LABELEXPO EUROPE BREAKS RECORDS

Download as PDF - Labels & Labeling

Download as PDF - Labels & Labeling

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

LABELS&LABELING |47<br />

The changing world<br />

of label printing<br />

FINAT has commissioned Mike Fairley to look at how label printing technology has evolved over the centuries<br />

and to consider some of the investment decisions facing converters today<br />

It’s now more than 400 years since the first recorded printed<br />

labels were being produced. At that time they would have been<br />

printed on hand-made paper using relief letterpress type or<br />

images cut into wood or metal, with impression pressure applied<br />

through a wooden hand press and simple screw mechanism.<br />

THE ‘PRE’ HISTORY OF LABELS<br />

It was a further 200 years before much began to change. Yes,<br />

the hand presses were now being made of iron with a lever<br />

system to apply pressure, but the paper was still made by hand.<br />

However, by the early 19th century the industrial revolution was<br />

bringing significant changes to the world of printing – the first<br />

cylinder printing presses (powered by steam), the offset printing<br />

process, continuous papermaking machines.<br />

The 1800s also brought coated paper, the halftone process,<br />

color printing – and a whole host of new label market application<br />

requirements that were to see the early beginnings of what we<br />

now call the label industry. These new 19th century applications<br />

included automatic volume production of standard-sized glass<br />

bottles and bottle filling lines, the first canning factories, the<br />

rapid growth of pharmacy products, labels on boxes, labels on<br />

luggage, labels on cigar boxes and bands, matchbox labels and<br />

all at this time now being printed on sheetfed offset or letterpress<br />

presses.<br />

The first part of the 20th century saw the introduction of the<br />

first narrow web presses for printing gummed and self-adhesive<br />

tape. The key innovations for the narrow web printer were<br />

developments by Stan Avery that enabled self-adhesive materials<br />

to have a backing carrier and be cut to shape on the press.<br />

It was die-cutting materials on a liner that now enables sticky<br />

labels to be produced on a roll. It was not long before press<br />

manufacturers such as Gallus, Nilpeter and Mark Andy were<br />

producing the early dedicated roll-label letterpress and flexo<br />

presses.<br />

At this time barcoded labels for labeling fresh produce in store<br />

and at pre-packers was being undertaken with heat-sensitive<br />

labelstocks. It was not until the 1980s that thermal direct and<br />

then thermal transfer printing of barcoded price-weigh labels<br />

using self-adhesive materials began to take place and grow<br />

rapidly by the later part of the decade.<br />

At about the same time the use of new types of polypropylene<br />

and polystyrene (later polyethylene) film materials for more<br />

demanding label applications were being introduced. High<br />

quality printing of filmic materials used for labeling shampoos,<br />

toiletries, industrial products, etc, were now required by the<br />

leading brand owners. This presented more demanding label<br />

printing and converting challenges for press manufacturers and<br />

converters.<br />

THREE DECADES OF EVOLUTIONARY CHANGES<br />

IN LABEL PRINTING TECHNOLOGY<br />

To meet changing label printing requirements over the past<br />

30 years the dominant label printing technology of the time<br />

has undergone several changes: In the 1980s it was rotary<br />

letterpress that dominated new press sales. Then came growth<br />

in the flexo process during the 1990s. Much of the early<br />

part of the 21st century has seen UV flexo as the dominant<br />

LATE 20TH CENTURY: EMERGENCE<br />

OF SELF-ADHESIVE IN <strong>EUROPE</strong><br />

Later came narrow web screen, hotfoil and combination process<br />

presses, UV-curing inks and more advanced platemaking<br />

technology. By the late 1970s self-adhesive labels had already<br />

attained a seven percent share of the European label market<br />

– with all printing processes being used. Today, self-adhesive<br />

labels make up around 40 percent of label usage, fuelled by a<br />

whole host of technology and press innovations over the last<br />

30 years that have enabled labels to be printed faster, on wider<br />

webs, using rotary and wrap-around tooling, servo-drive presses,<br />

and press controls that include web inspection, register control,<br />

color management, and much more.<br />

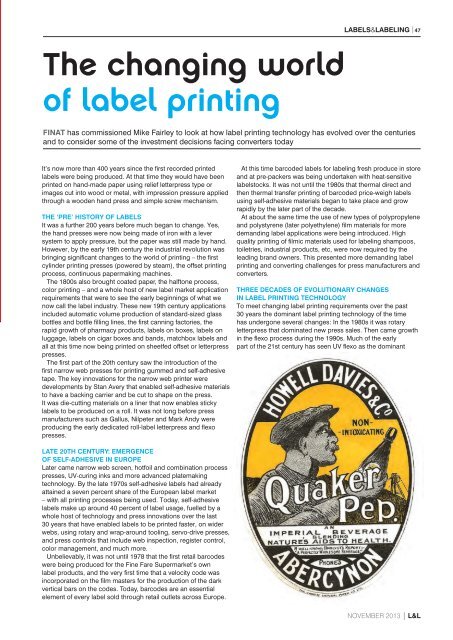

Unbelievably, it was not until 1978 that the first retail barcodes<br />

were being produced for the Fine Fare Supermarket’s own<br />

label products, and the very first time that a velocity code was<br />

incorporated on the film masters for the production of the dark<br />

vertical bars on the codes. Today, barcodes are an essential<br />

element of every label sold through retail outlets across Europe.<br />

NOVEMBER 2013 | L&L