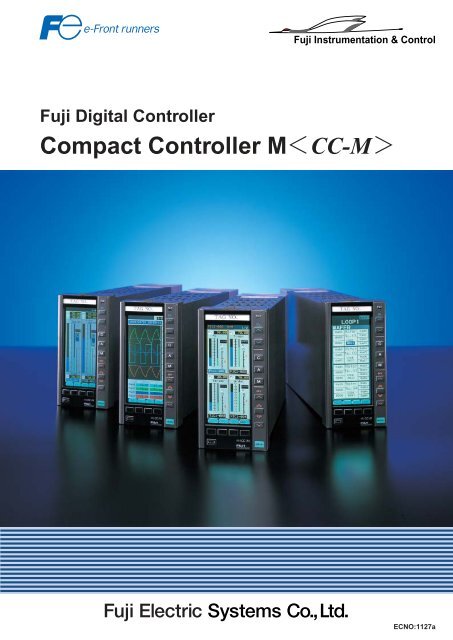

Compact Controller MCC-M

ECNO:1127a

ECNO:1127a

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Fuji Instrumentation & Control<br />

Fuji Digital <strong>Controller</strong><br />

<strong>Compact</strong> <strong>Controller</strong> <strong>MCC</strong>-M<br />

ECNO:1127a

Open network<br />

High-level communications using Modbus protocol allows the CC-M to be connected to a PLC or PC. OPTO22<br />

I/O modules can be connected to each CC-M using low-level communications.<br />

CC-M<br />

PLC<br />

Other System<br />

RS-485/Modbus<br />

CC-M<br />

Mainframe<br />

input/<br />

output<br />

PV PV PV<br />

OPTO-22<br />

MV<br />

MV<br />

MV<br />

Extended<br />

input/output<br />

A variety of control functions<br />

¡Single loop control<br />

¡Multi-loop control<br />

¡Cascade control<br />

¡Ratio control<br />

¡Program control<br />

¡Multi-point input selection control<br />

¡Various advanced control<br />

¡Sequence logic + loop control<br />

Examples of application system<br />

¡Water treatment<br />

Water distribution control, pump control, chemical injection control<br />

¡Utility plants<br />

Water supply control, drum water level control, combustion control<br />

¡Combustion furnaces<br />

Batch type furnace, continuous furnace<br />

¡City gas<br />

Manufacture process, heating power adjustment, distribution control<br />

¡Incinerator plants<br />

Combustion temperature control, blower and exhaust control<br />

¡Others<br />

Autoclave instrumentation, open channel flow computation, multi-point gas analyzer switching computation

FUJI Electric declares a multi-loop controller era<br />

The <strong>Compact</strong> <strong>Controller</strong> M is a multi-loop controller of a new era where functions of 4<br />

controllers are compactly built into a single unit.<br />

A 16-color liquid crystal display presents information in highly visible way, from multiloop<br />

bar graph display screen to trend screen and menu screen.<br />

Oriented to user friendly operation, the multi-loop controller with innovated operability<br />

and functionality configures a flexible high performance system.<br />

Controls up to 4 cascade control loops<br />

(4 control outputs)<br />

Up to 8 PID controls and 4 control outputs (4-20 mA DC) per unit are available.<br />

Use of OPTO 22 interface allows the increase of auxiliary analog input/output up to 4 points and auxiliary digital<br />

input/output up to 32 points in addition to the mainframe input/output (up to 16 points analog input/output & up to 21<br />

points digital input/output).<br />

For safety process operation, a backup operation unit for 1 to 4 loops of 4-20 mA DC output can be incorporated.<br />

As shown below, a combustion application controlled by four single loop controllers can be cmplemerded with a single<br />

CC-M.<br />

Heating furnace/continuous furnace combustion control<br />

Conventional system<br />

1 function fixed type SLC<br />

3 programmable type SLCs<br />

1 ratio setter<br />

Air/fuel ratio<br />

setter<br />

Atmosphere<br />

SLC<br />

CC-M system<br />

CC-M<br />

Integration<br />

Control MLC<br />

Temperature SLC<br />

PV1<br />

PV2<br />

PV3<br />

PV4<br />

Air<br />

SLC<br />

Gas SLC<br />

MV1<br />

MV2<br />

CO<br />

meter<br />

CO<br />

meter<br />

Heating furnace/continuous furnace<br />

Heating furnace/continuous furnace<br />

Soft logic functions (optional)<br />

Use of a PLC function programming language conforming to international standard IEC 61131-3 allows loop control<br />

and logic control functions (ladder: 2 k steps).<br />

As shown below, control applications which utillze single loop controllers and external alarm relays can be executed<br />

with the CC-M's advanced software capabilities.<br />

Sequence Logic & Loop control<br />

Conventional system<br />

ANN. Lamp<br />

CC-M system<br />

ANN. Lamp<br />

BZ<br />

BZ<br />

Lamp reset s.w.<br />

Buzzer stop s.w.<br />

SLC<br />

ANN.<br />

Ry<br />

Ry<br />

ANN.<br />

Ry<br />

Ry<br />

Ry<br />

Relay sequence<br />

circuit<br />

Ry<br />

Extend<br />

input/output<br />

OPTO-22<br />

Lamp reset s.w.<br />

Buzzer stop s.w.<br />

RS-485<br />

OPTO-22<br />

PV1<br />

PV2<br />

MV1<br />

MV2<br />

CC-M<br />

Integration<br />

Control MLC<br />

PV3<br />

PV4<br />

Trend data indication and saving<br />

Up to 32 trends can be indicated.<br />

IC memory card can save trend data.<br />

Storage capacity: Approx. 1.35 million points of data by <strong>Compact</strong> Flash memory of 30MB.

Versatile graphic indication<br />

Names of front panel<br />

Alarm Window<br />

Indicates an alarm, if occurred.<br />

Process value (PV)<br />

Set value (SV)<br />

Control manipulating value (MV)<br />

Chameleon key<br />

Digital indication<br />

Process value (PV)<br />

Set value (SV)<br />

Bar graph indication<br />

Control manipulating value (MV)<br />

Chameleon change key<br />

Chameleon key<br />

Performs an engineering operation.<br />

Operation keys<br />

For example mode is changed, set value is input<br />

or manipulating value is changed.<br />

Fault lamp<br />

SV up key<br />

SV down key<br />

Cascade mode key<br />

Auto mode key<br />

Manual mode key<br />

MV up key<br />

MV first key<br />

MV down key<br />

Menu key<br />

Versatile graphic indication<br />

There are 3 main menu screens<br />

from which all programming<br />

parameters and process<br />

displays can be selected. At any<br />

time during the selection<br />

process, the user can return to<br />

the main menu screen by<br />

pressing the "Menu" key.<br />

Menu screen 1/3<br />

can select any of<br />

8 different<br />

monitoring/operation<br />

screens.<br />

Menu screen 2/3<br />

can mainly select<br />

any of 8 different<br />

parameter setting<br />

screens.<br />

Menu screen 3/3<br />

can select any of<br />

5 different<br />

screens related to<br />

system definition.<br />

Password function provided for avoiding arong setting<br />

Monitoring screen for 8<br />

control loops<br />

Monitoring screen for 4<br />

control loops<br />

PID tuning screen<br />

Trend screen<br />

Monitoring<br />

screens for 1 or 2<br />

control loops.<br />

Parameter setting screen, segmented<br />

line table setting screen, alarm setting<br />

screen, etc.<br />

WAFER connection screen, system<br />

definition screen, function definition<br />

screen, communication setting<br />

screen, etc.<br />

Support screens which further details the supervision of process statuses<br />

Alarm logging screen<br />

: Records alarm ON/OFF times, alarm kinds and Tag No.<br />

Alarm status screen<br />

: Indicates currently occurred alarm.<br />

Input/output indication screen : A screen capable of monitoring all input/output data is provided.<br />

AI, AO, DI & DO monitoring<br />

Communication data<br />

Wafer input/output monitoring screen : Monitors all internal computation data.<br />

Analog data, ON-OFF data<br />

Indication loop setting screen : Can indicate arbitrary analog data as a loop.

Configuration<br />

Programming loader<br />

The CC-M can be programmed from the front display or<br />

by using Fuji's Windows-based configuration software.<br />

Using this software, the configuration file is downloaded<br />

via an RS-232 tranmission cable.<br />

Soft logic configurator<br />

Using the PLC control language conforming to IEC<br />

61131-3, a program is created on a PC. A program<br />

corresponding to 2 k steps of ladder can be created.<br />

Ladder diagram, sequential function chart, function<br />

block diagram can be handled.<br />

Configuration is also available through graphic display unit and keys.<br />

WAFER connection<br />

The CC-M software is configured by using function blocks called "WAFERS."<br />

The CC-M control and computation functions can be programmed by selecting among the 100 types of available<br />

WAFERS. Each WAFER contains I/O address locations which are used to link the WAFERS.<br />

For example, an input for a first-order PID computation is available from the screen using WAFER Nos. 21, 22<br />

and 23.<br />

W01 21<br />

0000 xxxxxx<br />

0000 xxxx<br />

0000<br />

0a00<br />

0a01<br />

0a02<br />

0a03<br />

W02 22<br />

0a00<br />

0a02<br />

0a02<br />

xxxxxx<br />

xxxx<br />

0a04<br />

0a05<br />

0a06<br />

0a07<br />

W03 23<br />

0a04<br />

0000<br />

0000<br />

xxxxxx<br />

xxxx<br />

0a08<br />

0a09<br />

0a0a<br />

0a0b<br />

W04<br />

0000<br />

0000<br />

0000<br />

0a0c<br />

0a0d<br />

0a0e<br />

0a0f<br />

W05<br />

0000<br />

0000<br />

0000<br />

0a10<br />

0a11<br />

0a12<br />

0a13<br />

W06<br />

0000<br />

0000<br />

0000<br />

0a14<br />

0a15<br />

0a16<br />

0a17<br />

W07<br />

0000<br />

0000<br />

0000<br />

0a18<br />

0a19<br />

0a1a<br />

0a1b<br />

W05<br />

0000<br />

0000<br />

0000<br />

0a10<br />

0a11<br />

0a12<br />

0a13<br />

PC-based control system<br />

Used together, the CC-M <strong>Controller</strong> and the<br />

Windows NT-based software package can offer a<br />

high-performance control and monitoring system.<br />

This software can connect a maximum of 8 CC-<br />

M's via an RS-485 communications (Modbus<br />

protocol) network. Because additional I/O devices<br />

can be connected to each CC-M via low-level RS-<br />

485 communications, a small-scale PC-based<br />

control system can be configured economically.<br />

CC-M<br />

OPTO22<br />

(software package)<br />

DOS/V machine<br />

O/S:Windows-NT<br />

Mainframe<br />

input/<br />

output<br />

Converter<br />

Plant screen<br />

Group screen<br />

Loop screen<br />

Trend screen<br />

Alarm summary screen<br />

RS-485(Modbus)<br />

Extended<br />

input/output

Specification<br />

Type PDA Specification<br />

Control and Computation Number of loops and PID 1 loop (1 control output/ 2PID)<br />

Functions<br />

2 loop (2 control output/ 4PID)<br />

4 loop (4 control output/ 8PID)<br />

Programming method WAFER connection method / Soft Logic method<br />

Program capacity<br />

48 WAFER x 4 loops (max. 192 WAFERS / max. 2k steps)<br />

Kind of WAFER<br />

about 100 kinds<br />

Computation cycle<br />

200 ms for 4 loop (8PID) control of simplicity PID<br />

Operation mode<br />

Cascade-Auto-Manual<br />

Analog Input signal Number of inputs : 8 *(7 input )<br />

Input signal type : DC voltage, Thermo couple, Resistance bulb.<br />

[Note] Two thermo couple or two resistance bulb inputs are selectable.<br />

Shunt resistor need to be connected to the analog input terminal.<br />

(250 shunt resistor is optional item)<br />

Output signal<br />

Control output: Selectable among 1, 2 and 4 outputs (DC4-20mA)<br />

Auxiliary output: 4 output (DC 0-5V, DC 1-5V, DC 0-10V)<br />

Digital Input signal 10 point (ON /0V, OFF /24V)<br />

Output signal<br />

11 output (Transistor open collector)<br />

Display<br />

Color graphic LCD with back light<br />

Power supply<br />

AC 100V (-15%)240V (+10%) 50/60Hz, DC24V(DC20V30V)<br />

Backup Function (Option) Built-in<br />

Number of control outputs: 1, 2 or 4 output selectable. (DC4-20mA)<br />

Communications (Option) RS-485 (Modbus protocol, OPTO22 interface)<br />

Memory Card Interface (Option) <strong>Compact</strong> Flash<br />

Capacity 4,20 and 30MB<br />

Configuration Software (Option) Programming loader and Soft logic configurator. (Windows 95)<br />

Soft logic Function (Option) Based on IEC61131-3 standard languages.<br />

*(5 output)<br />

*Screw terminal type.<br />

DimensionUnit:mm<br />

144<br />

72 21.6 280<br />

272 (Screw terminal type)<br />

Mass : 1.9kg<br />

Caution on Safety<br />

Before using this products, be sure to read its instruction manual in advice.<br />

[NOTE] Windows 95/NT is the registered trade mark of Microsoft Corporation.<br />

[NOTE] Modbus is the registered trade mark of Gould Modicon.<br />

[NOTE] <strong>Compact</strong> Flash is the registered trade mark of Sandisk corporation.<br />

[NOTE] OPTO22 interface is the registered trade mark of OPTO22.<br />

Head Office<br />

Gate City Ohsaki, East Tower,<br />

11-2, Osaki 1-chome, Shinagawa-ku, Tokyo 141-0032, Japan<br />

http://www.fesys.co.jp/eng<br />

Instrumentation Div.<br />

International Sales Dept.<br />

No.1 , Fuji-machi, Hino-city, Tokyo,191-8502 Japan<br />

Phone : 81-42-585-6201,6202<br />

Fax : 81-42-585-6187<br />

http://www.fic-net.jp/eng<br />

Information in this catalog is subject to change without notice.<br />

Printed in Japan 2005-7/5FIS