failsafe springpowered failsafe

SI-1-Q

SI-1-Q

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

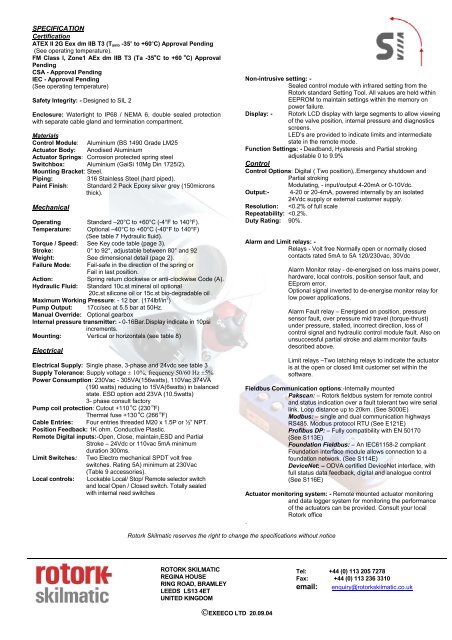

SPECIFICATION<br />

Certification<br />

ATEX II 2G Eex dm IIB T3 (T amb -35° to +60°C) Approval Pending<br />

(See operating temperature).<br />

FM Class I, Zone1 AEx dm IIB T3 (Ta -35 o C to +60 o C) Approval<br />

Pending<br />

CSA - Approval Pending<br />

IEC - Approval Pending<br />

(See operating temperature)<br />

Safety Integrity: - Designed to SIL 2<br />

Enclosure: Watertight to IP68 / NEMA 6, double sealed protection<br />

with separate cable gland and termination compartment.<br />

Materials<br />

Control Module: Aluminium (BS 1490 Grade LM25<br />

Actuator Body: Anodised Aluminium<br />

Actuator Springs: Corrosion protected spring steel<br />

Switchbox: Aluminium (GaiSi 10Mg Din 1725/2).<br />

Mounting Bracket: Steel.<br />

Piping:<br />

316 Stainless Steel (hard piped).<br />

Paint Finish: Standard 2 Pack Epoxy silver grey (150microns<br />

thick).<br />

Mechanical<br />

Operating<br />

Temperature:<br />

Standard –20°C to +60°C (-4°F to 140°F).<br />

Optional –40°C to +60°C (-40°F to 140°F)<br />

(See table 7 Hydraulic fluid).<br />

Torque / Speed: See Key code table (page 3).<br />

Stroke: 0° to 92°, adjustable between 80° and 92<br />

Weight: See dimensional detail (page 2).<br />

Failure Mode:<br />

Action:<br />

Hydraulic Fluid:<br />

Fail-safe in the direction of the spring or<br />

Fail in last position.<br />

Spring return clockwise or anti-clockwise Code (A).<br />

Standard 10c.st mineral oil optional<br />

20c.st silicone oil or 15c.st bio-degradable oil<br />

Maximum Working Pressure: - 12 bar. (174lbf/in 2 )<br />

Pump Output: 17cc/sec at 5.5 bar at 50Hz.<br />

Manual Override: Optional gearbox<br />

Internal pressure transmitter: - 0-16Bar.Display indicate in 10psi<br />

increments.<br />

Mounting: Vertical or horizontals (see table 8)<br />

Electrical<br />

Electrical Supply: Single phase, 3-phase and 24vdc see table 3<br />

Supply Tolerance: Supply voltage ± 10%, frequency 50/60 Hz ±5%<br />

Power Consumption: 230Vac - 305VA(156watts), 110Vac 374VA<br />

(190 watts) reducing to 15VA(6watts) in balanced<br />

state. ESD option add 23VA (10.5watts)<br />

3- phase consult factory<br />

Pump coil protection: Cutout +110 o C (230 o F)<br />

Thermal fuse +130 o C (266 o F)<br />

Cable Entries: Four entries threaded M20 x 1.5P or ½” NPT.<br />

Position Feedback: 1K ohm. Conductive Plastic.<br />

Remote Digital inputs:-Open, Close, maintain,ESD and Partial<br />

Stroke – 24Vdc or 110vac 5mA minimum<br />

duration 300ms.<br />

Limit Switches: Two Electro mechanical SPDT volt free<br />

switches. Rating 5A) minimum at 230Vac<br />

(Table 9 accessories).<br />

Local controls: Lockable Local/ Stop/ Remote selector switch<br />

and local Open / Closed switch. Totally sealed<br />

with internal reed switches<br />

Non-intrusive setting: -<br />

Sealed control module with infrared setting from the<br />

Rotork standard Setting Tool. All values are held within<br />

EEPROM to maintain settings within the memory on<br />

power failure.<br />

Display: -<br />

Rotork LCD display with large segments to allow viewing<br />

of the valve position, internal pressure and diagnostics<br />

screens.<br />

LED’s are provided to indicate limits and intermediate<br />

state in the remote mode.<br />

Function Settings: - Deadband, Hysteresis and Partial stroking<br />

adjustable 0 to 9.9%<br />

Control<br />

Control Options: Digital ( Two position),.Emergency shutdown and<br />

Partial stroking<br />

Modulating, - input/output 4-20mA or 0-10Vdc.<br />

Output:- 4-20 or 20-4mA, powered internally by an isolated<br />

24Vdc supply or external customer supply.<br />

Resolution:<br />

Repeatability: