Barbecue Secrets

Barbecue Secrets - Canadian Meat Business

Barbecue Secrets - Canadian Meat Business

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

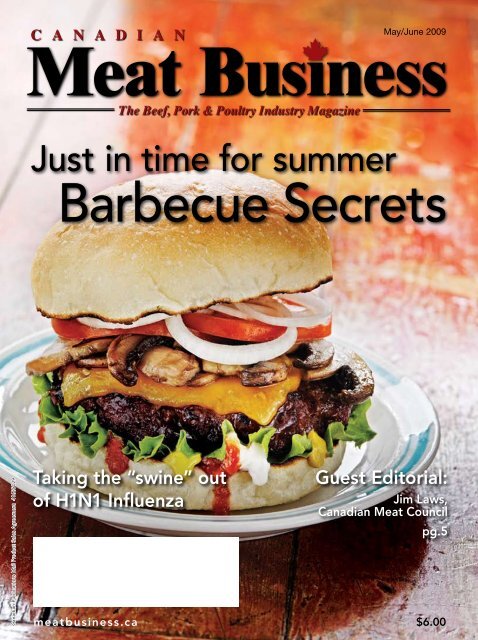

May/June 2009<br />

Just in time for summer<br />

<strong>Barbecue</strong> <strong>Secrets</strong><br />

Canadian Publications Mail Product Sales Agreement 41689029<br />

Taking the “swine” out<br />

of H1N1 Influenza<br />

Guest Editorial:<br />

Jim Laws,<br />

Canadian Meat Council<br />

pg.5<br />

meatbusiness.ca $6.00

Volume 8, Number 3 May/June 2009<br />

5 Guest Editorial<br />

by Jim Laws<br />

6 Rockin’ in the BBQ World: Rockin’ Ronnie’s <strong>Barbecue</strong> <strong>Secrets</strong><br />

by Alan MacKenzie<br />

6<br />

8 Canadian Cattle’s Roll in Caring for a Sustainable Earth<br />

10 Canadian Meat Council Annual Conference / PACKEX<br />

Toronto 2009<br />

12 Taking the “Swine” Out of H1N1 Influenza<br />

by Alan MacKenzie<br />

14 Assembly Line<br />

16 The Five Steps to Good Governance<br />

by Wayne Gelb<br />

18 Cross Country News<br />

20 The Kitchen is Open<br />

by David Rizzo<br />

23 Events Calendar<br />

24 Industry Roundup<br />

26 Be a Fly on the Wall in Your Own Facility<br />

by Bill Melville<br />

12<br />

30 Meat Industry Business Watch<br />

by James Sbrolla<br />

20<br />

10<br />

meatbusiness.ca<br />

May/June 2009 Canadian Meat Business

| Guest Editorial |<br />

May/June 2009 Volume 8 Number 3<br />

PUBLISHER<br />

Ray Blumenfeld<br />

ray@meatbusiness.ca<br />

The need for a Canada-U.S.<br />

food safety authority<br />

EXECUTIVE EDITOR<br />

Alan MacKenzie<br />

alan@meatbusiness.ca<br />

CONTRIBUTING WRITERS<br />

Jim Laws, Wayne Gelb, David Rizzo,<br />

Bill Melville, James Sbrolla<br />

CREATIVE DIRECTOR<br />

Krista Kline<br />

FINANCE<br />

Jerry Butler<br />

Canadian Meat Business is published<br />

six times a year by We Communications West Inc.<br />

COMMUNICATIONS WEST INC.<br />

We Communications West Inc.<br />

7-1080 Waverley Street<br />

Winnipeg, MB, Canada R3T 5S4<br />

Phone: 204.985.9502 Fax: 204.582.9800<br />

Toll Free: 1.800.344.7055<br />

E-mail: publishing@meatbusiness.ca<br />

Website: www.meatbusiness.ca<br />

Canadian Meat Business subscriptions are<br />

available for $28.00/year or $46.00/two years<br />

and includes the annual Buyers Guide issue.<br />

©2009 We Communications West Inc.<br />

All rights reserved.<br />

The contents of this publication may not be<br />

reproduced by any means in whole or in part,<br />

without prior written consent from the publisher.<br />

Printed in Canada.<br />

ISSN 1715-6726<br />

Cover photo: John Sinal<br />

T<br />

he Canadian Meat Council<br />

is now entering its 90th year<br />

of representing Canada’s<br />

federally inspected meat processors.<br />

And we’ve just returned from our 89th<br />

annual conference – this year held in<br />

Montreal. Just like last year, we reported<br />

that our Canadian meat processing<br />

industry is facing incredible challenges.<br />

But, this time, the challenges have all<br />

changed.<br />

What a difference a<br />

year makes<br />

Last year, a strong Canadian dollar,<br />

record high oil and feed grain prices<br />

and labour shortages were cutting<br />

into profitability. This year the recent<br />

H1N1 flu virus that has traumatized<br />

our pork sector, the U.S. mandatory<br />

country of origin labelling, new<br />

listeria control measures and the<br />

independent investigation along with<br />

the Subcommittee on Food Safety at<br />

the House of Commons are all top<br />

of mind.<br />

You will all recall the incredible<br />

political events of last year. Prime<br />

Minister Stephen Harper called for<br />

an independent investigation into the<br />

listeriosis event. A general election<br />

was then called and government<br />

officials went silent – including those<br />

from the CFIA and from the Public<br />

Health Agency of Canada. Once<br />

again, Canada elected a Conservative<br />

minority government. With calls for<br />

a full-blown public inquiry, and other<br />

political issues threatening to topple<br />

the government, our prime minister<br />

sought and received a rarely used<br />

prorogation of parliament granted by<br />

our Queen’s representative in Canada<br />

– Governor General Michaelle Jean.<br />

A gruelling and lengthy election<br />

campaign south of the border and a<br />

historic inauguration on Jan. 20, 2009,<br />

gave the U.S. its first African-American<br />

president. Since then President Obama<br />

has set his country on an ambitious<br />

plan with many large plans for reform.<br />

Canada’s prime minister, saddled with<br />

a minority government and a recession,<br />

seems to have no grand plans such as a<br />

new national high-speed railway system<br />

or a national electric power grid.<br />

Let’s offer them something big. Let’s<br />

tell them that we really believe that with<br />

these challenging economic times, we<br />

need to work more closely together.<br />

Let’s do what the many countries of<br />

Europe have done – agree on a common<br />

food safety system. Surely, if they can<br />

do it, we can do it. We’ve already seen<br />

how the misfortunes of one company<br />

in Canada on listeria control affect<br />

the entire industry, and now lately the<br />

new H1N1 virus in Mexico affected<br />

our entire North American industry.<br />

We’ve seen what happens in Canada<br />

when salmonella is traced to a peanut<br />

processor in the United States.<br />

Food safety systems<br />

With the new Obama administration<br />

now just past its 100 days, and Chrysler<br />

and GM seemingly put on life support<br />

by both the U.S. and Canadian<br />

governments, both our countries are<br />

turning their attention to their food<br />

safety systems.<br />

The Europeans have addressed<br />

their challenges with the creation of a<br />

European Food Safety Authority and<br />

their common economic union that<br />

allows for the freedom of exchange of<br />

goods and people travel without the<br />

need for border inspection between<br />

each country.<br />

Already, the North American Free<br />

Trade Agreement has helped to triple<br />

trade since 1993 among our three<br />

countries to a projected $1 trillion in<br />

2008. We can do a lot better.<br />

Our differences should be set aside<br />

and the strengths of our industry built<br />

on to compete in an ever competitive<br />

world. With the U.S. always ahead of us<br />

on access to new antimicrobial agents<br />

and interventions, and out-competing<br />

us on more favourable meat inspection<br />

fees and specified risk material<br />

regulations, it’s time we push for a new<br />

deal that sets common food safety rules<br />

for both of our countries.<br />

Jim Laws is the executive director of the<br />

Canadian Meat Council.<br />

meatbusiness.ca<br />

May/June 2009 Canadian Meat Business

Photo: John Sinal<br />

Photo: Whitecap Books<br />

Rockin’ in the BBQ World<br />

Vancouver’s Rockin’ Ronnie shares his <strong>Barbecue</strong> <strong>Secrets</strong> in an<br />

all-encompassing new cookbook.<br />

By Alan MacKenzie<br />

North Vancouver-based Rockin’<br />

Ronnie Shewchuck is so<br />

obsessed with outdoor cooking<br />

that he calls himself a “barbecue<br />

evangelist” – and his new cookbook may<br />

just be “the bible” for barbecue fans<br />

everywhere.<br />

Published by Vancouver-based<br />

cookbook specialists Whitecap Books,<br />

<strong>Barbecue</strong> <strong>Secrets</strong> Deluxe! is Shewchuck’s third<br />

book, a combination of his first two titles<br />

– <strong>Barbecue</strong> <strong>Secrets</strong> and Planking <strong>Secrets</strong> – that<br />

brings together the best of both with new<br />

photos, information and recipes. With<br />

over 200 recipes in total, charts, diagrams<br />

and entertaining extras, the book is sure<br />

to be a hit with everyone from the average<br />

backyard griller to the up-and-coming<br />

professional.<br />

With passion Shewchuck details the<br />

difference between grilling (what we do<br />

with our propane or charcoal grills at<br />

home) and the slow-cooking tradition<br />

Canadian Meat Business May/June 2009<br />

of southern-style barbecue – complete<br />

with diagrams of how to perform both<br />

methods properly. He also shows that<br />

plank-cooking can be used for much more<br />

than just salmon.<br />

But <strong>Barbecue</strong> <strong>Secrets</strong> Deluxe! is more<br />

than just a cookbook – it’s a celebration<br />

of barbecue as a lifestyle. It’s an allencompassing<br />

guide, that goes beyond<br />

recipes and tells readers what beverages<br />

and music will go best with their barbecue<br />

– not surprisingly beer and wine and<br />

country and classic rock top the lists, but<br />

Shewchuck gets much more specific with<br />

drink recipes and sample playlists.<br />

Shewchuck – a communications<br />

professional by day – has been barbecuing<br />

competitively for about 15 years and his<br />

team – Rockin’ Ronnie’s Butt Shredders<br />

– has won numerous awards on the<br />

championship barbecue circuit. The<br />

group won the 2004 Canadian National<br />

<strong>Barbecue</strong> Championships and is a twotime<br />

Alberta champion. The team has<br />

also competed in the American Royal<br />

Invitational in Kansas City (the “World<br />

Series of <strong>Barbecue</strong>”), as well as the Jack<br />

Daniel’s Invitational World <strong>Barbecue</strong><br />

Championship in Lynchburg, Tennessee<br />

– considered to be the most prestigious<br />

barbecue contest in the world. According<br />

to Whitecap Books, the Butt Shredders<br />

made barbecue history in 2001 when they<br />

became the only Canadian team ever to<br />

win a U.S.-based barbecue competition<br />

in a stunning upset at the Oregon State<br />

Open <strong>Barbecue</strong> Championship.<br />

Today Shewchuck not only competes,<br />

but also teaches cooking classes, writes<br />

articles for food publications and hosts a<br />

barbecue podcast.<br />

Born in Edmonton, Shewchuck grew<br />

up watching TV chef legend Graham<br />

Kerr, the Galloping Gourmet, on CBC TV.<br />

“I think I learned the spirit of really, truly<br />

enjoying food from him.”<br />

meatbusiness.ca

“I was brought up in a very meat and<br />

potatoes culture,” he adds. “I come from<br />

a Ukrainian family where we ate the three<br />

pork groups – bacon, ham and sausage.<br />

And I was always the guy as a teenager that<br />

whenever there was a backyard barbecue,<br />

I’d be the one who brought the threeinch<br />

thick porterhouse steak and have it<br />

all marinated beforehand – and I’d insist<br />

on grilling everyone else’s meat for them.<br />

I just always loved it.”<br />

Shewchuck adds that he is delighted<br />

by changes he is seeing in the Canadian<br />

meat industry that make it easier for him<br />

to use locally grown meat in competition,<br />

noting that better quality meat has been<br />

coming on the market in the last four or<br />

five years.<br />

“I think the cholesterol fascists have<br />

finally been at least displaced by people<br />

who like meat with really excellent flavour,”<br />

he says. “I try to (use locally grown meat)<br />

whenever possible. I’m starting to see<br />

changes that I like. When I first started to<br />

compete, I would look for pork and beef<br />

that was raised in the U.S., just because it<br />

had a higher fat content and was tastier and<br />

would stand up to the long, slow cooking<br />

of barbecue. Now I try to eat locally – I<br />

certainly look for Alberta beef, I try to buy<br />

local pork here in B.C.”<br />

Classic Dadburger Deluxe Recipe<br />

Makes<br />

12–16 patties,<br />

depending on<br />

how big you<br />

like them.<br />

Burger patties<br />

• 6 lb | 2.7 kg ground beef (or combine<br />

equal amounts of ground beef and<br />

ground pork)<br />

• 1 medium onion, finely chopped<br />

• 1 head roasted garlic, cloves squeezed<br />

out and mashed with a fork<br />

• 1 Tbsp | 15 mL toasted sesame oil<br />

• 2 Tbsp | 25 mL dark soy<br />

sauce, Worcestershire sauce or<br />

a combination<br />

• 1/2 tsp | 2 mL freshly grated nutmeg<br />

• 1/4 tsp | 1 mL cayenne (or more, if<br />

you like more heat)<br />

• lots of freshly ground black pepper<br />

• 2 eggs<br />

• 1/2 cup | 125 mL cold water<br />

Fixin’s<br />

• barbecue sauce<br />

• 12–16 cheese slices (optional)<br />

• 12–16 hamburger buns<br />

Line a baking sheet with waxed paper.<br />

Gently combine the burger ingredients<br />

in a large bowl with your hands, taking<br />

care not to overwork the meat. Wet<br />

your hands in cold water before you<br />

form the mixture into chunks the size<br />

of tennis balls. Flatten them into patties,<br />

placing them on the baking sheet. Each<br />

patty will be about 1/2 lb (250 g) before<br />

cooking. Place them in the freezer for<br />

one hour to firm them up.<br />

Preheat your grill for medium direct<br />

heat. Take the burgers out of the<br />

freezer and grill them for six minutes<br />

per side, or until they are springy to the<br />

touch, glazing them on both sides with<br />

barbecue sauce. Top each patty with<br />

a slice of cheese for the last couple of<br />

minutes of cooking. Serve the burgers<br />

on buns with your favorite condiments.<br />

- excerpted from Rockin’ Ronnie Shewchuck’s<br />

<strong>Barbecue</strong> <strong>Secrets</strong> Deluxe!<br />

meatbusiness.ca<br />

May/June 2009 Canadian Meat Business

Part of the<br />

Environmental Solution<br />

Canadian cattle’s role in caring for a sustainable Earth.<br />

W<br />

hen it comes to the<br />

environment, according to<br />

cattle producers – Canadian<br />

cattle have a bum rap. Contrary to<br />

reports, Canadian livestock make only<br />

a minor contribution to Canada’s<br />

greenhouse gas (GHG) emissions<br />

and energy use. Actually, cattle<br />

play an essential role in sustainable<br />

agriculture.<br />

Canadian cattle utilize natural<br />

resources very efficiently and cattle<br />

producers continuously look for<br />

ways to increase that efficiency. Good<br />

management of Canada’s approximate<br />

21 million hectares of pastureland is<br />

one of those ways. Not only do pastures<br />

support food production, but they<br />

provide wildlife habitat and serve an<br />

important role in GHG reductions. In<br />

some cases, pastureland stores carbon<br />

more efficiently than trees.<br />

Pastures can exist where our food<br />

crops can’t – on land that is too steep or<br />

cold or inaccessible to farm machinery.<br />

Pasture grasses play a significant role<br />

in feeding us. In Canada, since nearly<br />

one third of Canada’s agricultural<br />

land is unsuitable for crop production,<br />

utilizing it as pasture to raise cattle<br />

enables this land to still contribute to<br />

food production.<br />

More environmentally friendly<br />

than most other forms of producing<br />

food, properly managed cattle pasture<br />

lands control erosion and enrich the<br />

soil. Planted grasses are often used<br />

to rehabilitate soils where crops have<br />

grown. It is precisely because of these<br />

Better management<br />

practices have lowered<br />

the number of cattle<br />

required to produce<br />

the high-quality protein<br />

consumers require.<br />

benefits and more that cattle play<br />

such a pivotal role in our food supply.<br />

Without cattle those lands would not<br />

contribute to our food supply.<br />

For nearly 20 years, producers<br />

have worked hard to reduce the<br />

environmental footprint of Canadian<br />

agriculture by implementing best<br />

management practices to improve<br />

efficiency and reduce environmental<br />

impact. These practices include<br />

improving the diets of farm animals,<br />

selectively breeding for animals that<br />

use their diets more efficiently and<br />

improving animal health – all factors<br />

that contribute to the reduction of<br />

GHG emissions. Better management<br />

practices have lowered the number<br />

of cattle required to produce the<br />

high-quality protein consumers<br />

require. In addition, as stewards of<br />

the land, many producers adopt<br />

environmental farm plans tailored to<br />

their specific operations to enhance<br />

the environmental sustainability of<br />

their operations.<br />

Meanwhile the investments made<br />

in new technologies and agricultural<br />

research will certainly yield an even<br />

more sustainable future with cattle.<br />

They play a significant part in the<br />

burgeoning biogas industry; making<br />

it possible to turn manure, already<br />

a valuable soil amendment, into a<br />

renewable source of energy.<br />

When it comes to environmentally<br />

sustainable food production, let’s<br />

Canadian Meat Business May/June 2009<br />

meatbusiness.ca

eflect on the contributions the lowly<br />

Canadian cow makes to the environment<br />

and feeding the world.<br />

Canada’s beef and cattle producers<br />

make a valuable contribution to Canada’s<br />

economy and environment. Their good<br />

management practices maintain wildlife<br />

habitat and contribute to reducing<br />

GHG. They are committed to ensuring<br />

their practices prove beneficial to the<br />

environment, their animals and operations,<br />

plus the consumer.<br />

Sustaining Canada’s<br />

agricultural land<br />

• Canada’s cattle producers manage<br />

167 million acres of native grasses for<br />

livestock and wildlife – comprising<br />

about a quarter of Canada’s total<br />

agricultural land.<br />

• These native and tame grasses play an<br />

important role in sequestering carbon<br />

in the soil, filtering water, providing<br />

habitat for wildlife and birds and<br />

providing high-quality feed for cattle.<br />

• Producers annually convert additional<br />

cultivated crop land to tame grasses.<br />

Building and maintaining<br />

native grasses<br />

• Native grasses make a significant<br />

contribution to feeding practices that<br />

reduce methane output from cattle.<br />

• Science has proved that moving cattle<br />

from pasture-to-pasture, maintains<br />

the healthy, lush green grasses which<br />

provide easy-to-digest feed for cattle.<br />

• An easy-to-digest cattle feed promotes<br />

good weight gain and reduces methane<br />

production.<br />

• With more than 90 per cent of Canada’s<br />

beef cattle production pasture-based,<br />

the added bonus to these planned<br />

grazing practices is the flourishing<br />

wildlife habitat it creates.<br />

Eat meat and sustain the<br />

environment<br />

• Eating less meat will not save the<br />

environment. In fact, it may contribute<br />

to more demands on it.<br />

• Consuming less meat protein means<br />

that to maintain a healthy diet, people<br />

must consume more vegetablebased<br />

protein. Producing that requires<br />

the cultivation of more land, which<br />

increases use of fossil fuels and<br />

fertilizer application. Unfortunately<br />

valuable wildlife habitat is lost in the<br />

process.<br />

For more information visit the Canadian<br />

Cattlemen’s Association at cattle.ca.<br />

- Staff<br />

meatbusiness.ca<br />

May/June 2009 Canadian Meat Business

Canadian Meat Council Marks 90 Years at<br />

Annual Conference<br />

T<br />

he Canadian Meat Council<br />

(CMC) held its 89th Annual<br />

Conference on May 6 to 8 at<br />

the Fairmont Queen Elizabeth Hotel in<br />

Montreal. This year’s conference also<br />

marked the 90th anniversary of the<br />

Canadian Meat Council.<br />

The conference featured the<br />

popular Product Tasting Reception<br />

on Wednesday evening, with products<br />

from the Beef Information Centre, BSA<br />

Ingredients, Delft Blue Inc/Ecolait<br />

Ltee, FPBQ – Quebec grain-fed veal,<br />

Griffith Laboratories, Hermann Laue<br />

Spice Company, Kerry Ingredients &<br />

Flavours, Olymel and Viscofan Canada.<br />

Retail and foodservice guests were in<br />

attendance at this event.<br />

Throughout the day on Thursday,<br />

speakers addressed topics in the areas<br />

of sales and marketing, operations,<br />

and technical. Popular presentations<br />

included Current Perspective on<br />

Listeria Control by Dr. Randy Huffman<br />

of Maple Leaf Foods, and Supply Chain<br />

Alliance, by Jeff Kroll of MacDonald’s<br />

Restaurants of Canada.<br />

The program on Friday included an<br />

Photo: Jim Laws<br />

analysis of the agri-food commodities<br />

by Irene Nattel from the Royal Bank<br />

of Canada; an overview of the industry<br />

by Patrick Boyle and Rod Brenneman,<br />

the president and chairman of the<br />

American Meat Institute; a parallel<br />

between history of the CMC and current<br />

issues by Jim Laws and Don Davidson,<br />

the council’s executive director and<br />

Product Tasting Reception, Beef Information Centre booth.<br />

president; and an update on Canadian<br />

Food Inspection Agency activities by<br />

Jean Lamoureux, executive director of<br />

Quebec operations.<br />

The 90th Annual Conference will be<br />

held at the Fairmont Empress Hotel in<br />

Victoria, B.C. from May 5 to 7, 2010.<br />

-staff<br />

PACKed in for ’09<br />

PACKEX Toronto 2009 confirms its status of a<br />

Canadian must attend event for all packaging and<br />

supply chain professionals.<br />

F<br />

rom May 5 to 7 Canadian Meat<br />

Business was in attendance<br />

at PACKEX Toronto 2009,<br />

Canada’s largest packaging, material<br />

handling and logistics show.<br />

The 34th edition of PACKEX<br />

Toronto was a huge success. In spite<br />

of difficult economic times, both<br />

exhibitors and visitors communicated<br />

positive feedback to organizers with<br />

comments focusing on the quality of<br />

PACKEX Toronto as an essential show<br />

for the Canadian industry.<br />

PACKEX Toronto welcomed over<br />

354 exhibitors from Canada, the United<br />

States, and overseas. This edition<br />

presented a wider selection of exhibits<br />

represented by 143 new companies.<br />

Furthermore, PACKEX Toronto was<br />

co-located for the first time ever with<br />

IPA Canada, the National Food Process<br />

Exhibition. These two co-located events<br />

provided technologies and solutions<br />

under one roof, from food production<br />

to its shipment.<br />

PACKEX Toronto 2009 welcomed<br />

7,034 attendees, showing a thriving 17<br />

per cent increase from the previous<br />

edition in 2007.<br />

- staff<br />

Paul Medeiros and Carol Zweep,<br />

Guelph Food Technology Centre<br />

Photo:s Alan MacKenzie<br />

10 Canadian Meat Business May/June 2009 meatbusiness.ca

CUSTOM SIZES!!! CUSTOM WEIGHT LOADS!!! CUSTOM DESIGNS!!!<br />

STAINLESS STEEL PROCESSING SCREENS<br />

All BEACON Screens are custom manufactured<br />

from T-304 Stainless Steel.<br />

Our Challenge, considering the increasing cost<br />

of stainless, is to design a screen to carry the<br />

maximum weight with the minimum amount<br />

of stainless. Our nearly 60 years of experience<br />

allow us to do just that.<br />

BEACON will engineer the exact Screen for your processing requirements!!!<br />

Jerky Screens<br />

V-Screens<br />

Heavy-Duty<br />

Screens<br />

Double-Frame<br />

Screens<br />

Rib Screens<br />

CALL US FOR A<br />

QUOTATION!!!<br />

BEACON also manufacturers stainless steel<br />

Trucks, Racks, Cages & Trees for all custom<br />

designed Screens, as well as designs for<br />

Smokesticks.<br />

BEACON, Inc. 12223 S. Laramie Ave, Alsip, IL 60803 (708) 544-9900 Fax (708) 544-9999<br />

www.beaconmetals.com

Photo: Agriculture and Agri-Food Canada<br />

Agriculture Minister Gerry Ritz shows support<br />

for the pork industry on Parliament Hill.<br />

Derrick Pobereznek<br />

What’s in<br />

a Name?<br />

Governments, WHO take the “swine”<br />

out of H1N1 Influenza.<br />

By Alan MacKenzie<br />

W<br />

hat difference does a name make? Millions of<br />

dollars worth of exports, if that name is “swine<br />

flu.”<br />

In late April a deadly virus with origins in Mexico that<br />

beganspreading to the United States and Canada made<br />

headlines worldwide under the name “swine flu” – even<br />

though the virus includes genetic components of human,<br />

avian and swine origin.<br />

In the days following the outbreak, countries began<br />

halting imports of North American pork because of the<br />

association with the name, despite the fact that the virus<br />

in not a foodborne illness. Ukraine – which imported $11<br />

million worth of Canadian pork last year – banned pork<br />

from Canada and several others were reportedly considering<br />

it, including the Philippines – which imported $46 million<br />

worth of Canadian pork last year.<br />

Pork groups such as the Canadian Pork Council (CPC)<br />

and the Canadian Swine Health Board (CSHB) began<br />

pressuring the federal government to follow U.S. President<br />

Barack Obama’s lead to stop using the term. The Canadian<br />

government agreed and the virus became known as H1N1<br />

influenza – however mainstream media did not follow<br />

suit, and many pork industry officials are concerned<br />

that consumers and importers will continue to make the<br />

association between the illness and pork products.<br />

“The impact will be lessened, but it will not be back to what<br />

it was,” Jacques Pomerleau, executive director of Canada<br />

Pork International, told Canadian Meat Business. “It’s a good<br />

first step, but I think the industry will have to work very hard<br />

in the next while just to rebuild that confidence.”<br />

The situation was heightened April 28 when an Alberta<br />

farmer voluntarily reported influenza-like symptoms in his<br />

herd, resulting in a quarantine and the cull of approximately<br />

500 animals on his farm. According to the CPC the cull was<br />

made on Arnold Van Ginkel’s farm to alleviate overcrowding<br />

brought on by the quarantine.<br />

The CPC said Van Ginkel is owed a debt of gratitude by<br />

the Canadian pork industry for putting the health of the<br />

industry ahead of that of his own farm. “In addition to<br />

Arnold Van Ginkel, we would like to thank Alberta Pork,<br />

Alberta Agriculture and the Canadian Food Inspection<br />

Agency for their quick and efficient handling of the<br />

impending overcrowding issue on the farm,” CPC chair<br />

Jurgen Preugschas said in a release. “Thanks are also due<br />

to Van Ginkel's neighbours and industry partners for their<br />

ongoing support of the Van Ginkel family and for respecting<br />

and protecting the privacy of the family until they were ready<br />

to be publicly identified.”<br />

Agriculture Minister Gerry Ritz stated that the<br />

government will continue to reassure Canadian consumers<br />

12 Canadian Meat Business May/June 2009 meatbusiness.ca

and international trading partners that<br />

Canadian pork is safe.<br />

“The international scientific community,<br />

including the OIE (World Organization<br />

For Animal Health) and WHO (World<br />

Health Organization), agree that H1N1<br />

Influenza A is not a food safety issue,” he<br />

said in a release. Ritz added that Canadian<br />

consumers should show support by buying<br />

more pork.<br />

Review and strengthen<br />

biosecurity<br />

CPC and CSHB have urged hog<br />

producers to review and strengthen their<br />

existing biosecurity practices:<br />

• Visitor traffic to pig barns should be<br />

minimized to essential services only,<br />

and persons recently returning from<br />

affected regions should have no contact<br />

with pigs for at least seven days.<br />

• Barn entry requirements should be<br />

enhanced with a minimum of a change<br />

of clothes and boots and a thorough<br />

hand wash. If masks are available, they<br />

should be used, with a N95 respiratory<br />

mask and gloves being the preferred<br />

choice.<br />

• Insure ventilation systems are<br />

functioning and minimize recirculation<br />

of air inside animal housing<br />

facilities.<br />

• No workers suffering “flu” like illness<br />

should contact swine, workers should<br />

not return to swine facilities until<br />

seven days after having respiratory<br />

illness. The same should apply if a<br />

farm workers household has been<br />

diagnosed with influenza.<br />

• Influenza-like symptoms could include<br />

one or more of the following, fever,<br />

cough, body aches, and sometimes<br />

vomiting and diarrhea.<br />

• Any unusual respiratory disease in<br />

pig herds should be investigated by<br />

the herd veterinarian and diagnostic<br />

samples (lung tissues and nasal swabs)<br />

from acutely ill pigs with a fever should<br />

be sent to the regional veterinary<br />

diagnostic lab.<br />

• The decision to vaccinate swine herds<br />

with existing swine vaccines should be<br />

made with your herd veterinarian.<br />

For the health of workers in contact with<br />

swine, the groups recommended:<br />

• Report any unusual respiratory disease<br />

to your doctor.<br />

• Use masks and gloves are<br />

recommended and safety goggles<br />

when necessary.<br />

• Recommend that an annual flu<br />

vaccination be discussed with<br />

their doctor as part of their health<br />

management plan.<br />

meatbusiness.ca<br />

May/June 2009 Canadian Meat Business 13

| Assembly Line |<br />

Assembly Line is an opportunity for companies to feature new products for the meat<br />

producing, processing, packaging and distribution industry. To include information about your<br />

new product e-mail alan@meatbusiness.ca.<br />

Tamper Proof Greatness in NITA’s Newest<br />

Clamshell Labeller<br />

The new Shellshock clamshell<br />

labelling system from Montrealbased<br />

Nita Labeling Equipment is<br />

configurable to handle container<br />

sizes as small as four inches wide as a<br />

large as 15.5 inches in width.<br />

The labeller provides quality,<br />

accuracy, user friendliness, HMI<br />

(touch screen) operated, servomotor<br />

driven reliability. The over<br />

the top wipe-on labeller is specially adapted to plunge deeper<br />

through the conveyor for a consistent throughput and an<br />

exceptional accurate look to your clamshell container while<br />

offering a tamper-evident seal.<br />

The product feature stainless steel and anodized aluminium<br />

construction and no proprietary electronics.<br />

With only the clamshell and tray containers in mind, this<br />

device is aimed specifically at the baking, meats, poultry,<br />

produce and confectionary industries.<br />

nitalabelingequipment.com<br />

Protecting Your Products with Sodium<br />

Acetate and Diatcetate<br />

In December 2008 Health Canada issued an Interim<br />

Marketing Authority allowing sodium diacetate and sodium<br />

acetate to be used in meat and poultry products. Bombal<br />

(Fresh Amba) – available from Malabar Super Spice Co. Ltd.<br />

– is a special blend of these ingredients designed to slow the<br />

growth of microorganisms (including listeria monocytogenes,<br />

e.coli, bacilllus cereus and staphylococcus aureus).<br />

Bombal (Fresh Amba) is a fine powder that is easy to use,<br />

dissolves quickly, can be mixed at any stage of the process, and<br />

has a low usage rate of only 0.5 per cent calculated on the total<br />

weight.<br />

The blend is designed for both sausage emulsions and cured<br />

and injected meat and poultry products. There is no reaction<br />

with other spices or ingredients. It should be added after<br />

phosphates and salt. Sodium diacetate is a free flowing source<br />

of acetic acid (organic acid), most recognizable as a granular<br />

form of vinegar.<br />

Bombal (Fresh Amba) is available in 3 kg or 22 kg bags.<br />

malabarsuperspice.com<br />

Clarion Food Grade Lubricants Available in<br />

New Convenient Size<br />

Clarion Food Grade white oil lubricants are now available to<br />

food manufacturers in a convenient five-gallon pail.<br />

Representing the leading edge of purity and performance for<br />

more than 40 years, white mineral oil base products such as Clarion<br />

Food Grade, has given food manufacturers the opportunity to<br />

use lubricants that offer the same quality performance, or better,<br />

than traditional lubricants while helping to remove the risks of<br />

contamination or recall from operations.<br />

Clarion Food Grade white mineral oils are highly refined<br />

and stabilized so that they can be used for everything from food<br />

coatings to direct use in pharmaceutical products like suntan<br />

lotions and ointments.<br />

Clarion products meet the most stringent standards of<br />

purity and performance for food processing. White oils cannot<br />

be labelled as “food grade” unless the products pass special<br />

approval tests governed by the United States Food and Drug<br />

Administration (U.S. FDA). All Clarion Food Grade products are<br />

NSF H-1 registered for use in food processing plants under the<br />

jurisdiction of the U.S. FDA.<br />

A spokesperson for the company said applications have been<br />

submitted to Canadian Food Inspection Agency (CFIA) to<br />

register the Clarion Food Grade products in Canada.<br />

With a diverse product line, Clarion offers solutions to almost<br />

any food manufacturing need. Clarion food grade greases<br />

effectively lubricate most machinery used to manufacture,<br />

process, package and store food products. High-temperature,<br />

extreme pressure water-resistant food grade greases provide<br />

excellent rust protection and oxidation inhibition – ideal in<br />

applications where the greases may accidentally come into<br />

contact with food. Synthetic food grade oils allow extended<br />

drain intervals, in many cases, lowering the lubricant cost and<br />

reducing maintenance work. All Clarion Food Grade products<br />

are available in bulk, totes, drums or pails with the recent addition<br />

of the convenient five-gallon pail.<br />

clarionlubricants.com<br />

Food Safety is a Hands-On Issue<br />

Waterford, Ont.-based Deb<br />

Canada recently launched its Food<br />

Safety Hand Hygiene program in an<br />

e-learning format.<br />

The company says that foodborne<br />

illness is most often transmitted by<br />

food workers that fail to wash their<br />

hands effectively.<br />

The program, designed to help<br />

raise standards of food safety by<br />

reducing the risk of food being cross-contaminated as a result<br />

of poor hand hygiene, covers key topics including Centre of<br />

Disease Control statistics, communicable disease prevention<br />

and proper hand-washing techniques, according to marketing<br />

manager Patrick Boshell.<br />

The program, which is based on the Deb Skin Care System, is<br />

a combination of highly effective skin care products and support<br />

activities, designed to help food manufacturers implement and<br />

maintain effective hand hygiene. A preventative intervention,<br />

14 Canadian Meat Business May/June 2009 meatbusiness.ca

it consists of a six-step approach to skin care, which includes<br />

protection, cleansing, sanitizing, restoration, education and<br />

auditing.<br />

debcanada.com<br />

FKI Logistex Offers Sortation Equipment<br />

and System Audits<br />

FKI Logistex now offers a performance audit program<br />

for its sliding shoe, linear belt and pop-up wheel sortation<br />

equipment and systems, including the UniSort product line.<br />

The audit is designed to reveal cost-efficient ways to optimize<br />

system capacity and throughput, improve equipment<br />

utilization and extend system life.<br />

Performed by a certified FKI Logistex audit engineer, audits<br />

include a complete equipment inspection and review of<br />

operational and maintenance procedures. The comprehensive<br />

service also includes a detailed audit report containing<br />

equipment drawings, performance checklists and digital<br />

photographs for technical reference. Recommendations for<br />

maintenance, upgrades or modifications are accompanied<br />

by a complete list of recommended spare parts. The audit<br />

engineer will also provide schedules for recommended<br />

future audits and preventive maintenance.<br />

fkilogistex.com<br />

Petro-Canada Launches Environmentally<br />

Friendly Lubricant Line<br />

Petro-Canada has announced its new EcoSia brand, a<br />

suite of products that possess environmentally friendly<br />

characteristics. The product offering spans a diverse range<br />

of applications and customer segments including, but not<br />

limited to, lubricants and fluids for agriculture and general<br />

manufacturing.<br />

The EcoSia line-up includes products from many of Petro-<br />

Canada’s existing brands, including, but not limited to,<br />

ENVIRON hydraulic fluids, PUREDRILL drilling mud base<br />

fluids, CALFLO specialty heat transfer fluids, select PURITY<br />

FG food grade lubricants, PURETOL white oils, select<br />

COMPRO compressor fluids, and LUMINOL electrical<br />

insulating fluids.<br />

Petro-Canada blends and packages more than 350<br />

different lubricants, specialty fluids and greases that are<br />

exported to more than 60 countries on six continents.<br />

Majority of products are manufactured from 99.9 per cent<br />

pure base oils – among the purest in the world. As the world’s<br />

largest producer of white oils and the leading supplier of<br />

factory fill automatic transmission fluids, Petro-Canada is<br />

focused on going beyond today’s standards. With more<br />

than 30 years of experience in blending Groups II and III<br />

base oils, the company delivers a diverse line of innovative<br />

lubricants to meet an ever increasing range of international<br />

specifications.<br />

lubricants.petro-canada.ca/ecosia<br />

please visit us at: www.sperlingind.com<br />

“BOSS” equipment<br />

Industry providers to the food industry for over 100 years...<br />

• Focused on food safety with enhanced production reliability.<br />

• Specializing in engineering, fabrication, installations, Beef & Pork.<br />

• BOSS provides packers with reliable efficient equipment.<br />

Sperling<br />

Industries Ltd.<br />

51 Station St, (Box 100)<br />

Sperling, MB Canada R0G 2M0<br />

1-204-626-3401 or<br />

Fax 1-204-626-3252<br />

Also:<br />

Brandon, MB<br />

1-204-729-9190<br />

2420 Z Street, Omaha, NE 68107<br />

1-402-556-4070<br />

meatbusiness.ca<br />

May/June 2009 Canadian Meat Business 15

The Five Steps to<br />

Good Governance<br />

A company’s reputation with consumers and stakeholders is<br />

important to the bottom line.<br />

By Wayne Gelb, CA<br />

A<br />

s the population becomes<br />

increasingly sensitive to social<br />

accountability, a company’s<br />

reputation is as important to the bottom<br />

line as revenue growth. Managing your<br />

company’s reputation effectively begins<br />

with strong corporate governance.<br />

While every corporate governance<br />

strategy will have its own parameters,<br />

there are five fundamental steps that<br />

every organization should consider when<br />

putting a program in place.<br />

Step 1 – Understand stakeholders<br />

Until you truly define and understand<br />

your stakeholders, you cannot create a<br />

holistic governance program for your<br />

company. Traditionally, stakeholders are<br />

thought of as the owners, investors and<br />

the board of advisors, but you also need<br />

to consider and include management,<br />

employees, suppliers, customers, lenders<br />

and the community. For those in the meat<br />

processing industry, it is also important<br />

to consider the needs of the regulatory<br />

and health and safety bodies that govern<br />

your business.<br />

Step 2 - Identify key objectives<br />

This is essential to setting the expectations<br />

of your stakeholders and encouraging<br />

ethical decision making at all levels. Start<br />

by developing a long-term strategic plan<br />

that will satisfy all identified stakeholders.<br />

Build or revisit your company’s mission<br />

statement to ensure that it encompasses<br />

attributes such as honesty, trust, integrity,<br />

openness, accountability, responsibility,<br />

mutual respect and commitment to the<br />

organization. It is also important to make<br />

sure that growth remains a key element in<br />

defining your objectives.<br />

Step 3 – Define internal control and<br />

reporting requirements<br />

This step involves two elements. The<br />

first is to review financial reporting<br />

processes and the frequency of reporting.<br />

In this current economic climate, it is<br />

advisable to accelerate your cash flow<br />

forecasting to a quarterly, maybe even<br />

monthly, basis to accommodate rapidly<br />

changing assumptions and business<br />

conditions.<br />

The second element is to monitor your<br />

working capital carefully. This includes<br />

staying on top of your receivables and<br />

proactively identifying specific customer<br />

credit issues. Keep in mind that both your<br />

financial and operational processes need<br />

to be documented and communicated so<br />

that lenders and regulators can be sure<br />

you are taking the right steps to protect<br />

your finances, your products and the<br />

future of your operation.<br />

Step 4 – Ensure your team has the<br />

right tools and resources<br />

Ultimately a company needs to be<br />

prepared to make the necessary investment<br />

to ensure that the right tools are in<br />

place to meet the corporate governance<br />

objectives. If your management team does<br />

not have the adequate training, support<br />

and technology to run the business<br />

effectively, then the owners or board of<br />

advisors cannot hold them accountable.<br />

Consider surveying the management<br />

team to identify what resources will allow<br />

them to optimize their performance<br />

and encourage them to contribute their<br />

opinions to improve the success of the<br />

company. By doing so, you will not only<br />

gain loyalty, you will also enhance and<br />

strengthen the corporate culture.<br />

Step 5 – Enforce your policies<br />

Effective governance begins with a<br />

strong company culture. It is essential to<br />

communicate regularly and effectively<br />

so that you foster a culture where team<br />

members believe in and live the corporate<br />

values and responsibilities. That means<br />

setting clear expectations and guidelines<br />

for the team, rewarding achievements and<br />

behaviours that reinforce the company’s<br />

values, as well as celebrating company<br />

successes. However, effectively managing<br />

corporate culture also means dealing<br />

swiftly with behaviours that are not in<br />

congruence with the company’s values.<br />

It is important to remember that<br />

governance is an evolving process that<br />

demands a corporate wide effort.<br />

Wayne Gelb is a partner with Fuller Landau,<br />

Toronto-based, mid-market public accounting and<br />

business advisory firm. Wayne can be reached at 416-<br />

645-6546, or by email at wgelb@fullerlandau.com.<br />

16 Canadian Meat Business May/June 2009 meatbusiness.ca

| Cross Countr y News |<br />

Saskatchewan<br />

200 Laid Off at XL Foods Moose Jaw Plant<br />

XL Foods Inc. recently laid off all 200 staff at its Moose Jaw<br />

beef plant due to a shortage of cull and fed cattle supplies.<br />

According to the company, the shortage is “unusual” and<br />

expected to abate in the coming months. The company said<br />

the plant will remain closed until September.<br />

“We regret that we have had to take such extreme action<br />

but look forward to recalling the staff and recommencing<br />

operations on or before Sept. 28, 2009,” XL co-CEO Brian<br />

Nilsson said in a release.<br />

Manitoba<br />

Governments Launch Growing Forward<br />

Programs in Manitoba<br />

The federal government and Province of Manitoba have<br />

announced details of new agricultural programs for farmers in<br />

Manitoba under the Growing Forward framework.<br />

“Farmers expect all levels of government to work together to<br />

drive Canadian agriculture and this agreement is making that<br />

happen,” federal Agriculture Minister Gerry Ritz said in a release.<br />

“Growing Forward delivers stable and bankable programs that<br />

work for farmers. The agreement we signed today will kick-start<br />

the rollout of these essential programs in Manitoba.”<br />

“This combined support for Manitoba’s diverse agriculture<br />

industry will help advance timely programs and products<br />

that will expand agricultural business opportunities,” added<br />

Manitoba Agriculture, Food and Rural Initiatives Minister<br />

Rosann Wowchuk. “As new initiatives are created throughout the<br />

province, the ripple effect of the economic benefits will provide<br />

an even more positive growth factor in the future.”<br />

Growing Forward is a national agriculture framework to<br />

coordinate federal and provincial agriculture policy. Federal,<br />

provincial, and territorial governments are delivering $1.3<br />

billion for farm families over five years. Today’s agreement with<br />

Manitoba will deliver a total of $117.5 million from the federal<br />

and provincial governments for agriculture in this province.<br />

Growing Forward programs are tailored with the flexibility<br />

to meet Manitoba’s diverse regional requirements. The<br />

Government of Canada and Province of Manitoba have worked<br />

with farmers every step of the way to develop the Growing<br />

Forward framework.<br />

In Manitoba, the Growing Forward framework supports<br />

programs to encourage innovations such as new business<br />

initiatives and value-added products that will add to agriculturalbased<br />

value chains. Other programs include enhancements to<br />

food safety systems from the farm gate to the food plate and<br />

environmental protection planning.<br />

For a complete list of Growing Forward programs in Manitoba,<br />

visit gov.mb.ca/agriculture.<br />

Ontario<br />

Maple Leaf Foods to Wait for Sale of<br />

Burlington Business<br />

Maple Leaf Foods announced it will not continue a formal<br />

sale process for its Burlington, Ont. pork processing business<br />

until possibly early next year.<br />

“The current economic conditions and credit markets have<br />

created a less than ideal environment to sell any business,”<br />

Michael Vels, chief financial officer of Maple Leaf Foods said<br />

in a release. “There is no immediate urgency to selling the<br />

Burlington business. It is an efficient and profitable business<br />

and we want to ensure we negotiate an offer that recognizes the<br />

appropriate value for the business and meets the expectations<br />

of our shareholders”<br />

The decision to sell the Burlington business resulted from<br />

the company's decision to refocus its growth in the value-added<br />

meat, meals and bakery businesses in October 2006, involving<br />

the divestiture or exit of several of its primary processing and<br />

other operations.<br />

The company said it plans to wait until markets rebound<br />

to continue the process, which it estimates will not be likely<br />

before early 2010.<br />

Guelph Woman Arrested for Tampering with<br />

Schneider’s Meat Products<br />

Guelph, Ont. police arrested 41-year-old Mastoora Qezil in<br />

March for tampering with meat products at a grocery store.<br />

The woman, a former Maple Leaf Consumer Foods<br />

employee, was charged with one count of Common Nuisance<br />

18 Canadian Meat Business May/June 2009 meatbusiness.ca

under the Criminal Code.<br />

On March 18, Guelph police entered into an investigation<br />

when it was reported that sewing needles of various lengths<br />

had been inserted into various Schneider’s meat products at<br />

the No Frills Store located on Silvercreek Parkway.<br />

Aside from the original complaint none of the items<br />

tampered with were sold to the public. In all 12 packaged<br />

products containing 13 needles had been tampered with. No<br />

one was physically injured as result.<br />

According to Maple Leaf Foods, Qezil had worked at the<br />

company’s plant in Guelph for seven years and was terminated<br />

earlier that month.<br />

“We are very pleased that the police investigation has resulted<br />

in a charge being laid,” a Maple Leaf media statement said.<br />

“We also grateful to the cooperation extended by the police<br />

and the retailer throughout the investigation.”<br />

Bona Foods<br />

Our apologies to Bona Foods. In our last issue we<br />

did not correctly identify the company as Platinum<br />

Winners at the Ontario’s Finest Meat Competition in<br />

the “Fermented Sausage” category for its Paisanella<br />

Salami. Bona Foods is a food processing company that<br />

manufactures and distributes a variety of Italian-style<br />

deli meats throughout Canada. Visit Bona Foods at<br />

bonafoods.com.<br />

Why should people go<br />

hungry while food goes<br />

to waste?<br />

Do you...<br />

Work with a perishable or non-perishable<br />

food company in the Greater Toronto Area?<br />

Want to reduce waste and save on<br />

disposal costs?<br />

Need to free up storage space?<br />

Why not donate your surplus, close-to-code or<br />

damaged packaged food to Second Harvest?<br />

To arrange a food pickup, simply call 416-408-2594<br />

or email melissad@secondharvest.ca<br />

secondharvest.ca<br />

meatbusiness.ca<br />

May/June 2009 Canadian Meat Business 19

The Kitchen<br />

is Open<br />

A new way for processors to purchase<br />

equipment.<br />

Photo: Unitherm Food Systems<br />

By David Rizzo<br />

J<br />

ust as only a fool would buy a new car without going<br />

for a test drive, food processors now find themselves<br />

adopting a similar approach when it comes to<br />

purchasing equipment for their facilities. No longer<br />

content to simply sign-off on the delivery of large<br />

ovens and chillers at their docks, and then trying to adapt the<br />

machinery to their particular process, plant managers have long<br />

sought a means to ensure, in advance, that such equipment is<br />

optimally suited for their operation.<br />

With the advent of equipment manufacturers offering fully<br />

equipped kitchens so that food producers can “kick the tires”<br />

on new equipment by visiting the manufacturers with their<br />

product in tow, better results in terms of yield and quality are<br />

now becoming the norm.<br />

The most complete examples of these kitchens allow food<br />

processors to test varying cooking and freezing options and to<br />

optimize the equipment and the process before they put down a<br />

penny. Some manufacturers even go so far as to bring in design<br />

engineers to modify the equipment to further customize the<br />

equipment to actually improve the customer’s process.<br />

In effect, this new direction allows processors to perfect their<br />

product – be it cooked or frozen, vegetable or meat – in the<br />

“showroom” so that no surprises pop up on the production<br />

floor.<br />

Henry Ford was quoted as saying, “You can have any colour<br />

you want, as long as it’s black.” It’s not too far a stretch to<br />

make a comparison with the old paradigm of purchasing food<br />

processing machinery, where processors had to purchase “off<br />

the shelf.”<br />

In such instances, the capabilities of the equipment often<br />

dictated the cooking and freezing processes, resulting in a lessthan-optimal<br />

taste and quality of the final product for the sake<br />

of high volumes that only automated machinery can deliver.<br />

But the competitive food market takes no prisoners, and<br />

processors that don’t offer the best gustatory experience to the<br />

consumer will eventually go out of business. Hence, the need to<br />

get it right the first time.<br />

This is where the shift toward equipment-testing kitchens<br />

comes in.<br />

“The future of food process machinery purchasing is<br />

going this way, where the customer can demand to go into a<br />

kitchen and actually try out their product on the machinery,”<br />

predicts David Howard, CEO of Unitherm Food Systems of<br />

Bristow, Oklahoma. “Only then can they feel confident that<br />

the equipment best serves their operational parameters and<br />

expected results.”<br />

Already recognized throughout the food processing industry<br />

for its unique heat transfer systems that maximize yields and<br />

reduce processing times, Unitherm recently joined the, as yet,<br />

20 Canadian Meat Business May/June 2009 meatbusiness.ca

Photos: Unitherm Food Systems<br />

“The future of food process machinery purchasing is going this way.”<br />

– David Howard, CEO, Unitherm Food Systems<br />

small coterie of manufacturers that feature fully equipped test<br />

kitchens.<br />

As one of the newer, more modern, iterations of manufacturerowned<br />

test kitchens, it presents a textbook example of what<br />

type of environment awaits the producers of cooked vegetables,<br />

meats and frozen foods.<br />

Upon arrival, guests get introduced to a $2.5 million, 25,000-<br />

square-foot kitchen dedicated to high-volume, high-speed, food<br />

processing. Entry begins with a true “clean room” experience,<br />

with hygienic architectural products such as stainless steel<br />

curbing, hands-free sinks and stainless steel floor drains.<br />

“Test kitchens should be set up to resemble a high-quality<br />

food factory,” explains Howard. “Here, you walk in, change into<br />

your smock and boots, and put on a hair net. Then proceed<br />

through a hand wash station. There’s also a sanitizer to scrub<br />

and wash your boots.”<br />

The food processing area itself contains $8 million worth of<br />

fully operational production machines and product handling<br />

equipment that can continuously feed as many as 10 different<br />

cooking processes. Think: steaming, blanching, broiling,<br />

baking, searing, branding, grilling and pasteurizing; convection<br />

impingement to infrared; with gas, electric or thermal oil.<br />

Cooking temps range from below boiling point all the way to<br />

1,600° F.<br />

Continued on page 22<br />

meatbusiness.ca<br />

May/June 2009 Canadian Meat Business 21

Photos: Unitherm Food Systems<br />

Specific pieces of equipment include a flame broiler/griller<br />

with a series of eight ribbon burners to speed the browning<br />

and searing of foods such as mushrooms. In the case of poultry,<br />

the searing process seals in the natural oils before entering an<br />

oven. The oven, itself, incorporates a 16-inch wide belt that<br />

spirals around the burners to the equivalent of 150 ft. of belt,<br />

all within an 8 ft. x 8 ft. footprint.<br />

No kitchen, test or otherwise, would be complete without a<br />

gas infrared oven, the most innovative of which utilize a stainless<br />

steel burner head for increased durability.<br />

Likewise, quick cooling “crusters” have attained de rigueur<br />

status for any food processing plant that produces meat or<br />

poultry logs. Round out the chilling side of the business with a<br />

spiral freezer and a continuous impingement freezer. With the<br />

inclusion of an infrared or aquaflow pasteurizer, almost every<br />

imaginable aspect of the food processing industry gets covered<br />

in today’s modern kitchen.<br />

If that’s not enough, Unitherm’s kitchen, for one, comes<br />

staffed with design engineers willing to work hand-in-hand<br />

with food processors to modify any existing machinery into a<br />

customized cooking system. An on-site 3-D modelling system<br />

speeds the process.<br />

Test drives yield success<br />

Early feedback indicates that these kitchens are proving<br />

to be quite popular among food processors. Whether fireroasting<br />

Portobello mushrooms, steaming potatoes, cooking<br />

vegetables and other ingredients for sauces and ravioli fillings<br />

or baking chicken tenders, experimenting with the equipment<br />

emboldens processors to proceed with confidence, knowing<br />

that the equipment will maximize yields, reduce processing<br />

times, increase food safety and improve the taste of final<br />

product<br />

“One food processor based in Mexico flew directly from a<br />

trade show, where we met, to our plant near Tulsa,” recalls<br />

Howard. “We supplied the green peppers that he uses in his<br />

plant, that ultimately stuffs the peppers with other ingredients.<br />

Passing them through a correctly set-up roaster blackens the<br />

outer skin, which then gets removed to leave a slim, roasted<br />

pepper. We ran the test, and they bought a machine on the<br />

spot.”<br />

Howard tells of another processor who needed to speed up<br />

the roasting of tomatoes.<br />

“He came to our kitchen loaded with tomatoes just before<br />

Christmas,” continues Howard. “We put the tomatoes in the<br />

roaster and the project was finished in 10 minutes. In-and-out;<br />

done. In this case, we could adapt the machine to fit his exact<br />

purpose, which is why it worked out so well. But we couldn’t<br />

have done it unless he was in our kitchen with his product.”<br />

Such positive outcomes get repeated in these new kitchens<br />

throughout the country, with all manner of food products and<br />

purposes. Howard recounted stories of successfully achieving a<br />

roasting rate of 7,000 lbs. per hour of red bell peppers within<br />

four hours of having the client enter the kitchen. In the case<br />

of a producer of pre-cooked ready meals – such as lasagna,<br />

macaroni and cheese and potato salad – the producer booked<br />

two-days of stay at the Unitherm location.<br />

“We’re allowing food processors to first think about, ‘How<br />

am I going to maximize the quality of my product,’ as opposed<br />

to thinking about machinery,” adds Howard.<br />

David Rizzo, D.P.M., writes technical articles for Power PR, based in<br />

Torrance, Calif. He has published two trade books, 150 technical articles,<br />

and 300 newspaper columns.<br />

22 Canadian Meat Business May/June 2009 meatbusiness.ca

events calendar<br />

May 2009<br />

27 to 28<br />

Advanced Listeria Intervention and Control<br />

Workshop<br />

Allerton Hotel, Chicago, Illinois<br />

ami.com<br />

June 2009<br />

17 to 18<br />

Food Meets Function<br />

Best Western Lamplighter Inn and<br />

Conference Centre, London, Ont.<br />

foodmeetsfunction.ca<br />

17 to 21<br />

35th Annual Canadian Association<br />

of Foodservice Professionals (CAFP)<br />

Conference<br />

Calgary, Alta.<br />

cafp.com<br />

July 2009<br />

12 to 15<br />

IAFP 2009 96th Annual Meeting<br />

Gaylord Texan Resort<br />

Grapevine, Texas<br />

foodprotection.org<br />

September 2009<br />

10 to 13<br />

NAMP 67th Annual Convention<br />

The Broadmoor Hotel, Colorado Springs,<br />

Colorado<br />

namp.com<br />

27 to 28<br />

Alberta Foodservice Show<br />

Roundup Centre / Stampede Park<br />

Calgary, Alta.<br />

crfa.ca/tradeshows/Alberta<br />

March 2010<br />

7 to 9<br />

CRFA Show<br />

Toronto, Ont.<br />

crfa.ca/tradeshows<br />

April 2010<br />

18 to 19<br />

ApEx<br />

Halifax, N.S.<br />

crfa.ca/tradeshows<br />

29 to 30<br />

BC Foodservice Expo<br />

Vancouver, B.C.<br />

crfa.ca/tradeshows<br />

Thefoodnewz is an on line events calendar created by Debra Bradshaw of Zep Food<br />

& Beverage Division. To find out more about the events listed in this magazine visit<br />

thefoodnewz.com. If you know of events not listed please email Debra directly at<br />

zeprep@rogers.com.<br />

meatbusiness.ca<br />

May/June 2009 Canadian Meat Business 23

| Industr y Roundup |<br />

Depressed Margins in Packaged Meats<br />

Overshadows Maple Leaf’s Q1<br />

Maple Leaf Foods Inc. continues to recover<br />

from last summer’s massive product recall,<br />

the company reported today in its financial<br />

results for the first quarter ended March 31,<br />

2009.<br />

Sales for the first quarter increased<br />

6.3 per cent to $1.3 billion compared<br />

to $1.2 billion last year, reflecting price increases and the<br />

benefit of favourable foreign currency changes on fresh<br />

meat sales.<br />

Earnings from operations before restructuring and other<br />

related costs and other income decreased by 4.5 per cent<br />

to $31.6 million compared to $33.1 million last year, as<br />

significant declines in packaged meat earnings were mitigated<br />

by benefits from the restructuring of pork processing and hog<br />

production operations and price increases across the bakery<br />

business.<br />

Adjusted operating earnings in the company’s meat products<br />

group declined to $11.4 million in the first quarter of 2009<br />

compared to $25.0 million last year. Margins in packaged<br />

meat products were significantly lower than last year due to<br />

the impact of volume recovery efforts following last year's<br />

product recall. The company stated that over the next several<br />

months, its management will be implementing actions to<br />

restore margins, including appropriate price action, reducing<br />

internal costs and resuming more normalized investment<br />

in promotions. In response to the economic recession,<br />

marketing and innovation activities are focused on shifting<br />

the product mix to offer consumers a greater variety of value<br />

propositions.<br />

Earnings from fresh pork operations improved significantly<br />

in the first quarter, as the benefits from double shifting the<br />

pork processing plant in Brandon, Man., the consolidation<br />

of ham boning operations and the closure of less efficient<br />

plants were realized. A weaker Canadian dollar resulted in<br />

higher sales prices for fresh pork and increased earnings from<br />

international sales.<br />

In the first quarter, the company announced that due to<br />

difficult credit markets, it has suspended actively marketing its<br />

pork processing business in Burlington, Ont. The sale process<br />

for this business is expected to resume when credit markets<br />

stabilize and an appropriate sale value can be realized. The<br />

business is profitable and contributed to cash flow and<br />

earnings for the quarter. Earnings from the company’s poultry<br />

operations were consistent with last year.<br />

Rollstock Sales Director to be “Deeply Missed”<br />

Rollstock, Inc. released the following statement regarding<br />

the death of its sales director, Craig McBee.<br />

“Craig McBee began his sales career in automatic vacuum<br />

packaging in 1979. He joined Rollstock as the director of<br />

sales in 1998 where he was instrumental in establishing the<br />

company as the industry leader in entry-level to mid-range h/<br />

f/f/s packaging equipment. Craig found more than a job at<br />

Rollstock; he found a new family and lifted it to success. He<br />

was an authority in his field and his unique, jovial personality<br />

will be deeply missed by all who knew him.”<br />

CFC’s 2009 Executive Committee<br />

The Chicken Farmers of Canada (CFC) has announced the<br />

election of its 2009 executive committee.<br />

The 15-member Board of Directors, made up of farmers<br />

and other stakeholders from the chicken industry, provides<br />

leadership on CFC’s strategic plan and mission and has chosen<br />

the following representatives:<br />

David Fuller, a farmer from Blomidon, N.S., has been reelected<br />

as CFC’s chairman – a position he has held since 1999.<br />

He has been with CFC’s board since 1996, and has been active<br />

with the Chicken Farmers of Nova Scotia for over 15 years.<br />

Fuller and his family produce 1.4 million kilograms of chicken<br />

annually in the Annapolis Valley. Three generations of Fullers<br />

have been involved at all levels of the industry.<br />

Martin Dufresne, representing the province of Quebec, was<br />

re-elected to the position of first vice-chair. Also a member<br />

of CFC’s market development committee, Dufresne farms<br />

near St. Félix-de-Valois with his wife and three children. He<br />

produces approximately 1.7 million kilograms of chicken per<br />

year on the farm started by his father in 1954. He has been<br />

farming for over 20 years and is also the chair of the Quebec<br />

provincial board, Les Éleveurs de volailles du Quèbec.<br />

Urs Kressibucher, a second-generation farmer from<br />

Beaverton, Ont., was re-elected to the CFC executive committee<br />

as second vice-chair for 2009. Since 2004, Kressibucher has<br />

participated on the CFC market development committee,<br />

the CFC food safety committee and the CFC animal care<br />

committee. Representing District 9 (Eastern Ontario) for<br />

seven years for Chicken Farmers of Ontario and serving as<br />

vice-chair of the Poultry Industry Council, Kressibucher and<br />

24 Canadian Meat Business May/June 2009 meatbusiness.ca

his family have been chicken farmers for the past 20 years.<br />

Erna Ference has been involved with poultry farming for<br />

years and has been re-elected as the member at large. As a<br />

certified management accountant and a second-generation<br />

poultry farmer, she brings a breadth of experience to the<br />

table. Married to Reg, a former CFC board member from<br />

Alberta, they have five kids between the ages of 14 and 25.<br />

Their operation produces about 1.5 million kg per year and is<br />

located in the foothills of the Rocky Mountains.<br />

CFC’s main responsibility is to ensure that Canada’s 2,800<br />

chicken farmers produce the right amount of fresh, safe, high<br />

quality chicken to meet consumer needs. CFC is proud of its<br />

role in a continuing agriculture success story and over 30<br />

years of raising the quality chicken that Canadians trust.<br />

Reiser Begins Construction of New<br />

Customer Centre<br />

Food processing and packaging equipment company<br />

Reiser has begun construction of a new state-of-the-industry<br />

Customer Center at its Canton, Massachusetts headquarters.<br />

The Customer Center – a 6,600 square foot expansion to their<br />

existing building – builds on Reiser’s commitment to work<br />

with their customers to test and develop new products and<br />

processes. It is scheduled to open in September 2009.<br />

The center will feature a customizable processing room<br />

with space to run individual machines or fully automated<br />

lines, as well as a test kitchen for preparing finished product.<br />

The facility allows product to be processed under the same<br />

conditions found in most top-of-the-line plants in the industry.<br />

It also includes modern conference rooms for meetings and<br />

training, as well as comfortable work stations for visitors.<br />

“Reiser has a long history of providing the highest levels<br />

of customer support,” John McIsaac, Reiser’s vice president<br />

of strategic business development said in a release. “Our new<br />

Customer Center is one more way that we can help processors<br />

develop the best solution for their particular application.”<br />

Reiser’s full line of processing and packaging equipment<br />

can be tested at the Customer Center, including:<br />

• Vemag – stuffers, grinders, formers, fillers, portioners,<br />

depositors, extruders, coextruders and dough dividers<br />

• Holac – dicers, slicers, and cutting equipment<br />

• AMFEC – mixers, blenders, tumblers, massagers, and<br />

macerators<br />

• Fomaco – injectors, tenderizers, brine mixers, and tanks<br />

• Seydelmann – bowl cutters and choppers, mixers,<br />

grinders, and mixing grinders<br />

• Ross – tray sealers for case-ready and modified<br />

atmosphere packaging<br />

• Repak – horizontal form/fill/seal packaging machines<br />

• Supervac – automatic vacuum chamber<br />

packaging machines<br />

Processors are invited to contact Reiser and schedule a test or<br />

demonstration. Reiser is located in Canton, Massachusetts.<br />

reiser.com<br />

meatbusiness.ca<br />

May/June 2009 Canadian Meat Business 25

Be a Fly on the Wall in<br />

By Bill Melville<br />

Your Own Facility<br />

How to understand fly habits and prevent infestations.<br />

B<br />

eef, pork, poultry, flies? Which<br />

one doesn’t belong? While the<br />

answer might be obvious, flies<br />

are more than just nuisance<br />

pests, they are a health hazard and can<br />

cause serious problems for your facility<br />

– from contamination to shutting down<br />

operations.<br />

Flies carry more than 100 pathogens<br />

and can transmit bacteria such as<br />

staphylococcus, E. coli and salmonella<br />

every time they land. More importantly,<br />

flies can cover large distances in a short<br />

amount of time so they pose a serious<br />

contamination risk to facilities.<br />

Meat processing facilities provide<br />

the right ingredients for flies – plenty<br />

of water and food. An integrated pest<br />

management (IPM) plan, however,<br />

incorporates sanitation and facility<br />

maintenance to eliminate pests’ access to<br />

these survival needs.<br />

Do your homework<br />

Ask your pest management professional<br />

to inspect your facility for evidence of flies<br />

such as breeding sites, or conditions that<br />

attract them, like available food and water<br />

sources. In order to identify what specific<br />

flies might affect your facility, your pest<br />

management professional should be<br />

trained in pest biology and behavior.<br />

For example, he or she should be able<br />

to easily identify the difference between<br />