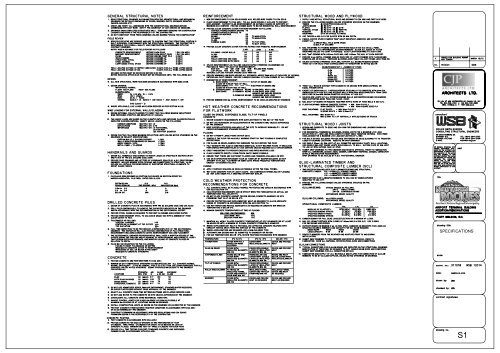

SPECIFICATIONS

Tender Documents.pdf - Northern Rockies Regional Municipality

Tender Documents.pdf - Northern Rockies Regional Municipality

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>SPECIFICATIONS</strong>

FOUNDATION<br />

PLAN<br />

1:50

ROOF FRAMING<br />

PLAN<br />

1:50

Geotechnical Assessment<br />

Airport Terminal Building Addition<br />

Fort Nelson Airport<br />

FORT NELSON, British Columbia<br />

File No.: FN321 27 February 2012<br />

Prepared By:<br />

Harder Associates Engineering Consulting Inc.<br />

P.O. Box 3055<br />

No. 7, 4916 - 50 th Avenue North<br />

Fort Nelson, British Columbia V0C 1R0<br />

Prepared For:<br />

Northern Rockies Regional Municipality<br />

C/O<br />

CJP Architects Ltd.<br />

301 - 6 th Street<br />

New Westminster, British Columbia<br />

V3L 3A7<br />

Distribution List:<br />

CJP Architects Ltd. - 3 Copies<br />

Harder Associates Engineering Consulting Inc. - 3 Copies<br />

NOTICE<br />

ACCESS TO INFORMATION ACT<br />

These documents and the information contained within them are the confidential property of Northern Rockies Regional Municipality<br />

and any disclosure of same is governed by the provisions of each of the applicable provincial or territorial Freedom of Information<br />

legislation, the Privacy Act (Canada) 1980-81-82-83, c.111, Sch. II ”2”, and the Access to Information Act (Canada) 1980-81-82-83,<br />

c.111, Sch. I”1”, as such legislation may be amended or replaced from time to time.

File No.: FN321<br />

Page i<br />

TABLE OF CONTENTS<br />

1.0 INTRODUCTION .................................................................................................... 1<br />

1.1 BACKGROUND .............................................................................................. 1<br />

1.2 OBJECTIVES .................................................................................................. 1<br />

2.0 REVIEW OF PREVIOUS REPORTS ........................................................................ 1<br />

3.0 FOUNDATION RECOMMENDATIONS ................................................................... 2<br />

3.1 SCREW PILES ................................................................................................ 2<br />

3.2 CAST-IN-PLACE CONCRETE PILES ............................................................... 4<br />

3.3 BASEMENT FOOTINGS .................................................................................. 7<br />

4.0 FLOOR RECOMMENDATIONS .............................................................................. 9<br />

4.1 GRADE SUPPORTED FLOORS ........................................................................ 9<br />

4.2 STRUCTURALLY SUPPORTED FLOORS ........................................................ 11<br />

5.0 SULPHATE ATTACK ........................................................................................... 12<br />

6.0 EARTHQUAKE DESIGN PARAMETERS .............................................................. 13<br />

7.0 CLOSURE ............................................................................................................ 14

File No.: FN321<br />

Page ii<br />

LIST OF TABLES<br />

TABLE 3.1: ULTIMATE SKIN FRICTION AND END BEARING RESISTANCE FOR CONCRETE PILES 5<br />

TABLE 3.2: ULTIMATE GEOTECHNICAL RESISTANCE ................................................................. 6<br />

TABLE 4.1: AGGREGATE GRADATIONS .................................................................................... 11<br />

TABLE 6.1: NATIONAL BUILDING CODE INTERPOLATED SEISMIC HAZARD VALUES ............... 14<br />

TABLE 6.2: BRITISH COLUMBIA BUILDING CODE - F A SITE COEFFICIENTS .............................. 14<br />

TABLE 6.3: BRITISH COLUMBIA BUILDING CODE - F V SITE COEFFICIENTS .............................. 14<br />

TABLE 6.4: DESIGN SPECTRAL ACCELERATION VALUES OF S(T) ............................................ 14<br />

APPENDIX A<br />

J.R. Paine & Associates Ltd. Geotechnical Investigation Report

File No.: FN321<br />

Page 1<br />

1.0 INTRODUCTION<br />

1.1 BACKGROUND<br />

Harder Associates Engineering Consulting Inc. (Harder Associates) was retained by<br />

CJP Architects Ltd. (CJP) on behalf of the Northern Rockies Regional Municipality<br />

(NRRM) to conduct a geotechnical assessment and provide foundation and floor<br />

recommendations, based on a previous report, for a washroom addition to the<br />

Terminal Building at the Fort Nelson Airport. The site is located approximately 7.5<br />

kilometres northeast of Fort Nelson, British Columbia.<br />

The proposed single storey addition, washroom facilities, proposed to be constructed<br />

on the north side of the existing Terminal Building, have a proposed footprint of 72.5<br />

m 2 . Due to the small footprint and possible temporary (a new terminal building is<br />

being discussed) nature of the addition, the client requested foundation and slab<br />

recommendations without performing a geotechnical investigation. Therefore, the<br />

recommendations provided in this report are based off a third party geotechnical<br />

investigation performed in 2004.<br />

Harder Associates cannot verify the authenticity of the third party report or that the<br />

subsurface soils in the proposed addition footprint will be similar to those<br />

encountered during the geotechnical investigation.<br />

1.2 OBJECTIVES<br />

The objectives of the geotechnical assessment were to:<br />

<br />

<br />

provide geotechnical recommendations for cast-in-place concrete piles,<br />

screw piles, and concrete footings; and,<br />

provide geotechnical recommendations for floating and structural floor<br />

slabs.<br />

2.0 REVIEW OF PREVIOUS REPORTS<br />

Harder Associates personnel reviewed a report provided by CJP personnel, written by<br />

J.R. Paine & Associates Ltd. titled “Geotechnical Investigation, Light Standard<br />

Supports, Fort Nelson Airport, Fort Nelson, B.C.”, dated April 2004, File No.

File No.: FN321<br />

Page 2<br />

GP6132-2. A brief summary of the information obtained from the referenced report<br />

is as follows:<br />

Three boreholes were drilled between the terminal building and apron on 05<br />

April 2004. The maximum depth of exploration was 9.5 m.<br />

<br />

<br />

Surficial topsoil and asphalt were encountered overlying silty sand and clay<br />

till. The clay till extended to the maximum exploration depth in all three<br />

boreholes.<br />

Seepage was encountered in boreholes BH04-1 and BH04-2 but no sloughing<br />

was encountered during drilling.<br />

The referenced report is included in Appendix A.<br />

3.0 FOUNDATION RECOMMENDATIONS<br />

There is more than one suitable option for the type of foundation system used<br />

however, most foundations systems mobilize their full support and behave<br />

differently. Therefore, the use of several different types of foundations systems to<br />

support the same structure is not recommended. It is recommended that the same<br />

type of foundation supporting the existing terminal building is used to support the<br />

proposed addition.<br />

3.1 SCREW PILES<br />

Lighter foundation loads may be supported by screw anchors. Frost jacking is not an<br />

issue for screw anchors; however, the helix plates/plates must be completely below<br />

the depth of frost penetration, estimated to be 2.5 m at this site.<br />

The desirable depth for screw anchors is 4.5 m. The design for screw anchor piles<br />

having a steel shaft diameter of 127 mm (5 inches) and a helix diameter of 457 mm<br />

(18 inches) is calculated using the following: 1<br />

h h u c h q 0.5 y <br />

<br />

1 Canadian Geotechnical Society, 2006. Canadian Foundation Engineering Manual 4 th<br />

Edition, p. 267.

File No.: FN321<br />

Page 3<br />

Where:<br />

h = Individual helix bearing capacity;<br />

h = Projected helix area (0.1514 m 2 );<br />

u = Undrained shear strength of the soil at helix (80 kPa);<br />

= Unit Weight of the soil (20 kN/m 3 );<br />

h = Depth to helical bearing plate (4.5 m);<br />

= Diameter of the helical plate (0.457 m); and,<br />

c , q y Bearing capacity factors for local shear conditions 2 (N c =31, N q =21,<br />

N y =10).<br />

Generally, across the site using an average undrained shear strength of 80 kPa, Q h =<br />

669 kN. The total capacity of the helical pile equals the bearing capacity of the soil<br />

applied to the individual helical plate(s) plus the skin friction of the shaft. Therefore,<br />

the total bearing capacity of the screw anchor with a shaft diameter exceeding 100<br />

mm is:<br />

Q f is calculated as:<br />

h f<br />

f s<br />

Where:<br />

= Diameter of the pile shaft (0.457 m);<br />

= Height from helix plate to top of soil in skin friction area (0.6 m and 1.9 m); and,<br />

F s = Skin friction of soil in h area (50 kPa and 54 kPa).<br />

Generally, across the site using an average undrained shear strength of 80 kPa, Q f =<br />

53 kN for a 4.5 m long screw pile.<br />

Using the above formula, the following outlines the bearing capacities:<br />

<br />

<br />

A single helix pile will have an ultimate load capacity of 722 kN;<br />

A double helix pile will have an allowable load capacity of 1171 kN;<br />

<br />

2 Das, Braja M., Principles of Foundation Engineering 6 th Edition, pg. 133. Values<br />

taken from Table 3.3.

File No.: FN321<br />

Page 4<br />

<br />

<br />

<br />

For double helix piles the minimal spacing between the helixes is three<br />

times the diameter of the largest helix (in this case 1.4 m);<br />

The minimal spacing between single helix screw piles is three times the<br />

diameter of the helix (in this case 1.4 m); and,<br />

The design for screw anchor piles having different dimensions than the one<br />

mentioned above can be provided on request.<br />

The factored geotechnical screw pile resistance is given as follows:<br />

ɸR n<br />

where:<br />

ɸ is the geotechnical resistance factors as follows:<br />

ɸ = 0.4 for axial compression piles; and,<br />

ɸ = 0.3 for axial tension (uplift) piles.<br />

Screw anchors may be installed in frozen soil. Screw anchors are a favourable<br />

foundation system for structures with lighter loads. These anchors are provided on a<br />

design-build basis. We recommend the anchor designs be prepared or reviewed by a<br />

qualified geotechnical engineer.<br />

3.2 CAST-IN-PLACE CONCRETE PILES<br />

Augered, cast-in-place concrete piles are an ideal system to support the proposed<br />

structure at this site.<br />

Our specific design criteria and recommendations for these foundation systems are as<br />

follows:<br />

1. Pile foundation loads may be supported on piles designed as straight shaft or end<br />

bearing cast-in-place concrete piles.<br />

2. Ultimate values for the design of skin friction and end bearing cast-in-place<br />

concrete piles are presented in Table 3.1:

File No.: FN321<br />

Page 5<br />

TABLE 3.1: ULTIMATE SKIN FRICTION AND END BEARING RESISTANCE FOR<br />

CONCRETE PILES<br />

Depth Below<br />

Existing<br />

Grade (m)<br />

0.0 to 2.0<br />

Soil Type<br />

Topsoil / Silty<br />

Sand<br />

End Bearing<br />

Resistance (kPa)<br />

Ultimate<br />

Skin Friction<br />

Resistance (kPa)<br />

-* 0<br />

2.0 to 2.6 Silty Sand -* 50<br />

Below 2.6 Clay Till 720 54<br />

*Not recommended<br />

The factored 3<br />

follows:<br />

geotechnical cast-in-place concrete pile resistance is given as<br />

ɸR n<br />

where:<br />

ɸ is the geotechnical resistance factor as follows:<br />

ɸ = 0.4, for axial compression piles; and,<br />

ɸ = 0.3, for axial tension (uplift) piles.<br />

R n is the ultimate geotechnical resistance and is determined as shown in Table<br />

3.2.<br />

<br />

3 Canadian Geotechnical Society, 2006. Canadian Foundation Engineering Manual, 4 th<br />

Edition, P. 136.

File No.: FN321<br />

Page 6<br />

TABLE 3.2: ULTIMATE GEOTECHNICAL RESISTANCE<br />

Depth (m)<br />

R n<br />

0.0 to 2.0 Nil<br />

2.0 to 2.6 50*A s<br />

Below 2.6<br />

720*A p + 54*A s<br />

Where:<br />

R n = ΣR n 0.0 m to 2.0 m + ΣR n 2.0 m to 2.6 m + ΣR n > 2.6 m<br />

and<br />

A p is the area of the pile tip (m 2 ); and,<br />

A s is the area of the pile shaft (m 2 ).<br />

The skin friction contribution of the upper 2.0 m of pile below finished grade<br />

should be ignored in the determination of pile capacity.<br />

3. Construct all piles, even lightly loaded piles, with tip depths three times the<br />

depth of seasonal frost penetration to provide sufficient pull out resistance to<br />

potential frost jacking. The frost penetration for exterior concrete piles is<br />

estimated at 2.5 m; therefore, the minimum pile tip depth will be 7.5 m.<br />

4. Typically, belled piles are used to support heavier loads than straight-shaft piles.<br />

In order to derive the design bearing capacity, the base of any belled pile must<br />

be at least five bell diameters below finished surface, or at least 4.0 m below<br />

ground surface in the clay till, whichever depth is greater. End bearing, belled,<br />

cast-in-place concrete piles formed in the clay till may be designed for an<br />

ultimate end bearing of 720 kPa. There is no skin friction contribution in<br />

calculating the capacity of belled piles.<br />

5. The bell base must be at least 200 mm high and the roof of the bell must be no<br />

steeper than 60 degrees, measured from horizontal.<br />

6. Seepage was encountered during borehole drilling so seepage or sloughing will<br />

occur during pile excavations. Casing will be required if seepage or sloughing is

File No.: FN321<br />

Page 7<br />

encountered. Cobbles and boulders are commonly found in till, were visible at<br />

surface, and may cause problems during excavation.<br />

7. During construction, steel reinforcement and concrete must be placed<br />

immediately following pile drilling (and belling if undertaken). Water or slough<br />

must be immediately pumped or otherwise removed prior to placement of<br />

concrete. As such, the immediate placement of concrete following drilling and<br />

belling can improve construction progress and quality of pile construction.<br />

8. Pile shafts must be adequately reinforced to withstand the imposed stresses.<br />

9. Place a void-forming material with a thickness of at least 150 mm beneath grade<br />

beams, foundation concrete or other structural elements supported by piles (all<br />

pile types) to prevent uplifting by soil heaving.<br />

10. The building design must allow no load transfer from stable building elements<br />

supported by the pile and grade beam foundation to potentially vertically<br />

moving building elements supported by the soil or grade supported floors.<br />

3.3 BASEMENT FOOTINGS<br />

Basement footings founded at depths below 2.5 m will likely not be subject to<br />

movements by frost. Footings founded above this depth are subject to movement by<br />

frost, and therefore, will require insulation and heating to prevent frost penetration<br />

below the footing. The recommended insulation configuration for footings above<br />

2.5 m can be provided if required. Temporary structures or structures tolerant to<br />

some movement may be placed on footings at depths within 2.5 m of finished grades.<br />

The following recommendations are made for shallow footings:<br />

1. The footings must be founded on undisturbed native soil. No footings should<br />

be constructed on fill or topsoil.<br />

2. Excavate and remove all topsoil and fill to expose undisturbed native soil as<br />

the founding stratum for footings.<br />

3. Prepare the founding surface by removing any pockets of soft or organic soil<br />

to a uniform bearing surface. The founding surface must be maintained in an<br />

undisturbed state. The surface should not be left exposed to the environment<br />

which could result in wetting, softening or drying.

File No.: FN321<br />

Page 8<br />

<br />

4. In areas beneath footings, excavate to expose the founding stratum below the<br />

footing level. Backfill over-excavated areas below the footing with concrete.<br />

5. The footings must be adequately reinforced to distribute the applied loads<br />

and also have sufficient stiffness to distribute local overstresses.<br />

6. Design footings for an allowable bearing pressure of 160 kPa for the silty<br />

sand and clay till. The minimum width for a footing as required by the<br />

applicable building code must be used in design regardless of bearing<br />

capacity considerations.<br />

7. A qualified geotechnical engineer should inspect all footing bearing surfaces<br />

prior to casting footings.<br />

8. Granular backfill for non-basement footings is not recommended because<br />

frost penetration is greater in granular soils than in clayey soils. In cases<br />

where the footing supports a basement wall however, granular backfill is<br />

preferred because it provides better subsurface drainage on the exterior of the<br />

basement wall (lowers the hydrostatic pressure) and tends to settle less than<br />

uncompacted clayey soil backfill. Where granular backfill of basement walls<br />

is used, insulation boards may be required above the footings to prevent frost<br />

penetration below the footing.<br />

9. Settlement of the footings will be less than 25 mm total or differential for the<br />

allowable bearing pressures recommended herein.<br />

Basement and retaining walls must be designed to support the horizontal loads<br />

imposed by the earth behind the wall. If the backfill behind the walls cannot be fully<br />

drained, the hydrostatic forces from impounded water must be added to the wall<br />

loads. Any surcharge loading at the top of these walls, such as parked vehicles, must<br />

be included in the wall loading. The structural design of these walls must provide<br />

mechanisms to prevent leakage, such as water stops and planned shrinkage joints to<br />

minimize random cracking. The exterior of the walls require heavy water proofing<br />

materials.<br />

Place a minimum 600 mm of impermeable clay soil at surface to reduce surface<br />

infiltration into the granular backfill. Provide factory installed geotextile wrapped<br />

plastic perforated subdrain pipes around the base of the basement or retaining wall.<br />

Provide for gravity discharge of the subdrain pipe to a frost-free sump, which is<br />

drained by gravity or level activated pumping.

File No.: FN321<br />

Page 9<br />

The soil properties to use in the design of the basement and retaining walls are<br />

provided in Appendix A.<br />

4.0 FLOOR RECOMMENDATIONS<br />

4.1 GRADE SUPPORTED FLOORS<br />

Our recommendations for a grade supported floor slab are as follows:<br />

1. Excavate the existing subgrade soils below the proposed floor slab to<br />

undisturbed, native silty sand. Construction on fill material of unknown quality<br />

and composition can result in uneven settlement or heave. Remove all topsoil<br />

from the floor area during subgrade preparation. Remove all loose soil and<br />

debris. Soft, wet areas, which do not have sufficient trafficability for<br />

construction purposes, should be further excavated and replaced with the pit run<br />

sand or gravel that complies to the specifications in Table 4.1.<br />

2. Scarify and uniformly compacted the upper 200 mm of the subgrade to a<br />

minimum 95% of its maximum dry density as determined by test ASTM D698.<br />

Adjust the water content of the subgrade to within 2.0% wet of the optimum<br />

water content.<br />

3. Any fill material required to raise the grade before construction of the grade<br />

supported floor should be a non-frost active granular soil. Place the structural<br />

fill in lifts not exceeding 150 mm uncompacted thickness and compact to a<br />

minimum 95% of its SPDD as determined by test ASTM D698. Adjust the<br />

water content of the subgrade clay to within 2.0% of the optimum water content.<br />

4. Place 25 mm crushed granular base course, which complies with the<br />

specifications as shown on Table 4.1 and 150 mm thick, on the compacted<br />

subgrade or sub-base. The granular base should be compacted to a minimum<br />

98% of its SPDD as determined by test ASTM D698 using a vibratory<br />

compactor. Water may be used as a compaction aid.<br />

5. Install a layer of polyethylene sheeting 150 m (minimum) thick between the<br />

granular base and the concrete slab to prevent the migration of moisture through<br />

the floor.

File No.: FN321<br />

Page 10<br />

6. Care must be taken during the installation of water and sewer lines to ensure that<br />

any leaks will drain to a sump and will not collect under the floor slab.<br />

7. The building design must allow no load transfer from stable building elements<br />

supported by the foundation to potentially vertically moving building elements<br />

supported by the soil or grade supported floors.<br />

8. Provide positive site drainage away from the building. Minimum slopes of at<br />

least 2% are recommended. Down spouts must have extensions to direct their<br />

flow to discharge points at least 2.0 m away from the building face and<br />

discharge to an area with clearly defined drainage away from the building.<br />

9. Provide separation boards between the floor slab and any footing-supported<br />

structures. This separation prevents load transfer from the moving floor to the<br />

stable, footing supported structure.<br />

10. ABSOLUTELY DO NOT place reinforcing steel to connect the grade supported<br />

floor slab to the edge of the footing. Such reinforcement has two consequences.<br />

First, there will be a major crack and fault in the floor along a line parallel to the<br />

grade beam face at exactly the end of the connecting steel. Second, a strongly<br />

reinforced connection can rotate the top of the footing outward as the floor<br />

adjacent heaves. Structural damage, such as the displacement and pop out of<br />

plate glass windows, has been observed.<br />

11. Use sleeves through the grade-supported floor slab and telescoping or collapsing<br />

connections for all pipes passing through or supported by the grade-supported<br />

floor.<br />

12. Review the building design to identify and revise any construction details which<br />

allow load transfer from moving grade-supported building elements to stable<br />

structurally supported building elements.

File No.: FN321<br />

Page 11<br />

TABLE 4.1: AGGREGATE GRADATIONS<br />

Sieve Size<br />

% Passing For Nominal Maximum Size<br />

(mm)<br />

25 mm (Base Course) 75 mm (Sub-base Course)<br />

75 --- 100<br />

25 100 ---<br />

19 80 – 100 15 – 100<br />

9.5 50 – 85 0 – 100<br />

4.75 35 – 70 ---<br />

2.36 25 – 50 ---<br />

1.18 15 – 35 ---<br />

0.6 --- 0 – 100<br />

0.3 5 – 20 0 – 15<br />

0.075 0 – 5 0 – 5<br />

NOTE: 2009 Standard Specifications for Highway Construction, Ministry of Transportation and<br />

Infrastructure, Section 202, Table 202-C.<br />

4.2 STRUCTURALLY SUPPORTED FLOORS<br />

Where heaving or settlement will have unacceptable impacts on floor serviceability,<br />

local areas of structurally supported floors should be provided. For example,<br />

structural floors are often placed below the door swing areas of external doors.<br />

Alternatively, ensure that the top of floor slabs below the exterior door swing is at<br />

least 150 mm below the underside of the door. Floor slabs can heave to block the<br />

swing of doors that are structurally supported by perimeter grade beams.<br />

Our recommendations for structurally supported floors are as follows:<br />

1. The floor should be designed to derive its support structurally from the pile and<br />

grade beam foundation system.<br />

2. The void or crawl space must be a minimum 150 mm below the underside of the<br />

floor slab.<br />

3. If a crawl space is used, provision must be made for accumulated waters to drain<br />

to a frost-free sump by sloping the crawl space floor. Additionally, the soil<br />

below the crawl space should be covered with 150 m polyethylene sheeting<br />

held in place by at least 50 mm of sand. Alternately, a thin concrete mud floor<br />

may be used on the bottom of the crawl space. Ventilation must be provided to

File No.: FN321<br />

Page 12<br />

the crawl space during the non-freezing season to remove moisture<br />

accumulations. It is desirable to design the ventilation system with vents that<br />

may be closed with insulated covers during freezing weather.<br />

Void form systems that rely on the decomposition of an organic void forming<br />

material should be avoided.<br />

5.0 SULPHATE ATTACK<br />

No testing was conducted for water-soluble sulphate contents. As the sulphate<br />

content is unknown, Harder Associates would recommend that the concrete be<br />

designed for severe sulphate levels (Class S-2) with sulphate resistant Portland<br />

Cement (Type 50) having a minimum specified 28-day compressive strength of 32<br />

MPa and a maximum water-cement ratio of 0.45 (see Table 3 in CAN/CSA A23.1-<br />

2009). Calcium chloride or any other admixture containing chlorides should not be<br />

used since the sulphate resisting property of the cement would be reduced. Calcium<br />

salts used as an accelerating admixture should also be avoided as they may increase<br />

the severity of sulphate attack.<br />

If Portland Cement (Type 50) is unavailable or cannot be used due to adverse<br />

construction considerations, then Type 10 cement in combination with 30% by mass<br />

of cement (a little less that 30% by mass of cementing materials) of a Type F or CI<br />

fly ash, is expected to produce sulphate resistance equivalent or superior to concrete<br />

made with a Type 50.<br />

Such concretes have demonstrated good performance in CSA A23.1-09 Table 3 S-1,<br />

S-2 and S-3 sulphate exposure environments. The technical basis for this practice<br />

had its origins in work done by HBT, AGRA Limited and AGRA Earth &<br />

Environmental Ltd in the late 1980’s for the major cement companies in British<br />

Columbia. Referenced publications are:<br />

Sulphate Resistance of Different Types of Portland Cements with and without<br />

Supplementary Cementing Materials by D. Hatch and D.R Morgan<br />

Supplying Concrete for Sulphate Conditions by Mark Stewart

File No.: FN321<br />

Page 13<br />

To enhance durability, an appropriate amount of air entrainment as per CSA<br />

Specification CAN/CSA A23.1-2009, Clause 4.3.3 and Table 4, is also recommended<br />

for all concrete exposed to freezing and thawing at this site.<br />

There may be other design criteria or exposure conditions as outlined in Tables 11<br />

and 14 of CSA A23.1-2009 that could necessitate additional requirements for<br />

subsurface concrete.<br />

If concrete construction proceeds during the winter, Harder Associates recommends<br />

that the concrete be manufactured and placed in a manner that complies with the cold<br />

weather provisions of CSA Concrete Specifications CAN/CSA-A23.1. This<br />

includes:<br />

<br />

<br />

<br />

<br />

using a minimum concrete temperature of 10 degrees Celsius;<br />

heating formwork and reinforcing steel to at least 10 degrees Celsius prior to<br />

placing concrete;<br />

heating and hoarding the concrete as soon as practicable after the concrete is<br />

placed and maintaining the temperature of concrete made to CSA exposure<br />

class S-2 at 10 degrees Celsius for a period of at least 7 days or for the time<br />

necessary to attain 70% of the specified design strength; and,<br />

removing the protection at an appropriate rate at the end of the curing period<br />

to avoid cracking the concrete due to sudden temperature change.<br />

6.0 EARTHQUAKE DESIGN PARAMETERS<br />

The soils at the site are generally clay fill overlying clay till. Pertinent seismic data 4<br />

for the proposed office building is provided in Table 6.1 through 6.4, inclusive.<br />

<br />

<br />

The undrained shear strength is: 50 kPa > S u > 100 kPa;<br />

Site Classification for Seismic Response is Site Class “D” with a<br />

corresponding Average Shear Wave Velocity of 180 m/s < Vs < 360 m/s;<br />

<br />

4 Data was obtained from the Geological Survey of Canada and The British Columbia<br />

Building Code, 2006.

File No.: FN321<br />

Page 14<br />

Seismic Data which has a 2% probability of exceedance in 50 years for Fort Nelson<br />

is as follows:<br />

TABLE 6.1: NATIONAL BUILDING CODE INTERPOLATED SEISMIC HAZARD<br />

VALUES<br />

S a (0.2) S a (0.5) S a (1.0) S a (2.0) PGA (g)<br />

0.095 0.058 0.033 0.021 0.039<br />

The acceleration- and velocity-based site coefficients F a and F v , for Site Class “D”<br />

shall be as follows:<br />

TABLE 6.2: BRITISH COLUMBIA BUILDING CODE - F A SITE COEFFICIENTS<br />

S a (0.2) ≤ 0.25 S a (0.2) = 0.50 S a (0.2) = 0.75 S a (0.2) = 1.00 S a (0.2) ≥ 1.25<br />

1.3 1.2 1.1 1.1 1.0<br />

TABLE 6.3: BRITISH COLUMBIA BUILDING CODE - F V SITE COEFFICIENTS<br />

S a (1.0) ≤ 0.1 S a (1.0) = 0.2 S a (1.0) = 0.3 S a (1.0) = 0.4 S a (1.0) ≥ 0.5<br />

1.4 1.3 1.2 1.1 1.1<br />

The design spectral acceleration values of S(T) shall be as follows:<br />

TABLE 6.4: DESIGN SPECTRAL ACCELERATION VALUES OF S(T)<br />

T<br />

S(T)<br />

T ≤ 0.2 s 0.124<br />

T = 0.5 s 0.081<br />

T = 1.0 s 0.046<br />

T = 2.0 s 0.029<br />

T ≥ 4.0 s 0.015<br />

7.0 CLOSURE<br />

<br />

Harder Associates Engineering Consulting Inc. prepared this report for the use of the<br />

Northern Rockies Regional Municipality and their agents for the geotechnical<br />

assessment and foundation recommendations for an addition to the terminal building

File No.: FN321<br />

Page 15<br />

of the Fort Nelson Airport located approximately 7.5 Km northeast of Fort Nelson,<br />

British Columbia. The contents herein reflect Harder Associates’ best judgment<br />

available to it at the time of preparation with recommendations provided based on the<br />

soil parameters outlined in J.R. Paine & Associates Ltd. report. Any use which a<br />

third party makes of this report, or any reliance on or decisions to be made based on<br />

it, are the responsibility of such third parties. Harder Associates Engineering<br />

Consulting Inc. accepts no responsibility for damages, if any, suffered by any third<br />

party as a result of decisions made or actions based on this report.<br />

This report has been prepared in accordance with generally accepted engineering<br />

practice common to the local area. No other warranty, expressed or implied is made<br />

as Harder Associates can not verify the contects of J.R. Paine & Associates Ltd.’s<br />

report and can provide no assurance the subsurface soil conditions will be similar to<br />

those encountered in the referenced geotechnical report.<br />

Our conclusions and recommendations are based upon the information obtained from<br />

a third party report. If variations or other latent conditions do become evident,<br />

Harder Associates Engineering Consulting Inc. should be notified immediately so<br />

that we may re-evaluate our conclusions and recommendations. Although surface<br />

conditions have been explored, we have not conducted the investigations, sampling,<br />

laboratory testing and can not verify the results. The subsurface soil conditions may<br />

also differ between the proposed addition footprint and the location of the boreholes.<br />

This report contains the results of our review as well as certain recommendations<br />

arising out of such review. Our recommendations do not constitute a design, in<br />

whole or in part, of any of the elements of the proposed work. Incorporation of any<br />

or all of our recommendations into the design of any such element does not constitute<br />

us as designers or co-designers of such elements, nor does it mean that such design is<br />

appropriate in geotechnical terms. The designers of such elements must consider the<br />

appropriateness of our recommendations in the light of all design criteria known to<br />

them, many of which may not be known to us. Our mandate has been to investigate<br />

and recommend which we have completed by means of this report. We have had no<br />

mandate to design, or review the design of any elements of the proposed work and<br />

accept no responsibility for such design or design review.

File No.: FN321<br />

Page 16<br />

Yours truly,<br />

Harder Associates Engineering Consulting Inc.<br />

Joshua Wilson, E.I.T.<br />

Project Engineer<br />

Ian H. Harder, P. Eng.<br />

V.P. N.E. B.C. & Northern AB.

Appendix A

J.R. Paine &Associates<br />

Ltd.<br />

FILE NO: GP6132-2<br />

I<br />

I<br />

I<br />

I<br />

GEOTECHNICAL INVESTIGATION<br />

LIGHT STANDARD SUPPORTS<br />

FORT NELSON AIRPORT<br />

FORT NELSON, B.c.<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

April, 2004<br />

J.R. PAINE & ASSOCIATES LTD.<br />

11020-89 Avenue<br />

GRANDE PRAIRIE, Alberta<br />

T8W 4W4<br />

PHONE:<br />

FAX:<br />

(780) 532-1515<br />

(780) 538-2262<br />

I

J.R. Paine &Associates Ltd.<br />

FILE NO: GP6132-2<br />

GEOTECHNICAL INVESTIGATION<br />

PROPOSED LIGHT STANDARDS<br />

FORT NELSON AIRPORT<br />

FORT NELSON, B.c.<br />

CHAPTER<br />

INTRODUCTION<br />

SITE DESCRIPTION<br />

FIELD INVESTIGATION<br />

LABORATORY TESTING<br />

TABLE OF CONTENTS<br />

PAGE<br />

1<br />

1<br />

2<br />

2<br />

SUBSURFACE<br />

SOIL CONDITIONS<br />

3<br />

RECOMMENDATIONS<br />

CLOSURE<br />

3<br />

5<br />

APPENDIX<br />

Site Plan, Testhole Logs, Test Data Sheets

~<br />

J.R. Paine &Associates Ltd.<br />

GEOTECHNICAL<br />

INVESTIGATION<br />

PROJECT:<br />

LOCATION:<br />

CLIENT:<br />

Proposed Light Standards<br />

Fort Nelson Airport<br />

Fort Nelson, RC.<br />

XTC ENGINEERING LTD.<br />

96 Lancaster Drive<br />

EDMONTON, Alberta<br />

T8N 2N8<br />

Attention: Stan Kolomyjec<br />

INTRODUCTION<br />

This report presents the results of the geotechnical investigation undertaken for the<br />

proposed light standards upgrade at the Fort Nelson Airport near Fort Nelson, Rc. The new<br />

standards will be replacing existing lighting situated on the airside of the main terminal building,<br />

between the building and apron. A total of 3 light standards will be replaced. It is understood<br />

that few details with respect to the method, size, and condition 0 f the existing 1ight standard<br />

foundation supports are known. At this time, it is understood that new foundations will be<br />

constructed for the new lighting. The easiest and least intrusive method of foundation would<br />

appear to be a pile foundation system.<br />

FIELD INVESTI GATI0 N<br />

. The field investigation for this project consisted of drilling and sampling 3 deep testholes<br />

within each existing light standard. Testhole 04-1 was located at the center standard. Testholes<br />

04-2 and 04-3 were located at the north end standard and south end standard respectively. The<br />

testholes were drilled to depths of 9.5m (Testhole 04-1), and to 6.Om(Testholes 04-2 and 04-3).

J.R. Paine &Associates Ltd. 2<br />

The deep testholes were placed to establish a continuous soil profile complete with strength<br />

parameter testing for foundation design requirements.<br />

The field investigation was undertaken utilizing a truck-mounted soils testing drill unit.<br />

All boreholes were advanced with l50mm diameter solid stem augers in 1.5m depth increments.<br />

A continuous log of the soils encountered was maintained on site during the drilling operation of<br />

each testhole. Noted were soil types, transitions, color, plasticity, relative moisture, consistency,<br />

inclusions, and any other notable physical feature. The auger cuttings were sampled at 0.75m<br />

depth intervals for laboratory analysis. Standard penetration tests were performed at regular<br />

intervals of 1.5m in TH04-l. Upon completion of the drilling program all testholes were<br />

backfilled with drill cuttings.<br />

LABORATORY TESTING<br />

All samples removed from the augers were submitted to the J.R. Paine and AssoCiates<br />

I<br />

Ltd. Grande Prairie laboratory for routine indice testing. All samples were tested for m6isture<br />

content. From these, selected sand samples were processed for grain size distribution. ..J single<br />

sample of clay was tested for liquid limit and plastic'limit determination.<br />

SUBSURFACE SOIL CONDITIONS<br />

For a detailed description of the soils encountered and testing performed specific to each<br />

testhole location, refer to the testhole logs attached. Sod and topsoil, l50mm in thickness, was<br />

encountered at Testholes 04-1 and 04-3. Testhole 04-2 was placed in a paved area revealing<br />

60mm of ACP structure. No gravel was encountered beneath the ACP.<br />

The native inorganic soils encountered at this site initiated with a sand deposit. The sand<br />

exhibited 15% to 32% silt based upon the results of 2 sieve analysis (attached). The sand was of<br />

fine to medium grain size.<br />

A standard penetration test (SPT) 'N' value of 16 blows per 300mm<br />

denoted a sand of medium density. The sand stratum was, primarily, in a damp state although a<br />

zone of saturation was encountered at the bottom of the deposit (where situated directly above<br />

the base clay soils). The sand terminated at depths of2.0m to 2.6m below the ground surface.<br />

The base deposit encountered to full termination depth of all testholes was a glacial<br />

deposit of clay till. The till was characteristically a dense silty clay base deposit exhibiting a<br />

sandy texture and containing occasional pebble to gravel size stones. Liquid limit and plastic

J.R. Paine &Associates Ltd. 3<br />

limit test results of 30% and 14% respectively denote a clay of low to medium plasticity.<br />

Moisture content values were in the mid to upper teen range. Standard penetration test results of<br />

12 blows per 300mm penetration to 16 blows per 300mm penetration denote a clay of stiff<br />

consistency.<br />

Some minor free water seepage was encountered during the advancement of TH04-1 and<br />

TH04-2. The water was dribbling into these testholes at the sand-clay interface, 2.5m to 2.6m<br />

below the ground surface. No significant accumulation of water was encountered at the end of<br />

drilling. No testhole sloughing was encountered.<br />

RECOMMENDATIONS<br />

The soil conditions encountered at this site are considered to be suitable for bored, castin-place<br />

concrete piles.<br />

The lighting standards will subject the piles to both lateral loads and<br />

vertical loads. The following design parameters may be applied to the pile sizing and reinforcing<br />

requirements:<br />

Table A Pile Design Parameters<br />

---<br />

Soil Property " Sand Clay Till<br />

Shaft Friction!Adhesion 20 kPa 20 kPa<br />

--..--..--------.....--..----..----..-----------------...-..------..--..<br />

!?~~!_!:!~~!__~~i~~!~(YQ !_~_..~~!~~ ?g-~~!~=_.._......<br />

Undrained Shear Strength, (Su)<br />

1<br />

- ....--..------------- 80 kPa<br />

Strain at 50% Su 0.007<br />

--...-..---------......------....<br />

_!?!~~~!~?~!~_?f!'.~~~!~?_~~J

I<br />

- ~<br />

J.R. Paine &Associates Ltd. 4<br />

the concrete placement.<br />

All holes should be carefully inspected to ensure that no water or slough<br />

material is present in the hole during concrete placement. Casing for piles and should be readily<br />

available on site to accommodate sloughing conditions or an excess of ingressing ground water.<br />

It is recommended that all piles be adequately reinforced. Concrete for all piles should be<br />

adequately compacted. The pile concrete should be placed as soon as possible after the pile has<br />

been bored.<br />

Screw piles may be considered as an alternative to conventional bored, cast-in-place<br />

concrete piles. It will be difficult to install screw piles through the frozen ground surface. An<br />

allowable soil end bearing value of 200 kilopascals (Clay Till) may be applied to the size<br />

selection calculations of individual screw piles. This value includes the total of all live and dead<br />

loads. If multiple helixes are utilized for individual screw piles, vertical spacing of the helixes<br />

should be at least 5 helix diameters. The bearing depth of the screw piles should be at least 4.6m<br />

below the ground surface. Where multiple helixes are utilized, the upper most helix must be<br />

situated at least I.8m below the ground surface. Lateral spacing between screw piles should be<br />

no less than 4 helix diameters. Pile groupings have not been considered. It is recommended that<br />

torque values measured during the installation process not be used as an estimate of the<br />

geotechnical capacity of the pile. Individual screw piles are not recommended for supporting<br />

laterally loaded structures.<br />

-

~<br />

.I<br />

.<br />

~<br />

J.R. Paine &Associates Ltd. 5<br />

CLOSURE<br />

This report is prepared for the exclusive and confidential use of XTC Engineering Ltd.<br />

and applies only to the subject project. The recommendations given are based on the subsurface<br />

soil conditions encountered during testhole boring, current construction techniques, and generally<br />

accepted engineering practices. No other warrantee, expressed or implied, is made. Due to the<br />

geological randomness of many soil formations, no interpolation of soil conditions between or<br />

away from the testholes has been made or implied. Soil conditions are known only at the test<br />

boring locations. Should other soils be encountered during construction 0 r 0 ther information<br />

III<br />

11<br />

"<br />

pertinent to the structures become available, the recommendations<br />

writing by the undersigned.<br />

may be altered or modified in<br />

We trust this information to be satisfactory. If you should have any further questions,<br />

please contact our office.<br />

Yours truly,<br />

J.R. PAINE & ASSOCIATES LTD.<br />

AL/aIlSOIL366<br />

Al Lang, P. Eng.<br />

11

[<br />

J.R. Paine &Associates Ltd.<br />

6<br />

APPENDIX<br />

11

I<br />

J.R. Paine &Associates Ltd.<br />

drawing light standards (1728x2146x2<br />

tiff)<br />

\)<br />

Cl<br />

:;z:<br />

!if<br />

;;j<br />

t<br />

(<br />

.'w ~.~<br />

t-<br />

TESTHOLE 04-1 ~<br />

. r J it<br />

n~I<br />

TESTHOLE 04-3<br />

.-/~ ~<br />

MAIN TERMINAL BUILDING<br />

--, ""

~<br />

PROJECT: Ft. NelsonAirportLight Stands CenterLightStandard TESTHOLENO: 04- 1<br />

CLIENT:XTCEngineeringLtd. WestSideof TerminalBuilding PROJECTNO:GP6132-2<br />

DRillER:FRONTIERENYIRO-DRllLlNG LTD.<br />

ELEVATION:<br />

SAMPLETYPE .DISTURBED I2J SP.T. [;g] LOSTSAMPLE a CHEM. ANALYSIS[illA-CASING [JJ SHELBYTUBE<br />

--' w<br />

:z:<br />

0<br />

-----<br />

-----<br />

OD-<br />

E<br />

E Soil<br />

§ji'= TEST :z:<br />

:z:<br />

:c<br />

>-w<br />

0<br />

(J) --'<br />

w

-'"<br />

I<br />

I<br />

PROJECT:Ft. Nelson Airport Light Sjands North light Standard TESTHOLENO: 04-2<br />

CUENT:XTCEngineering Ltd. West Side of Terminal Building PROJECTNO: GP6132-2<br />

DRillER: FRONTIERENVIRO-DRILUNGlTD.<br />

ELEVATION:<br />

SAMPLETYPE .DISTURBED [ZI S.PJ. kZJ LOSTSAMPLE 8 CHEM.ANALYSIS DJ] A-CASING [[] SHEL8YTUBE<br />

--.J w Z ---.<br />

0<br />

---.<br />

0 0- E<br />

E<br />

Soil<br />

TEST :z:<br />

:c<br />

>-w 0<br />

V) --.J w

~<br />

I<br />

PROJECT: Ft. NelsonAirportLight Steads SouthLight Standard TESTHOLENO: 04-3<br />

CLIENT:XTCEngineeringLtd. WestSideof TerminalBuilding PROJECTNO: GP6132-2<br />

DRIUIR:FRONTIERENVIRO-DRILLlNG LTD.<br />

ELEVATION:<br />

SAMPLETYPE .DISTURBED [Z] S.P.I [ZJ LOSTSAMPLE El CHEM.ANALYSIS []] A-CASING m SHELBYTUBE<br />

:z:<br />

-I .--....<br />

W<br />

0<br />

.--.... 00....<br />

E<br />

E Soil TEST<br />

:Z:<br />

!z;=;<br />

::r:<br />

>-w<br />

0<br />

(/) -I W4:<br />

r- CI<br />

0.... Pt...AST1C M.C. LKJUID<br />

-10....<br />

RESULTS 0:: ::><br />

W<br />

W<br />

Description<br />

o<br />

I-<br />

en -I<br />

(/) (/) :z: W<br />

Cl<br />

I . I<br />

-<br />

20 40 60 SO<br />

0.0 TOPSOIL(PT) O.OO-O.15m - 0.0<br />

1\withsod,sandy<br />

...<br />

f<br />

SIL1YSAND(SM)<br />

O.15-2.00m<br />

I<br />

brown-reddish brown,coarse,dense<br />

1.0 -1.0<br />

.. \ dry to damp,<br />

free draining,some small stones<br />

iliilt"<br />

2.0<br />

.::.=t<br />

CLAYTILL(Cl-CH) 2.00-6.00m -<br />

-2.0<br />

darkgrey,moist,<br />

firm/stiffto 4.0m,thenstiff<br />

3.0<br />

pebbles, occ.stones,siltpieces,<br />

occasional fissures, tracefreewater ,/-<br />

-3.0<br />

..<br />

4.0 -4.0<br />

,'<br />

'/ ..<br />

5.0<br />

/ -<br />

'1 I<br />

I<br />

-5.0<br />

6.0<br />

-<br />

ENDOFTESTHOLE 6.00m<br />

-6.0<br />

7.0 -7.0<br />

8.0 -8.0<br />

9.0 -9.0<br />

10.0 -10.0<br />

, .. n, ..t<br />

J.R. PAINE& ASSOCIATES<br />

LOGGEDBY: D.C.<br />

COMPLETIONDEPTH:6.0 m<br />

REVIEWEDBY: D.G.<br />

COMPLETE: 05/04/04<br />

Edmonton, Alberta Fio.No:3 of 3 Paqe1 of 1<br />

.,J

I<br />

I<br />

-<br />

I<br />

I<br />

I<br />

I<br />

I<br />

1I<br />

11<br />

@<br />

SCREEN ANALYSIS<br />

Sample:<br />

Location:<br />

0.8m Dept~ Depth:<br />

Testhole 04 - 3<br />

Sieve No.<br />

J.R. Paine & Associates Ltd.<br />

CONSULTING<br />

AND TESTING ENGINEERS<br />

EDMONTON - GRANDE PRAIRIE - WHITEHORSE - PEACE RIVER<br />

Size of Opening millimetres<br />

Client:<br />

Project:<br />

Made By:<br />

Ck'd By:<br />

XTC Engineering Ltd.<br />

Fort Nelson Airport<br />

File:<br />

Date:<br />

SM<br />

GP6132-2<br />

April 7, 2004<br />

Specifications<br />

Percent Finer Than Basis<br />

Percent Finer Than<br />

Minimum Maximum Original Sample<br />

125,000 125.0<br />

80,000 80.0<br />

50,000 50.0<br />

40,000 40.0<br />

25,000 25.0<br />

20,000 20.0<br />

16,000 16.0 100.0<br />

12,500 12.5 98.1<br />

10,000 10.0 98.1<br />

5,000 5.0 95.2<br />

1,250 1.25 80.7<br />

630 0.630 63.9<br />

315 0.315 44.4<br />

160 0.160 36.8<br />

80 0.080 32.7<br />

Description of Sample:<br />

Silty Sand (SM)<br />

Method of Preparation:<br />

Moisture Content:<br />

Remarks:<br />

Dry 0<br />

%<br />

Washed 0<br />

2 FaceCrushCount= %<br />

Time of Sieving: 15 minutes<br />

100<br />

90<br />

125 80 5040 25 20 16 10 5000 1250 630 315 160 80<br />

......<br />

"""',<br />

..............<br />

------<br />

80<br />

70<br />

c:<br />

ro .t:: 60<br />

l-<br />

Q;<br />

c:<br />

u: 50<br />

C<br />

ID 40<br />

a..<br />

30<br />

1\<br />

\<br />

1\ -- ----<br />

"'"<br />

f'., .......<br />

20<br />

10<br />

0<br />

1000 100 10 0.1 0.01<br />

Grain Size - millimetres<br />

-"

I<br />

@<br />

SCREEN ANALYSIS<br />

Sample:<br />

Location:<br />

0.8m Dep~ Depth:<br />

Testhole 04 - 1<br />

SieveNo.<br />

J.R. Paine &Associates Ltd.<br />

CONSULTING AND TESTING ENGINEERS<br />

EDMONTON - GRANDE PRAIRIE - WHITEHORSE - PEACE RIVER<br />

Size of Openingmillimetres<br />

Client:<br />

Project:<br />

Made By:<br />

Ck'd By:<br />

SM<br />

XTC Engineering Ltd.<br />

Fort Nelson Airport<br />

File:<br />

Date:<br />

GP6132-2<br />

April 7, 2004<br />

Specifications<br />

Percent Finer Than Basis<br />

PercentFinerThan<br />

Minimum Maximum OriginalSample<br />

125,000 125.0<br />

80,000 80.0<br />

50,000 50.0<br />

40,000 40.0<br />

25,000 25.0<br />

20,000 20.0<br />

16,000 16.0 100.0<br />

12,500 12.5 97.0<br />

10,000 10.0 97.0<br />

5,000 5.0 94.1<br />

1,250 1.25 82.7<br />

630 0.630 63.8<br />

315 0.315 34.6<br />

160 0.160 18.5<br />

'<br />

80 0.080<br />

15.2<br />

Description of Sample:<br />

Sand, Some Silt (SM)<br />

Method of Preparation:<br />

Moisture Content:<br />

Remarks:<br />

Dry 0<br />

%<br />

Washed 0<br />

2 FaceCrushCount= %<br />

Time of Sieving: 15 minutes<br />

100<br />

125 80 50 40 252016 10 5000 1250 630 315 160 80<br />

" ......<br />

""""<br />

""""<br />

90<br />

"""""'<br />

80<br />

..........<br />

70<br />

c<br />

~ 60<br />

l-<br />

Q;<br />

c<br />

u::: 50<br />

c<br />

Q)<br />

<br />

Q; 40<br />

0...<br />

1\<br />

\<br />

\ --<br />

\<br />

\<br />

'\<br />

30<br />

20<br />

r\<br />

'--.<br />

10<br />

0<br />

1000 100 10 0.1 0.01<br />

Grain<br />

Size - millimetres

MECHANICAL <strong>SPECIFICATIONS</strong><br />

NORTHERN ROCKIES REGIONAL MUNICIPALITY<br />

FORT NELSON<br />

AIRPORT TERMINAL BUILDING<br />

WASHROOM RENOVATIONS<br />

For<br />

CJP ARCHITECTS LTD.<br />

301 Sixth Street<br />

New Westminster, BC<br />

V3L 3A7<br />

February 2012<br />

File No. 1130.10<br />

Consulting Mechanical Engineers<br />

201 – 1661 West 2 nd Avenue, Vancouver, British Columbia V6J 1H3<br />

Phone 604-736-6724 Facsimile 604-736-6726

Fort Nelson NRRM TABLE OF CONTENTS Page: 1<br />

Airport Terminal Building<br />

Washroom Renovations<br />

SECTION<br />

PAGES<br />

15010 BASIC MECHANICAL REQUIREMENTS Pages 1-9<br />

15010 GENERAL ...............................................................................................................................1<br />

15011 SCOPE .....................................................................................................................................1<br />

15012 DISCREPANCIES, OMISSIONS, ETC ..................................................................................1<br />

15013 EQUAL & ALTERNATE EQUIPMENT................................................................................2<br />

15015 DRAWINGS ............................................................................................................................2<br />

15016 DEFINITIONS .........................................................................................................................3<br />

15017 GUARANTEE-WARRANTY .................................................................................................4<br />

15018 SITE VISIT...............................................................................................................................4<br />

15019 SHUTTING DOWN OR CUTTING INTO EXISTING SERVICES ......................................4<br />

15023 CODES, PERMITS & PLAN APPROVAL ............................................................................4<br />

15025 CUTTING & PATCHING .......................................................................................................5<br />

15026 RECORD DRAWINGS ...........................................................................................................5<br />

15028 TEMPORARY HEAT..............................................................................................................5<br />

15029 MATERIAL .............................................................................................................................6<br />

15031 SELECTIVE DEMOLITION...................................................................................................6<br />

15035 ELECTRICAL POWER CHARACTERISTICS & WIRING..................................................7<br />

15036 ELECTRIC MOTORS .............................................................................................................7<br />

15037 SERVICES ...............................................................................................................................8<br />

15044 CLEAN UP...............................................................................................................................8<br />

15045 PRIOR TESTS .........................................................................................................................8<br />

15046 SUBSTANTIAL PERFORMANCE ........................................................................................8<br />

15047 FINAL CONSTRUCTION REVIEW ......................................................................................9<br />

15048 PAINTING, FINISHING..........................................................................................................9<br />

15050 BASIC MECHANICAL MATERIALS METHODS Pages 1-12<br />

15050 ACCESS DOORS ....................................................................................................................1<br />

15051 DRAINS ...................................................................................................................................1<br />

15060 PIPING METHODS.................................................................................................................2<br />

15061 PLUMBING PIPING................................................................................................................3<br />

15062 UNDERGROUND PIPE AND FITTINGS (NOT IN CONTRACT) ......................................5<br />

15066 HEATING PIPING...................................................................................................................6<br />

15067 HEATING SYSTEM CLEANSING........................................................................................7<br />

15070 GAS PIPING ............................................................................................................................7<br />

15084 FIRESTOPPING FOR MECHANICAL SYSTEMS ...............................................................7<br />

15089 CANNINGS, OPENINGS & FIXINGS ...................................................................................9<br />

15094 PIPE EXPANSION, HANGERS & SUPPORTS ....................................................................9<br />

15135 FLOW MEASUREMENT VALVES.....................................................................................11<br />

15160 CIRCULATING PUMPS.......................................................................................................11<br />

15190 DENTIFICATION & STENCILLING...................................................................................11<br />

February 2012 JM BEAN & CO. LTD 1130.10

Fort Nelson NRRM TABLE OF CONTENTS Page: 2<br />

Airport Terminal Building<br />

Washroom Renovations<br />

SECTION<br />

PAGES<br />

15200 NOISE VIBRATION AND SEISMIC CONTROL Pages 1-5<br />

15245 SEISMIC RESTRAINTS .........................................................................................................1<br />

15250 MECHANICAL INSULATION Pages 1-5<br />

15261 PIPE INSULATION.................................................................................................................1<br />

15291 DUCT INSULATION ..............................................................................................................3<br />

15400 PLUMBING Pages 1-6<br />

15410 PLUMBING SYSTEM PIPING...............................................................................................1<br />

15430 DRAINAGE SPECIALTIES....................................................................................................2<br />

15440 PLUMBING FIXTURES & TRIM ..........................................................................................2<br />

15450 BACKFLOW PREVENTION..................................................................................................5<br />

15650 REFRIGERATION Pages 1-2<br />

15665 ROOF TOP HEATING & COOLING UNITS - GAS HEATING...........................................1<br />

15750 HEAT TRANSFER Pages 1-2<br />

15830 RADIATION............................................................................................................................1<br />

15850 AIR HANDLING Page 1-1<br />

15870 EXHAUST FANS ....................................................................................................................1<br />

15880 AIR DISTRIBUTION Pages 1-3<br />

15890 DUCTWORK...........................................................................................................................1<br />

15901 DIFFUSERS, GRILLES & REGISTERS ................................................................................3<br />

15920 CONTROLS Pages 1-4<br />

15921 GENERAL ...............................................................................................................................1<br />

15936 ELECTRICAL COMPONENTS, WIRING AND CONDUIT ................................................1<br />

15937 RELATED WORK...................................................................................................................2<br />

15958 CONTROL VALVES & ACTUATORS .................................................................................3<br />

15980 ROOM TEMPERATURE CONTROL....................................................................................4<br />

15984 PACKAGED ROOF TOP A/C UNITS....................................................................................4<br />

February 2012 JM BEAN & CO. LTD 1130.10

Fort Nelson NRRM TABLE OF CONTENTS Page: 3<br />

Airport Terminal Building<br />

Washroom Renovations<br />

SECTION<br />

PAGES<br />

15990 TESTING, ADJUSTING & BALANCING Pages 1-3<br />

15991 TESTS ......................................................................................................................................1<br />

15992 BALANCING & TESTING.....................................................................................................1<br />

15996 OPERATING INSTRUCTIONS..............................................................................................3<br />

15997 EQUIPMENT MANUALS ......................................................................................................3<br />

MECHANICAL SCHEDULES Pages 1-5<br />

• ROOF TOP AIR CONDITIONING UNITS ......................................................................1<br />

• EXHAUST FANS ..............................................................................................................2<br />

• GRILLES, REGISTERS, DIFFUSERS .............................................................................3<br />

• CONTROL VALVES ........................................................................................................4<br />

• WALL FIN RADIATION ..................................................................................................5<br />

February 2012 JM BEAN & CO. LTD 1130.10

Fort Nelson NRRM BASIC MECHANICAL SECTION 15010<br />

Airport Terminal Building REQUIREMENTS Page: 1<br />

Washroom Renovations<br />

15010 GENERAL<br />

1. This section shall be read in conjunction with the General Conditions and Supplementary<br />

General Conditions of the Specifications.<br />

2. All work shall be performed by qualified tradesmen working for a reputable Contracting<br />

Company experienced in this type of work and shall be strictly in accordance with the best<br />

commercial practice.<br />

3. Co-ordinate work with the Contractor’s working schedule and co-operate to achieve the earliest<br />

possible completion of the work.<br />

15011 SCOPE<br />

1. Work covered by this Division is to provide complete systems as indicated on drawings and<br />

specified herein.<br />

2. These Specifications cover information, work, equipment, accessories listed under the following<br />

Division Sections:<br />

15010 Basic Mechanical Requirements<br />

15050 Basic Mechanical Materials & Methods<br />

15200 Noise Vibration & Seismic Control<br />

15250 Mechanical Insulation<br />

15400 Plumbing<br />

15650 Refrigeration<br />

15750 Heat Transfer<br />

15850 Air Handling<br />

15880 Air Distribution<br />

15920 Controls<br />

15990 Testing, Adjusting & Balancing<br />

3. This work shall include the employment of an approved, independent Balancing Firm for<br />

balancing of all air handling and heating systems installed under this contract, to the Engineer's<br />

requirements. Reports of Balancing Firm shall be submitted to the Engineer prior to<br />

establishment of substantial completion. This work shall include the preparation of equipment<br />

manuals as specified in Section 15990.<br />

15012 DISCREPANCIES, OMISSIONS<br />

1. Bidders finding discrepancies in, or omissions from, Drawings, Specifications, or other<br />

documents, or having any doubt as to the meaning or intent of any part thereof, shall at once<br />

notify the Engineer, J.M. Bean & Co. Ltd., who will send explanatory written instructions to all<br />

bidders. Neither the Engineer nor the Owner will be responsible for oral instructions.<br />

February 2012 JM BEAN & CO. LTD 1130.10

Fort Nelson NRRM BASIC MECHANICAL SECTION 15010<br />

Airport Terminal Building REQUIREMENTS Page: 2<br />

Washroom Renovations<br />

2. Should there be a conflict within or between the Specifications or Drawings, the most stringent<br />

or higher quality requirement shall apply.<br />

3. Addenda, corrections or drawing revisions issued during time of bidding shall be included in<br />

tender and shall become part of Contract documents.<br />

15013 EQUAL & ALTERNATE EQUIPMENT<br />

1. Equipment, other than that specified, of equal quality, will be allowed. Acceptable equipment<br />

shall be that which has been reviewed by the Engineer five working days prior to the closing of<br />

bid depository or tenders if bid depository is not used.<br />

2. Should the Mechanical Contractor propose to substitute equipment having different dimensions,<br />

electrical wiring connections, or requiring connections or piping layout at variance with the<br />

Drawing, it shall be the Mechanical Contractor's responsibility to submit a detailed drawing<br />

showing how proposed substitute equipment is to be installed and connected in the available<br />

space. Any proposed variations from Contract Drawings shall be specifically indicated.<br />

3. Equipment, other than that specified, which has been considered by the Engineer as "EQUAL"<br />

prior to the closing of tenders may be substituted at the Mechanical Contractor's discretion<br />

provided aforementioned conditions are met.<br />

4. Equipment, other than that specified, which has been considered by the Engineer as an<br />

"ALTERNATE" prior to the closing of tenders, may be substituted by the Mechanical<br />

Contractor at the discretion of the Engineer provided suitable adjustment of Contract Price is<br />

negotiated.<br />

5. The Mechanical Contractor shall be responsible for all expenses incurred in the work of other<br />

trades made necessary because of substitution.<br />

6. Prior to placing orders submit to the Engineer a complete listing of sub-contractors, materials<br />

and equipment to be used. This listing shall be submitted to the Engineer within 14 calendar<br />

days of signing of Construction Contract.<br />

7. Where two or more items of equipment or materials of similar design are to be installed, they<br />

shall be the products of one manufacturer.<br />

15015 DRAWINGS<br />

1. The drawings, together with the specifications are intended to cover the complete installation of<br />

systems to function as described. The omission of the express reference to any items of labour<br />

or material necessary for the proper execution of the work, in accordance with present day<br />

practice shall not relieve responsibility of supplying such additional labour or material.<br />

2. The drawings are mainly schematic and do not attempt to show all offsets. Make such offsets at<br />

no additional cost to contract. Offset angles shall be as small as possible.<br />

February 2012 JM BEAN & CO. LTD 1130.10

Fort Nelson NRRM BASIC MECHANICAL SECTION 15010<br />

Airport Terminal Building REQUIREMENTS Page: 3<br />

Washroom Renovations<br />

3. All figured dimensions shall have precedence over scale. Detail drawings shall have precedence<br />

over small scale drawings; any difference between same shall be decided upon by the Engineer.<br />

4. The Drawings and Specifications are the property of the Engineer and they shall be returned to<br />

him on request.<br />

5. Submit shop drawings to the standard of the Mechanical Contractor's Association of B.C. for all<br />

equipment to be installed on the job. Each shop drawing shall be submitted in the form of a<br />

"Master" drawing 8-1/2" x 11", 8-1/2" x 14" or multiples thereof suitable for photocopying.<br />

Drawings shall be submitted for review within 30 days of awarding of contract and bear<br />

contractors stamp indicating project name, date and signature of a responsible person who has<br />

reviewed the drawings for the contractor. By his review the contractor represents that he has<br />

determined and verified all field measurements, field construction criteria, materials, catalogue<br />

numbers and similar data. In addition he has checked and coordinated each shop drawing with<br />

the requirement of the work and contract documents.<br />

6. This review by J.M. Bean & Co. Ltd. is for the sole purpose of ascertaining conformance with<br />

the general design concept. This review shall not mean that J.M. Bean & Co. Ltd., approves the<br />

detail design inherent in the shop drawings, responsibility for which shall remain with<br />

Contractor submitting same, and such review shall not relieve the Contractor of his<br />

responsibility for errors or omissions in the shop drawings or of his responsibility for meeting all<br />

requirements of the Contract Documents. The Contractor is responsible for quantities and<br />

dimensions to be confirmed and correlated at the job site, for information that pertains solely to<br />

fabrication processes or to techniques of construction and installation and for co-ordination of<br />

the work of all sub-trades.<br />

7. Manufacture shall not commence until these shop drawings are reviewed. Shop drawings for<br />

fans and pumps shall include an operating curve. See additional requirements in Clause 15245<br />

SEISMIC RESTRAINTS.<br />

15016 DEFINITIONS<br />

1. The word "provide" shall mean "furnish and install, complete and ready for use".<br />

2. "Concealed" where used in connection with insulation and painting of piping, ducts and<br />

accessories, shall mean that they are hidden from sight as in trenches, chases, furred spaces, pipe<br />

shafts or hung ceilings: also, where they are not hidden from sight in the following locations: in<br />

partly excavated or crawl spaces and in service spaces used solely for repairs and maintenance.<br />

3. "Exposed" where used in connection with insulation and painting of piping, ducts and<br />

accessories shall mean that they are not "concealed" as defined above. Equipment rooms and<br />

fan rooms are to be considered as "exposed" areas.<br />

4. "Piping" includes, in addition to pipe, fittings, valves, hangers, other accessories which comprise<br />

a system.<br />

February 2012 JM BEAN & CO. LTD 1130.10

Fort Nelson NRRM BASIC MECHANICAL SECTION 15010<br />

Airport Terminal Building REQUIREMENTS Page: 4<br />

Washroom Renovations<br />

15017 GUARANTEE-WARRANTY<br />

1. Correct promptly at own expense, defects or deficiencies in the work in accordance with the<br />

Warranty requirements of the Contract.<br />

2. The Engineer shall be the judge as to whether the failure is due to defective workmanship,<br />

improper usage or ordinary wear and tear.<br />

3. Make good any damage resulting from defective materials or workmanship.<br />

4. Rectify any deficiencies or omissions in respect to plans or Specifications which may appear<br />

during the guarantee period even though work has been accepted as complete.<br />

15018 SITE VISIT<br />

1. Before submitting prices, visit the site to determine working conditions and existing<br />

constructions. Particular attention shall be paid to proposed methods of construction and<br />

connection to existing system.<br />

2. Claims of lack of knowledge of existing conditions when bidding will not be acceptable as<br />

reason for authorization of extra charges to Contract Price.<br />

15019 SHUTTING DOWN OR CUTTING INTO EXISTING SERVICES<br />

1. No active existing service pipe shall be shut down or cut into without prior arrangement with the<br />

Owner or designated representative who will schedule the work to minimize inconvenience to<br />

Owner. When a critical service must be shut down, this contractor shall be held responsible to<br />

meet scheduled reactivation time. He shall provide overtime work, with no increase to the<br />

contract price if directed by the General Contractor to do so, in order to meet agreed schedules<br />

set for service reactivation.<br />

2. The domestic water systems shall not be shut down for longer than 6 hours in any 24 hour<br />

period, and shut down shall be scheduled between the hours of 9:00 a.m. to 4:00 p.m.<br />

15023 CODES, PERMITS & PLAN APPROVAL<br />

1. All work done under this section of the Specifications shall be in accordance with all National,<br />

Municipal and Provincial Codes applicable.<br />

2. All mechanical equipment furnished shall meet all specific requirements of, and be in<br />

accordance with, the current edition of the British Columbia Energy Efficiency Standards<br />

Regulation issued under the British Columbia Energy Efficiency Act.<br />

3. Abide by all public ordinances, pay all fees, obtain all permits and give all necessary notices to<br />

authorities having jurisdiction. The Contractor shall submit the required number of Drawings<br />

and Specifications to all authorities having jurisdiction for approval purposes.<br />

February 2012 JM BEAN & CO. LTD 1130.10

Fort Nelson NRRM BASIC MECHANICAL SECTION 15010<br />

Airport Terminal Building REQUIREMENTS Page: 5<br />

Washroom Renovations<br />

4. Comply with the most stringent requirements of the B.C. Building Code and Provincial and<br />

Municipal Regulations and By-Laws, specified standards, codes and this specification.<br />

15025 CUTTING & PATCHING<br />

1. Make arrangements for all necessary cutting and patching required for this work.<br />

15026 RECORD DRAWINGS<br />

1. Keep a record set of drawings showing any changes made to original layout of piping, ducts,<br />

equipment rooms, etc. Record drawings shall be continuously updated, shall be available on site<br />

for examination, and shall be turned over to the Engineer for Owner's use upon completion. The<br />

drawings shall indicate the inverts and dimensioned locations of all services at the property line<br />

and where they penetrate the building perimeter. Each drawing shall be stamped “PROJECT<br />

RECORD DRAWINGS, CERTIFIED BY THE CONTRACTOR” the current “DATE” and<br />

signed by the Contractor.<br />

2. Prior to acceptance of the work, arrange and pay for a set of CAD drawing files of the tender<br />

drawings. Alter these using CAD drafting procedures, to show all changes made and obtain<br />

Engineer's approval of completed work. A charge of $25.00 per CAD drawing file will be made<br />

for each CAD drawing file provided. An "Authorization to use CAD Drawing File" agreement,<br />

restricting the use of the CAD files to the preparation of "As Installed" drawings, must be signed<br />

prior to obtaining the files.<br />

3. The revised CAD files along with three sets of record prints shall then be delivered to the<br />

Engineer for the Owner's use.<br />

15028 TEMPORARY HEAT<br />