failsafe springpowered failsafe

SI-1-Q

SI-1-Q

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PRODUCT SPECIFICATION<br />

GENERAL DESCRIPTION<br />

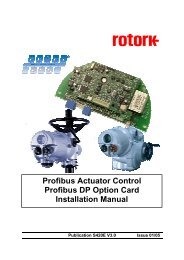

Rotork Skilmatic SI intelligent actuators offer a unique<br />

combination of the renowned features of Rotork actuation,<br />

such as the double sealing system and non-intrusive<br />

infrared commissioning capability, with the benefits of control<br />

and safety from Skilmatic range.<br />

SI-1-Q<br />

ELECTRIC QUARTER TURN<br />

ACTUATOR<br />

The SI-1-Q are compact and robust electrically operated <strong>failsafe</strong><br />

spring return quarter turn actuators. The actuators are<br />

designed to provide a 90-degree travel for two-position, ESD<br />

or modulating applications. The actuators are suitable for all<br />

types of ¼ turn valves and are supplied with a mounting<br />

flange to ISO 5211<br />

The SI-1-Q is watertight and dustight to IP68 / NEMA6 with<br />

the Rotork double seal system with separated termination<br />

and cable gland compartment. The actuators are also<br />

available certified explosionproof for hazardous area<br />

applications.<br />

Consisting of a self-contained Electro-hydraulic control<br />

module and Scotch yoke spring return drive. The actuators<br />

combine the simplicity of electrical operation, with the<br />

precision of hydraulic control, and reliability of <strong>springpowered</strong><br />

fail-safe action. The spring return mechanism<br />

provides the most reliable means of positioning a valve to<br />

the safe condition and can be provided as fail-safe close,<br />

open or lock in last position on power or signal failure. The<br />

actuators are available as spring return clockwise or<br />

anticlockwise, with end of spring torque from 70Nm<br />

(620inlbs) to 472 Nm (4177 inlbs)<br />

The actuators can be programmed with the infrared setting<br />

tool to accept an analogue or digital input, with ESD and<br />

partial stroking or network cards options. A wide range of<br />

functions can also be set through the setting tool such as<br />

zero & span limits, deadband, hysteresis, slow band, and<br />

partial stroke position. Optional internal fieldbus<br />

communication boards are also available for the Rotork<br />

Pakscan, DeviceNet, Profibus, Foundation fieldbus and<br />

Modbus digital control systems.<br />

Specifically designed for on/off duties particularly where <strong>failsafe</strong><br />

ESD action is required, lockable local controls are<br />

provided as standard and on safety critical applications the<br />

local selection can be overridden depending on the actuator<br />

configuration. Electro-mechanical ends of stroke limit<br />

switches are offered for safety critical applications<br />

Operating from a standard single phase, three phase or<br />

24Vdc supply the actuators are also ideal for modulating<br />

control applications, the Control module provides a pulsed<br />

hydraulic signal to accurately position the spring-opposed<br />

cylinder. Resulting in accurately positioning a valve with a<br />

resolution better than 0.2 of a degree.<br />

Manual override gearbox is available on all sizes.<br />

FEATURES<br />

• Self-contained electrically operated with internal low<br />

pressure Electro hydraulic control module.<br />

• Spring return, Fail - Safe or lock in position<br />

• Dual redundant hydraulic oscillating pumps.<br />

• Single phase, Three phase and dc power supply<br />

• Non- Intrusive commissioning and configuration<br />

• Local LCD display – for position indication, internal<br />

pressure and fault diagnostics.<br />

• Local controls - Lockable Local/ Stop/ Remote selector<br />

switch with local Open / Closed switch.<br />

• Modulating control - 4- 20 mA input & output with a<br />

resolution < 0.2 Deg.<br />

• Digital Control – ESD and partial stroking capabilities.<br />

• Output relays for Monitoring / Fault alarms and Open /<br />

Closed limits<br />

• Optional Fieldbus communications<br />

• Watertight & Explosionproof<br />

• Double sealed – with separate terminal compartment.

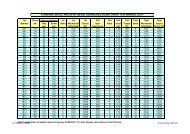

SI-1-Q DIMENSION & MOUNTING DETAILS<br />

334<br />

394<br />

A<br />

B C<br />

436<br />

178<br />

G<br />

OE<br />

226<br />

D<br />

GEARBOX OPTIONAL<br />

F<br />

Dimensions<br />

Actuator Code<br />

SI-1-Q31 /<br />

SI-1-QA31<br />

SI- 1-Q41<br />

SI- 1-QA41<br />

SI-1-Q51<br />

SI-1-QA51<br />

SI-1-Q60<br />

SI-1-QA60<br />

SI-1-Q61<br />

SI-1-QA61<br />

A 374 374 394 394 394<br />

B 65 200 90 285 285<br />

C 200 200 285 285 285<br />

D 269 269 292 292 292<br />

ØE 400 400 400 600 600<br />

F 272 272 292 312 312<br />

G 119 119 131 131 131<br />

L 17 22 22 27 27<br />

M 30 30 30 37 37<br />

P 22.2 28.2 28.2 36.2 36.2<br />

ØV 70 70 102 102 102<br />

ØV1 102 102 125 125 125<br />

W M8x14 M8x14 M10x17 M10x17 M10x17<br />

W1 M10x17 M10x17 M12x21 M12x21 M12x21<br />

Weight (Kg)<br />

Weight With<br />

Gearbox (Kg)<br />

Note: - All 3-Phase actuators will have an extended Control Module. Dimension 436 mm will change to 491 mm<br />

OV<br />

+0.13<br />

-0.00<br />

x M DEEP<br />

OV1<br />

L P +0.5<br />

- 0.0<br />

Flange & Square Drive Details<br />

to ISO 5211<br />

Page 2 of 4

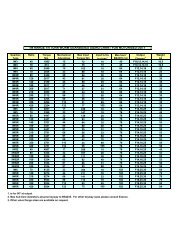

KEY MODEL CODE<br />

SI-1-Q50 - 0 0 2 1 - 0 0 0 - A - A<br />

Table 1 - Failure Mode<br />

Table 2 - Return speed options<br />

Table 3 - Supply voltage<br />

Table 4 - Control option<br />

Table 5 – Certification<br />

Table 6 - Cable entries<br />

Table 7 - Hydraulic fluid<br />

Table 8 – Mounting<br />

Table 9 - Accessories<br />

KEY MODEL CODE – ACTUATOR SIZE<br />

Code Torque Nm (Inlbs) Stroke speed (Seconds)<br />

Spring Return Hydraulic stroke Spring return<br />

clockwise<br />

Anticlockwise<br />

Start Mid Finish Start Mid Finish<br />

Hydrauli<br />

c<br />

Stroke<br />

Speed<br />

Spring Return Speed<br />

(See table 2)<br />

Std<br />

Single<br />

Std<br />

Dual<br />

ESD<br />

SI-1-Q31 SI-1-QA31 108 (956) 42 (372) 56 (495) 101 (894) 50 (442) 70 (620) 15 5 3 1.5<br />

SI-1-Q41 SI-1-QA41 221 (1956) 86 (761) 115 (1018) 206 (1823) 102 (903) 143 (1265) 30 9 5 2<br />

SI-1-Q51 SI-1-QA51 324 (2867) 125 (1106) 166 (1469) 330 (2920) 164 (1451) 233 (2062) 50 18 10 4<br />

SI-1-Q60 SI-1-QA60 580 (5133) 250 (2212) 310 (2743) 490 (4336) 240 (2124) 333 (2947) 100 33 18 6<br />

SI-1-Q61 SI-1-QA61 658 (5823) 252 (2230) 337 (2982) 671 (5938) 334 (2956) 472 (4177) 100 33 18 6<br />

TABLE 1 - FAILURE MODE<br />

CODE DESCRIPTION<br />

0 Fail- Safe (to release pressure)<br />

1 Fail in Position (lock pressure)<br />

2 Fail- Safe without pressure monitoring<br />

3 Fail in Position without pressure monitoring<br />

TABLE 2 – SPRING RETURN SPEED<br />

CODE DESCRIPTION<br />

0 Standard single internal solenoid.<br />

1 Std single internal solenoid & ESD<br />

2 Std dual internal solenoid<br />

3 Std dual internal solenoid & ESD<br />

4 Slow acting single internal solenoid<br />

TABLE 3 - SUPPLY VOLTAGE<br />

CODE DESCRIPTION<br />

0 Single phase 110V ac 50/60 Hz ± 10%<br />

1 Single phase 120V ac 50/60 Hz ± 10%<br />

2 Single phase 230V ac 50/60 Hz ± 10%<br />

3 Three phase 380V ac 50/60 Hz ± 10%<br />

4 Three phase 415V ac 50/60 Hz ± 10%<br />

5 Three phase 440V ac 50/60 Hz ± 10%<br />

6 Three phase 460V ac 50/60 Hz ± 10%<br />

7 Three phase 480V ac 50/60 Hz ± 10%<br />

8<br />

9 24V dc<br />

TABLE 4 - CONTROL<br />

CODE<br />

DESCRIPTION<br />

0 Digital control<br />

1 Analogue controls<br />

2 Pakscan<br />

3 Pakscan- analogue input<br />

4 Modbus single channel<br />

5 Modbus dual channel<br />

6 Profibus dual channel<br />

7 DeviceNet<br />

8 Foundation fieldbus<br />

9 Profibus single channel<br />

TABLE 5 –CERTIFICATIONS<br />

CODE DESCRIPTION<br />

0 WT – Watertight IP68<br />

1 ATEX ( European – Hazardous area)<br />

2 IEC (International – Hazardous area)<br />

3 FM ( US – Hazardous area)<br />

4 CSA ( Canada- Hazardous area)<br />

TABLE 6 – CABLE ENTRIES<br />

CODE DESCRIPTION<br />

0 M20 x 1.5P<br />

1 ½” NPT<br />

TABLE 7 – HYDRAULIC FLUID<br />

CODE DESCRIPTION<br />

0 Std 10 cSt mineral fluid<br />

1 20 cSt silicone fluid (low temperature –15 to -35 o C)<br />

2 15 cSt bio-degradable fluid<br />

TABLE 8 - MOUNTING<br />

CODE<br />

A<br />

B<br />

C<br />

DESCRIPTION<br />

Vertical stem above valve<br />

Vertical stem below-valve<br />

Valve stem horizontal<br />

TABLE 9 – ACCESSORIES<br />

CODE<br />

A<br />

B<br />

DESCRIPTION<br />

None<br />

Manual override<br />

NOTE:<br />

Stroke speed is typical for all actuators with no load at 20 o C ±10%<br />

Non standard torque’s are available on requests.<br />

All actuators are available with 4-20 or 20-4mA output, powered<br />

internally by an isolated 24Vdc supply or external customer supply.<br />

Page 3 of 4

SPECIFICATION<br />

Certification<br />

ATEX II 2G Eex dm IIB T3 (T amb -35° to +60°C) Approval Pending<br />

(See operating temperature).<br />

FM Class I, Zone1 AEx dm IIB T3 (Ta -35 o C to +60 o C) Approval<br />

Pending<br />

CSA - Approval Pending<br />

IEC - Approval Pending<br />

(See operating temperature)<br />

Safety Integrity: - Designed to SIL 2<br />

Enclosure: Watertight to IP68 / NEMA 6, double sealed protection<br />

with separate cable gland and termination compartment.<br />

Materials<br />

Control Module: Aluminium (BS 1490 Grade LM25<br />

Actuator Body: Anodised Aluminium<br />

Actuator Springs: Corrosion protected spring steel<br />

Switchbox: Aluminium (GaiSi 10Mg Din 1725/2).<br />

Mounting Bracket: Steel.<br />

Piping:<br />

316 Stainless Steel (hard piped).<br />

Paint Finish: Standard 2 Pack Epoxy silver grey (150microns<br />

thick).<br />

Mechanical<br />

Operating<br />

Temperature:<br />

Standard –20°C to +60°C (-4°F to 140°F).<br />

Optional –40°C to +60°C (-40°F to 140°F)<br />

(See table 7 Hydraulic fluid).<br />

Torque / Speed: See Key code table (page 3).<br />

Stroke: 0° to 92°, adjustable between 80° and 92<br />

Weight: See dimensional detail (page 2).<br />

Failure Mode:<br />

Action:<br />

Hydraulic Fluid:<br />

Fail-safe in the direction of the spring or<br />

Fail in last position.<br />

Spring return clockwise or anti-clockwise Code (A).<br />

Standard 10c.st mineral oil optional<br />

20c.st silicone oil or 15c.st bio-degradable oil<br />

Maximum Working Pressure: - 12 bar. (174lbf/in 2 )<br />

Pump Output: 17cc/sec at 5.5 bar at 50Hz.<br />

Manual Override: Optional gearbox<br />

Internal pressure transmitter: - 0-16Bar.Display indicate in 10psi<br />

increments.<br />

Mounting: Vertical or horizontals (see table 8)<br />

Electrical<br />

Electrical Supply: Single phase, 3-phase and 24vdc see table 3<br />

Supply Tolerance: Supply voltage ± 10%, frequency 50/60 Hz ±5%<br />

Power Consumption: 230Vac - 305VA(156watts), 110Vac 374VA<br />

(190 watts) reducing to 15VA(6watts) in balanced<br />

state. ESD option add 23VA (10.5watts)<br />

3- phase consult factory<br />

Pump coil protection: Cutout +110 o C (230 o F)<br />

Thermal fuse +130 o C (266 o F)<br />

Cable Entries: Four entries threaded M20 x 1.5P or ½” NPT.<br />

Position Feedback: 1K ohm. Conductive Plastic.<br />

Remote Digital inputs:-Open, Close, maintain,ESD and Partial<br />

Stroke – 24Vdc or 110vac 5mA minimum<br />

duration 300ms.<br />

Limit Switches: Two Electro mechanical SPDT volt free<br />

switches. Rating 5A) minimum at 230Vac<br />

(Table 9 accessories).<br />

Local controls: Lockable Local/ Stop/ Remote selector switch<br />

and local Open / Closed switch. Totally sealed<br />

with internal reed switches<br />

Non-intrusive setting: -<br />

Sealed control module with infrared setting from the<br />

Rotork standard Setting Tool. All values are held within<br />

EEPROM to maintain settings within the memory on<br />

power failure.<br />

Display: -<br />

Rotork LCD display with large segments to allow viewing<br />

of the valve position, internal pressure and diagnostics<br />

screens.<br />

LED’s are provided to indicate limits and intermediate<br />

state in the remote mode.<br />

Function Settings: - Deadband, Hysteresis and Partial stroking<br />

adjustable 0 to 9.9%<br />

Control<br />

Control Options: Digital ( Two position),.Emergency shutdown and<br />

Partial stroking<br />

Modulating, - input/output 4-20mA or 0-10Vdc.<br />

Output:- 4-20 or 20-4mA, powered internally by an isolated<br />

24Vdc supply or external customer supply.<br />

Resolution:<br />

Repeatability: