CNC lathes

CNC lathes - WD Hearn

CNC lathes - WD Hearn

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

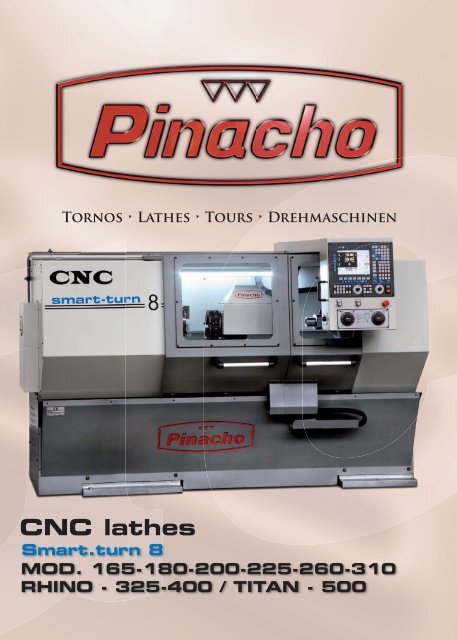

Tornos • Lathes • Tours • Drehmaschinen<br />

<strong>CNC</strong> <strong>lathes</strong><br />

Smart.turn 8<br />

MOD. 165-180-200-225-260-310<br />

RHINO - 325-400 / TITAN - 500

maincharacteristics<br />

The Precision and high performance parallel horizontal <strong>CNC</strong> SMART-TURN 8 PINACHO <strong>lathes</strong><br />

are manufactured and developed using high quality components and materials and the most<br />

advanced manufacturing technology.<br />

technicalcharacteristics<br />

The hardened and ground (400-450 HB) slides and guideways for the carriage and bed assure a long life<br />

and allow high speed displacement.<br />

The special design of the headstock guarantees quiet running, high removal rate of chips, and an<br />

excellent quality finish of the machined pieces.<br />

The main spindle has great rigidity and is mounted on high precision angular contact bearings, which<br />

have been pre-loaded and greased for their working life and guarantees extremely accurate turning.<br />

Hardened and ground ballscrews on both the X and Z axes guarantee long life and great accuracy.<br />

The combination of the high speeds of the headstock and slides, allows the operator to take advantage<br />

of the latest modern techniques in machining.<br />

Thanks to the ergonomic design of the handwheels for use in manual mode, the machine is able to<br />

function similar to a conventional lathe.<br />

Maintenance free AC motors drive the main spindle and ballscrews.<br />

Automatic lubrication of all the slide ways.<br />

The lathe is completely enclosed allowing safe and high removal rate of chips *.<br />

The modern, well l thought out design of the<br />

machine combines safety with<br />

comfort, allowing free e and<br />

easy access to<br />

any<br />

part<br />

of the<br />

lathe.<br />

The whole<br />

machine has<br />

been en<br />

built to conform to oCE En<br />

norms.<br />

directdrive<br />

New spindle assembly with large diameter bea<br />

belt transmission from the motor to the main s<br />

For:<br />

- More cutting performances.<br />

- Smoother spindle running.<br />

ng.<br />

- Better er surface quality.<br />

- More<br />

reliability.

standardaccessories<br />

• Complete enclosure and chip collecting<br />

tray.<br />

• Coolant equipment<br />

• Automatic lubrication of the slide<br />

ways.<br />

• Constant surface speed, including<br />

automatic speed change ranges.<br />

• Electronic handwheels for the X and<br />

Z axis.<br />

• Dynamic solid and trajectory graphics.<br />

Profile editor. Colour screen.<br />

• Low voltage work light.<br />

• Main spindle reducing bush and<br />

fixed centers.<br />

• Instruction manual.<br />

• CE compliant.<br />

advantages<br />

Intuitive ease of use. Even the most complex pieces can be machined<br />

without any programming knowledge.<br />

Minimization of preparation time.<br />

Large capacity memory to store user programs.<br />

Constant cutting speed.<br />

RS-232 output to enable communication with<br />

a PC.<br />

Port USB y Ethernet connection (Fagor / Siemens std.).<br />

manualmode<br />

Working with the handwheels:<br />

r bearings and with direct<br />

ain spindle.<br />

Operation is as easy as working with a conventional lathe.<br />

Allows the resolution of the wheels to be varied depending on the task<br />

being carried out.<br />

automaticoperations<br />

Designed to adapt to traditional turning methods.<br />

Availability for working cycles for all turning operations.<br />

Full and highly advanced ISO programming.<br />

The profile editor creates the program automatically from the geometry<br />

of the finished workpiece.<br />

graphics<br />

• Solid and trajectory graphic simulations.<br />

• Choice of different visualization zones as well as a zoom facility to<br />

examine parts of the component in detail.<br />

• Full colour screen.<br />

180 (Ø42)<br />

200 / 225 (Ø65)<br />

12<br />

12 Kw (S6-40%)<br />

18<br />

18,2 Kw (S6-40%)<br />

Spindle Power (Kw)<br />

10<br />

7,5<br />

115 Nm<br />

72 Nm<br />

7,5 Kw (S1-continuous)<br />

Spindle Power (Kw)<br />

12<br />

9<br />

340 Nm<br />

230 Nm<br />

12,25Kw (S1-continuous)<br />

800 1200<br />

Spindle Speed (rpm)<br />

3200<br />

3600<br />

4000<br />

300<br />

600<br />

1500<br />

Spindle Speed (rpm)<br />

2400<br />

3000<br />

260 / 310 (Ø80)<br />

260 / 310 (Ø105)<br />

Spindle Power (Kw)<br />

11<br />

395 Nm<br />

11 Kw (S1-continuous)<br />

Spindle Power (Kw)<br />

11<br />

395 Nm<br />

11 Kw (S1-continuous)<br />

250<br />

500<br />

Spindle Speed (rpm)<br />

2500<br />

200<br />

400<br />

Spindle Speed (rpm)<br />

2000<br />

mod. 225

The <strong>CNC</strong> SMART-TURN 8 lathe maintains the ease of use of a manual lathe, provides<br />

increased productivity and flexibility by replacing mechanical controls with the latest<br />

numerical control technology.<br />

Electronic handwheels are fitted for the operators to handle the<br />

machine as on a conventional lathe.<br />

Machining is carried out by using a comprehensive choice of cycles selected<br />

through the screen.<br />

standard control unit<br />

FAGOR 8055 iA/TC<br />

10.4” LCD Colour display.<br />

Solid 3D graphics.<br />

Operator can use either the ISO programming system or the conversational<br />

programming.<br />

RAM memory 256 Kb + User memory in CF (compact flash) 512Mb<br />

I/O RS 232 + USB port for pen-drives use only.<br />

Ethernet.<br />

Fagor motor and drives.<br />

optional controls units<br />

FANUC 0i Mate TD<br />

Basic control Fanuc Oi Mate TD + Turnmate i for conversational programming.<br />

Large icons to guide the operator through the multiple cycles.<br />

Conversational + ISO programming.<br />

I/O RS 232 + slot for CF (compact flash) card.<br />

Fanuc motor and drives.<br />

FANUC 0i TD<br />

Basic control Fanuc Oi TD + Manual guide i.<br />

10,4” colour screen.<br />

Solid 3D graphics.<br />

Conversational + ISO programming.<br />

I/O RS 232 + slot for CF (compact flash) card.<br />

Ethernet (optional).<br />

Fanuc motor and drives.<br />

Sinumerik 802D SL<br />

10,4” TFT colour screen.<br />

Conversational programming (MM+) and ISO programming.<br />

Up to 1 Mb memory.<br />

I/O RS 232 + slot for CF (compact flash) card + USB port.<br />

Ethernet.<br />

Siemens motor and drives.

optionalaccessories<br />

SK KIT.<br />

SKC KIT.<br />

Transformer.<br />

rmer<br />

Quick change toolpost.<br />

olp<br />

ost.<br />

4 way indexing ng quick-change cha<br />

toolpost<br />

o<br />

(8 positions).<br />

ons<br />

Toolholders for<br />

indexing ing<br />

quick-change c toolpost.<br />

Automatic 8 station tion toolpost.<br />

t.<br />

Octogonal disc toolholders.<br />

lde<br />

VDI disc.<br />

VDI disc toolholders.<br />

Power driven tooling.<br />

Live tool.<br />

‘C’ axis.<br />

Steel universal 3/4 jaw chucks.<br />

Hydraulic chuck through hole, through cylinder.<br />

Hard jaws for hydraulic chuck.<br />

Soft jaws for hydraulic chuck.<br />

Hydraulic tailstock<br />

Hydraulic power unit.<br />

Chip conveyor.<br />

Communication program.<br />

Backplate.<br />

Driving plate.<br />

Independent 4 jaw chuck.<br />

Face plate.<br />

Jaws for universal chucks.<br />

Fixed steady rest.<br />

Follow rest.<br />

Steady rest arms sw<br />

with rollers.<br />

le<br />

rs.<br />

Rear toolpost. ost.<br />

Morse taper live ecent<br />

center.<br />

er.<br />

Drill chuck.<br />

Manual collet let chuck.<br />

Hydraulic collet chuck.<br />

Collets.<br />

Set of spanners and keys.<br />

Levelling plates.<br />

Foundation nbolts<br />

bolts.<br />

For more information you can visit our web page www.metosa-pinacho.com<br />

SKkit<br />

INCLUDES:<br />

• 8 Station Automatic Turret.<br />

• Hydraulic Power unit.<br />

• Hydraulic Tailstock.<br />

• Hydraulic chuck through hole and<br />

through cylinder.<br />

• Live Center.<br />

SKCkit<br />

C Axis & Power driving tooling<br />

Available for models 225 / 310 with spindle bore 80 and 105.<br />

INCLUDES:<br />

• Automatic turret with VDI disc and power tooling.<br />

• C Axis on headspindle + hydraulic disc brake.<br />

• Hydraulic Power unit.<br />

• Hydraulic Tailstock.<br />

• Through hole hydraulic chuck.<br />

• Live Center MT5.

interactivegraphiccontrol<br />

INCLUDING:<br />

• Different programming languages which can be combined when<br />

preparing the programs as it has been developped for operators who<br />

don´t have programming knowledge and also for well experience erience<br />

experts.<br />

ISO programming for large series to optimize productivity getting the<br />

shortest execution time.<br />

CONVERSATIONAL programming for short series or unit workpieces<br />

where programming time is essential (intuitive navigation with direct<br />

access keys).<br />

Large range of cycles that cover most of the operations the operator<br />

might need.<br />

Machining fixed cycles:<br />

- Grooving cycle.<br />

- Threading cycle.<br />

- Rounding cycle.<br />

- Taper cycle.<br />

- Facing cycle.<br />

- Turning cycle.<br />

- Positioning cycle.<br />

- Tapping cycle.<br />

- Profiling cycle.<br />

• Possibility to import files with CAD designs.<br />

• Connectivity: Ethernet, USB port or RS 232 ready to connect in the<br />

net and CF (compact flash) cards.<br />

• mm / inch display.<br />

• Possibility to program cutting conditions.<br />

• Graphic support with graphic preview of the drawn shape, solid<br />

graphics (depending on <strong>CNC</strong> control type), profile edytor.<br />

The tool calibration before and after machining is made through easy<br />

and intuitive operations that makes the job of the operator easier,<br />

having capacity to save a large variety of tools .<br />

• Large capacity for saving programs.<br />

advantages of <strong>CNC</strong> Smart-turn turn<br />

8<br />

• Takes advantage of the possibilities that offers a <strong>CNC</strong> at the same<br />

time that<br />

maintaining the flexibility and ease of use and handling of a conventional ntiona<br />

onal llath<br />

lathe.<br />

• Components of complicated geometries can be machined, without the setting<br />

of complicated attachments .<br />

• Increased productivity and precision.<br />

• Full automatic operations that reduce working time and increase productivity.<br />

310 (Ø155)<br />

largemain<br />

spindle<br />

bore<strong>lathes</strong><br />

Main spindle bore:<br />

• Mod. 310-155 . . . . . . 155mm - 6”<br />

Spindle Power (Kw)<br />

11<br />

R1=1640 Nm<br />

R2=410 Nm<br />

11 Kw (S1-continuous)<br />

R1: Low Range<br />

R2: High Range<br />

100 200<br />

300<br />

400<br />

500<br />

Spindle Speed (rpm)<br />

1000

mod. 225<br />

Special executions or equipments (upon request)<br />

mod. 310-155<br />

Example of a model <strong>CNC</strong> Smart-turn 8 equipped with 2 pneumatic chucks with full through bore.<br />

Manual chucks for the front and the rear side of the main spindle as special execution available for all models.

<strong>CNC</strong> SMART-TURN 8 RHINO & TITAN - 500<br />

LATHES WITH LARGE CAPACITY<br />

Swing over crosslide.<br />

- Rhino 325 : 365 mm.<br />

- Rhino 400 : 515 mm.<br />

- Titan 500 : 718 mm.<br />

400 (Ø230) (Ø155)<br />

Spindle Power (Kw)<br />

25<br />

17<br />

16<br />

14<br />

R1=2380 R1=3330 Nm<br />

R1=2275 Nm<br />

R1=1630 Nm<br />

R2=850 R2=620 Nm Nm<br />

R2=530 R2=380 Nm Nm<br />

25 Kw (S6-40%)<br />

17 Kw (S1-continuous)<br />

R1: Low Range<br />

R2: High Range<br />

100<br />

80<br />

160 300<br />

240 400 320 500<br />

Spindle Speed (rpm)<br />

1000<br />

800<br />

325/400 (Ø105)<br />

400 (Ø155)<br />

500 (Ø130)<br />

Spindle Power (Kw)<br />

25<br />

21<br />

16<br />

R1=2160 Nm<br />

R1=1460 Nm<br />

R2=540 Nm<br />

R2=360 Nm<br />

25 Kw (S6-40%)<br />

17 Kw (S1-continuous)<br />

R1: Low Range<br />

R2: High Range<br />

Spindle Power (Kw)<br />

25<br />

17<br />

16<br />

14<br />

R1=2380 Nm<br />

R1=1630 R1=1630 Nm Nm<br />

R2=620 R2=620 Nm Nm<br />

R2=380 R2=380 Nm Nm<br />

25 Kw (S6-40%)<br />

17 Kw (S1-continuous)<br />

R1: Low Range<br />

R2: High Range<br />

Spindle Power (Kw)<br />

33<br />

22<br />

20<br />

R1=3515 Nm<br />

R1=2345 Nm<br />

R2=865 Nm<br />

R2=555 Nm<br />

33 Kw (S6-40%)<br />

22 Kw (S1-continuous)<br />

R1: Low Range<br />

R2: High Range<br />

170<br />

340 510 1190<br />

Spindle Speed (rpm)<br />

1700<br />

100<br />

300<br />

400 500<br />

Spindle Speed (rpm)<br />

1000<br />

140<br />

280<br />

420<br />

Spindle Speed (rpm)<br />

980<br />

1400

DD<br />

directdrive<br />

New spindle assembly with large diameter bearings and direct belt transmission<br />

from the motor to the main spindle.<br />

For:<br />

- More cutting performances.<br />

- Smoother spindle running.<br />

- Better surface quality.<br />

- More reliability.<br />

* Mod. 325, 400 & 500 are equiped with one single door in standard execution.<br />

Full enclosure is available as an option.

MOD. 165-180-200-225-260-310<br />

Descripción<br />

MAIN CHARACTERISTICS OF <strong>CNC</strong> SMART-TURN 8<br />

Unidad<br />

165<br />

180<br />

200<br />

225<br />

260<br />

310<br />

310/155<br />

Centre heigth<br />

mm<br />

165<br />

180<br />

200<br />

225<br />

260<br />

310<br />

310<br />

Capacities<br />

Distance between centres<br />

Swing over bed<br />

mm<br />

mm<br />

750 - 1000<br />

335<br />

360<br />

1000 - 1500<br />

400<br />

450<br />

1000 - 1500 - 2000 - 3000<br />

530<br />

620<br />

620<br />

Swing over carriage<br />

mm<br />

310<br />

335<br />

370<br />

410<br />

475<br />

580<br />

580<br />

Swing over cross slide<br />

mm<br />

168<br />

198<br />

210<br />

260<br />

315<br />

415<br />

415<br />

Headstock<br />

Variable spindle speed<br />

Variable speed<br />

(option Ø 105)<br />

Main spindle nose<br />

Main spindle bore<br />

GAMA I<br />

GAMA I<br />

0 - 4000<br />

0 - 4000<br />

0 - 3000<br />

0 - 3000<br />

0 - 2500<br />

0 - 2500<br />

0 - 450<br />

GAMA II - -<br />

- -<br />

- -<br />

450 - 1000<br />

-<br />

-<br />

-<br />

-<br />

0 - 2000<br />

0 - 2000<br />

-<br />

DIN 55027 Nº.5<br />

ASA B 5,9<br />

ASA B 5,9<br />

ASA B 5,9<br />

CAMLOCK Nº.5<br />

Nº.6 - A2<br />

Nº.8 - A2<br />

Nº.11 - A2<br />

mm<br />

42<br />

65<br />

80 (opción Ø105)<br />

155<br />

Main motor<br />

Main spindle morse taper 4 4<br />

5 5<br />

5 5<br />

5<br />

Power Kw 7,5<br />

15<br />

17<br />

17<br />

Z, X working feed mm/min<br />

0 - 7000<br />

0 - 7000<br />

0 - 7000<br />

Feeds<br />

Z, X rapid feed m/min 10<br />

Bed width<br />

mm 250<br />

10<br />

300<br />

10<br />

350<br />

Crosslide width<br />

mm<br />

160<br />

205<br />

220<br />

Ball screw<br />

X axis diameter mm 20 20 20<br />

Z axis diameter mm 40 40 40<br />

Shank travelling<br />

mm<br />

200<br />

220<br />

235<br />

Tailstock<br />

Shank diameter<br />

mm<br />

58<br />

68<br />

82<br />

Shank internal taper<br />

Morse 4<br />

Morse 5<br />

Morse 5<br />

Coolant<br />

pump<br />

Power<br />

W<br />

570<br />

570<br />

570<br />

Dimensions<br />

3065 - 3815<br />

3175 - 3925<br />

Length mm<br />

2095 - 2375 2910 - 3655<br />

4190 - 5095<br />

4300 - 5205<br />

Width mm 1400 1580 1675 1675<br />

Height mm 1565 1670 1835 1835<br />

For distance between centers 750 Kg. 1545 1595<br />

- -<br />

- -<br />

-<br />

Weights<br />

For distance between centers 1000 Kg. 1630 1680<br />

2180 2380<br />

2875 3180<br />

3275<br />

For distance between centers 1500<br />

Kg.<br />

-<br />

-<br />

2290<br />

2650<br />

3095<br />

3265<br />

3350<br />

For distance between centers 2000<br />

Kg.<br />

-<br />

-<br />

-<br />

-<br />

3350<br />

3510<br />

3600<br />

For distance between centers 3000<br />

Kg. -<br />

-<br />

- -<br />

3500 3725<br />

3800<br />

The executions or inclusions of some of the specifications, characteristics and accessories described in this catalogue depend on the model of lathe and numeric control type.

MAIN CHARACTERISTICS OF <strong>CNC</strong> SMART-TURN 8<br />

MOD. RHINO 325-400 TITAN 500<br />

RHINO 400<br />

Descripción<br />

Unidad<br />

RHINO 325<br />

TITAN 500<br />

Estandar 105<br />

Opción 155 Opción 230<br />

Capacities<br />

Centre heigth<br />

Distance between centres<br />

Swing over bed<br />

mm<br />

mm<br />

mm<br />

325<br />

655<br />

400<br />

1000 - 2000 - 3000 - 4000 - 5000<br />

805<br />

500<br />

2000 - 3000<br />

4000 - 5000<br />

1010<br />

Swing over carriage<br />

mm<br />

580<br />

720<br />

935<br />

Swing over cross slide<br />

mm<br />

365<br />

515<br />

718<br />

Headstock<br />

Variable spindle speed<br />

Main spindle nose<br />

GAMA I<br />

0 - 360<br />

0 - 360<br />

0 - 450<br />

0 - 425<br />

0 - 375<br />

GAMA II 360 - 1700 360 - 1700<br />

450 - 1000 425 - 800 375 - 1400<br />

ASA B 5,9<br />

ASA B 5,9<br />

ASA B 5,9<br />

ASA B 5,9<br />

ASA B 5,9<br />

Nº8 - A2<br />

Nº.8 - A2<br />

Nº.11 - A2<br />

Nº.15 - A2<br />

Nº.11 - A2<br />

Main spindle bore mm 105 105<br />

155 230 130<br />

Main spindle morse taper<br />

Morse 5<br />

Morse 5<br />

Morse 5<br />

Morse 6<br />

Metric 80<br />

Main motor<br />

Power Kw 17<br />

17<br />

17<br />

17<br />

22<br />

Z, X working feed mm/min<br />

0 - 7000<br />

0 - 7000<br />

0 - 7000<br />

Feeds<br />

Z, X rapid feed m/min 10<br />

Bed width<br />

mm 425<br />

10<br />

425<br />

8<br />

500<br />

Crosslide width<br />

mm<br />

260<br />

260<br />

310<br />

Ball screw<br />

X axis diameter mm 32 32 32<br />

Z axis diameter mm 50 50 50<br />

Shank travelling<br />

mm<br />

215<br />

215<br />

300<br />

Tailstock<br />

Shank diameter<br />

mm<br />

96<br />

96<br />

120<br />

Shank internal taper<br />

Morse 6<br />

Morse 6<br />

Metric 80<br />

Coolant<br />

pump<br />

Dimensions<br />

Power<br />

W<br />

570<br />

570<br />

570<br />

Flow L/min. 25 25 25<br />

Length mm<br />

3630 - 4630 - 5630 - 6630 - 7630<br />

4325 - 5325<br />

6325 - 7325<br />

Width mm 1800 2300<br />

Height mm 1890 2250<br />

For distance between centers 1000 Kg. 4400 4480<br />

4820 5460 -<br />

Weights<br />

For distance between centers 2000 Kg. 4700 4780<br />

5120 5760 6400<br />

For distance between centers 3000<br />

Kg.<br />

5400<br />

5480<br />

5820<br />

6460<br />

7600<br />

For distance between centers 4000<br />

Kg.<br />

6500<br />

6580<br />

6920<br />

7560<br />

8800<br />

For distance between centers 5000<br />

Kg. 8000<br />

8080<br />

8420 9060 10000<br />

In our constant efforts to improve our machines, we reserve the right to modify any of the technical details, design and color of the machines described in this catalogue.

©METOSA • 2011/5<br />

metosa<br />

Metalúrgica Torrent, S.A.<br />

Partida la Sierra s/n • 22310 CASTEJÓN DEL PUENTE • (SPAIN)<br />

Tel. +34 974 401 650 / +34 974 416 930 • Fax +34 974 401 654 / +34 974 417 733<br />

info@metosa-pinacho.com • www.metosa-pinacho.com