Page 10:

The two activities which are the co

- Page 14 and 15:

You maybe did not know that many ac

- Page 16:

If the production is proud of its

- Page 20 and 21:

60 TP Threaded spindle model with t

- Page 22 and 23:

72 CS TP model screw jacks with saf

- Page 24 and 25:

79 FP TP model screw jacks with pas

- Page 26 and 27:

Models TP MODEL: threaded spindle w

- Page 28 and 29:

LOAD ANALYSIS AND COMPOSITION Choos

- Page 30 and 31:

BACKLASH Backlash on the worm screw

- Page 32 and 33:

LUBRICATION Inner lubrication The l

- Page 34 and 35:

INSTALLATION AND MAINTENANCE Instal

- Page 36 and 37:

TP MODEL 21 1 2 3 4 5 5.1 6 8 8.1 9

- Page 38 and 39:

DIMENSIONING OF THE SCREW JACK For

- Page 40 and 41:

C - THE EQUIVALENT LOAD All the val

- Page 42 and 43:

E - BUCKLING In case of compression

- Page 44 and 45:

F - THE LATERAL LOAD As stated in t

- Page 46 and 47:

Size 183 Ratio 1/5 Load [daN] 500 4

- Page 48 and 49:

Size 306 Ratio 1/5 Load [daN] 2500

- Page 50 and 51:

Size 559 Ratio 1/5 Load [daN] 10000

- Page 52 and 53:

Size 8010 Ratio 1/5 Load [daN] 2500

- Page 54 and 55:

Size 10012 Ratio 1/10 Load [daN] 40

- Page 56 and 57:

Size 14014 Ratio 1/12 Load [daN] 80

- Page 58 and 59:

Size 20018 Ratio 1/12 Load [daN] 15

- Page 60 and 61:

Series construction models B model

- Page 62 and 63:

Series construction models stroke t

- Page 64 and 65:

Series construction models MBD mode

- Page 66 and 67:

PR rigid protection The application

- Page 68 and 69:

PE elastic protection The purpose o

- Page 70 and 71:

PRA double guide anti-rotation As a

- Page 72 and 73:

CS Safety lead nut for monitored we

- Page 74 and 75:

SU Lead nut for monitored wear cont

- Page 76 and 77:

RG Anti axial backlash lead nut As

- Page 78 and 79:

SP Additional mounting plates If fo

- Page 80 and 81:

PO Rigid rocking protection When it

- Page 82 and 83:

AM Over-size spindle stroke stroke

- Page 84 and 85:

MOUNTING SCHEMES Scheme 1 B5 form m

- Page 86 and 87:

aleph New market demands, the growt

- Page 88 and 89:

aleph Models TP MODEL: threaded spi

- Page 90 and 91:

HANDLING Manual operation The Aleph

- Page 92 and 93:

TP MODEL 21 1 Casing (half-shell) 4

- Page 94 and 95:

DIMENSIONING OF THE SCREW JACK For

- Page 96 and 97:

The temperature factor f t By means

- Page 98 and 99:

D - THE POWER TABLES AND THE EQUIVA

- Page 100 and 101:

E - BUCKLING In case of compression

- Page 102 and 103: In order to complete the calculatio

- Page 104 and 105: Series construction models B model

- Page 106 and 107: PR rigid protection The application

- Page 108 and 109: PRF stroke control In order to meet

- Page 110: The ball screw jacks proposed in th

- Page 113 and 114: CK Screw jack suitable for applicat

- Page 115 and 116: CR K model screw jack with worm whe

- Page 117 and 118: GLOSSARY A = maximum angular speed

- Page 119 and 120: LUBRICATION Inner lubrication The l

- Page 121 and 122: Routine maintenance Screw jacks mus

- Page 123 and 124: MK MODEL 13 8 6 2 Casing Cover Holl

- Page 125 and 126: A - THE APPLICATION DATA For a righ

- Page 127 and 128: Rotation speed [rpm] time [s] Rotat

- Page 129 and 130: I - LOAD STRENGHT As a last step in

- Page 131 and 132: Static Load C [N] Ball screw type S

- Page 133 and 134: BALL LEAD NUTS MOUNTING KT Models M

- Page 135 and 136: d) FLANGED LEAD NUT WITH DIAMETER =

- Page 137 and 138: f) FLANGED LEAD NUT WITH DIAMETER >

- Page 139 and 140: Series construction models B model

- Page 141 and 142: GR rotating guide The rotating guid

- Page 143 and 144: GSS upper static guide The upper st

- Page 145 and 146: PRO oil bath rigid protection The a

- Page 147 and 148: PRF stroke control In order to meet

- Page 149 and 150: CR rotation control In some cases i

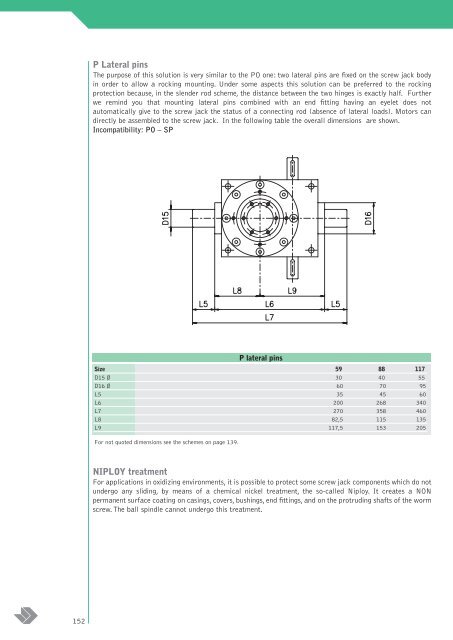

- Page 151: PO rigid rocking protection When it

- Page 155 and 156: Scheme 5 Scheme 6 Scheme 7 155 moun

- Page 157 and 158: 157 capitolo

- Page 159 and 160: RM Bevel gearboxes with fast double

- Page 161 and 162: MRZ Two hub shafts bevel gearboxes

- Page 163 and 164: GLOSSARY A = maximum input angular

- Page 165 and 166: RC RR RB RA RS RP Size 54 86 110 13

- Page 167 and 168: RC RR RB RA RS RP Size 54 86 110 13

- Page 169 and 170: HANDLING All bevel gearboxes can be

- Page 171 and 172: 4000 Input revolution shaft [rpm] 3

- Page 173 and 174: ORDERING CODES RC 86 C1 1/1 model s

- Page 175 and 176: RIS Model 17 22 18 2 8 14 23 12 13

- Page 177 and 178: RH Model 23 22 21 38 17 10 18 3 2 8

- Page 179 and 180: A - The application data For a righ

- Page 181 and 182: D - THE INERTIA POWER In case of im

- Page 183 and 184: E - LUBRICATION After a first dimen

- Page 185 and 186: RC RR RB RA RS RP RX RZ RIS Ratio 1

- Page 187 and 188: RC RR RB RA RS RP RX RZ Ratio 1/4 5

- Page 189 and 190: NIPLOY treatment For applications i

- Page 191 and 192: Base mounting schemes ratio: 1/1 C1

- Page 193 and 194: Base mounting schemes ratio: 1/1 C1

- Page 195 and 196: Base mounting schemes ratio: 1/1 S1

- Page 197 and 198: Base mounting schemes ratio: 1/1 S3

- Page 199 and 200: Base mounting schemes ratio: 1/1 -

- Page 201 and 202: atio: 1/4,5 - 1/6 - 1/9 - 1/12 High

- Page 203 and 204:

atio: 1/4,5 - 1/6 - 1/9 - 1/12 High

- Page 205 and 206:

atio: 1/2 - 1/3 - 1/4,5 Inverted be

- Page 207 and 208:

atio: 1/2 - 1/3 - 1/4,5 Inverted ge

- Page 209 and 210:

Base mounting schemes ratio: 1/1 MC

- Page 211 and 212:

Base mounting schemes ratio: 1/1 MS

- Page 213 and 214:

Base mounting schemes ratio: 1/1 MS

- Page 215 and 216:

215 high reduction motor gearboxes

- Page 217 and 218:

S11 S12 S13 S15 RS - RP m2 m2 m2 m2

- Page 219 and 220:

219 capitolo

- Page 221 and 222:

Acetylene Vinegar Vinegar (vapours)

- Page 224 and 225:

248 F One stage speed modulation ge

- Page 226 and 227:

Casings The speed modulation gearbo

- Page 228 and 229:

LOAD ANALYSIS AND COMPOSITION The a

- Page 230 and 231:

BACKLASHES The gears connection pre

- Page 232 and 233:

LUBRICATION The lubrication of the

- Page 234 and 235:

INSTALLATION AND MAINTENANCE Instal

- Page 236 and 237:

DIMENSIONING OF THE SPEED MODULATIO

- Page 238 and 239:

The usage factor f g The graph belo

- Page 240 and 241:

Given ω v the fast revolution spee

- Page 242 and 243:

F Model Ratio 1/3 Size 32 42 55 Fas

- Page 244 and 245:

RC/F-RS/F Model Ratio 1/2 Size 32 4

- Page 246 and 247:

RC/FP-RS/FP-RIS/FP Model Ratio 1/3

- Page 248 and 249:

Series construction models model 1

- Page 250 and 251:

Series construction models model 7

- Page 252 and 253:

Series construction models model 11

- Page 254 and 255:

M Models M Models Size IEC Flange D

- Page 256 and 257:

42 43 44 45 46 47 48 49 50 51 52 53

- Page 258 and 259:

NIPLOY treatment For applications i

- Page 260:

To complete its range of production

- Page 263 and 264:

UMM couplings UM6M UM7M UM8M UM9M U

- Page 265 and 266:

265 units of measure

- Page 267 and 268:

This catalogue cancels and replaces

- Page 269 and 270:

SOLAR SERIES

- Page 271 and 272:

La production d’énergies propres

- Page 273 and 274:

SOLAR model SOLAR 1 SOLAR 2 SOLAR 3