Exolit® for

ExOLIT FOR THERMOSETS - Clariant

ExOLIT FOR THERMOSETS - Clariant

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Unsaturated polyester resins<br />

(UP resins)<br />

Lightweight constructions<br />

with Exolit<br />

Fiberglass rein<strong>for</strong>ced composites play an important part in construction,<br />

transportation, tanks, pipes and electrical components.<br />

These composites can be manufactured by Sheet Moulding<br />

Compound (SMC)/Bulk Moulding Compound (BMC), Resin<br />

Transfer Moulding (RTM) processing or open mold techniques.<br />

Unsaturated polyester resins are important <strong>for</strong> those applications.<br />

Very often these composites have to fulfill stringent fire and<br />

safety regulations, necessitating the use of flame retardants.<br />

To meet these requirements, the use of halogenated UP resins<br />

(frequently combined with antimony trioxide as synergist) and<br />

aluminium trihydroxide (ATH, flame retardant filler) has become<br />

standard practice in recent years. But ATH in particular is likely<br />

to bring an increase in viscosity (owing to higher filler levels to<br />

reach the required fire retardation) and higher densities of the<br />

components. Moreover, halogenated flame retardants have come<br />

under public and legislative pressure because of widespread findings<br />

in the environment, toxic effects and the potential <strong>for</strong>mation<br />

of halogenated dioxins by uncontrolled combustion [ lit.: Beard A.,<br />

Angeler D. (2010): Flame Retardants: Chemistry, Applications,<br />

and Environmental Impacts. Wiley-VCH, Weinheim. Wiley-VCH.<br />

pp. 415-439. ]<br />

The Exolit grades offer major advantages especially in construction<br />

and rolling stock applications. By combining the Exolit products<br />

with aluminium trihydroxide stringent flammability requirements<br />

can be met even with low filler levels. In addition, Exolit grades can<br />

be used to <strong>for</strong>mulate intumescent (gel)-coats which drastically<br />

improve the fire endurance of the whole composite part. Clariant<br />

is a world wide leader in the manufacturing of ammonium polyphosphate,<br />

one of the key raw materials <strong>for</strong> the <strong>for</strong>mulation of<br />

intumescent (gel)-coatings.<br />

In addition to the traditional hand lay-up process, the Exolit<br />

flame retardants can be used in pultrusion and other advanced<br />

techniques.<br />

Advantages of systems with Exolit:<br />

· Low density of the components<br />

· Low processing viscosity<br />

· High glass contents are possible<br />

· Halogen free hand lay-up <strong>for</strong>mulations are possible<br />

· Pultrusion and advanced composite techniques possible<br />

· Low smoke density, no corrosive combustion gases<br />

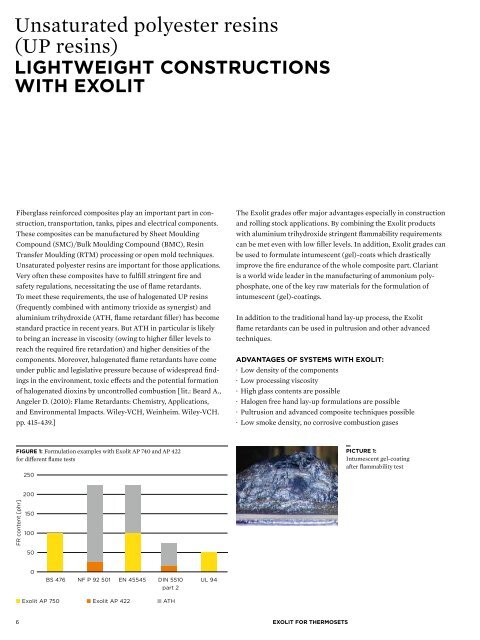

Figure 1: Formulation examples with Exolit AP 740 and AP 422<br />

<strong>for</strong> different flame tests<br />

250<br />

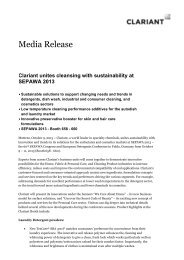

Picture 1:<br />

Intumescent gel-coating<br />

after flammability test<br />

200<br />

FR content [phr]<br />

150<br />

100<br />

50<br />

0<br />

BS 476 NF P 92 501 EN 45545 DIN 5510<br />

part 2<br />

UL 94<br />

n Exolit AP 750 n Exolit AP 422 n ATH<br />

6<br />

Exolit <strong>for</strong> Thermosets