Punch Former - WD Hearn

Punch Former - WD Hearn

Punch Former - WD Hearn

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

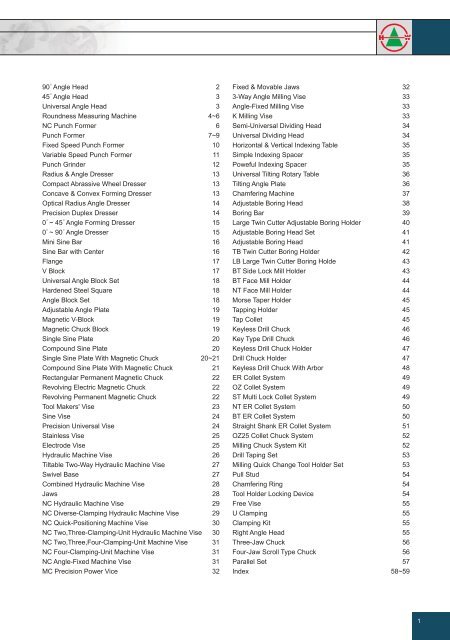

90Angle Head 2<br />

45Angle Head 3<br />

Universal Angle Head 3<br />

Roundness Measuring Machine 4~6<br />

NC <strong>Punch</strong> <strong>Former</strong> 6<br />

<strong>Punch</strong> <strong>Former</strong> 7~9<br />

Fixed Speed <strong>Punch</strong> <strong>Former</strong> 10<br />

Variable Speed <strong>Punch</strong> <strong>Former</strong> 11<br />

<strong>Punch</strong> Grinder 12<br />

Radius & Angle Dresser 13<br />

Compact Abrassive Wheel Dresser 13<br />

Concave & Convex Forming Dresser 13<br />

Optical Radius Angle Dresser 14<br />

Precision Duplex Dresser 14<br />

0~ 45Angle Forming Dresser 15<br />

0~ 90Angle Dresser 15<br />

Mini Sine Bar 16<br />

Sine Bar with Center 16<br />

Flange 17<br />

V Block 17<br />

Universal Angle Block Set 18<br />

Hardened Steel Square 18<br />

Angle Block Set 18<br />

Adjustable Angle Plate 19<br />

Magnetic V-Block 19<br />

Magnetic Chuck Block 19<br />

Single Sine Plate 20<br />

Compound Sine Plate 20<br />

Single Sine Plate With Magnetic Chuck 20~21<br />

Compound Sine Plate With Magnetic Chuck 21<br />

Rectangular Permanent Magnetic Chuck 22<br />

Revolving Electric Magnetic Chuck 22<br />

Revolving Permanent Magnetic Chuck 22<br />

Tool Makers' Vise 23<br />

Sine Vise 24<br />

Precision Universal Vise 24<br />

Stainless Vise 25<br />

Electrode Vise 25<br />

Hydraulic Machine Vise 26<br />

Tiltable Two-Way Hydraulic Machine Vise 27<br />

Swivel Base 27<br />

Combined Hydraulic Machine Vise 28<br />

Jaws 28<br />

NC Hydraulic Machine Vise 29<br />

NC Diverse-Clamping Hydraulic Machine Vise 29<br />

NC Quick-Positioning Machine Vise 30<br />

NC Two,Three-Clamping-Unit Hydraulic Machine Vise 30<br />

NC Two,Three,Four-Clamping-Unit Machine Vise 31<br />

NC Four-Clamping-Unit Machine Vise 31<br />

NC Angle-Fixed Machine Vise 31<br />

MC Precision Power Vice 32<br />

Fixed & Movable Jaws 32<br />

3-Way Angle Milling Vise 33<br />

Angle-Fixed Milling Vise 33<br />

K Milling Vise 33<br />

Semi-Universal Dividing Head 34<br />

Universal Dividing Head 34<br />

Horizontal & Vertical Indexing Table 35<br />

Simple Indexing Spacer 35<br />

Poweful Indexing Spacer 35<br />

Universal Tilting Rotary Table 36<br />

Tilting Angle Plate 36<br />

Chamfering Machine 37<br />

Adjustable Boring Head 38<br />

Boring Bar 39<br />

Large Twin Cutter Adjustable Boring Holder 40<br />

Adjustable Boring Head Set 41<br />

Adjustable Boring Head 41<br />

TB Twin Cutter Boring Holder 42<br />

LB Large Twin Cutter Boring Holde 43<br />

BT Side Lock Mill Holder 43<br />

BT Face Mill Holder 44<br />

NT Face Mill Holder 44<br />

Morse Taper Holder 45<br />

Tapping Holder 45<br />

Tap Collet 45<br />

Keyless Drill Chuck 46<br />

Key Type Drill Chuck 46<br />

Keyless Drill Chuck Holder 47<br />

Drill Chuck Holder 47<br />

Keyless Drill Chuck With Arbor 48<br />

ER Collet System 49<br />

OZ Collet System 49<br />

ST Multi Lock Collet System 49<br />

NT ER Collet System 50<br />

BT ER Collet System 50<br />

Straight Shank ER Collet System 51<br />

OZ25 Collet Chuck System 52<br />

Milling Chuck System Kit 52<br />

Drill Taping Set 53<br />

Milling Quick Change Tool Holder Set 53<br />

Pull Stud 54<br />

Chamfering Ring 54<br />

Tool Holder Locking Device 54<br />

Free Vise 55<br />

U Clamping 55<br />

Clamping Kit 55<br />

Right Angle Head 55<br />

Three-Jaw Chuck 56<br />

Four-Jaw Scroll Type Chuck 56<br />

Parallel Set 57<br />

Index 58~59<br />

1

Precision Accessories for Machine Center<br />

AHA(BT-ER Type) AHB(BT-BT Type) AHC(BT-FA Type)<br />

90°Angle Head<br />

● These series can be applied to Machine Center,<br />

Boring Machine, and Milling Machine.<br />

● The base is made of FCD60~65 with tensile<br />

strength 60~65 kg/cm 2 .<br />

● It is used German P4 class bearing.<br />

Concentricity0.002 mm<br />

Squareness10 Arc Second<br />

MaterialFCD60~FCD65<br />

R.P.M.Max. 4000 RPM<br />

AHA ( BT-ER Type )<br />

AHB ( BT-BT Type ) AHC ( BT-FA Type )<br />

Unitmm<br />

Model A B C D E F G H I<br />

J Gear N.W.<br />

(Range) Ration (kg)<br />

BT40-ER32-AHA 160 40 43 98 86 65 95 50 88 3-20 1:0.81 7.8<br />

BT40-ER40-AHA 160 40 43 98 86 65 95 63 88 4-26 1:0.81 7.8<br />

BT50-ER32-AHA 171 40 54 98 86 65 95 50 88 3-20 1:0.81 9.5<br />

BT50-ER40-AHA 171 40 54 98 86 65 95 63 88 4-26 1:0.81 9.5<br />

BT40-BT30-AHB 192 44 51 122 97 70 110 66 90 BT-30 1:0.96 12.1<br />

BT50-BT30-AHB 195 44 54 122 97 70 110 66 90 BT-30 1:0.96 14.7<br />

BT40-FA25.4-AHC 192 44 51 122 97 70 110 66 90 Face Milling 1:0.96 12.1<br />

BT40-FA22-AHC 192 44 51 122 97 70 110 66 90 Face Milling 1:0.96 12.1<br />

BT50-FA25.4-AHC 195 44 54 122 97 70 110 66 90 Face Milling 1:0.96 14.7<br />

BT50-FA22-AHC 195 44 54 122 97 70 110 66 90 Face Milling 1:0.96 14.7<br />

2

Precision Accessories for Machine Center<br />

AHD ( BT-ER Type ) AHF ( BT-ER Type )<br />

45°Angle Head<br />

● AHD series has same feature as AHA series.<br />

● Splash Coolant-Thru-Body system can prevent<br />

overheated and cutting chips.<br />

● Cutting direction can easily be set by indicating<br />

the datum face.<br />

AHD ( BT-ER Type )<br />

Concentricity0.002 mm<br />

MaterialFCD60~FCD65<br />

R.P.M.Max. 6000 RPM<br />

Universal Angle Head<br />

● AHF series has same feature as AHA and AHD<br />

series.<br />

● Cutting angle can be set from 0~ 360.<br />

AHF ( BT-ER Type )<br />

Unitmm<br />

Model A B C D E F G Gear N.W.<br />

Ration (kg)<br />

BT40-ER20-AHD 1-13 232 110 100 132 33 46 1:1 7.3<br />

BT50-ER20-AHD 1-13 242 110 110 132 33 46 1:1 10<br />

Concentricity0.002 mm<br />

MaterialFCD60~FCD65<br />

R.P.M.Max. 4500 RPM<br />

Unitmm<br />

Model A B C D E F G Gear N.W.<br />

Ration (kg)<br />

BT50-ER32-AHF 3-20 200.5 128.5 59 52 70 50 1:1 15.8<br />

3

Roundness Measuring Machine<br />

HWF-C300,400,500,600 HWF-CJ300,400,500,600<br />

Roundness Measuring Machine<br />

Parallelism0.002 mm / 100 mm Roundness0.002 mm / 100 mm<br />

HWF-C300,400,500,600<br />

HWF-CJ300,400,500,600<br />

Unitmm<br />

Model A B C L Roundness Parallelism Squareness Graduation N.W. (kg)<br />

HWF-C300 300 80 133 0-120 0.002/100 0.002/100 0.002/100 360 22<br />

HWF-C400 400 80 133 0-220 0.002/100 0.002/100 0.002/100 360 25<br />

HWF-C500 500 80 133 20-320 0.002/100 0.002/100 0.002/100 360 28<br />

HWF-C600 600 80 133 120-420 0.002/100 0.002/100 0.002/100 360 31.5<br />

Unitmm<br />

Model O.D. I.D. A B C L Roundness Parallelism Squareness Graduation N.W. (kg)<br />

HWF-CJ300 2-70 24-64 300 80 133 0-120 0.002/100 0.002/100 0.002/100 360 22<br />

HWF-CJ400 2-70 24-64 400 80 133 0-220 0.002/100 0.002/100 0.002/100 360 25<br />

HWF-CJ500 2-70 24-64 500 80 133 20-320 0.002/100 0.002/100 0.002/100 360 28<br />

HWF-CJ600 2-70 24-64 600 80 133 120-420 0.002/100 0.002/100 0.002/100 360 31.5<br />

4

Roundness Measuring Machine<br />

HWF-CM300,400,500,600 HWF-CJM300,400,500,600<br />

Roundness Measuring Machine ( Fixed Speed )<br />

Parallelism0.002 mm / 100 mm Roundness0.002 mm / 100 mm<br />

HWF-CM300,400,500,600<br />

Model A B C L<br />

Motor Output-W<br />

Input-V<br />

Roundness Parallelism Squareness Graduation N.W. (kg)<br />

HWF-CM300 300 80 133 0-120 15W 110 / 220V 0.002/100 0.002/100 0.002/100 360 22<br />

HWF-CM400 400 80 133 0-220 15W 110 / 220V 0.002/100 0.002/100 0.002/100 360 25<br />

HWF-CM500 500 80 133 20-320 15W 110 / 220V 0.002/100 0.002/100 0.002/100 360 28<br />

HWF-CM600 600 80 133 120-420 15W 110 / 220V 0.002/100 0.002/100 0.002/100 360 31.5<br />

HWF-CJM300,400,500,600<br />

Unitmm<br />

Model O.D. I.D. A B C L<br />

Motor Output-W<br />

Input-V<br />

Roundness Parallelism Squareness Graduation N.W. (kg)<br />

HWF-CJM300 2-70 24-64 300 80 133 0-120 15W 110 / 220V 0.002/100 0.002/100 0.002/100 360 22<br />

HWF-CJM400 2-70 24-64 400 80 133 0-220 15W 110 / 220V 0.002/100 0.002/100 0.002/100 360 25<br />

HWF-CJM500 2-70 24-64 500 80 133 20-320 15W 110 / 220V 0.002/100 0.002/100 0.002/100 360 28<br />

HWF-CJM600 2-70 24-64 600 80 133 120-420 15W 110 / 220V 0.002/100 0.002/100 0.002/100 360 31.5<br />

Unitmm<br />

5

Roundness Measuring Machine<br />

HWF-CMB300,400,500,600 HWF-CJMB300,400,500,600 HWF-JNC<br />

Roundness Measuring Machine ( Variable Speed )<br />

Parallelism0.002 mm / 100 mm Roundness0.002 mm / 100 mm<br />

HWF-CMB300,400,500,600<br />

HWF-CJMB300,400,500,600<br />

NC <strong>Punch</strong> <strong>Former</strong><br />

● This type is programmable and can follow the<br />

instructions to perform different processing.<br />

HWF-JNC<br />

Unitmm<br />

Model O.D. I.D. A B C L<br />

Motor<br />

Output-W Roundness Parallelism Squareness Graduation N.W. (kg)<br />

Input-V<br />

HWF-CMB300 300 80 133 0-120 15W 110/220V 0.002/100 0.002/100 0.002/100 360 22<br />

HWF-CMB400 400 80 133 0-220 15W 110/220V 0.002/100 0.002/100 0.002/100 360 25<br />

HWF-CMB500 500 80 133 20-320 15W 110/220V 0.002/100 0.002/100 0.002/100 360 28<br />

HWF-CMB600 600 80 133 120-420 15W 110/220V 0.002/100 0.002/100 0.002/100 360 31.5<br />

HWF-CJMB300 2-70 24-64 300 80 133 0-120 15W 110/220V 0.002/100 0.002/100 0.002/100 360 22<br />

HWF-CJMB400 2-70 24-64 400 80 133 0-220 15W 110/220V 0.002/100 0.002/100 0.002/100 360 25<br />

HWF-CJMB500 2-70 24-64 500 80 133 20-320 15W 110/220V 0.002/100 0.002/100 0.002/100 360 28<br />

HWF-CJMB600 2-70 24-64 600 80 133 120-420 15W 110/220V 0.002/100 0.002/100 0.002/100 360 31.5<br />

6

Roundness Measuring Machine<br />

HWF-A80 ( General Type ) HWF-AS80 ( Sine Type )<br />

HWF-80 Wheel Dresser( Optional Accessory )<br />

<strong>Punch</strong> <strong>Former</strong><br />

● The parts are made of alloy steel processed<br />

by heat and subzero treatment for relieving<br />

stress against distortion, and the inherent high<br />

accuracy can be maintained permanently.<br />

● The <strong>Punch</strong> <strong>Former</strong> can be applied to precisely<br />

grind standard or longer punches to round,<br />

elliptical, multi-angle or any particular shapes.<br />

● V Block cross slide design provides fi ne<br />

adjustment. When moving from center to either<br />

side, the punch can be precisely ground to<br />

various shapes.<br />

HWF-A80 ( General Type )<br />

● Forming Lever can make convex radius,<br />

concave radius and parallel dress for grinding<br />

wheel.<br />

● General angles can be quickly set up. It can be<br />

applied to Electric Discharge Machines, index,<br />

inspection, panel gradient grinding, lightmilling,<br />

boring and radius dressing.<br />

● Angle machining is possible by using combined<br />

sine plate.<br />

HWF-AS80 ( Sine Type )<br />

HWF-80 Wheel Dresser<br />

( Optional Accessory )<br />

Model<br />

Max. Dia.<br />

of Workpiece<br />

Through<br />

Center<br />

Hole<br />

V Block<br />

Tangential<br />

Travel of<br />

Sider<br />

HWF-A80 Ø4-30 Ø23 100<br />

HWF-AS80 Ø4-30 Ø23 100<br />

V Block<br />

Center<br />

Adjusting<br />

Heignt<br />

System<br />

Rack<br />

& Pinion<br />

Rack<br />

& Pinion<br />

80<br />

114<br />

Unitmm<br />

Indexing<br />

Division Roundness Parallelism Squareness Graduation N.W.<br />

(kg)<br />

24<br />

(1510<br />

seconds)<br />

24<br />

(1510<br />

seconds)<br />

0.002 0.002/100 0.002/100 360 7<br />

0.002 0.002/100 0.002/100 360 10<br />

7

Precision Accessories for Grinding Machine<br />

HWG-A80 ( General Type ) HWG-AS80 ( Sine Type )<br />

HWF-J80 ( Chuck Type ) HWF-JS80 ( Chuck-Sine Type )<br />

<strong>Punch</strong> <strong>Former</strong><br />

● HWG series has the same features as HWF-A<br />

series.<br />

● The <strong>Punch</strong> <strong>Former</strong> has the perfect advices<br />

of self-alignment center shaft and transverse<br />

movement by rack, pull-out/push-in by key<br />

control, without vibration but just through the<br />

integral operation.<br />

HWG-A80 ( General Type )<br />

● The bearing construction is completely<br />

sealed and protected from cutting chips. The<br />

inherent high accuracy can maintain almost<br />

permanently, as the character of minimum bias.<br />

● Dresser arm attached.<br />

HWG-AS80 ( Sine Type )<br />

● HWF-J series has the same features as HWF-B series.<br />

HWF-J80 ( Chuck Type )<br />

HWF-JS80 ( Chuck-Sine Type )<br />

Model O.D. I.D.<br />

Max. Dia.<br />

of<br />

Workpiece<br />

Through<br />

Center<br />

Hole<br />

Tangential<br />

Travel of<br />

Sider<br />

HWG-A80 Ø4-30 12.5<br />

HWG-AS80 Ø4-30 12.5<br />

V Block<br />

Center<br />

Adjusting<br />

Heignt<br />

System<br />

Rack<br />

& Pinion<br />

Rack<br />

& Pinion<br />

HWF-J80 2-70 24-64 Ø16 80<br />

HWF-JS80 2-70 24-64 Ø16 114<br />

80<br />

114<br />

Indexing<br />

Division<br />

24<br />

(1510<br />

seconds)<br />

24<br />

(1510<br />

seconds)<br />

24<br />

(1510<br />

seconds)<br />

24<br />

(1510<br />

seconds)<br />

Unitmm<br />

Roundness Parallelism Squareness Graduation<br />

N.W.<br />

(kg)<br />

0.002 0.002/100 0.002/100 360 8<br />

0.002 0.002/100 0.002/100 360 11<br />

0.002 0.002/100 0.002/100 360 8<br />

0.002 0.002/100 0.002/100 360 11<br />

8

Precision Accessories for Grinding Machine<br />

HWF-B8016,8032 ( ER Collet Type ) HWF-BS8016,8032 ( ER Sine Type )<br />

HWF-B8050 ( ER Collet Type ) HWF-BS8050 ( ER Sine Type )<br />

<strong>Punch</strong> <strong>Former</strong><br />

● Cylindrical grinding, dividing, and hole making<br />

of small size workpieces can be very effectively<br />

performed by mounting ER collet type on<br />

profi le grinders milling machines, and drilling<br />

machines.<br />

● HWF-B series can clamp workpieces in a wide<br />

range of sizes.<br />

HWF-B8016,8032 ( ER Collet Type )<br />

● Saves time; does not need V Block to fi nd<br />

center.<br />

● Angle machining is possible by using the<br />

combined sine plate.<br />

HWF-BS8016,8032 ( ER Sine Type )<br />

HWF-B8050 ( ER Collet Type ) HWF-BS8050 ( ER Sine Type )<br />

Model<br />

Max. Dia.<br />

of<br />

Workpiece<br />

Through<br />

Center<br />

Hole<br />

Center<br />

Heignt<br />

Unitmm<br />

Indexing Division Roundness Parallelism Squareness Graduation N.W. (kg)<br />

HWF-B8016 Ø1-10 Ø20 80 24(1510 seconds) 0.002 0.002/100 0.002/100 360 5.4<br />

HWF-BS8016 Ø1-10 Ø20 114 24(1510 seconds) 0.002 0.002/100 0.002/100 360 8.4<br />

HWF-B8032 Ø3-20 Ø20 80 24(1510 seconds) 0.002 0.002/100 0.002/100 360 6.9<br />

HWF-BS8032 Ø3-20 Ø20 114 24(1510 seconds) 0.002 0.002/100 0.002/100 360 9.9<br />

HWF-B8050 Ø12-34 Ø30 80 24(1510 seconds) 0.002 0.002/100 0.002/100 360 7<br />

HWF-BS8050 Ø12-34 Ø30 114 24(1510 seconds) 0.002 0.002/100 0.002/100 360 10<br />

9

Precision Accessories for Grinding Machine<br />

HWF-AM80 ( Motorized Type ) HWF-BM8016,8032,8050 ( Motorized Type )<br />

HWF-JM80 ( Motorized Type )<br />

Fixed Speed <strong>Punch</strong> <strong>Former</strong><br />

● The <strong>Punch</strong> <strong>Former</strong> with a motor attached can<br />

be applied to precisely grind a punch to round<br />

in a short time and saves the processing time.<br />

HWF-AM80 ( Motorized Type )<br />

● ER Collet Type and Chuck Type can clamp<br />

workpieces in a wide range.<br />

HWF-BM8016,8032,8050 ( Motorized Type )<br />

HWF-JM80 ( Motorized Type )<br />

Unitmm<br />

Model O.D. I.D.<br />

Max. Dia. Center Motor Output-W<br />

of Workpiece Heignt Input-V<br />

Roundness Parallelism Squareness Graduation N.W. (kg)<br />

HWF-AM80 Ø4-30 80 15W 110/220V 0.002 0.002/100 0.002/100 360 10<br />

HWF-BM8016 Ø1-10 80 15W 110/220V 0.002 0.002/100 0.002/100 360 8.4<br />

HWF-BM8032 Ø3-20 80 15W 110/220V 0.002 0.002/100 0.002/100 360 9.9<br />

HWF-BM8050 Ø12-34 80 15W 110/220V 0.002 0.002/100 0.002/100 360 9.9<br />

HWF-JM80 2-70 24-64 Ø50 80 15W 110/220V 0.002 0.002/100 0.002/100 360 9.9<br />

10

Precision Accessories for Grinding Machine<br />

HWF-AMB80 ( Motorized Type ) HWF-BMB8016,8032,8050 ( Motorized Type )<br />

HWF-JMB80 ( Motorized Type )<br />

Variable Speed <strong>Punch</strong> <strong>Former</strong><br />

● HWF-AMB series has the same features as<br />

HWF-AM/BM/JM series.<br />

● This series has 40~100 rpm and 80~200 rpm<br />

speed motors. (Different speed motor can be<br />

applied upon request.)<br />

HWF-AMB80 ( Motorized Type )<br />

● After long time working, the motor’s<br />

temperature doesn’t increase.<br />

● Any types of "Hold Well" <strong>Punch</strong> <strong>Former</strong> can<br />

be installed with variable speed motor (Except<br />

HWG Type).<br />

HWF-BMB8016,8032,8050 ( Motorized Type )<br />

HWF-JMB80 ( Motorized Type )<br />

Unitmm<br />

Model O.D. I.D.<br />

Max. Dia. Center Motor Output-W<br />

of Workpiece Heignt Input-V<br />

Roundness Parallelism Squareness Graduation N.W. (kg)<br />

HWF-AMB80 Ø4-30 80 15W 110/220V 0.002 0.002/100 0.002/100 360 10.5<br />

HWF-BMB8016 Ø1-10 80 15W 110/220V 0.002 0.002/100 0.002/100 360 8.5<br />

HWF-BMB8032 Ø3-20 80 15W 110/220V 0.002 0.002/100 0.002/100 360 10<br />

HWF-BMB8050 Ø12-34 80 15W 110/220V 0.002 0.002/100 0.002/100 360 10<br />

HWF-JMB80 2-70 24-64 Ø50 80 15W 110/220V 0.002 0.002/100 0.002/100 360 10<br />

11

Precision Accessories for Grinding Machine<br />

HWM-PG HWM-PGSS HWM-PGM<br />

<strong>Punch</strong> Grinder<br />

● <strong>Punch</strong> Grinder is a tool which can be put on the<br />

table of grinding machine for grinding punches.<br />

It can perform cylindrical grinding automatically.<br />

● Accuracy of roller is within 0.005 mm. It can<br />

grind punches diameter 3~25 mm.<br />

Weight8kg<br />

HWM-PG<br />

<strong>Punch</strong> Grinder<br />

HWM-PGSS<br />

<strong>Punch</strong> Grinder (Motorized Type)<br />

HWM-PGM<br />

D 2-25 mm<br />

d 1.5-25 mm<br />

L Max.120 mm<br />

I Min.22 mm<br />

12

Precision Accessories for Grinding Machine<br />

HWM-RA HWM-RC HWM-RDA,RDB<br />

Radius & Angle Dresser<br />

● This dresser can dress max. diameter 250 mm<br />

wheel, and the wheel extending diameter is<br />

375 mm.<br />

● The sliding travel from left to right is 40 mm.<br />

HWM-RA<br />

Weight10.5kg<br />

Max Convex0.8~40R<br />

Max Convex0~40R<br />

Compact Abrassive Wheel Dresser<br />

● This dresser facilitates the dressing of various<br />

convex and concave forms.<br />

● Easy operation and economical application.<br />

HWM-RC<br />

Weight3.2kg<br />

Convex Radius0-85R<br />

Concave Radius0-85R<br />

Concave & Convex Forming Dresser<br />

HWM-RDA,RDB<br />

Unitmm<br />

Model<br />

Convex Concave Max. Wheel<br />

Radius Radius Dia<br />

N.W. (kg)<br />

HWM-RDA 0-40 0-90 8 12<br />

HWM-RDB 10-200 10-350 14 25<br />

13

Precision Accessories for Grinding Machine<br />

HWM-RAD HWM-RD<br />

Optical Radius Angle Dresser<br />

● This dresser can dress grinding wheel to any<br />

angle from 0°~95°, and the max. dressing<br />

range of wheel diameter is 205 mm.<br />

Weight3.2kg<br />

Convex Radius0~13R<br />

Concave Radius0~25.4R<br />

Tangential Travel22 mm<br />

HWM-RAD<br />

Precision Duplex Dresser<br />

HWM-RD<br />

Weight3.5kg<br />

Width of wheelMax. 40mm<br />

Dressing depthMax. 40mm<br />

Dressing widthMin. 0.2mm<br />

GraduationMin. 0.2mm<br />

Max. Thickness Min. Max. Min.<br />

0.02mm<br />

/DIV<br />

14

Precision Accessories for Grinding Machine<br />

HWN-A HWN-B36,56<br />

0~ 45Angle Forming Dresser<br />

● This fi ne precision-made unit dresses grinding<br />

wheel to any angle from 0~ 60.<br />

● Sliding feed up to 50 mm, center distance<br />

0.01 mm. Sine angle absolutely accurate.<br />

HWN-A<br />

Weight7.2kg<br />

0~ 90Angle Dresser<br />

● This series can dress the grinding wheel from<br />

45to 90instead of <strong>Punch</strong> <strong>Former</strong>.<br />

● Direction can be interchanged without<br />

infl uencing accuracy. 45angle is obtained<br />

without using block gauges.<br />

● Not only 0~ 45angles, but also can be tilted<br />

accurately at any required angle using block<br />

gauges.<br />

HWN-B36,56<br />

Application 1: (HWN-B56)<br />

70angle tilt<br />

70- 45= 25<br />

Sin25= 0.4226<br />

75 mm 0.4226=31.695 mm<br />

70angle tilt can be obtained<br />

by stacking the total height of<br />

31.695 mm block gauges.<br />

Application 2: (HWN-B56)<br />

15angle tilt<br />

45- 15= 30<br />

Sin30= 0.5<br />

75 mm 0.5 = 37.5 mm<br />

15angle tilt can be obtained<br />

by stacking the total height of<br />

37.5 mm block gauges.<br />

Model A B<br />

C<br />

0.002<br />

D<br />

Angle<br />

Dreseing<br />

Range<br />

Unitmm<br />

N.W. (kg)<br />

HWN-B36 70 105 50 36 0-90 2<br />

HWN-B56 106 124 75 56 0-90 5<br />

15

Precision Accessories for Grinding Machine<br />

HWS-A100,150 HWS-B200,250 HWS-BS200,250<br />

Mini Sine Bar<br />

● Accurate; easy to operate; no mathematics<br />

needed.<br />

● 5~10 minutes tolerance.<br />

HWS-A100,150<br />

● Set with Gauge Blocks, Height Gauge, Master<br />

Gauge, and Micrometer & Adjustable Parallel.<br />

Sine Bar with Center<br />

● It can be applied to measure the roundness of<br />

centerless or centering cylinder and measure<br />

the angle of squareness.<br />

HWS-B200,250<br />

Unitmm<br />

Model A B<br />

C<br />

0.002<br />

D N.W. (kg)<br />

HWS-A100 150 45 100 39 1.6<br />

HWS-A150 200 45 150 56 2<br />

● It also can measure the taper of centerless or<br />

centering cylinder.<br />

HWS-BS200,250<br />

Unitmm<br />

Model A B C D E N.W. (kg)<br />

HWS-B200 200 70 58 100 12<br />

HWS-B250 250 70 58 150 13<br />

HWS-BS200 200 70 58 100 90 15<br />

HWS-BS250 250 70 58 150 90 16<br />

16

Precision Accessories for Grinding Machine<br />

HWP-250 HWP-350 HWT<br />

Flange<br />

HWP-250<br />

Weight0.8kg<br />

HWP-350<br />

Weight0.9kg<br />

V Block<br />

● V Block is made of alloy steel, and all surfaces<br />

are ground square and parallel to each other.<br />

● V’s are ground central, parallel and square to<br />

the ends.<br />

● V-Angle is 90.<br />

Weight1.1kg<br />

HWT<br />

17

Precision Accessories for Grinding Machine<br />

HWT-UA130,UB130 HWT-S HWT-A36,B56<br />

Universal Angle Block Set<br />

HWT-UA130,UB130<br />

Hardened Steel Square<br />

Unitmm<br />

Model LWH N.W. (kg)<br />

HWT-UA130 31-3 / 161-3 / 16 1.8<br />

HWT-UB130 41-1 / 21-1 / 2 3.6<br />

MaterialSK2<br />

Squareness0.05 mm / 1000 mm<br />

HardnessHRC55<br />

HWT-S<br />

Unitmm<br />

Model A B C D E N.W. (kg)<br />

HWT-S302 50 40 4 13 13 0.03<br />

HWT-S303 75 50 4 15 15 0.05<br />

HWT-S304 100 70 5 19 19 0.11<br />

HWT-S306 150 100 6 28 28 0.26<br />

HWT-S308 200 130 6 32.5 32.5 0.42<br />

HWT-S310 250 165 8 34 34 0.74<br />

HWT-S312 300 200 8 39 39 1.00<br />

Angle Block Set<br />

HWT-A36,B56<br />

Unitmm<br />

Model Angle Degrees WL<br />

N.W.<br />

(kg)<br />

HWT-A36 1,2,3,4,5,10,15,20,25,30-10pcs 6.3576.2 1<br />

HWT-B56 1/4,1/2,1,2,3,4,5,10,15,20,25,30-12pcs 6.3576.2 1.1<br />

18

Precision Accessories for Grinding Machine<br />

HWT-AP1,2,3 HWT-MV208,212 HWT-CBT<br />

HWT-CBV HWT-CBV1<br />

Adjustable Angle Plate<br />

MaterialSK2<br />

Squareness0.005 / 100 mm<br />

Tolerance of angle10<br />

HardnessHRC50~ 54<br />

HWT-AP1,2,3<br />

Unitmm<br />

Model H W L h N.W. (kg)<br />

HWT-AP1 47 46 102 28 1.5<br />

HWT-AP2 47 30 102 28 1<br />

HWT-AP3 32 25 75 22 0.5<br />

Magnetic V-Block<br />

● Powerful magnetic force functions on all 3<br />

surfaces of upper, base and V-shaped.<br />

● Magnetic force is easily changeable simply by<br />

lever operation.<br />

HWT-MV208,212<br />

Magnetic Chuck Block<br />

Unitmm<br />

Model<br />

Holding Power Dimension<br />

V-Face Surface B H L<br />

N.W. (kg)<br />

HWT-MV208 55Kgf 70Kgf 56 72 80 3<br />

HWT-MV212 90Kgf 110Kgf 75 100 115 5.1<br />

HWT-CBT<br />

HWT-CBV<br />

HWT-CBV1<br />

Unitmm<br />

Model<br />

Dimension<br />

Pole Pitch<br />

N.W.<br />

B H L<br />

(kg)<br />

HWT-CBT 4" 2" 1" 6(33) 1.3<br />

HWT-CBV 2" 2-3/8" 1-7/8" 6(33) 1.3<br />

HWT-CBV1 4-3/8" 2-3/8" 1-7/8" 6(33) 1.4<br />

19

Precision Accessories for Grinding Machine<br />

HWJ-150,175,300 HWJ-2W-150,175,300 HWK-SAK,SBK-150,175,300<br />

Single Sine Plate<br />

● Sine Plates are made of alloy steel processed<br />

by heat, subzero treatment against distortion,<br />

hardened up to HRC58and fi nished by<br />

grinding.<br />

● The angle can be adjusted from 0~ 45.<br />

Rollers are processed by heat treatment and<br />

precisely ground within 0.002 mm.<br />

HWJ-150,175,300<br />

Parallelismwithin 0.003 mm / 100 mm<br />

Squarenesswithin 0.005 mm / 100 mm<br />

Roller Center Distancewithin 0.002 mm<br />

Compound Sine Plate<br />

Unitmm<br />

D N.W.<br />

Model A B C<br />

0.002 (kg)<br />

HWJ-150 150 150 60 100 11<br />

HWJ-175 100 175 60 75 10<br />

HWJ-300 150 300 60 100 21<br />

HWJ-2W-150,175,300<br />

Single Sine Plate with<br />

Magnetic Chuck (Simple Type)<br />

Unitmm<br />

D N.W.<br />

Model A B C<br />

0.002 (kg)<br />

HWJ-2W-150 150 150 102 100 13<br />

HWJ-2W-175 100 175 102 75 12<br />

HWJ-2W-300 150 300 102 100 32<br />

HWK-SAK,SBK-150,175,300<br />

Unitmm<br />

Model A B C<br />

D<br />

N.W.<br />

E<br />

0.002<br />

(kg)<br />

HWK-SAK-150 150 150 60 100 97 13<br />

HWK-SBK-150 150 150 56 100 93 14<br />

HWK-SAK-175 100 175 60 75 97 12<br />

HWK-SBK-175 150 175 50 75 87 13<br />

HWK-SAK-300 150 300 60 100 97 34<br />

HWK-SBK-300 150 300 60 100 97 35<br />

AStandard Poles / Pole Pitch 2+6<br />

BFine Poles / Pole Pitch1+1.5<br />

20

Precision Accessories for Grinding Machine<br />

HWK-AK,BK,BH-150,175,300 HWL-2WAK,BK,BH-150,175,300<br />

Single Sine Plate with Magnetic Chuck<br />

● Fine magnetic chuck is suitable for grinding<br />

small workpieces.<br />

● The base has a positive locking device which<br />

can provide a positive lock at any angle.<br />

● Sine plates are made of alloy steel processed<br />

by heat, subzero treatment against distortion,<br />

hardened up to HRC58, fi nished by grinding.<br />

● Rollers are processed by heat treatment and<br />

precisely ground within 0.002 mm.<br />

Parallelismwithin 0.003 mm / 100 mm<br />

Squarenesswithin 0.005 mm / 100 mm<br />

Roller Center Distancewithin 0.002 mm<br />

HWK-AK,BK,BH-150,175,300<br />

Unitmm<br />

Model A B C<br />

D<br />

N.W.<br />

E<br />

0.002 (kg)<br />

HWK-AK-150 150 150 60 100 125 15<br />

HWK-BK-150 150 150 56 100 121 16<br />

HWK-BH-150 150 150 40 100 100 16<br />

HWK-AK-175 100 175 60 75 125 14<br />

HWK-BK-175 100 175 50 75 125 15<br />

HWK-AK-300 150 300 60 100 125 36<br />

HWK-BK-300 150 300 60 100 125 37<br />

HWK-BH-300 150 300 40 100 125 37<br />

Compound Sine Plate with<br />

Magnetic Chuck<br />

AStandard Poles / Pole Pitch 2+6<br />

BFine Poles / Pole Pitch1+1.5<br />

CHolland Magnetic Chuck-Fine Poles / Pole Pitch0.8+1.5<br />

HWL-2WAK,BK,BH-150,175,300<br />

Unitmm<br />

Model A B C<br />

D<br />

N.W.<br />

E<br />

0.002 (kg)<br />

HWL-2WAK-150 150 150 60 100 162 18<br />

HWL-2WBK-150 150 150 60 100 162 20<br />

HWL-2WBH-150 150 150 40 100 142 20<br />

HWL-2WAK-175 100 175 60 75 162 17<br />

HWL-2WBK-175 100 175 60 75 162 19<br />

HWL-2WAK-300 150 300 60 100 162 46<br />

HWL-2WBK-300 150 300 60 100 162 48<br />

HWL-2WBH-300 150 300 40 100 142 48<br />

AStandard Poles / Pole Pitch 2+6<br />

BFine Poles / Pole Pitch1+1.5<br />

CHolland Magnetic Chuck-Fine Poles / Pole Pitch0.8+1.5<br />

21

Precision Accessories for Grinding Machine<br />

HWK-PC-A,B,BH HWK-EC-A,B HWK-RC-A<br />

Rectangular Permanent Magnetic Chuck<br />

● Hold Well Permanent Magnetic Chucks are the<br />

perfect companion for the surface grinder, mill<br />

or other metal removing machines.<br />

● The top plate is laminated from steel<br />

& stainless steel, then furnace brazed<br />

into one solid piece & precision<br />

ground.<br />

● The convenient front mounted on-off handle is<br />

removable to eliminate interference.<br />

Revolving Electric<br />

Magnetic Chuck<br />

HWK-EC-A,B<br />

HWK-PC-A,B,BH<br />

Unitmm<br />

Model Size<br />

Operation Plane Pole Pitch Fixed Plane<br />

B L L2 P B1 L1<br />

Height N.W. (kg)<br />

HWK-PC-407A 100180 100 175 143<br />

96 187<br />

8<br />

HWK-PC-510A 125250 125 250 202 121 262 15<br />

HWK-PC-612A 150300<br />

300 255<br />

312 22<br />

HWK-PC-614A 150350 150 350 299 8 (2+6) 146 362 55 25<br />

HWK-PC-618A 150450 450 409 462 33<br />

HWK-PC-816A 200400<br />

400 365<br />

412 39<br />

200<br />

196<br />

HWK-PC-818A 200450 450 409 462 44<br />

HWK-PC-510B 125250 125 250 191<br />

130 270<br />

12<br />

HWK-PC-612B 150300<br />

300 256 2.5 (1+1.5) 150 318 50 14<br />

150<br />

HWK-PC-618B 150450 450 406 150 368 23<br />

HWK-PC-606BH 150150<br />

150<br />

165<br />

8<br />

2.3<br />

HWK-PC-612BH 150300 150 300 315 40 15<br />

(0.8+1.5)<br />

HWK-PC-618BH 150450 450 465 13<br />

Revolving Permanent<br />

Magnetic Chuck<br />

HWK-RC-A<br />

Unitmm<br />

Operation Plane Pole Pitch Rotary Seat Plane<br />

Model Size<br />

Voltage Current Height N.W. (kg)<br />

B L L2 P d c F L1<br />

HWK-EC-510A 125250 125 250 190<br />

380<br />

0.35 A<br />

34<br />

15 (3+12)<br />

HWK-EC-612A 150300 150 300 240 430 0.45 A 43<br />

16 100 96 90V<br />

150<br />

HWK-EC-510B 125250 125 250 190<br />

380 0.35 A 34<br />

4 (1+3)<br />

HWK-EC-612B 150300 150 300 240 430 0.45 A 43<br />

Unitmm<br />

Model Size<br />

Operation Plane Pole Pitch Rotary Seat Plane<br />

B L L2 P A b t F L1 d<br />

Height N.W. (kg)<br />

HWK-RC-510A 125250 125 250 191<br />

380<br />

26<br />

8.5 (2.5+6) 50 35 17 96<br />

16 150<br />

HWK-RC-612A 150300 150 300 245 430 36<br />

22

Precision Accessories for Grinding Machine<br />

HWH-A50,60,70,100,125,150( General Type ) <br />

HWH-B50,60,70,100 ( Screw Type ) HWH-C50,60,70,100 ( Longer Type )<br />

Tool Makers' Vise<br />

● The materials are made of alloy steel<br />

processed by heat, subzero treatment for stress<br />

relief against distortion, hardened up to HRC58<br />

and fi nished by grinding.<br />

● This vise can be applied to Milling and Grinding<br />

Machine. It also can be a reference for<br />

inspection.<br />

● Smooth movement backward and forward.<br />

Parallelismwithin 0.003 mm / 100 mm<br />

Squarenesswithin 0.005 mm / 100 mm<br />

HWH-A50,60,70,100,125,150<br />

( General Type )<br />

Unitmm<br />

Model A B C D E F N.W. (kg)<br />

HWH-A50 48 150 62 30 32 0-65 2<br />

HWH-A60 63 170 63 35 35 0-90 3<br />

HWH-A70 73 190 67 40 35 0-100 4<br />

HWH-A100 100 230 102 48 52 0-125 10<br />

HWH-A125 125 280 102 50 52 0-150 13<br />

HWH-A150 150 350 130 50 80 0-200 16<br />

HWH-B50,60,70,100 ( Screw Type )<br />

Unitmm<br />

Model A B C D E F N.W. (kg)<br />

HWH-B50 48 150 62 30 32 0-80 2.5<br />

HWH-B60 63 180 72 35 37 0-100 4<br />

HWH-B70 73 190 82 40 42 0-110 6<br />

HWH-B100 100 230 102 48 52 0-120 12<br />

HWH-C50,60,70,100 ( Longer Type )<br />

Unitmm<br />

Model A B C D E F N.W. (kg)<br />

HWH-C50 48 170 50 24 26 0-95 3<br />

HWH-C60 63 235 72 37 35 0-135 4<br />

HWH-C70 73 235 72 37 35 0-135 4.5<br />

HWH-C100 100 280 82 42 40 0-170 12<br />

23

Precision Accessories for Grinding Machine<br />

HWI-A60,70 ( General Type ) HWI-B60,70 ( Screw Type )<br />

HWH-UV80<br />

Sine Vise<br />

● Accurate angle setting by Gauge Blocks.<br />

Rollers are processed by heat treatment and<br />

precisely ground.<br />

● HWI series has same features as HWH series.<br />

● The base has a positive locking device, which<br />

can provide a positive lock at any angle.<br />

Parallelism0.003 mm / 100 mm<br />

Squareness0.005 mm / 100 mm<br />

Roller Center Distance0.005 mm<br />

HWI-A60,70 ( General Type )<br />

Unitmm<br />

G N.W.<br />

Model A B C D E F<br />

0.005 (kg)<br />

HWI-A60 63 180 90 0~45 32 0-100 100 5<br />

HWI-A70 73 190 102 0~45 36 0-100 100 9<br />

HWI-B60,70<br />

( Screw Type )<br />

Unitmm<br />

G N.W.<br />

Model A B C D E F<br />

0.005 (kg)<br />

HWI-B60 63 180 99 0~45 37 0-100 100 6<br />

HWI-B70 73 190 119 0~45 42 0-100 100 10<br />

Precision Universal Vise<br />

Parallelism0.005 mm / 100 mm<br />

Squareness0.005 mm / 100 mm<br />

HWH-UV80<br />

Unitmm<br />

N.W.<br />

Model A B C D E F G H I<br />

(kg)<br />

HWH-UV80 137 75 32 80 137 180 110 70 12.5 12<br />

24

Precision Accessories for Grinding Machine<br />

HWH-VBST HWH-WST HWH-EH50<br />

Stainless Vise<br />

● The materials are made of stainless steel<br />

processed by heat and subzero treatment, and<br />

hardened up to HRC58°~60°.<br />

HWH-VBST<br />

Parallelism0.005 mm / 100 mm<br />

Squareness0.004 mm / 100 mm<br />

Weight4kg<br />

HWH-WST<br />

HardnessHRC55<br />

Weight1.4kg<br />

Electrode Vise<br />

HWH-EH50<br />

MaterialSUS440<br />

HardnessHRC56~58<br />

Weight1.4kg<br />

25

Precision Accessories for Milling Machine<br />

HWA-100 HWA-125,150,200<br />

Hydraulic Machine Vise<br />

● The vise provide a steady clamping force<br />

against shocks and vibrations during operation,<br />

since it fastens the work resiliently with the aid<br />

of dish springs mounted inside.<br />

● High quality, high precision, easy operation and<br />

without distortion. Reliability for Light & Heavy<br />

Duty cutting.<br />

HWA-100<br />

HWA-125,150,200<br />

Unitmm<br />

Model (A) (B) (C) a b c d e f g h i j k<br />

Max. Clamp. N.W.<br />

Force (kg) (kg)<br />

HWA-100 (4) 100 36 0-170 525 435 395 160 94 58 78 101 155 263 120 2500 18<br />

HWA-125 (5) 125 45 0-220 670 540 490 185 117 72 98 112 184 341 145 4000 32<br />

HWA-150 (6) 150 51 0-300 800 610 570 240 133 82 116 127 205 380 200 5000 60<br />

HWA-200 (8) 200 62 0-300 900 700 650 280 162 100 160 165 265 435 240 7000 90<br />

26

Precision Accessories for Milling Machine<br />

HWB-100 HWB-150 100,125,150,200-S<br />

Tiltable Two-Way Hydraulic Machine Vise<br />

● Tiltable angle from 0~ 50, the required angles<br />

are easily to read from indicator label.<br />

● Effi cient index autozeroing saves operating<br />

time and simplifi es the operating process.<br />

HWB-100<br />

● Used with Pull-Down-Jaw & Mini Sine Bar,<br />

angular accuracy will reach to second unit.<br />

● Tilting seat set by two locking screws, provides<br />

high stability, without vibration.<br />

HWB-150<br />

Unitmm<br />

Model (A) (B) (C) (D) a b c d e f g h<br />

Max. Clamp. N.W.<br />

Force (kg) (kg)<br />

HWB-100 (4) 100 36 0-170 50 505 325 65 160 177 141 80 184 2500 23<br />

HWB-150 (6) 150 51 0-300 50 775 410 95 240 237 186 100 240 5000 60<br />

Jaws : Swivel Base<br />

100,125,150,200-S<br />

Unitmm<br />

Model a b c d N.W. (kg)<br />

100-S 280 210 28 16 4<br />

125-S 287 267 33 18 7<br />

150-S 335 310 36 19 10<br />

200-S 373 355 41 19 16<br />

27

Precision Accessories for Milling Machine<br />

HWC-100,125,150-2W,3W,4W<br />

100,125,150,200-VJ 100,125,150,200-SJ 100,125,150,200-PJ<br />

Combined Hydraulic Machine Vise<br />

● This series is more preferable working in Milling<br />

Machine, NC Machines, and CNC Machine<br />

Centers.<br />

● These vises can fi rmly clamp various<br />

forms and sizes of workpieces, minimizing<br />

loading/unloading time.<br />

HWC-100,125,150-2W,3W,4W<br />

Unitmm<br />

Model (A) (B) (C) (E) a b<br />

c<br />

e<br />

Max. Clamp. N.W.<br />

d<br />

f g h i j o<br />

0.01 0.01<br />

Force (kg) (kg)<br />

HWC-125-2W (5) 429 45 0-220 18 653 490 300 540 300 118 97 83 134 341 86 4000 90<br />

HWC-150-2W (6) 484 51 0-300 18 807 610 330 550 330 139 116 128 210 380 98 5000 130<br />

HWC-150-3W (6) 594 51 0-300 18 807 610 220 660 220 139 116 128 210 380 98 5000 175<br />

HWC-100-4W (4) 599 36 0-170 16 519 400 165 695 165 107 78 70 112 263 72 2500 100<br />

HWC-125-4W (5) 729 46 0-220 16 653 490 200 840 200 118 97 83 134 341 86 4000 180<br />

Jaws<br />

Prism-Jaw<br />

● Can clamp round workpiece.<br />

Stripe-Jaw<br />

● Can prevent the workpiece<br />

from vibrating.<br />

Pull Down-Jaw<br />

● Can prevent the workpiece<br />

from lift up.<br />

100,125,150,200-VJ 100,125,150,200-SJ 100,125,150,200-PJ<br />

Unitmm<br />

Model A B C D E<br />

100-VJ 104 12 36 11 11<br />

125-VJ 130 15 46 13 13<br />

150-VJ 153 18 53 15 15<br />

200-VJ 206 21 62 17 17<br />

Unitmm<br />

Model A B C D<br />

100-SJ 104 12 36 6<br />

125-SJ 130 15 46 6<br />

150-SJ 153 18 53 6<br />

200-SJ 206 21 62 6<br />

Model A B C<br />

Unitmm<br />

100-PJ 104 30 38<br />

125-PJ 130 32 38<br />

150-PJ 153 34 38<br />

200-PJ 206 36 38<br />

28

Precision Accessories for Milling Machine<br />

H<strong>WD</strong>-A130,150 H<strong>WD</strong>-B130,150<br />

NC Hydraulic Machine Vise<br />

● All types of NC Vise surface are processed by<br />

high frequency heat-treatment. Guide ways are<br />

ground on all sides. The accuracy of parallelism<br />

and squareness is within 0.005 mm.<br />

● Basic body and fi xed jaw are mono-block<br />

casting. It is suitable for using under high<br />

pressure without distortion due to the tensile<br />

strength 65 kg/cm 2 .<br />

● All types of the parallelism and squareness of<br />

H<strong>WD</strong>-A130,150<br />

slots on the vise base are very precise.<br />

● The movable jaw is specially designed to hold<br />

down the workpiece, so that the workpiece has<br />

optimum accuracy after maching.<br />

● It is suitable for various materials and can be<br />

used with low pressure and high pressure.<br />

It is possible to combine with other H<strong>WD</strong>-A<br />

Hydraulic Machine Vises. The tolerance of<br />

matched height is within 0.005 mm.<br />

NC Diverse-Clamping Hydraulic Machine Vise<br />

Unitmm<br />

Model (A) (B) (C) (D) a b c d e f g h i j<br />

Max. Clamp.<br />

Force (kg)<br />

N.W. (kg)<br />

H<strong>WD</strong>-A130 (5) 130 49 0-205 205-300 460 207 128 145 80 72 87 334 72 161 4000 50<br />

H<strong>WD</strong>-A150 (6) 156 53 0-284 284-460 554 207 143 159 90 80 100 339 83 173 4400 60<br />

● H<strong>WD</strong>-B series also has the same features as<br />

H<strong>WD</strong>-A series.<br />

● All sides of the diverse-clamping jaw can easily<br />

be adjusted by parallel key.<br />

● This series can clamp different shape<br />

workpieces, such as the cylindrical end face,<br />

V-shape, trapezoidal, and ball workpieces.<br />

H<strong>WD</strong>-B130,150<br />

Unitmm<br />

Model (A) (B) (C) (D) a b c d e f g h i<br />

Max. Clamp.<br />

Force (kg)<br />

N.W. (kg)<br />

H<strong>WD</strong>-B130 (5) 130 49 0-180 180-400 500 207 129 145 80 72 128 334 161 4000 52<br />

H<strong>WD</strong>-B150 (6) 156 53 0-276 276-556 600 207 143 159 90 80 154 339 173 4400 62<br />

29

Precision Accessories for Milling Machine<br />

H<strong>WD</strong>-C130,150<br />

H<strong>WD</strong>-D130,150-2W,3W<br />

NC Quick-Positioning Machine Vise<br />

● The sliding stock can be quickly situated and<br />

clamped the workpiece down because of easy<br />

positioning steel ball.<br />

● The movable jaw is specially designed to hold<br />

down the workpiece, so that the workpiece has<br />

optimum accuracy after machining.<br />

● The sliding stock is moved forward and<br />

backword by a screw, so that the workpiece<br />

can be clamped and loosened quickly.<br />

● This vise can clamp max. 480 mm workpieces.<br />

H<strong>WD</strong>-C130,150<br />

Unitmm<br />

Model (A) (B) (C) (D) a b c d e f g h j<br />

Max. Clamp. N.W.<br />

Force (kg) (kg)<br />

H<strong>WD</strong>-C130 (5) 130 49 0-170 170-370 500 200 129 145 80 72 128 250 160 2000 54<br />

H<strong>WD</strong>-C150 (6) 156 53 0-240 240-480 600 200 143 159 90 80 154 260 174 2000 64<br />

NC Two,Three-Clamping-Unit Hydraulic Machine Vise<br />

● This vise can clamp two or three workpieces at<br />

the same time; therefore, the equipment cost<br />

and the set-up time are reduced.<br />

H<strong>WD</strong>-D130,150-2W,3W<br />

Unitmm<br />

Model (A) (B) (C) (D) (E) (F) a c d e f g i k l<br />

Max. Clamp. N.W.<br />

Force (kg) (kg)<br />

H<strong>WD</strong>-D130-2W (5) 130 48 80 90 38 220 500 128 118 80 72 71 65 46 36 4000 46<br />

H<strong>WD</strong>-D130-3W (5) 130 48 38 48 38 220 500 128 118 80 72 71 65 46 36 4000 50<br />

H<strong>WD</strong>-D150-2W (6) 156 53 150 160 43 256 600 143 133 90 80 71 65 50 40 4400 56<br />

H<strong>WD</strong>-D150-3W (6) 156 53 83 93 43 256 600 143 133 90 80 71 65 50 40 4400 60<br />

30

Precision Accessories for Milling Machine<br />

H<strong>WD</strong>-E130,150-2W,3W,4W H<strong>WD</strong>-F130,150-4W<br />

H<strong>WD</strong>-G100,150<br />

NC Two,Three,Four-Clamping-Unit Machine Vise<br />

● This vise can clamp two, three, or four<br />

workpieces at the same time; therefore, the<br />

equipment cost and set-up time is reduced.<br />

H<strong>WD</strong>-E130,150-2W,3W,4W<br />

Unitmm<br />

Model (A) (B) (C) (D) (E) (F) a c d e f g i k l<br />

Max. Clamp. N.W.<br />

Force (kg) (kg)<br />

H<strong>WD</strong>-E130-2W (5) 130 48 126 136 38 380 500 128 118 80 72 46 36 46 36 800 39<br />

H<strong>WD</strong>-E130-3W (5) 130 48 68 78 38 380 500 128 118 80 72 46 36 46 36 800 43<br />

H<strong>WD</strong>-E130-4W (5) 130 48 40 50 38 380 500 128 118 80 72 46 36 46 36 800 47<br />

H<strong>WD</strong>-E150-2W (6) 156 53 174 184 43 470 600 143 133 90 80 50 40 50 40 800 49<br />

H<strong>WD</strong>-E150-3W (6) 156 53 99 109 43 470 600 143 133 90 80 50 40 50 40 800 53<br />

H<strong>WD</strong>-E150-4W (6) 156 53 60 70 43 470 600 143 133 90 80 50 40 50 40 800 57<br />

NC Four-Clamping-Unit Machine Vise<br />

● This vise can clamp four workpieces at the<br />

same time; therefore, the equipment cost and<br />

the set-up time are reduced.<br />

H<strong>WD</strong>-F130,150-4W<br />

Unitmm<br />

Model (A) (B) (C) (D) (E) a c d e f Max. Clamp. Force (kg) N.W. (kg)<br />

H<strong>WD</strong>-F130-4W (5) 130 30 0-68 68-82 15 500 120 95 80 72 800 48<br />

H<strong>WD</strong>-F150-4W (6) 156 30 0-93 93-107 15 600 120 105 90 80 800 58<br />

NC Angle-Fixed Machine Vise<br />

H<strong>WD</strong>-G100,150<br />

Unitmm<br />

Model A B C E F G I<br />

N.W.<br />

(kg)<br />

H<strong>WD</strong>-G100 (4) 106 285 330 96 61 35 100 13<br />

H<strong>WD</strong>-G150 (6) 160 368 425 120 75 45 150 27<br />

31

Precision Accessories for Milling Machine<br />

HWE-MPV160,200,160L,200L<br />

MPV160,200-FHJ MPV160,200-FLJ MPV160,200-MHJ MPV160,200-MLJ<br />

MC Precision Power Vice<br />

● Down trust "Leaf-Spring" mechanism<br />

eliminates work lift. Effort-saving by using high<br />

Thrust-Power-Ratio system.<br />

● Movable jaw can quickly move forward and<br />

backward by dia. 42 mm double thread master<br />

screw.<br />

HWE-MPV160,200,160L,200L<br />

● Vise bed fl ame is processed by high frequency<br />

heat-treatment, which ensured high precision<br />

and durable.<br />

● Short body is suitable for large & small machine<br />

Center. The solid body is made of ductile iron<br />

FCD60.<br />

Fixed & Movable Jaws<br />

Unitmm<br />

Model A B C D E F G H I J K L M N N.W. (kg)<br />

HWE-MPV125 365 145 78 74 208 45 18 100 145 98.5 126 463.5 125 135 35<br />

HWE-MPV160 455 160 86 86 275 45 18 115 145 98.5 162 553.5 160 171 57<br />

HWE-MPV200 505 180 100 97 300 55 18 125 177 100 202 603.5 200 211 90<br />

HWE-MPV160L 535 160 86 86 355 45 18 115 177 98.5 162 633.5 160 174 64<br />

HWE-MPV200L 610 180 100 97 405 55 18 125 177 100 202 708.5 200 214 103<br />

MPV160,200-FHJ MPV160,200-FLJ MPV160,200-MHJ MPV160,200-MLJ<br />

Fixed Jaw<br />

Unitmm<br />

Model A B b C D E H h W<br />

MPV125-FHJ 24 78 8 45 88 50 125<br />

MPV160-FHJ 28 86 9 50 124 60 160<br />

MPV200-FHJ 28 100 9 62 140 85 200<br />

MPV125-FLJ 24 78 39 8 45 88 50 30 125<br />

MPV160-FLJ 28 86 43 9 50 124 60 40 160<br />

MPV200-FLJ 28 100 50 9 62 140 85 61 200<br />

Movable Jaw<br />

Unitmm<br />

Model A B b C D E H h W<br />

MPV125-MHJ 24 78 8 42 35 50 125<br />

MPV160-MHJ 28 86 9 50 56 60 160<br />

MPV200-MHJ 28 100 9 59 62 85 200<br />

MPV125-MLJ 24 78 39 8 42 35 50 30 125<br />

MPV160-MLJ 28 86 43 9 50 56 60 40 160<br />

MPV200-MLJ 28 100 50 9 59 62 85 61 200<br />

32

Precision Accessories for Milling Machine<br />

HWY-C80,100,130 HWY-100,125,150,200<br />

HWY-K100,125,150,200<br />

3-Way Angle Milling Vise<br />

HWY-C80,100,130<br />

Angle-Fixed Milling Vise<br />

Unitmm<br />

Model A B C H L N.W. (kg)<br />

HWY-C80 90 30 80 150 396 20<br />

HWY-C100 105 38 106 172 460 40<br />

HWY-C130 140 40 132 205 625 60<br />

HWY-100,125,150,200<br />

K Milling Vise<br />

Unitmm<br />

Model A B C E F G H I N.W. (kg)<br />

HWY-110 100 220 320 133 65 38 115 110 19<br />

HWY-125 125 240 360 146 70 38 132 130 29<br />

HWY-150 150 290 430 161 72 48 170 150 48<br />

HWY-200 200 370 600 193 85 58 190 210 82<br />

HWY-K100,125,150,200<br />

Unitmm<br />

Model A B C E F G H I N.W. (kg)<br />

HWY-K110 100 120 95 81 55 38 90 62 9<br />

HWY-K125 125 160 380 135 60 40 115 80 16<br />

HWY-K150 150 190 460 150 65 43 135 115 28<br />

HWY-K200 200 240 620 185 85 60 190 150 53<br />

33

Precision Accessories for Milling Machine<br />

HWU-BS0,BS1 HWU-BS2<br />

Semi-Universal Dividing Head<br />

HWU-BS0,BS1<br />

Dividing Plate<br />

Number of Holes<br />

A 15 16 17 18 19 20<br />

B 21 23 27 29 31 33<br />

C 37 39 41 43 47 49<br />

Warm Gear Reduction<br />

Ration<br />

140<br />

Unit : mm<br />

Tail Stock<br />

Model A1 B1 H1 h a1 b1 g1<br />

TS-0 182 82 123 100 155 1.10 16<br />

TS-1 182 82 133 126 155 1.10 16<br />

Unit : mm<br />

Dividing Head<br />

Model A B H h a b g Taper of Center Dia. of Spindle hole N.W. (kg)<br />

HWU-BS0 196 133 173 100 160 91 16 B & S No.7 16 22<br />

HWU-BS1 253 163 220 126 207 114 16 B & S No.9 20 36<br />

Optional Accessories : 4" or 5" Three-Jaw Chuck for HWU-BS0; 5" or 6" Three-Jaw Chuck for HWU-BS1<br />

Universal Dividing Head<br />

HWU-BS2<br />

Unit : mm<br />

Tail Stock<br />

Model A1 B1 H1 h a1 b1 g1<br />

TS-2 182 88 156 135 175 124 16<br />

Unit : mm<br />

Dividing Head<br />

Model A B H h a b g1 Taper of Center Dia. of Spindle hole N.W. (kg)<br />

HWU-BS2 365 272 236 135 213 134 16 B & S No.10 25.4 73<br />

Optional Accessories : 5" or 7" Three-Jaw Chuck<br />

34

Precision Accessories for Milling Machine<br />

HWV-6,8,10,12,14 HWV-CC6,8<br />

HWV-CS6,8<br />

Horizontal & Vertical Indexing Table<br />

HWV-6,8,10,12,14<br />

Simple Indexing Spacer<br />

Unit : mm<br />

Model<br />

Table<br />

Widthof Bolt<br />

Base Dimension<br />

Taper Dia. of<br />

Outer Dia Height<br />

T-slot Slots<br />

of Center Spindle hole<br />

A D H H1 A B e g<br />

N.W. (kg)<br />

HWV-6 80 150 82 100 200 195 11 14 MT-2<br />

12<br />

HWV-8 110 204 106 130 265 220 11 16 MT-3 30<br />

HWV-10 110 254 115 162 322 280 13 17 MT-3 90 : 1 48<br />

HWV-12 128 303 132 197 592 330 16 17 MT-4 77<br />

HWV-14 130 350 140 230 450 380 16 18 MT-4 95<br />

Optional Accessories : Tail Stock, Dividing Plate, and Three-Jaw Chuck<br />

Model<br />

Poweful Indexing Spacer<br />

HWV-CS6,8<br />

Direct<br />

Dividing<br />

A B C D a b g h<br />

Inner<br />

Jaw<br />

Outter<br />

Jaw<br />

Dia. of Inside Hole of<br />

Hole (chuck) Rotary Tower<br />

Unit : mm<br />

N.W. (kg)<br />

HWV-CC6 2,3,4,6,8,12,24 260 218 156 167 220 130 16 130 4-42 10~156 44 36 32<br />

HWV-CC8 2,3,4,6,8,12,24 318 265 117 210 228 140 140 150 4-62 10~180 63 63 47<br />

Optional Accessories : 6" Three-Jaw Chuck for HWV-CC6, 8" Three-Jaw Chuck for HWV-CC8<br />

Direct<br />

Dividing<br />

Chuck<br />

Face Plate<br />

Unit : mm<br />

Model<br />

Outter Inner Outter Inner Outter<br />

A B C a b c d e f g h i j k<br />

Thickness<br />

Dia. Dia. Jaw Jaw Dia.<br />

HWV-CS6 2,3,4,6,8,12,24 167 44 10-156 4-42 203 50 250 235 221 220 150 184 82 112 66 16 130 186 80 18 35<br />

HWV-CS8 2,3,4,6,8,12,24 210 63 10-180 4-62 254 58 315 292 243 225 160 195 100 125 75 16 157 241 90 18 70<br />

Optional Accessories : 6" Three-Jaw Chuck for HWV-CS6, 8" Three-Jaw Chuck for HWV-CS8<br />

N.W.<br />

(kg)<br />

35

Precision Accessories for Milling Machine<br />

HWV-UT300 HWCK-180,250,380,600<br />

Universal Tilting Rotary Table<br />

HWV-UT300<br />

Center Hight : Max. 230 mm<br />

Min. 113 mm<br />

Dividing Plate<br />

A<br />

B<br />

Number of Holes<br />

24.25.26.28.32.34<br />

37.38.41.42.43.44<br />

46.47.49.51.53<br />

57.58.59.62.66<br />

Model<br />

A<br />

Table<br />

Diameter<br />

B<br />

Table Height<br />

(Horizontal)<br />

C<br />

Table Height<br />

(Vertical)<br />

D<br />

Center Height<br />

(Vertical)<br />

E<br />

F<br />

Gear<br />

Ratiio<br />

Center<br />

Hole<br />

Direct<br />

Indexing<br />

Unit : mm<br />

HWV-UT300 Ø305 172 366 192 340 460 90:1 MT-3 24 97<br />

Optional Accessories : Tail Stock and Dividing Plate<br />

Tilting Angle Plate<br />

HWCK-180,250,380,600<br />

N.W.<br />

(kg)<br />

Unit : mm<br />

Model A B C H N.W. (kg)<br />

HWCK-180 184 132 13 92 8<br />

HWCK-250 260 182 16 139 22<br />

HWCK-380 386 266 16 189 62<br />

HWCK-600 600 305 16 215 128<br />

36

Precision Accessories for Milling Machine<br />

HWQ-320A ( Sand Cloth Roller ) HWQ-500B ( Side Milling Cutter )<br />

HWQ-500C ( Abrasive Wheel ) HWQ-500BR ( Face Milling Cutter )<br />

Chamfering Machine<br />

HWQ-320A ( Sand Cloth Roller ) HWQ-500B ( Side Milling Cutter )<br />

HWQ-500C ( Abrasive Wheel ) HWQ-500BR ( Face Milling Cutter )<br />

Unit : mm<br />

Model<br />

HWQ-320A<br />

HWQ-500B<br />

HWQ-500C<br />

HWQ-500BR<br />

Space<br />

Requirement<br />

330410<br />

500320<br />

500440<br />

500220<br />

Voltage<br />

3 Phase / 220V<br />

1Phase / 110V / 220V<br />

50HZ / 60HZ<br />

3 Phase / 220V<br />

1Phase / 110V / 220V<br />

50HZ / 60HZ<br />

3 Phase / 220V<br />

50HZ / 60HZ<br />

3 Phase / 220V<br />

50HZ / 60HZ<br />

Motor<br />

Output (kw)<br />

Speed<br />

R.P.M<br />

Length of<br />

guide rails<br />

0.7 3500 320<br />

0.7 3500 500<br />

0.7 3500 500<br />

0.7 3500 500<br />

Height of<br />

Bevel<br />

Adjustable<br />

0~3mm<br />

Adjustable<br />

0~3mm<br />

Adjustable<br />

0~2mm<br />

Adjustable<br />

0~3mm<br />

Bevel<br />

angle<br />

N.W. (kg)<br />

45 25<br />

15~45 30<br />

45 35<br />

45 35<br />

37

Precision Accessories for Milling Machine<br />

HWO-A18,23,30,40,63 HWO-B18,23,30,40,63<br />

Adjustable Boring Head<br />

● Fine adjustment can be made to 0.01 mm.<br />

● Materials are made of alloy steel processed by<br />

heat and subzero treatment.<br />

● Internal construction is completely sealed and<br />

protected from cutting chips.<br />

● Compact construction minimizes the<br />

occurrence of faults.<br />

● A wide range adjustment can be made.<br />

HWO-A18,23,30,40,63<br />

HWO-B18,23,30,40,63<br />

Unit : mm<br />

Model C1<br />

Boring Hole<br />

Slide<br />

Dia<br />

Space A1 Dial Indicating Insert<br />

H1<br />

Index<br />

Min. Max. W1 D1<br />

H2 H3 H C2 G N.W. (kg)<br />

HWO-A18 18 19 32 4 Ø0.05 Ø0.01 50 Ø6 5 12 14 Ø11 M10 P=1.5 0.1<br />

HWO-A23 23 24 46 6 Ø0.05 Ø0.01 65 Ø8 Ø8 7 15 19 Ø14 M12 P=1.75 0.2<br />

HWO-A30 30 31 60 8 Ø0.05 Ø0.01 80 Ø10 Ø10 7 23 26 Ø22 M16 P=2.0 0.4<br />

HWO-A40 40 41 80 10 Ø0.05 Ø0.01 90 Ø13 Ø10 7 23 35 Ø28 M18 P=2.5 0.8<br />

HWO-A63 63 64 130 20 Ø0.05 Ø0.01 97 Ø16 Ø18 5 22 52 Ø36 M25 P=2.0 2.3<br />

Unit : mm<br />

Model C1<br />

Boring Hole Slide<br />

Indicating<br />

Dia Space Dial<br />

H1 Inserts NO Screw<br />

Index<br />

NO<br />

Min. Max. A1<br />

H2 H3 H C2 G N.W. (kg)<br />

HWO-B18 18 24 31 4 Ø0.05 Ø0.01 50 CCMT0602 MS1153 5 12 14 Ø11 M10 P=1.5 0.14<br />

HWO-B23 23 29 40 6 Ø0.05 Ø0.01 65 CCMT09T3 MS1155 7 15 19 Ø14 M12 P=1.75 0.22<br />

HWO-B30 30 37 52 8 Ø0.05 Ø0.01 80 CCMT09T3 MS1155 7 23 26 Ø22 M16 P=2.0 0.48<br />

HWO-B40 40 47 67 10 Ø0.05 Ø0.01 90 CCMT09T3 MS1155 7 23 35 Ø28 M18 P=2.5 0.95<br />

HWO-B63 63 72 112 20 Ø0.05 Ø0.01 97 CCMT1204 MS1157 5 22 52 Ø36 M25 P=2.0 2.50<br />

38

Precision Accessories for Milling Machine<br />

BT40,50-18A,23A,30A,40A,63A NT40,50-18A,23A,30A,40A,63A<br />

HWO-18A,23A,30A,40A,63A<br />

Boring Bar for Adjustable Boring Head<br />

BT40,50-18A,23A,30A,40A,63A<br />

NT40,50-18A,23A,30A,40A,63A<br />

Unit : mm<br />

Model L1 L2<br />

BT40-18A 60 72<br />

BT40-23A 60 92<br />

BT40-30A 60 102<br />

BT40-40A 60 122<br />

BT40-63A 60 122<br />

BT50-18A 22 62<br />

BT50-23A 42 82<br />

BT50-30A 42 92<br />

BT50-40A 42 112<br />

BT50-63A 42 112<br />

HWO-18A,23A,30A,40A,63A<br />

Unit : mm<br />

Model L1 L2<br />

NT40-18A 80 120<br />

NT40-23A 80 120<br />

NT40-30A 80 130<br />

NT40-40A 80 150<br />

NT40-63A 80 <br />

NT50-18A 80 120<br />

NT50-23A 80 120<br />

NT50-30A 80 130<br />

NT50-40A 80 150<br />

NT50-63A 80 150<br />

Unit : mm<br />

Model L1 L2<br />

HWO-18A 50 100<br />

HWO-23A 50 100<br />

HWO-30A 50 100<br />

HWO-40A 50 100<br />

HWO-63A 70 <br />

39

Precision Accessories for Milling Machine<br />

BT50,NT50-LC1,2,3,4 BT50,NT50-LA1,2,3,4<br />

LC Large Twin Cutter Adjustable Boring Holder<br />

BT50,NT50-LC1,2,3,4<br />

Unit : mm<br />

Boring Range<br />

Model L1 L2 L3 L4<br />

W1 W2<br />

BT50-LC1 100 170 220 290 130 220<br />

BT50-LC2 100 170 220 290 190 280<br />

BT50-LC3 100 170 220 290 250 420<br />

BT50-LC4 100 170 220 290 390 560<br />

Unit : mm<br />

Boring Range<br />

Model L1 L2 L3 L4<br />

W1 W2<br />

NT50-LC1 100 170 220 290 130 220<br />

NT50-LC2 100 170 220 290 190 280<br />

NT50-LC3 100 170 220 290 250 420<br />

NT50-LC4 100 170 220 290 390 560<br />

LA Large Twin Cutter Adjustable Boring Holder<br />

BT50,NT50-LA1,2,3,4<br />

Unit : mm<br />

Boring Range<br />

Model L1 L2 L3 L4<br />

W1 W2<br />

BT50-LA1 100 170 220 290 130 220<br />

BT50-LA2 100 170 220 290 190 280<br />

BT50-LA3 100 170 220 290 250 420<br />

BT50-LA4 100 170 220 290 390 560<br />

Unit : mm<br />

Boring Range<br />

Model L1 L2 L3 L4<br />

W1 W2<br />

NT50-LA1 100 170 220 290 130 220<br />

NT50-LA2 100 170 220 290 190 280<br />

NT50-LA3 100 170 220 290 250 420<br />

NT50-LA4 100 170 220 290 390 560<br />

40

Precision Accessories for Milling Machine<br />

HWO-BB HWO-BC2,3,4<br />

Adjustable Boring Head Set<br />

HWO-BB<br />

Unit : mm<br />

Model Actual Size Body Boring Bar Hole Size Center Dist Between Holes Cross Hole Dia Offset N.W. (kg)<br />

HWO-BB 84 95 18 27 18 15 6<br />

Optional Boring Head : R8,NT30,NT40,NT50,MT3,MT4,BT40<br />

Adjustable Boring Head<br />

HWO-BC2,3,4<br />

Unit : mm<br />

Model<br />

Actual Size Body Length Boring Bar Hole Size Center Dist Cross Hole Dia<br />

A<br />

L<br />

B<br />

Between Holes C<br />

Offset N.W. (kg)<br />

HWO-BC2-1 (Inch) 2" 2~7/16" 1/2" 5/8" 1/2" 5/8" 0.5<br />

HWO-BC2-2 (mm) 50 62 12 15 12 15 0.5<br />

HWO-BC3-1 (Inch) 3" 3~5/32" 3/4" 15/16" 3/4" 1" 2<br />

HWO-BC3-2 (mm) 75 80 18 23 18 25 2<br />

HWO-BC4-1 (Inch) 4" 3~1/2" 25.4" 11/4" 25.4" 1" 4<br />

HWO-BC4-2 (mm) 100 90 25 32 25 25 4<br />

41

Precision Accessories for Milling Machine<br />

BT-TB NT-TB ST-TB<br />

TB Twin Cutter Boring Holder<br />

BT-TB<br />

NT-TB<br />

ST-TB<br />

Unit : mm<br />

Boring Range<br />

Model L1 L2 L3 L4<br />

W1 W2<br />

BT30-TB1 32 82 132 182 22 30<br />

BT30-TB2 52 102 152 202 29 38<br />

BT30-TB3 60 120 180 240 38 49<br />

BT40-TB1 53 83 133 183 22 30<br />

BT40-TB2 73 103 153 203 29 38<br />

BT40-TB3 91 121 181 241 38 49<br />

BT40-TB4 65 125 185 245 48 60<br />

BT40-TB5 75 145 195 265 59 75<br />

BT40-TB6 85 155 205 275 74 105<br />

BT50-TB1 54 84 134 184 22 30<br />

BT50-TB2 74 104 154 204 29 38<br />

BT50-TB3 92 122 182 242 38 49<br />

BT50-TB4 96 126 186 246 48 60<br />

BT50-TB5 76 146 196 266 59 75<br />

BT50-TB6 86 156 206 276 74 105<br />

BT50-TB7 86 156 206 276 104 140<br />

Unit : mm<br />

Boring Range<br />

Model L1 L2 L3 L4<br />

W1 W2<br />

NT30-TB1 36 86 136 186 22 30<br />

NT30-TB2 56 106 156 206 29 38<br />

NT30-TB3 64 124 184 244 38 49<br />

NT40-TB1 56 106 156 206 22 30<br />

NT40-TB2 76 126 176 226 29 38<br />

NT40-TB3 94 154 214 274 38 49<br />

NT40-TB4 68 128 188 248 48 60<br />

NT40-TB5 78 148 198 268 59 75<br />

NT40-TB6 88 158 208 278 74 105<br />

NT50-TB1 60 110 160 210 22 30<br />

NT50-TB2 80 130 180 230 29 38<br />

NT50-TB3 98 158 218 278 38 49<br />

NT50-TB4 102 162 222 282 48 60<br />

NT50-TB5 82 152 222 292 59 75<br />

NT50-TB6 92 162 232 302 74 105<br />

NT50-TB7 92 162 232 302 104 140<br />

Unit : mm<br />

Boring Range<br />

Model L1 L2 L3 L4<br />

W1 W2<br />

ST25-TB1 32 82 132 182 20 30<br />

ST25-TB2 52 102 152 202 29 38<br />

ST25-TB3 101 161 221 281 38 49<br />

ST32-TB1 48 88 138 188 22 30<br />

ST32-TB2 68 143 193 243 29 38<br />

ST32-TB3 66 161 221 281 38 49<br />

ST32-TB4 105 165 225 285 48 60<br />

ST32-TB5 115 185 235 305 59 75<br />

ST42-TB1 48 128 178 228 22 30<br />

ST42-TB2 68 148 198 248 29 38<br />

ST42-TB3 66 166 226 286 38 49<br />

ST42-TB4 105 180 240 300 48 60<br />

ST42-TB5 115 200 250 320 59 75<br />

ST42-TB6 125 210 260 330 74 105<br />

ST42-TB7 125 210 260 330 104 140<br />

42

Precision Accessories for Milling Machine<br />

BT50,NT50-LB1,2,3,4 BT30,40,50-SLA<br />

LB Large Twin Cutter Boring Holder<br />

BT50,NT50-LB1,2,3,4<br />

Unit : mm<br />

Boring Range<br />

Model L1 L2 L3 L4<br />

W1 W2<br />

BT50-LB1 80 150 200 270 130 190<br />

BT50-LB2 80 150 200 270 190 250<br />

BT50-LB3 80 150 200 270 250 390<br />

BT50-LB4 80 150 200 270 390 530<br />

Unit : mm<br />

Boring Range<br />

Model L1 L2 L3 L4<br />

W1 W2<br />

NT50-LB1 80 150 200 270 130 190<br />

NT50-LB2 80 150 200 270 190 250<br />

NT50-LB3 80 150 200 270 250 390<br />

NT50-LB4 80 150 200 270 390 530<br />

BT Side Lock Mill Holder<br />

BT30,40,50-SLA<br />

Unit : mm<br />

Model D L C H H1 H2 G<br />

BT30-SLA6-60L 6 60 25 32 10 10 M6<br />

BT30-SLA8-60L 8 60 28 36 12 12<br />

BT30-SLA10-60L 10 60 35 40 15 12<br />

M8<br />

BT30-SLA12-60L 12 60 40 45 18 16<br />

BT30-SLA16-75L 16 75 45 50 20 18<br />

M10<br />

BT30-SLA20-75L 20 75 50 60 25 20<br />

BT30-SLA25-75L 25 75 55 65 24 25<br />

M12<br />

BT40-SLA6-75L 6 75 25 32 10 10 M6<br />

BT40-SLA8-75L 8 75 28 36 12 12<br />

BT40-SLA10-75L 10 75 35 40 15 12<br />

M8<br />

BT40-SLA12-75L 12 75 40 45 18 16<br />

BT40-SLA14-75L 14 75 42 45 18 16 M10<br />

BT40-SLA16-75L 16 75 45 50 20 18<br />

Unit : mm<br />

Model D L C H H1 H2 G<br />

BT40-SLA20-90L 20 90 50 65 25 20 M12<br />

BT40-SLA25-90L 25 90 60 65 24 25<br />

BT40-SLA32-90L 32 90 60 70 24 28<br />

BT40-SLA40-105L 40 105 80 80 24 28<br />

M16<br />

BT40-SLA42-105L 42 105 80 80 24 28<br />

BT50-SLA6-105L 6 105 25 32 10 10 M6<br />

BT50-SLA8-105L 8 105 28 36 12 12<br />

BT50-SLA10-105L 10 105 35 40 15 12<br />

M8<br />

BT50-SLA12-105L 12 105 40 45 18 16<br />

BT50-SLA16-105L 16 105 45 50 20 18<br />

M10<br />

BT50-SLA20-105L 105 50 60 25 20<br />

BT50-SLA20-150L 20 150 40/50 60 25 20 M12<br />

BT50-SLA20-200L 200 40/50 60 25 20<br />

BT50-SLA25-105L 105 60 60 25 22<br />

BT50-SLA25-150L 150 50/60 65 24 25<br />

25<br />

BT50-SLA25-200L 200 50/60 65 24 25<br />

BT50-SLA25-250L 250 50/60 65 24 25<br />

BT50-SLA32-105L 105 60 70 24 28<br />

M16<br />

BT50-SLA32-150L 150 50/60 70 24 28<br />

32<br />

BT50-SLA32-200L 200 50/60 70 24 28<br />

BT50-SLA32-250L 250 50/60 70 24 28<br />

BT50-SLA40-120L 40 120 80 80 30 32<br />

BT50-SLA42-120L 120 80 80 30 32<br />

BT50-SLA42-150L 42 150 80 80 30 32<br />

BT50-SLA42-200L 200 80 80 30 32<br />

M20<br />

BT50-SLA50.8-<br />

120L<br />

50.8 120 95 90 30 32<br />

43

Precision Accessories for Milling Machine<br />

BT-FMA,FMB NT-FMA,FMB<br />

BT Face Mill Holder<br />

BT-FMA,FMB<br />

Unit : mm<br />

Model D L C H W G<br />

BT30-FMA25.4-45L<br />

45 45 20 9.5<br />

BT30-FMA25.4-60L 60 45 20 9.5<br />

BT40-FMA25.4-45L 45 55 20 9.5<br />

25.4<br />

BT40-FMA25.4-60L 60 55 20 9.5<br />

BT40-FMA25.4-90L 90 62-55 20 9.5 M12<br />

BT40-FMA25.4-105L 105 62-55 20 9.5<br />

BT40-FMA31.75-45L<br />

45 62 22 12.7<br />

BT40-FMA31.75-75L 31.75 75 62 22 12.7<br />

BT40-FMA31.75-105L 105 70-62 22 12.7<br />

BT40-FMA38.1-60L 38.1 75 80 23 15.9 M16<br />

BT50-FMA25.4-45L<br />

45 60 20 9.5<br />

BT50-FMA25.4-75L 60 60 20 9.5<br />

BT50-FMA25.4-105L 25.4 105 60 20 9.5 M12<br />

BT50-FMA25.4-125L 125 60 20 9.5<br />

BT50-FMA25.4-150L 150 63-58 20 9.5<br />

BT50-FMA31.75-45L<br />

45 70 22 12.7<br />

BT50-FMA31.75-75L 75 70 22 12.7<br />

31.75<br />

BT50-FMA31.75-105L 105 75-70 22 12.7<br />

BT50-FMA31.75-150L 150 75-70 22 12.7<br />

BT50-FMA38.1-45L<br />

45 85 23 15.9<br />

BT50-FMA38.1-75L 38.1 75 85-80 23 15.9<br />

M16<br />

BT50-FMA38.1-105L 105 85-80 23 15.9<br />

BT50-FMA50.8-45L<br />

45 95 24 19.05<br />

BT50-FMA50.8-75L 50.8 75 95 24 19.05<br />

BT50-FMA50.8-105L 105 95 24 19.05<br />

NT Face Mill Holder<br />

Unit : mm<br />

Model D L C H W G<br />

BT30-FMB22-45L 22 45 45 18 10 M10<br />

BT30-FMB27-45L 27 45 55 20 12 M12<br />

BT40-FMB22-60L<br />

60 45 18 10<br />

22<br />

BT40-FMB22-105L 105 50-45 18 10<br />

BT40-FMB27-60L<br />

60 60 20 12<br />

27<br />

BT40-FMB27-105L 105 60 20 12<br />

BT40-FMB32-60L<br />

60 63 21 14<br />

32<br />

BT40-FMB32-105L 105 63 21 14<br />

BT40-FMB40-60L 40 60 78 22 16<br />

BT50-FMB22-60L<br />

60 45 18 10<br />

BT50-FMB22-105L 105 50-45 18 10<br />

BT50-FMB22-125L 125 50-45 18 10<br />

22<br />

BT50-FMB22-150L 150 50-45 18 10<br />

BT50-FMB22-200L 200 50-45 18 10<br />

BT50-FMB22-250L 250 50-45 18 10<br />

BT50-FMB27-60L<br />

60 60 20 12<br />

BT50-FMB27-105L 105 60 20 12<br />

27<br />

BT50-FMB27-125L 125 65-60 20 12<br />

BT50-FMB27-150L 150 65-60 20 12<br />

BT50-FMB32-60L<br />

60 70 21 14<br />

BT50-FMB32-105L 32 105 70 21 14<br />

BT50-FMB32-150L 150 75-70 21 14<br />

BT50-FMB40-60L<br />

60 85 23 16<br />

BT50-FMB40-105L 40 105 85 23 16<br />

BT50-FMB40-150L 150 85 23 16<br />

M10<br />

M12<br />

M16<br />

M10<br />

M12<br />

M16<br />

NT-FMA,FMB<br />

44<br />

Unit : mm<br />

Model D L C H W G<br />

NT30-FMA25.4-20L 25.4 20 65 20 9.57 M12<br />

NT30-FMA31.75-20L 31.75 20 73 22 12.75 M12<br />

NT40-FMA25.4-20L 25.4 20 65 20 9.57 M12<br />

NT40-FMA31.75-20L 31.75 20 73 22 12.75 M12<br />

NT40-FMA38.1-20L 38.1 20 82 23 15.9 M16<br />

NT40-FMA50.8-20L 50.8 20 95 24 19.05 M16<br />

NT50-FMA25.4-20L 25.4 20 65 20 0.57 M12<br />

NT50-FMA31.75-20L 31.75 20 73 22 12.75 M12<br />

NT50-FMA38.1-20L 38.1 20 82 23 15.9 M16<br />

NT50-FMA50.8-20L 50.8 20 95 24 19.05 M16<br />

Unit : mm<br />

Model D L C H W G<br />

NT30-FMB22-20L 22 20 44 18 10 <br />

NT30-FMB27-20L 27 20 54 20 12 <br />

NT30-FMB32-20L 32 20 64 23 14 <br />

NT40-FMB22-20L 22 20 44 18 10 <br />

NT40-FMB27-20L 27 20 65 20 12 <br />

NT40-FMB32-20L 32 20 73 21 14 <br />

NT40-FMB40-20L 40 20 85 23 16 M12<br />

NT50-FMB22-20L 22 20 44 18 10 <br />

NT50-FMB27-20L 27 20 65 20 12 <br />

NT50-FMB32-20L 32 20 73 21 14 <br />

NT50-FMB40-20L 40 20 85 23 16 M12

Precision Accessories for Milling Machine<br />

BT-MT NT-MT<br />

BT30,40,50-TP316,830 TP316,830<br />

Morse Taper Holder<br />

BT-MT<br />

NT-MT<br />

Model L1 L2<br />

BT30-MT1 45 <br />

BT30-MT2 60 <br />

BT30-MT3 80 <br />

BT40-MT1 45 120<br />

BT40-MT2 45 120<br />

BT40-MT3 75 135<br />

BT40-MT4 90 <br />

Tapping Holder<br />

BT30,40,50-TP316,830<br />

Unit : mm<br />

Model L1 L2<br />

BT50-MT1 45 120<br />

BT50-MT2 45 135<br />

BT50-MT3 60 150<br />

BT50-MT4 75 180<br />

BT50-MT5 105 210<br />

Unit : mm<br />

Model<br />

NT40-MT1 100<br />

NT40-MT2 100<br />

NT40-MT3 130<br />

NT40-MT4 150<br />

NT50-MT2 150<br />

NT50-MT3 160<br />

NT50-MT4 180<br />

NT50-MT5 200<br />

L<br />

Unit : mm<br />

Tap Collet<br />

TP316,830<br />

Unit : mm<br />

Model C1 F1 F2 L<br />

Tapping Adapter<br />

range Type<br />

BT40-TP316 48 10 20 150 M3-M16 TP316<br />

BT50-TP316 48 10 20 150 M3-M16 TP316<br />

BT40-TP830 66 10 25 150 M8-M30 TP830<br />

BT50-TP830 66 10<br />

25<br />

(80)<br />

150 M8-M30 TP830<br />

Unit : mm<br />

Model D H1 H2 C1 C2<br />

TP316 M3,M4.M5,M6,M8,M10,M12,M14 27 47 33 20<br />

TP316 W1/8,W3/16,W1/4,W5/16,W3/8,W7/16 27 47 33 20<br />

TP316 M16,W1/2,W5/8,PT1/8,PT1/4 27 47 33 25<br />

TP830 M8,M10,M12,M14,M16,W5/16,W3/4,W7/16,W1/2,W5/8 43 62 51 30<br />

TP830 M18,M20,M22,M24,M27,M30,W3/4,W7/8,W1,PT1/8,PT3/8,PT1/4,PT1/2,PT5/8,PT3/4 43 62 51 36<br />

45

Precision Accessories for Milling Machine<br />

H Type S Type Key Type<br />

Keyless Drill Chuck<br />

H Type<br />

Unit : mm<br />

Model Size<br />

Capacity Taper Length<br />

Outer<br />

Mount<br />

mm Inch Open Closed Dia<br />

No<br />

N.W. (g)<br />

12302-1 8H 0~8 0~5/16 JT1 68 76 38 395<br />

12302-2 8H 0~8 0~5/16 JT2S 68 76 38 395<br />

12302-3 8H 0~8 0~5/16 B10 68 76 38 395<br />

12302-4 8H 0~8 0~5/16 B12 68 76 38 395<br />

12303-1 10H 0~10 0~3/8 JT33 80 92 43 610<br />

12303-2 10H 0~10 0~3/8 JT2S 80 92 43 610<br />

12303-3 10H 0~10 0~3/8 B10 80 92 43 610<br />

12303-4 10H 0~10 0~3/8 B12 80 92 43 610<br />

12304-1 13H 0~13 0~1/2 JT33 90 102 49 920<br />

12304-2 13H 0~13 0~1/2 JT6 90 102 49 920<br />

12304-3 13H 0~13 0~1/2 B12 90 102 49 920<br />

12304-4 13H 0~13 0~1/2 B16 90 102 49 920<br />

12304-5 13H 0~13 0~1/2 JT2 90 102 49 920<br />

12305-1 16H 3~16 1/8~5/8 JT6 97 110 55 1200<br />

12305-2 16H 3~16 1/8~5/8 JT3 97 110 55 1200<br />

12305-3 16H 3~16 1/8~5/8 B16 97 110 55 1200<br />

12305-4 16H 3~16 1/8~5/8 B18 97 110 55 1200<br />

S Type<br />

Key Type Drill Chuck<br />

Key Type<br />

Unit : mm<br />

Model Size<br />

Capacity Taper Length<br />

Outer N.W.<br />

Mount<br />

mm Inch Open Closed Dia (g)<br />

No<br />

12200-1 3S 0~3 0~1/8 JT0 44 48.5 24 110<br />

12200-3 6S 0~6.5 0~1/4 JT1 62 68 33 300<br />

12201-1 8S 0~8 0~5/16 JT1 68 76 38 395<br />

12201-2 8S 0~8 0~5/16 JT2S 68 76 38 395<br />

12201-3 8S 0~8 0~5/16 B10 68 76 38 395<br />

12201-4 8S 0~8 0~5/16 B12 68 76 38 395<br />

12202-1 10S 0~10 0~3/8 JT2S 80 92 43 610<br />

12202-2 10S 0~10 0~3/8 JT33 80 92 43 610<br />

12202-3 10S 0~10 0~3/8 B10 80 92 43 610<br />

12202-4 10S 0~10 0~3/8 B12 80 92 43 610<br />

12203-1 13S 0~13 0~1/2 JT33 90 102 49 920<br />

12203-2 13S 0~13 0~1/2 JT6 90 102 49 920<br />

12203-3 13S 0~13 0~1/2 B12 90 102 49 920<br />

12203-4 13S 0~13 0~1/2 B16 90 102 49 920<br />

12205-1 16S 3~16 1/8~5/8 JT6 97 110 55 1200<br />

12205-2 16S 3~16 1/8~5/8 JT3 97 110 55 1200<br />

12205-3 16S 3~16 1/8~5/8 B16 97 110 55 1200<br />

12205-4 16S 3~16 1/8~5/8 B18 97 110 55 1200<br />

Unit : mm<br />

Model Size<br />

Capacity Taper Length<br />

Outer<br />

Mount<br />

mm Inch Open Closed Dia<br />

No<br />

N.W. (kg)<br />

11201-1K 6MPT 0~6.5 0~1/4 JT1 39 52 32 14<br />

11202-1K 10MPT 0~10 0~3/8 JT2S 51 63 38 22<br />

11204-K 13MPT 0~13 0~1/2 JT33 63 78 45 21<br />

11207-1K 16MPT 0~16 0~5/8 JT3 76 91 55 22<br />

46

Precision Accessories for Milling Machine<br />

BT-JT BT-JT<br />

Keyless Drill Chuck Holder<br />

BT-JT<br />

BT-JT<br />

Model<br />

BT30-JT1-45L 45<br />

BT30-JT1-90L 90<br />

BT30-JT2-45L 45<br />

BT30-JT2-90L 90<br />

BT30-JT6-45L 45<br />

BT30-JT6-90L 90<br />

BT40-JT1-45L 45<br />

BT40-JT1-90L 90<br />

L<br />

Unit : mm<br />

Model<br />

BT40-JT2-45L 45<br />

BT40-JT2-90L 90<br />

BT40-JT6-45L 45<br />

BT40-JT6-90L 90<br />

BT50-JT6-45L 45<br />

BT50-JT6-105L 105<br />

L<br />

Unit : mm<br />

Model<br />

NT30-JT1-20L 20<br />

NT30-JT2-20L 20<br />

NT30-JT6-20L 20<br />

NT40-JT1-20L 20<br />

NT40-JT2-20L 20<br />

NT40-JT6-20L 20<br />

NT50-JT1-20L 20<br />

NT50-JT2-20L 20<br />

NT50-JT6-20L 20<br />

L<br />

Unit : mm<br />

Drill Chuck Holder<br />

BT-APU<br />

NT-APU<br />

Model Capacity C L<br />

Unit : mm<br />

BT30-APU08-80L 0~8 36 80<br />

BT30-APU13-105L 0~13 51 105<br />