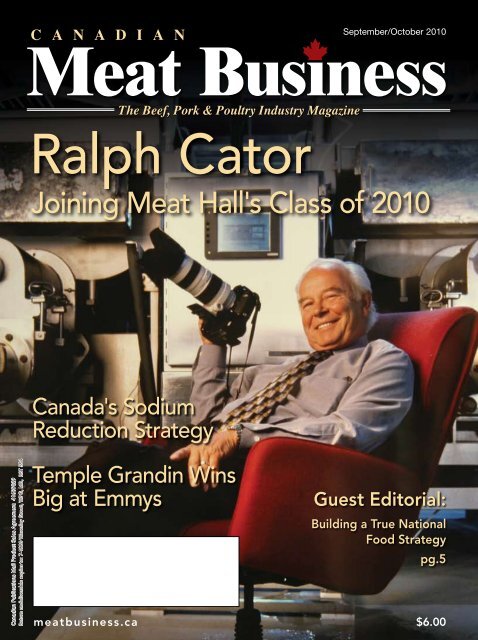

Ralph Cator

Joining Meat Hall's Class of 2010 - Canadian Meat Business

Joining Meat Hall's Class of 2010 - Canadian Meat Business

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

September/October 2010<br />

<strong>Ralph</strong> <strong>Cator</strong><br />

Joining Meat Hall's Class of 2010<br />

Canada's Sodium<br />

Reduction Strategy<br />

Canadian Publications Mail Product Sales Agreement 41689029<br />

Return undeliverable copies to: 7-1080 Waverley Street, WPG, MB, R3T 5S4<br />

Temple Grandin Wins<br />

Big at Emmys<br />

Guest Editorial:<br />

Building a True National<br />

Food Strategy<br />

pg.5<br />

meatbusiness.ca $6.00

201 Don Park Road Unit 1, Markham, Ontario, L3R 1C2<br />

Phone: 905-470-1135 1-800-465-3536 Fax: 905-470-8417<br />

Website: www.yesgroup.ca email: sales@yesgroup.ca<br />

Remco and The Yes Group<br />

Protecting your Customers<br />

Remco products are colour-coded to help<br />

divide the production cycle into different zones.<br />

By identifying these zones as different cleaning<br />

areas, the movement of bacteria around the<br />

production area can be blocked.<br />

Our products were developed with<br />

the Hazard Analysis Critical<br />

Control Point (HACCP) in mind.<br />

No matter what colour-coding plan is<br />

implemented, Remco Products from The Yes<br />

Group provides significant added value at no<br />

additional cost. From scoops to squeegees, from<br />

brushes to shovels, we have the products and<br />

the colours to enhance any professional quality<br />

assurance program.

Volume 9, Number 5 September/October 2010<br />

5 Guest Editorial<br />

by Robert de Valk<br />

6 Hold the Salt: Health Canada’s new sodium strategy<br />

by Alan MacKenzie<br />

9 Joining the Class of 2010: <strong>Ralph</strong> <strong>Cator</strong><br />

6<br />

12 Temple Grandin Wins Big at TV Awards Show<br />

14 The Evolution of a Classic Pairing: Wine-fed beef<br />

by Alan MacKenzie<br />

16 The Value of Challenge and Shelf-Life Studies<br />

by Dawn Van Dam<br />

17 Raising Awareness of Canadian Beef with Chefs<br />

18 Assembly Line<br />

20 Cross Country News<br />

22 Early vs. Late Calving<br />

by Debbie Lockrey-Wessel<br />

24 One Step Closer: Novel genes combat costly poultry disease<br />

by Debbie Lockrey-Wessel<br />

26 Manitoba Urges Producers to Target Halal and Kosher Markets<br />

by Alan MacKenzie<br />

28 Industry Roundup<br />

30 Canadian Beef: Goodness in Every Bite<br />

by Susan Evans<br />

9<br />

34 Meat Industry Business Watch<br />

by Gerry Kaplan<br />

12<br />

14<br />

meatbusiness.ca<br />

September/October 2010 Canadian Meat Business

| Guest Editorial |<br />

September/October 2010 Volume 9 Number 5<br />

PUBLISHER<br />

Ray Blumenfeld<br />

ray@meatbusiness.ca<br />

EXECUTIVE EDITOR<br />

Alan MacKenzie<br />

alan@meatbusiness.ca<br />

ADVERTISING SALES<br />

Sam Mayer<br />

sam@meatbusiness.ca<br />

CONTRIBUTING WRITERS<br />

Robert de Valk, Dawn Van Dam, Debbie<br />

Lockrey-Wessel, Susan Evans, Gerry Kaplan<br />

CREATIVE DIRECTOR<br />

Krista Rutledge<br />

FINANCE<br />

Jerry Butler<br />

Canadian Meat Business is published<br />

six times a year by We Communications West Inc.<br />

COMMUNICATIONS WEST INC.<br />

We Communications West Inc.<br />

7-1080 Waverley Street<br />

Winnipeg, MB, Canada R3T 5S4<br />

Phone: 204.985.9502 Fax: 204.582.9800<br />

Toll Free: 1.800.344.7055<br />

E-mail: publishing@meatbusiness.ca<br />

Website: www.meatbusiness.ca<br />

Canadian Meat Business subscriptions are<br />

available for $28.00/year or $46.00/two years<br />

and includes the annual Buyers Guide issue.<br />

©2010 We Communications West Inc.<br />

All rights reserved.<br />

The contents of this publication may not be<br />

reproduced by any means in whole or in part,<br />

without prior written consent from the publisher.<br />

Printed in Canada.<br />

ISSN 1715-6726<br />

Cover Photo: Cardinal Meat Specialists<br />

Building a True<br />

National Food Strategy<br />

I<br />

t seems that over the last 30<br />

years there have been numerous<br />

attempts at developing a national<br />

food strategy (NFS). All these efforts<br />

produced many good ideas and there<br />

are many similar themes found in<br />

each. What usually is missing, however,<br />

is the fundamental recognition by<br />

all players that Canada’s agricultural<br />

endowments are a key asset upon which<br />

Canadian prosperity and economic<br />

success depends and, therefore, should<br />

have a higher priority standing.<br />

For example, agriculture and food<br />

resources should have the same status<br />

politically and economically as oil and<br />

gas, lumber and minerals. After all, the<br />

food industry is one of Canada’s largest<br />

employers and it makes a significant<br />

contribution to the Canadian economy.<br />

Yet, although agriculture has its own<br />

minister federally and provincially, no<br />

department or minister represents the<br />

beyond the farmgate food industry.<br />

Agriculture ministers often add<br />

food to their departments, but such<br />

additions are usually more cosmetic<br />

than real. A credible and lasting food<br />

strategy must recognize and correct<br />

both these deficiencies. Making<br />

food a higher priority is particularly<br />

essential for Canada since agriculture<br />

and food is a shared jurisdiction. The<br />

only successful agriculture program to<br />

overcome the shared jurisdiction issue<br />

is the federal supply management<br />

programs.<br />

Perhaps this approach of combining<br />

powers into one national agency<br />

needs to be more broadly applied to<br />

achieve a truly national food industry.<br />

This does not mean more production<br />

and pricing powers should be put in<br />

the hands of only farmers, but rather<br />

that the entire food production and<br />

distribution chain works together on<br />

a national basis under one umbrella.<br />

The current value chain round tables<br />

are a good example but they are<br />

limited to examining areas under<br />

federal jurisdiction. Much has been<br />

tried and hopefully learned from past<br />

efforts at building a food strategy and<br />

now such efforts have become even<br />

more complicated as environmental,<br />

health and animal welfare issues<br />

have to be encompassed in a holistic<br />

approach. The past efforts have been<br />

driven mainly by government.<br />

CFA's new attempt<br />

In the new attempt at an NFS by the<br />

Canadian Federation of Agriculture<br />

(CFA) the foundation mentioned<br />

above is still missing – however the<br />

ten principles developed so far are<br />

well thought out. If the consultation<br />

phase now taking place with the entire<br />

food industry is equally successful,<br />

the possibility of developing a<br />

meaningful NFS is real. The key will<br />

be the degree of buy-in achieved from<br />

federal and provincial governments<br />

as well as industry participants. How<br />

to implement the principles will need<br />

to be worked out later. However, if<br />

we can get the governments to agree<br />

to the principles put forward by a<br />

united Canadian food industry all<br />

sending the same message, a true NFS<br />

may finally be put in place. This will<br />

allow Canada’s full potential as a food<br />

producer to be reached and allow<br />

Canada to take its rightful place among<br />

the food producers of the world.<br />

It will also make it easier to allow<br />

both provincial and federal plants to<br />

ship meat and poultry to Canadian<br />

consumers, as the differences<br />

between such plants would disappear.<br />

Anyone producing food in Canada or<br />

importers of food into Canada should<br />

be subject to the same rules and food<br />

safety criteria. These are all elements<br />

of a sound NFS.<br />

Finally, the strategy should ensure<br />

that sufficient resources are in place<br />

to carry out effective enforcement by<br />

the CFIA. The enforcement aspect of<br />

food policy is often an afterthought.<br />

Let’s make it part of the process this<br />

time.<br />

Robert de Valk is an Ottawa-based food<br />

consultant who has served the Canadian meat<br />

and poultry industry for over 25 years.<br />

Cert no. SW-COC000952<br />

meatbusiness.ca<br />

September/October 2010 Canadian Meat Business

Salt<br />

Hold the<br />

Health Canada working group makes recommendations toward reducing<br />

Canada’s overall sodium intake.<br />

By Alan MacKenzie<br />

H<br />

ealth Canada’s federally<br />

mandated Sodium Working<br />

Group (SWG) in July released<br />

the Sodium Reduction Strategy for<br />

Canada, a report that contains a “threepronged<br />

approach,” six overarching<br />

recommendations and 27 specific<br />

recommendations to reduce sodium<br />

intake among Canadians.<br />

The group said the average Canadian<br />

consumes 3,400 mg of sodium per day<br />

– more than double what is needed<br />

according to Health Canada guidelines.<br />

“The Sodium Reduction Strategy for<br />

Canada has an interim sodium intake<br />

goal of a population average of 2,300 mg<br />

of sodium per day to be achieved by 2016,”<br />

group member Dr. Norm Campbell of the<br />

University of Calgary said in a release.<br />

The group also noted there is a<br />

significant body of evidence linking high<br />

sodium intake to elevated blood pressure,<br />

cardiovascular disease, strokes and kidney<br />

disease. There is also evidence to suggest<br />

that a diet high in sodium is a risk factor<br />

for osteoporosis, stomach cancer and<br />

asthma. The group estimates that<br />

commercially processed foods currently<br />

account for 77 per cent of sodium<br />

intake.<br />

The three prongs outlined in the<br />

strategy are: research, education and a<br />

structured voluntary reduction of sodium<br />

levels in processed foods and foods sold<br />

at foodservice.<br />

The SWG was established in late<br />

2007 and includes representatives from<br />

food manufacturing and foodservice<br />

industry groups, health-focused nongovernmental<br />

organizations, the scientific<br />

community, consumer advocacy groups,<br />

health professional organizations and<br />

government representatives.<br />

Each of these representatives heads a<br />

sub-working group that deals specifically<br />

Canadian Meat Business September/October 2010<br />

meatbusiness.ca

with his or her sector – Mary Ann Binnie<br />

of the Canadian Meat Council (CMC)<br />

leads one looking at sodium in processed<br />

meat products. While fresh meat is<br />

naturally low in sodium, many processed<br />

meats have high levels due to salts and<br />

phosphates that are added to improve<br />

flavour and functionality, as well as for<br />

food safety as a preservative. According<br />

to Malabar Super Spice president Doris<br />

Valade, one of 12 members of the CMC<br />

group, processed meats are one of the<br />

main sources of sodium, along with<br />

breads and snack foods.<br />

Finding alternatives<br />

The challenge for meat processors<br />

looking to develop low-sodium options<br />

using salt replacers, Valade said, is that<br />

salt plays a significant role not only in the<br />

taste of processed meats but in the<br />

functionality as well, as salt works to<br />

increase ions in the meat.<br />

“In meat products you need to find<br />

something that will replace the ionic<br />

activity that you lose when you reduce<br />

sodium,” she said. “You can’t simply<br />

reduce sodium by 25 per cent because<br />

you also decrease the functionality.”<br />

Valade said one strategy to reduce<br />

sodium is to replace it with potassium,<br />

noting the most functional alternative<br />

to sodium chloride is potassium chloride<br />

– meaning meat made using potassium<br />

chloride will have a similar texture to its<br />

higher-sodium counterpart. However,<br />

she added, traditionally the drawback of<br />

using potassium chloride is the presence<br />

of a metallic aftertaste in the meat.<br />

“The Sodium Reduction<br />

Strategy for Canada has<br />

an interim sodium intake<br />

goal of a population<br />

average of 2,300 mg of<br />

sodium per day to be<br />

achieved by 2016.”<br />

– Dr. Norm Campbell, Sodium<br />

Working Group<br />

“We’ve been testing different meat<br />

products and we’ve found some that<br />

were lower sodium, but then we noticed<br />

that the product would be much softer<br />

– the whole mouth feel and the texture<br />

of the product becomes affected,” she<br />

explained. “So some meat processors<br />

have looked at adding just flavour<br />

enhancers, but the flavour enhancers had<br />

no function, and so we find that the meat<br />

product is not palatable.”<br />

Valade noted that earlier this year her<br />

company began working with a modified<br />

potassium chloride product from<br />

Minnestoa-based Nu-Tek to create a new<br />

line of low sodium seasonings.<br />

“We’d been actively looking at<br />

alternatives to flavour enhancers,” she<br />

said. “We looked at a pure potassium<br />

blend two years ago, but we didn’t like the<br />

taste at all. It wasn’t until about six months<br />

ago that we came across this one in the<br />

U.S.. We started working on seasonings<br />

that incorporate it and we have had some<br />

very good success with it.”<br />

Consumer acceptance<br />

In a recent statement supporting the<br />

strategy, CMC executive director Jim Laws<br />

said a well-funded consumer education<br />

program needs to be developed to explain<br />

the health benefits of reducing sodium<br />

intake. He also noted there is a need for<br />

continued research into sodium reduction<br />

techniques and the development of salt<br />

replacers with full functionality.<br />

meatbusiness.ca<br />

September/October 2010 Canadian Meat Business

“Critical to the success of this new voluntary sodium reduction<br />

strategy is consumer acceptance,” Laws stated. “Consumers<br />

need to be aware of why the changes are occurring and they<br />

need to accept the changes in products for the strategy to be<br />

successful.”<br />

Laws also stressed that the meat industry is fully aware of the<br />

importance of reducing sodium intake in Canada.<br />

“Our members are committed to providing Canadians with<br />

sodium-reduced options – and have been for several years<br />

– evidenced by the many sodium reduced processed meat<br />

products already available to consumers in grocery stores,” he<br />

stated.<br />

Looking ahead<br />

According to Valade, the work of the SWG is far from over. She<br />

said she expects one of the next steps may be the development<br />

of a labelling system, similar to one used in the United Kingdom<br />

(which, she noted, inspired Health Canada to create the SWG).<br />

The U.K. system is based on using coloured traffic lights<br />

symbols to warn consumers of sodium levels – for example a<br />

product containing 1.25g of salt (or 0.5g sodium) is labelled red<br />

while 0.25g salt (0.1g sodium) is labelled green.<br />

“We’ll be looking at labelling options to support lower sodium<br />

products and at a review as to whether the targets recommended<br />

are in fact being met by industry,” she said.<br />

Some specific targets for sodium reduction have been set (see<br />

table) and more will be finalized in 2011. However, these targets<br />

will be re-established over time as progress toward the 2016<br />

interim goal is tracked.<br />

For more information on the Sodium Reduction Strategy and how it<br />

affects the meat industry, read Susan Evans’ article on page 30.<br />

Sodium Reduction Strategy's<br />

six overarching recommendations:<br />

• Interim intake goal of 2,300 mg of sodium/day by<br />

2016 – with a longer-term goal of 95 per cent of<br />

population with a daily intake below the UL.<br />

• Widespread collaboration across governments,<br />

health professional organizations, NGOs, media,<br />

industry and academia to implement the SWG’s<br />

full slate of recommendations.<br />

• Adequate federal/provincial/territorial funding to<br />

support the SWGs full slate of recommendations.<br />

• Integration of sodium reduction into government<br />

and stakeholder nutrition programs, guidelines<br />

and policies.<br />

• Implementation process to include identifying<br />

individual steps (including timelines) for each<br />

recommendation, as well as monitoring completion<br />

of each step.<br />

• Canadians take personal steps to reduce sodium<br />

consumption as part of a healthy diet.<br />

Targeted Recommendations in Four<br />

Areas:<br />

• Food supply<br />

• Awareness and education<br />

• Research<br />

• Monitoring and evaluation<br />

For more information, read the full report, Sodium<br />

Reduction Strategy for Canada, at www.hc-sc.gc.ca.<br />

Draft Targets for Meat Products<br />

The Sodium Working Group divided the food<br />

supply into two groups: Group I foods (combined<br />

contribute over 50% of the sodium in the diet) and<br />

Group II foods which includes the remaining food<br />

categories and restaurant and foodservice. Table 1<br />

compares the current average sodium content of<br />

the Group I meat products to the draft maximum<br />

sodium levels to be achieved by 2016.<br />

Categorization<br />

Sodium average<br />

mg/100g<br />

Maximum<br />

sodium level by<br />

2016 (mg/100 g)<br />

Uncooked Bacon - Belly and Back<br />

Bacon<br />

Fully Cooked Bacon - Breakfast<br />

Strips, Substitutes and Back Bacon<br />

Packaged Deli Meats - Pâtés and<br />

Spreads<br />

Packaged Deli Meats - excludes<br />

Pâté and Spreads<br />

Packaged Deli Meats – Dry Cured,<br />

Fermented, No Thermal Processing<br />

Uncooked Fresh Sausage -<br />

Breakfast and Dinner Varieties<br />

Fully Cooked Sausage - Smoked,<br />

Not Smoked and Wieners<br />

808.9 610<br />

1388.2 1150<br />

781.5 600<br />

1029.7 890<br />

1617.4 1400<br />

789.1 690<br />

992.7 870<br />

Data compiled by Mary Ann Binne based on label<br />

data and the proposed draft targets found at the<br />

Health Canada website (www.hc-sc.gc.ca).<br />

Canadian Meat Business September/October 2010<br />

meatbusiness.ca

| Cover Stor y |<br />

Joining the<br />

Class of 2010<br />

Cardinal Meat Specialists’ <strong>Ralph</strong> <strong>Cator</strong> among 12 new Meat<br />

Industry Hall of Fame Members.<br />

L<br />

eading the list of industry greats<br />

being nominated into the Meat<br />

Industry Hall of Fame’s (MIHoF)<br />

Class of 2010 is <strong>Ralph</strong> <strong>Cator</strong>, founder<br />

and chairman of the board of Cardinal<br />

Meat Specialists, a major supplier of<br />

beef patties and further processed meats<br />

based in Mississauga, Ont. He is the first<br />

Canadian to be inducted into the hall.<br />

<strong>Cator</strong> is one of 12 new members<br />

chosen from a list of over 50 nominees<br />

by the hall’s board of trustees and<br />

inductees from last year’s inaugural class.<br />

The nominees included an all-star list of<br />

executives, academicians, innovators and<br />

association leaders from all sectors of the<br />

industry.<br />

The Induction Ceremony for the new MIHoF members will<br />

be on Oct. 30, 2010 at the Fairmont Scottsdale in Scottsdale,<br />

Arizona. The gala event will begin with a Reception at 5:00<br />

p.m. and the evening’s festivities will conclude with the North<br />

Photos: Cardinal Meat Specialists<br />

American Meat Processors Association<br />

(NAMP) President’s Reception, Dinner<br />

& Ball which closes the association’s<br />

Annual Outlook Conference.<br />

“It will be a special evening to formally<br />

honour a ‘who’s who’ of the industry,”<br />

said Chuck Jolley, MIHoF president and<br />

co-founder. “Our thanks to our board of<br />

trustees and our members who elected<br />

an elite group from an impressive list of<br />

nominees. We are thrilled to be able to<br />

induct people who truly represent the<br />

best of the best.”<br />

<strong>Cator</strong> started his meat career at the age<br />

of eight while working after school in one<br />

of his father’s butcher shops in Toronto.<br />

By the ripe old age of 18, he found himself managing one of<br />

those shops. An ambitious young man, he soon persuaded his<br />

father to sell him part ownership in all four stores.<br />

<strong>Cator</strong> founded Cardinal Meat Specialists, now one of<br />

Canada’s largest producers of ground beef patties, in 1966 to<br />

<strong>Ralph</strong> <strong>Cator</strong> also enjoys a second<br />

career as a photographer.<br />

meatbusiness.ca<br />

September/October 2010 Canadian Meat Business

(<strong>Ralph</strong> <strong>Cator</strong>) focused on being an innovative player in the meat industry by<br />

seeking out the best minds in each field and then capitalized on their knowledge.<br />

serve the rapidly growing food service market. He focused on<br />

being an innovative player in the meat industry by seeking<br />

out the best minds in each field and then capitalized on their<br />

knowledge. He continues to be a huge believer in “no one of<br />

us is as smart as all of us” and made this a key business strategy<br />

while driving the company’s growth.<br />

<strong>Cator</strong> was always active in the industry and knew that<br />

expanding the knowledge of the Cardinal team was<br />

imperative to remaining innovative and competitive. By<br />

joining the National Association of Meat Purveyors in 1969,<br />

He established Cardinal’s long-standing relationship with<br />

NAMP and in 1992 became the association’s first Canadian<br />

president. <strong>Cator</strong> helped broaden the association’s scope to<br />

become a truly North American organization leading the<br />

group to change their name to the North American Meat<br />

Processors Association.<br />

At the forefront<br />

To keep his company of the forefront of the industry, he was<br />

always seeking new and improved technologies. Cardinal’s<br />

ability to differentiate itself from the competition was driven<br />

in large part by its innovation. His efforts to expand the<br />

business and provide superior products to the market led<br />

Cardinal to become the first meat processor to utilize many<br />

new technologies that have become industry standards today.<br />

Under <strong>Cator</strong>’s leadership, the company continued a steady<br />

introduction of new equipment, production methods and<br />

product innovation, many of which are the basis of Cardinal’s<br />

leading position today. Always a risk taker, he spearheaded a<br />

bold move for Cardinal introducing Canada’s first national<br />

brand premium burger in foodservice: Cardinal’s Roadhouse<br />

Beef Burger.<br />

Today, Cardinal’s product line covers the gamut of meatbased<br />

proteins. Pork mini-ribs, pulled beef au jus, meatloaf<br />

and gravy, and Kettle Cooked Ribs are all on their menu.<br />

In 1990, <strong>Cator</strong> turned over day-to-day management of the<br />

company to his two sons, Mark and Brent, allowing him to<br />

return to school to pursue his love of art. He graduated from<br />

Humber College in 1992 and soon after, became a licentiate of<br />

the Professional Photographers of Canada – a second career,<br />

which he pursues to this day.<br />

Next generation<br />

<strong>Cator</strong> continues as chairman of the board for Cardinal<br />

Meat Specialists, advising his son Brent, who now owns the<br />

company and continues the growth of this third generation<br />

business at an astounding pace.<br />

His lifetime of service is far broader than his<br />

accomplishments in the meat industry. During his term with<br />

NAMP, he was presented with the NAMP President’s Award,<br />

The Angus Award and The Fifty Year Service Award. He<br />

has also served as the Foundation Chair for the Canadian<br />

Association of Family Enterprise and is an Associate of the<br />

Trillium Health Centre Foundation.<br />

Along with a successful stock photography business, his<br />

photographs have been used to promote such things as the<br />

Canadian Open Golf Tournament and charitable causes such<br />

as the United Way, Rally for the Cure, the Hospital for Sick<br />

Children and Habitat for Humanity.<br />

Other inductees<br />

Other members of MIHoF’s Class of 2010 include:<br />

• Richard Bond, CEO, president and director of Tyson<br />

Foods Inc.<br />

• William D. Farr, of Farr Feeders (deceased)<br />

• Joel Johnson, chairman, president and CEO of Hormel<br />

Foods Corporation<br />

• H. Kenneth Johnson, vice president of meat science for the<br />

National Live Stock and Meat Board; executive director of<br />

the National Cattlemen's Beef Association<br />

• Ray Kroc, founder and chairman of McDonald's<br />

Corporation (deceased)<br />

• Dr. Roger Mandigo, professor at the animal science<br />

department of the University of Nebraska<br />

• Robert E. Rust, professor emeritus, animal science at Iowa<br />

State University<br />

• Col. Harland Sanders, founder of Kentucky Fried Chicken<br />

(deceased)<br />

• Dr. Jeff W. Savell, regents professor and E.M. "Manny"<br />

Rosenthal, chairholder in animal science at Texas A&M<br />

University<br />

• Deven Scott, vice president - member services for the<br />

American Meat Institute; executive vice president of<br />

NAMP<br />

• Dave Thomas, founder, CEO, Wendy's Old Fashioned<br />

Hamburgers (deceased)<br />

-staff<br />

10 Canadian Meat Business September/October 2010 meatbusiness.ca

Let BEACON customize<br />

our standard designs for you<br />

STAINLESS STEEL PROCESSING TRUCKS<br />

All Trucks, Racks & Cages are manufactured from<br />

heavy-duty T-304 Stainless Steel. We can engineer<br />

to your exact specifications, and whatever product<br />

you are processing - BEACON has the right product<br />

for you.<br />

The Nesting design allows the<br />

processor greater versatility,<br />

by providing a heavy-duty<br />

Truck that can save on storage<br />

space when not in use.<br />

BEACON also manufactures<br />

the Stainless Steel SCREENS<br />

& SHELVES for all Truck<br />

designs.<br />

CALL US FOR A<br />

QUOTATION!!!<br />

BEACON has many designs for many products!!!<br />

• Four-upright design • Nesting Trucks • Bacon Racks<br />

• Trucks for Smokesticks • Bologna trucks<br />

...and many more designs.<br />

BEACON, Inc. 12223 S. Laramie Ave, Alsip, IL 60803 (708) 544-9900 Fax (708) 544-9999<br />

www.beaconmetals.com

Grandin Wins Big at<br />

TV Awards<br />

Show<br />

Photos: Corus Entertainment / HBO Canada<br />

Temple Grandin and Claire Danes on the set of the film.<br />

Claire Danes in a scene from Temple Grandin.<br />

HBO bio-film about meat<br />

industry legend Temple Grandin<br />

takes home top honours at<br />

Primetime Emmy Awards.<br />

By Alan MacKenzie<br />

A<br />

Alongside what can easily be described as more<br />

glamorous fare – including the acclaimed TV<br />

series Mad Men and Steven Spielberg/Tom Hanks<br />

miniseries The Pacific – one of the big winners at this year’s<br />

Primetime Emmy Awards was the true story of one of the meat<br />

industry’s most fascinating innovators.<br />

The HBO film Temple Grandin tells the story of Dr. Temple<br />

Grandin, the well-respected autistic animal welfare activist who<br />

uses her unique view of the world to develop more humane<br />

treatment methods for livestock.<br />

The film took home honours for Outstanding Made for<br />

Television Movie and Outstanding Directing for a Miniseries,<br />

Movie or a Dramatic Special, as well as acting awards for Julia<br />

Ormond, David Strathairn and Claire Danes, who played<br />

Grandin.<br />

The made-for-TV movie won a total of five awards at the<br />

Aug. 30 ceremony (and previously won two for its score and<br />

single-camera editing at the Creative Arts Primetime Emmy<br />

Awards, which were announced on Aug. 21, coincidentally<br />

Grandin’s 63rd birthday). Grandin herself attended the<br />

ceremony and was noted for her enthusiastic response to each<br />

win (at one point she rose from her chair and excitedly swung<br />

her hand “lasso-style”, the Los Angeles Times reported). She<br />

even received a standing ovation from the audience.<br />

In her acceptance speech, Danes called Grandin “the most<br />

brave woman I've known.”<br />

Born in 1947 in Boston, Massachusetts, Grandin was<br />

diagnosed with autism at the age of three, at a time when<br />

little was known about the condition. Through the support<br />

of family and teachers she pursued higher education and<br />

obtained a B.A. in psychology at Frankin Pierce College in 1970<br />

and a Master of Science in Animal Science at Arizona State<br />

University in 1975. The curved livestock handling facilities<br />

that she designed to reduce animal stress are used not only<br />

in the United States and Canada, but throughout the world<br />

– including in Europe, Mexico, Australia and New Zealand.<br />

Almost half of all cattle in North America are handled in a<br />

centre track restrainer system that she designed.<br />

The film chronicles Grandin’s life from her adolescence<br />

through her university career to becoming an unexpected<br />

pioneer in the male-dominated meat industry and eventually<br />

a spokesperson for autism (she has written several books on<br />

the subject including the acclaimed Thinking in Pictures).<br />

12 Canadian Meat Business September/October 2010 meatbusiness.ca

To show how Grandin views the world<br />

around her director Mick Jackson utilized<br />

several visual effects, such as onscreen<br />

diagrams, a technique that Grandin<br />

herself praised.<br />

“It did a very good job of accurately<br />

showing my visual thinking, sensory<br />

issues, anxiety issues. That was the work<br />

of Mick Jackson, the director – he just did<br />

a fabulous job on that,” Grandin recently<br />

told Canadian Meat Business. She also<br />

praised Danes’ performance, saying it<br />

was “like watching myself.”<br />

“The movie also did a great job of<br />

showing that I was in a man’s world<br />

back in the early ’70s with a bunch of<br />

male chauvinist pigs,” the Meat Industry<br />

Hall of Fame member added, noting<br />

that an emotional scene in which her<br />

car was vandalized by being covered in<br />

bull testicles at a slaughter facility was<br />

accurate.<br />

Grandin was originally approached<br />

about the film over 10 years ago by<br />

executive producer Emily Gerson Saines.<br />

Saines has an autistic child and after<br />

reading some of Grandin’s books wanted<br />

to bring her inspirational story to the<br />

screen. Grandin was involved in the<br />

project from the beginning and spent<br />

time working with Jackson, Danes and<br />

the film’s writers, Christopher Monger<br />

and Merritt Johnson.<br />

Claire Danes as Temple Grandin.<br />

“I had a lot of input into it on cattle<br />

accuracy,” she said. “I spent a half a day<br />

with Clare Danes and I gave her all of<br />

these ancient VHS tapes from the ’80s<br />

and early ’90s of interviews and lectures<br />

– they were the oldest tapes I had.”<br />

The film was considered an<br />

unexpected winner, beating out five<br />

other nominees including HBO’s You<br />

In her acceptance speech,<br />

Danes called Grandin<br />

“the most brave woman<br />

I've known.”<br />

Don’t Know Jack, which stars Al Pacino<br />

as Dr. Jack Kevorkian, and The Special<br />

Relationship, featuring Michael Sheen<br />

as Tony Blair and Dennis Quaid as Bill<br />

Clinton. Danes won her trophy over<br />

such notable actresses as Dame Judy<br />

Dench, Maggie Smith and Hope Davis.<br />

It was released on DVD in August.<br />

This year Grandin was also named<br />

one of Time magazine’s Most Influential<br />

People and in July the National<br />

Cattlemen’s Beef Association gave her a<br />

lifetime achievement award. Watch for<br />

a full interview with Grandin about her<br />

extraordinary year in our next issue.<br />

meatbusiness.ca<br />

September/October 2010 Canadian Meat Business 13

The Evolution of a<br />

Classic Pairing<br />

By Alan MacKenzie<br />

B.C. restaurants put locally produced wine-fed beef on their menus.<br />

A<br />

s most foodies know, red wine and beef make a great<br />

pairing. So, what if that wine is added directly to the<br />

meat before it’s even led to slaughter? That question is<br />

being answered at Sezmu Meats, a Kelowna, British Columbia<br />

company that specializes in producing wine-fed beef.<br />

Janice Ravndahl, who owns the company with her brother<br />

Darrel Timm, began experimenting with feeding wine to<br />

bovine in April 2009 and earlier this year brought their product<br />

to the marketplace.<br />

For 90 days prior to slaughter her cattle is fed one litre of<br />

wine a day per head.<br />

“The beef is really, really red – it’s much more red than<br />

regular beef. And the smell – I opened a container of ground<br />

beef here the other night and it smelled like I opened a bottle<br />

of wine for a few moments,” she said, noting the flavour of the<br />

meat is also affected by feeding the cattle wine. “It does give it a<br />

slight sweet tinge to the taste.”<br />

Ravndahl said the idea of feeding wine to cattle came to<br />

her while watching The F Word, a reality TV show featuring<br />

renowned British chef Gordon Ramsay.<br />

“One of the objectives of his show is to show his kids where<br />

food comes from, so every season he raises a different animal.<br />

In his third season he raised pigs, and he decided to do a little<br />

experiment – he fed one of them beer,” Ravndahl said. “That<br />

got my brain ticking. I grew up on a beef farm, I live in the<br />

Okanagan Valley and I’m surrounded by vineyards – I just<br />

thought red wine would make a better combination for beef,<br />

as opposed to beer.”<br />

In Japan, Kobe beef is produced using beer-fed cattle, but<br />

Ravndahl said she only knows of one other company – in<br />

Australia – that produces wine-fed beef.<br />

Response<br />

The response to the product, Ravndahl said, has been very<br />

enthusiastic. Michael Allemeier, a culinary arts instructor at<br />

SAIT Polytechnic College in Calgary, was so impressed that it<br />

led to the product being served at Mission Hill Family Estate,<br />

a Kelowna winery where he recently served as executive chef.<br />

A handful of other restaurants in the area also serve the<br />

company’s wine-fed beef – and Sezmu steaks are now available<br />

at the retail counter of Cook’s Quality Meats in nearby<br />

Westbank.<br />

Ken Briden, owner of Cook’s Quality Meats, said the feedback<br />

from customers has been very positive.<br />

“It’s definitely AAA, and it’s better than most of the stuff<br />

that’s out there,” he said. “As soon as I sampled it I knew it<br />

would sell for sure.”<br />

Ravndahl noted the product is also being used in processed<br />

meat products such as smokies, sausages and pepperoni at<br />

Johnny’s Meats and Deli in the nearby community of Rutland.<br />

CFIA approval<br />

But just as Sezmu Meats began gaining momentum for its<br />

wine-fed meat, the company hit a snag – in late August the<br />

Canadian Food Inspection Agency (CFIA) called Ravndahl and<br />

told her that wine is not an approved feed ingredient for cattle<br />

and that she could no longer sell the product. The agency told<br />

her the concern was mostly about sediments in the wine. The<br />

unfortunate news quickly made headlines across the country<br />

and within days the CFIA backed off, Ravndahl said.<br />

Ravndahl and Dr. John Church, a professor and cattle<br />

research chair at Thompson Rivers University in Kamloops,<br />

both said they didn’t understand the CFIA’s initial stance, as all<br />

ingredients in the wine are also approved ingredients for feed.<br />

“This is wine that we’re using for human consumption – so<br />

if we’re worried about feeding it to cattle, maybe we should be<br />

re-examining giving it to people,” Church said with a laugh,<br />

adding that he’s relieved that the agency backed off, as he is<br />

in the early planning stages of a research study on the wine-fed<br />

cattle.<br />

14 Canadian Meat Business September/October 2010 meatbusiness.ca

Research study<br />

Specifically, Church said,<br />

the study – which, pending<br />

provincial funding, he hopes<br />

will start in October – will<br />

look at the effects of certain<br />

ingredients that may reduce<br />

methane emissions and<br />

harmful bacteria.<br />

“ Wine is a very good source<br />

of tannins, a secondary plant<br />

metabolite has been shown<br />

to be one of the best ways to<br />

reduce methane. We want to<br />

look at the tannins found in<br />

wine and see if the addition to<br />

the feed actually reduces the<br />

methane,” he explained.<br />

“There’s also a compound<br />

found in wine called reservatrol<br />

that has been shown in vitro to<br />

be quite a powerful microbial.<br />

So we’re also geared up to look<br />

at the microbiology – we want<br />

to see what the impact is on E. coli and antibiotic resistance<br />

in general,” he said, adding that fatty acid profiles will also<br />

be examined to see if there are any changes to omega-3 or<br />

conjugated linoleic acid (CLA) content.<br />

Church also noted that the effect on the meat itself,<br />

specifically its tenderness and flavour and colour, will be<br />

studied. “I’ve certainly had the wine-fed beef myself and at the<br />

time it seemed sweeter. It was a really nice product, but it’s kind<br />

Photos: Trudephoto.com<br />

of anecdotal – you don’t know if<br />

that’s how the steak would have<br />

been anyway,” he said.<br />

Church added that he’s<br />

surprised there has been little<br />

backlash about boozing-up the<br />

cows, particularly from “activist<br />

types” – but he noted that part<br />

of his study will look into the<br />

alcohol’s effect on the animals.<br />

“We’re going to set up a<br />

behavioural test and measure<br />

their chute exit speed,” he<br />

said. “I’ve actually gone to the<br />

feedlot and seen the cattle.<br />

My academic background is in<br />

animal behaviour and I certainly<br />

couldn’t see a difference.”<br />

He estimated that, based on<br />

body mass alone, a litre of wine a<br />

day for a cow may be equivalent to<br />

a glass of wine a day for a person<br />

– an amount widely determined<br />

to be heart-healthy for humans.<br />

“Cows are also ruminants, so<br />

I’m not sure how much wine would actually get through the<br />

rumen,” he said. “I can’t see it having any impact on them<br />

whatsoever.”<br />

Ravndahl said the only difference she’s seen after adding<br />

wine to the cattle’s feed is that the animals are calmer.<br />

Currently Sezmu’s wine-fed beef is only available in B.C., but<br />

there are plans to expand to other markets in the near future.<br />

Janice Ravndahl and Darrel Timm<br />

operate Sezmu Meats in Kelowna, B.C.<br />

“I opened a container of ground beef<br />

here the other night and it smelled<br />

like I opened a bottle of wine for a<br />

few moments.” – Janice Ravndahl<br />

please visit us at: www.sperlingind.com<br />

“BOSS” equipment<br />

Industry providers to the food industry for over 100 years...<br />

• Focused on food safety with enhanced production reliability.<br />

• Specializing in engineering, fabrication, installations, Beef & Pork.<br />

• BOSS provides packers with reliable efficient equipment.<br />

Sperling<br />

Industries Ltd.<br />

51 Station St, (Box 100)<br />

Sperling, MB Canada R0G 2M0<br />

1-204-626-3401 or<br />

Fax 1-204-626-3252<br />

Also:<br />

Brandon, MB<br />

1-204-729-9190<br />

2420 Z Street, Omaha, NE 68107<br />

1-402-556-4070<br />

meatbusiness.ca<br />

September/October 2010 Canadian Meat Business 15

LifeStudies<br />

Challenge and Shelf<br />

Testing for the worst-case scenario, and pushing the limits of your<br />

food product.<br />

By Dawn Van Dam<br />

D<br />

etermining how your<br />

product reacts to microbial<br />

contamination and confirming<br />

shelf life provides invaluable information<br />

to the food industry in terms of product<br />

quality and safety. Challenge and shelf<br />

life studies provide this information by<br />

evaluating a product over the course of<br />

the intended shelf life.<br />

Challenge studies<br />

Drills are an essential component<br />

of safety; fire drills, lifeboat drills, CPR<br />

drills...their merit is unquestioned. The reason: learning<br />

how to deal with the worst-case scenario – safely. Challenge<br />

studies are of the same nature. They allow food producers<br />

to reduce risks to food safety by preparing for the worst-case<br />

scenario.<br />

Challenge studies are similar to shelf life studies in that<br />

they examine how microorganisms in a product change<br />

over time. The main difference is that in a challenge study<br />

the product is purposefully inoculated with pathogens,<br />

simulating a chance contamination.<br />

There are two types of challenge studies. The type<br />

known as an inactivation study determines the ability of a<br />

processing step or formulation to ‘inactivate’ the growth<br />

of pathogens of concern (pathogens that historically have<br />

been identified as a risk for a certain type of product). For<br />

example, physical processes such as heating, irradiation and<br />

high pressure treatments can ‘inactivate’ pathogens in a<br />

product.<br />

The other type of challenge study is called an inhibition<br />

study. This type of study confirms the success of a specific<br />

formulation and/or packaging strategy in inhibiting<br />

the growth of pathogens of concern. For example, the<br />

application of sodium acetate or diacetate has been shown<br />

to inhibit the growth of listeria during post-processing steps.<br />

For products like ready-to-eat meats, the application of<br />

antimicrobial additives can decrease the risk to consumers.<br />

So, with challenge studies you can determine how well<br />

your product stands up against microbial contamination.<br />

Shelf life studies<br />

While challenge studies address the issue of chance<br />

contamination, shelf life testing determines the length of<br />

time that a food product will maintain its quality before it<br />

begins to spoil.<br />

As a means of providing consumers with the most reliable<br />

information about the lifespan of a product, and as a measure<br />

of the success of your shelf life-extending strategies, these<br />

studies provide invaluable information to the food industry.<br />

Consumer preferences have shifted towards labels such<br />

as ‘no additives or preservatives’ or<br />

‘no sugar/sodium added.’ The food<br />

industry is continuously looking for<br />

new ways to preserve the freshness and<br />

quality of food over an extended period<br />

of time without the addition of such<br />

additives. Shelf life studies evaluate the<br />

efficacy of new technologies/methods<br />

for extending shelf life, so you can<br />

maintain product quality while adapting<br />

to consumer demands.<br />

Periodic reexamination of shelf life<br />

can also determine if changes made<br />

in your manufacturing process, such as new materials or<br />

suppliers, or new equipment or formulations have affected<br />

the microbiological profile and changed the shelf life.<br />

Shelf life studies are not simple step-by-step procedures;<br />

they rely heavily upon the experience and expertise of the<br />

scientists involved. Each individual shelf life study must<br />

be designed to reflect the unique conditions of a product<br />

including pH, moisture and temperature. Microbial<br />

examination is then conducted over the course of the<br />

intended shelf life, or even beyond to determine the point of<br />

spoilage. Ultimately, consumers use their senses to determine<br />

whether or not a product is desirable, but microbial growth<br />

can reach unsafe levels before any unpleasant changes are<br />

noted.<br />

Evaluating shelf life can help you identify and minimize<br />

risks, determine the most effective methods to prolong your<br />

products’ freshness or marketability, and provide information<br />

to consumers about the lifespan of your product.<br />

University of Guelph<br />

The University of Guelph, Agriculture & Food Laboratory<br />

(AFL) offers customized studies that provide reliable results<br />

and information on how your products react to microbial<br />

contaminations, and how to confirm the shelf life of your<br />

products. When it comes to protecting consumers and brand<br />

names, accurate results are paramount. The AFL is supported<br />

by an integrated quality management system that achieves<br />

the ISO 9001:2008 and ISO/IEC 17025 international quality<br />

standards as well as for specific tests listed on our Scope of<br />

Accreditation, and is happy to work with you to customize<br />

studies, providing the scientific support you need to have<br />

peace of mind.<br />

For more information about conducting shelf life or<br />

challenge studies, you can reach AFL at 519-767-6299 or<br />

1-877-863-4235 (1-877-UofG-AFL), or through email at<br />

aflinfo@uoguelph.ca.<br />

Dawn Van Dam is the Chief Marketing Officer for the University of<br />

Guelph, Laboratory Services, Agriculture & Food Laboratory.<br />

16 Canadian Meat Business September/October 2010 meatbusiness.ca

Raising Awareness of Canadian Beef with Chefs<br />

T<br />

he American Culinary Federation (ACF),<br />

established in 1929, is the premier professional<br />

organization for chefs in the United States. With<br />

more than 20,000 members spanning 225 chapters<br />

nationwide, ACF is the culinary leader in offering<br />

educational resources, training, apprenticeship and<br />

program accreditation. In addition, ACF operates the<br />

most comprehensive certification program for chefs in<br />

the United States.<br />

The Beef Information Centre (BIC) continues to work<br />

with the ACF to educate chefs on the Canadian Beef<br />

Advantage (CBA), communicating how these advantages<br />

align with the foodservice sectors. These educational<br />

seminars are aimed at raising awareness of Canadian beef<br />

products and highlighting how Canadian beef’s strong<br />

quality attributes fit the American guest’s expectations for<br />

an outstanding eating experience.<br />

“BIC is very active with the ACF because we recognize<br />

the importance of speaking directly with these key decision<br />

makers at the grassroots level,” says Judy Nelson, BIC<br />

chair and a cow-calf producer at Lundbreck, Alta. “Our<br />

presentations at seminars and conferences in key markets<br />

provide the opportunity to educate as well as network and<br />

develop relationships with potential partners.”<br />

Since July 2006, BIC has presented to thousands of<br />

local American chefs over the course of more than<br />

25 ACF national, regional and chapter events. These<br />

events are integral to BIC’s objectives of working with<br />

the ACF chapters to establish a better understanding of<br />

the Canadian beef quality attributes with chef members<br />

and to connect with local distributors to seek additional<br />

volume opportunities in these key markets.<br />

“The American Culinary Federation appreciates the<br />

expertise and unrivalled insight our sponsors bring to<br />

our annual events series,” says Michael Ty, ACF national<br />

president. “The Beef Information Centre is a recognized<br />

leader in the industry, and their presentations educate our<br />

chefs about beef trends. Then, in turn, our chefs put that<br />

knowledge into action in their dining establishments.”<br />

At the ACF National Convention in August, BIC<br />

and well-known Canadian Chef Michael Allemeier<br />

presented an hour-long seminar on Canadian beef, and<br />

demonstrated some fantastic new beef recipes created<br />

just for the event. The seminar left ACF members with a<br />

strong understanding of Canadian beef and key resources<br />

to promote Canadian beef within the foodservice<br />

industry. ACF continues to invite BIC to present at their<br />

national and regional events, recognizing the value of this<br />

information to their members.<br />

- Beef Information Centre (www.beefinfo.org)<br />

meatbusiness.ca<br />

September/October 2010 Canadian Meat Business 17

| Assembly Line |<br />

Assembly Line is an opportunity for companies to feature new products for the meat<br />

producing, processing, packaging and distribution industry. To include information about your<br />

new product e-mail alan@meatbusiness.ca.<br />

EasyPeelPoint a revolutionary opening aid<br />

for sealed trays<br />

Around 60 per cent of today’s<br />

fresh meat is sold pre-packed<br />

at retail. The case-ready tray,<br />

often 190 x 144 mm in size, has<br />

become an established standard,<br />

to which many logistical processes<br />

have been tuned. However, these<br />

hermetically closed packs often<br />

feature a disadvantage: the top<br />

film cannot be removed easily.<br />

Only too often, consumers need to use auxiliary tools,<br />

such as scissors or a knife, to attain the contents of the<br />

pack.<br />

By introducing an exceptionally consumer-friendly<br />

opening aid, SEALPAC makes the use of additional tools<br />

redundant. With its revolutionary EasyPeelPoint system,<br />

sealed trays can now be opened without effort.<br />

With EasyPeelPoint, the peel corner within the contours<br />

of the tray. This is how it works: the top film of the pack<br />

is pressed into a round cavity in one of the tray’s corners<br />

and is thus released from the sealing edge. The system<br />

convinces due to its natural feel: the peel corner can easily<br />

be gripped, after which the top film is removed from the<br />

tray with minimum effort.<br />

To guarantee an efficient production process, the trays<br />

are equipped with two opening points that are positioned<br />

diagonally opposite each other. This makes it irrelevant<br />

in which way the trays are placed on the in-feed conveyor,<br />

thus preventing costly errors due to rotation of the trays.<br />

Also in transport and storage, the system proves its<br />

added value. EasyPeelPoint can be applied on every<br />

standard packaging format and does not intervene<br />

with the existing logistical chain. It is feasible on all<br />

common SEALPAC traysealers and toolings, without<br />

demanding costly changes to existing formats. As a result,<br />

EasyPeelPoint complies with every demand towards a userfriendly<br />

and modern opening aid.<br />

(Please note: in the last issue of CMB a photo of the<br />

EasyPeelPoint system was mistakenly included with an entry on<br />

SEALPAC’s TenderPac meat packaging solution – our apologies<br />

for any confusion this may have caused.)<br />

sealpacinternational.com<br />

Metal detection system for<br />

food industry protects both<br />

equipment and reputation<br />

The new<br />

SANICON<br />

high<br />

performance<br />

metal<br />

detection<br />

system<br />

manufactured<br />

by Niagara,<br />

New Yorkbased<br />

S+S Inspection Inc. in Niagara<br />

N.Y. is designed to meet the needs<br />

of the domestic food industry for<br />

goods-in, in-process and end of line<br />

applications. Units with standard<br />

size aperture are available for quick<br />

delivery.<br />

The risk of foreign body<br />

contamination is ever present in<br />

all manufacturing activities but<br />

it is in the food industry that the<br />

risk must be minimized, if not<br />

eliminated entirely, if productivity<br />

and profitability are to be optimized.<br />

Inspection of the packaged, finished<br />

product is almost universal to avoid<br />

any contaminated product reaching<br />

18 Canadian Meat Business September/October 2010 meatbusiness.ca

the end consumer. There is equally good reason for<br />

similar inspection of incoming ingredients to minimize<br />

the amount of finished product that has to be rejected<br />

and eliminate the risk of introducing potentially<br />

machine-damaging materials into the production<br />

process.<br />

At the heart of the SANICON system is an advanced<br />

detection coil technology using multi-frequency, twochannel<br />

techniques to achieve the best sensitivity to<br />

all types of metals and the smallest possible metal-free<br />

zone for easy integration with existing production lines.<br />

The Genius+ control unit using digital signal<br />

processing and quartz stabilized search frequencies<br />

combined with microprocessor control allows precise<br />

matching to the demands of specific applications. The<br />

standard control unit may be configured to match over<br />

200 standard aperture sizes. Self-monitoring, autobalancing,<br />

and temperature compensation are standard<br />

as are product effect compensation with auto-learn.<br />

Non-volatile memory is used to store multiple product<br />

specifications to simplify product changeover and all<br />

machine parameters are password protected. An EMC<br />

filter is used to suppress external electromagnetic<br />

interference.<br />

A range of coil aperture size and belt width in<br />

both dry and wet area types offers IFS and HACCP<br />

compliance. All SANICON configurations can be fitted<br />

with a wide variety of separation systems to match<br />

specific operational requirements.<br />

sesotec-usa.com<br />

Automatic Hog Splitter provides<br />

perfectly split carcasses<br />

Jarvis’ new Automatic Hog<br />

Splitter, incorporating the latest,<br />

patented technology, perfectly<br />

splits up to 650 hogs per hour,<br />

in one operation, with uniform<br />

featherbone division – regardless<br />

of size or weight.<br />

Other features include<br />

customized PLC programs<br />

to handle individual plant<br />

processing requirements, a variable speed cutting head,<br />

and a unique Jarvis manufactured blade providing clean<br />

cuts with minimum saw dust and bone splinters. This<br />

rugged, stainless steel constructed machine provides<br />

higher production rates (including an increase in<br />

specialty products), cleaner cuts, easier spinal cord<br />

removal, reduced labour costs and faster line operations.<br />

Perfectly split carcasses have less loin damage, and also<br />

provide more bones being sent to a plant’s meat recovery<br />

system.<br />

The company has 28 Automatic Hog Splitters operating<br />

in the United States and Europe.<br />

Jarvis Products provides free customer service and<br />

training.<br />

jarviscanada.com<br />

| Assembly Line |

| Cross Countr y News |<br />

British Cloumbia<br />

Restaurants hit hard by HST: CRFA survey<br />

According to the Canadian Restaurant and<br />

Foodservices Association (CRFA), restaurants in British<br />

Columbia experienced a 10 per cent sales drop since the<br />

implementation of the harmonized sales tax (HST).<br />

“There’s no question the HST is hurting B.C. restaurants of<br />

all types, from fine dining to take-out,” CRFA president and<br />

CEO Garth Whyte said in a release. “On behalf of our members,<br />

we will continue to press premier Gordon Campbell for action.<br />

With numbers like these, we urgently need government to work<br />

with us to mitigate the negative impact of tax harmonization.”<br />

A province-wide survey by the CRFA found that:<br />

• only three per cent of respondents report the HST is having<br />

a positive impact on their business;<br />

• 72 per cent say the HST is having a negative impact;<br />

• 53 per cent say their customers are spending less;<br />

• 56 per cent have fewer customers;<br />

• 47 per cent have been forced to cut back on staff/staff<br />

hours to adjust to the HST; and<br />

• 26 per cent have had to offer more deals and promotions to<br />

mitigate the HST fallout.<br />

Since HST was first announced over a year ago, the CRFA<br />

has warned government that the new tax would result in<br />

significantly lower sales for B.C.’s fourth-largest private-sector<br />

employer.<br />

The CRFA survey was conducted online between July 26 and<br />

31, 2010. The findings represent 802 B.C. restaurants.<br />

Saskatchewan<br />

Ag council names new directors<br />

The Agriculture Council of Saskatchewan (ACS) announced<br />

three new members to its board of directors at its annual<br />

general meeting in June.<br />

ACS industry members, who represent all facets of<br />

Saskatchewan's agriculture and agri-food sector, welcomed<br />

the following new directors: Joy Smith, representing the<br />

Saskatchewan Egg Producers; Tim Wiens of the Saskatchewan<br />

Canola Development Commission; and Dan Prefontaine of the<br />

Saskatchewan Food Industry Development Centre. The new<br />

directors will join the newly elected executive which includes<br />

chair Neil Ketilson, of the Saskatchewan Pork Development<br />

Board, vice-chair Allen Kuhlmann of the Saskatchewan Flax<br />

Development Commission and secretary/treasurer Jason Dean<br />

of the Saskatchewan Cattle Feeders Association. Kirk Flaman of<br />

the Saskatchewan Seed Potato Growers Association, and Darrell<br />

Schneider of the Saskatchewan Food Processors Association<br />

remain on the ACS Board.<br />

ACS also paid tribute to three retiring board<br />

members at the AGM: Valerie Pearson of the<br />

Saskatchewan 4-H Council, who served on<br />

the board since 2004; Murray Purcell of the<br />

Saskatchewan Pulse Growers, first elected to<br />

the Board in 2003; and Bob Morgan, who<br />

represented the POS Pilot Plant Corporation<br />

and has served on the board since 2008.<br />

Manitoba<br />

New Manitoba building code<br />

offers increased fire protection to<br />

farms<br />

The Manitoba Government announced it will<br />

strengthen the building code for agriculture<br />

buildings to make them safer and offer increased<br />

fire protection to livestock and property.<br />

This year a number of fires caused millions<br />

of dollars in damages to large animal farming<br />

facilities in the province. On May 3 a blaze at<br />

a dairy farm outside of La Broquerie killed 450<br />

cows, causing $8.5 million in damage; a fire<br />

estimated at about $6 million at a southeastern<br />

Manitoba farm killed up to 7,500 hogs on May<br />

7, also in La Broquerie; on May 19 a chicken<br />

farm just outside of Steinbach was destroyed in<br />

a fire estimated at $1 million; and on June 23 a<br />

hog barn located approximately 100 kilometres<br />

southwest of Winnipeg was destroyed in a fire,<br />

just days after RCMP officers in the area began<br />

investigating the facility for possible animal<br />

cruelty.<br />

The new Farm Building Code includes the<br />

20 Canadian Meat Business September/October 2010 meatbusiness.ca

| Cross Countr y News |<br />

following requirements:<br />

• attic spaces must have fire stops every 300 square metres;<br />

• fire alarm systems are to be installed in all farm buildings<br />

covered under the code;<br />

• travel distance to an exit must be less than 30 metres in all<br />

buildings; and<br />

• all new buildings and major renovations must be certified by<br />

a structural engineer.<br />

Before these changes, the Buildings and Mobile Homes Act<br />

excluded all farm buildings, with the exception of dwellings,<br />

from the requirements of the Manitoba Building Code. The<br />

changes mean all farm buildings more than 600 square metres,<br />

built after the legislation takes effect Nov. 1, must comply with<br />

the Farm Building Code.<br />

The changes will only affect new construction or buildings<br />

undergoing extensive renovation and there will be some<br />

flexibility within the regulations to allow for the construction<br />

to meet the goal of fire safety, the release said. Because of the<br />

variety of building designs, the codes will allow for equivalencies<br />

that will be reviewed by the Manitoba Farm Building Code<br />

Committee under the Office of the Fire Commissioner. Having<br />

codes in place will also set a standard, which will make it easier<br />

for producers to get insurance, the minister added.<br />

Ontario<br />

Province funds upgrades at Conestoga Meat<br />

Packers plant<br />

The Province of Ontario announced it will contribute $350,000<br />

in funding for upgrades to pork processor Conestoga Meat<br />

Packers’ plant in Breslau, Ont.<br />

The company is making improvements<br />

to the plant to increase its productivity and<br />

enhance its competitiveness, including<br />

new deboning technologies and a better<br />

product-packaging system.<br />

According to a release from the Ontario<br />

government, these improvements will<br />

retain 350 existing jobs, create as many<br />

as 40 new positions, provide specialized<br />

training for employees, and bolster export<br />

activity.<br />

“Conestoga Meat Packers is a vital<br />

contributor to our province’s agri-food<br />

sector and our workforce,” provincial<br />

agriculture minister Carol Mitchell said<br />

in the release. “This investment will help<br />

them respond to the growing demand for<br />

Ontario pork at home and abroad.”<br />

According to the CRFA:<br />

• the foodservice industry is the third largest employer in the<br />

province, with nearly 250,000 employees – more than finance<br />

and insurance, agriculture and forestry combined;<br />

• foodservice provides jobs for nearly one in five Quebec youth<br />

– which equals almost 100,000 young people;<br />

• with more than 20,500 establishments, the restaurant industry<br />

is a key element of the province’s social and economic fabric,<br />

creating jobs and investment across communities.<br />

New Brunswick<br />

Restaurant industry to hit $1B in sales<br />

This year, New Brunswick’s commercial foodservice industry<br />

will hit $1 billion in sales, the Canadian Restaurant and<br />

Foodservices Association (CRFA) announced.<br />

According to the CRFA, the restaurant industry is one of<br />

the province’s largest private-sector employers, with more<br />

than 24,000 direct employees – more than farming, fishing,<br />

forestry and mining combined. The CRFA also noted:<br />

• foodservice provides nearly one in five jobs for young<br />

people under the age of 25;<br />

• with more than 1,600 commercial establishments, the<br />

restaurant industry is a core part of the province’s social<br />

and economic fabric, generating jobs and investment<br />

across communities;<br />

• the restaurant industry supports and promotes local cuisine<br />

and agriculture and is a major buyer of chicken, dairy,<br />

seafood, potatoes and emerging crops such as cranberries<br />

and blueberries.<br />

Quebec<br />

CRFA celebrates provine’s $10-<br />

billion milestone<br />

According to the Canadian Restaurant<br />

and Foodservices Association (CRFA),<br />

Quebec’s commercial foodservice industry<br />

is poised to reach $10 billion in sales this<br />

year.<br />

meatbusiness.ca<br />

September/October 2010 Canadian Meat Business 21

Early vs. LateCalving<br />

The effect of spring or summer born calves on a farmer’s bottom line.<br />

By Debbie Lockrey-Wessel<br />

M<br />

any factors affect cattle<br />

performance and impact a<br />

farmer’s bottom line. We often<br />

think of things like weather and feed,<br />

and how much a calf gains before going<br />

to market. Now scientists are discovering<br />

that the season in which a calf is born<br />

can impact the bottom line as well.<br />

To help farmers in Western<br />

Canada make an informed decision,<br />

a collaborative project is underway<br />

involving scientists from Agriculture<br />

and Agri-Food Canada (AAFC) and<br />

the Western Beef Development Centre<br />

(WBDC). The project will be completed early in 2011 and<br />

involves Dr. Shannon Scott and Dr. Hushton Block of AAFC’s<br />

Brandon Research Centre in Manitoba, Dr. Alan Iwaasa at<br />

AAFC’s Semiarid Prairie Agricultural Research Centre in<br />

Swift Current, Sask., and Dr. Bart Lardner at the WBDC in<br />

Lanigan, Sask. These scientists have joined forces to examine<br />

how early versus late calving under western Canadian<br />

conditions can affect the economics,<br />

labour requirements and energy use<br />

efficiency of cow-calf production.<br />

In Saskatchewan, late calving is not a<br />

very common practice – only about 10-<br />

15 per cent of producers are currently<br />

calving in the summer. However, some<br />

producers may want to move their calving<br />

season later to take advantage of reduced<br />

labour requirements or may want to<br />

match the cow’s feed requirements with<br />

the available feed resources.<br />

“We’re trying to look at the impact<br />

of matching the feed resources that<br />

are available at different times of the year with the cow’s<br />

nutritional requirements,” explains Dr. Iwaasa. “Beef-cow<br />

feeding is 60 to 70 per cent of the total cost of production<br />

and the cow’s highest nutrient demand is 30 to 90 days after<br />

calving. How the cow takes in nutrients and processes those<br />

nutrients will also impact the calf’s growth. What we’re<br />

trying to do with a later calving season is work with Mother<br />

Nature.”<br />

“The May and June period is when pastures are starting<br />

to grow and you have the most forage production in the<br />

pastures,” he adds. “And that is also the same time when a<br />

cow has the greatest nutrient needs. Forages are used most<br />

efficiently when the nutrient requirements of the cow are<br />

matched with the nutrients available from forages. So we’re<br />

trying to just match those up.”<br />

While similar studies have been conducted in the United<br />

States, in places like Nebraska and Montana, and under<br />

Canadian conditions in Ontario, the conditions in Western<br />

Canada are quite different.<br />

“In Western Canada, where the bulk of the Canadian cowcalf<br />

herd is located, the climatic conditions, the types of<br />

feed that we have, and the marketing systems are all quite<br />

different,” explains Dr. Lardner. “We wanted to be able to<br />

provide the information to beef producers here who may<br />

be thinking about making a transition from early calving<br />

system, which would be somewhere around March and April,<br />

to a later calving season, which would be more like May and<br />

June.”<br />

Previous Canadian studies from Alberta showed no<br />

difference in calving and weaning rates, but lower birth<br />

weights for the early calving group compared with the late<br />

calving group, while studies from Ontario show heavier<br />

cow weights for the late calving group. Since Manitoba and<br />

Saskatchewan are physically located in the middle of the<br />

two Canadian studies, scientists needed to determine if the<br />

results from the other Canadian studies are applicable in<br />

these prairie provinces.<br />

To determine this, Drs. Iwaasa, Scott and Lardner<br />

launched a three-year study, beginning in January 2007<br />

with the first early calving season and ending in December<br />

22 Canadian Meat Business September/October 2010 meatbusiness.ca

2009 with the last weaning date for the<br />

late-calving group, which involved two<br />

cow herds calving at different times at<br />

each of the research sites in Brandon,<br />

Swift Current and Lanigan. There the<br />

scientists followed the cow herds right<br />

from calving through to the time that<br />

the calves were weaned or separated<br />

from their mothers. After the calves<br />

were weaned, the male calves, or steers,<br />

were brought from all three sites to<br />

the Brandon Research Centre for the<br />

next phase of production, the finishing<br />

phase.<br />

During the finishing phase, the steers<br />

were split into two different feeding<br />

programs: a rapid (conventional)<br />

finishing with a short backgrounding<br />

period before high-grain feedlot<br />

finishing; or, a slow finishing system<br />

with a longer backgrounding period,<br />

pasture, swath grazing, and then highgrain<br />

feedlot finishing.<br />

“We wanted to be<br />

able to provide the<br />

information to beef<br />

producers here who may<br />

be thinking about making<br />

a transition from early<br />

calving system…to a<br />

later calving season…”<br />

– Dr. Bart Lardner, Western Beef<br />

Development Centre<br />

“This allows us to look at different<br />

opportunities for marketing those<br />

steers at different times of the year<br />

and varying the input necessary to<br />

get the animals ready for slaughter,”<br />

explains Dr. Scott. “Right now higher<br />

grain prices can increase the feed costs<br />

compared to lower forage costs. You<br />

can also weigh off the costs of the feed<br />

against the length of time that it’s going<br />

to take to finish them. Our colleagues<br />

at the University of Manitoba, Ms. Tanis<br />

Sirski and Dr. Derek Brewin and at<br />

AAFC Brandon and Summerland, Drs.<br />

Mohammad Khakbazan and Richard<br />

Carew, are looking at the economics<br />

of the whole system so we can provide<br />

the information to producers in terms<br />

of the different variables that we’ve<br />

examined and the impact they’ve had<br />

on profitability.”<br />

Preliminary results indicate that calf<br />

growth rate was significantly affected by<br />

location (Swift Current versus Lanigan<br />

and Brandon) and calving system<br />

(spring – early versus summer – late).<br />

Calf performance (average daily gain)<br />