COMPOSITES

solutions for automated composites processing - WD Hearn

solutions for automated composites processing - WD Hearn

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CHARGER Tape Layers<br />

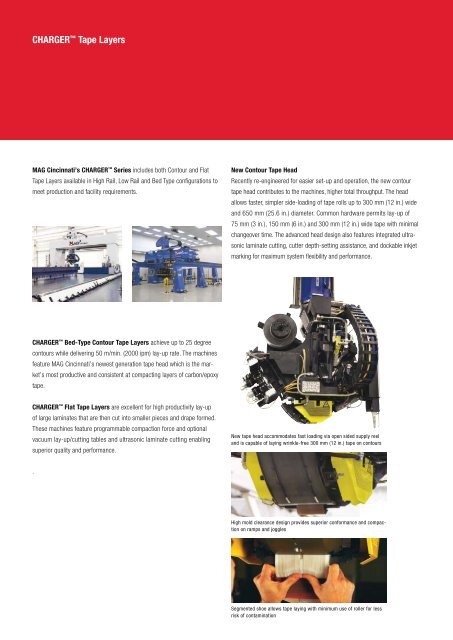

MAG Cincinnati’s CHARGER Series includes both Contour and Flat<br />

Tape Layers available in High Rail, Low Rail and Bed Type configurations to<br />

meet production and facility requirements.<br />

New Contour Tape Head<br />

Recently re-engineered for easier set-up and operation, the new contour<br />

tape head contributes to the machines, higher total throughput. The head<br />

allows faster, simpler side-loading of tape rolls up to 300 mm (12 in.) wide<br />

and 650 mm (25.6 in.) diameter. Common hardware permits lay-up of<br />

75 mm (3 in.), 150 mm (6 in.) and 300 mm (12 in.) wide tape with minimal<br />

changeover time. The advanced head design also features integrated ultrasonic<br />

laminate cutting, cutter depth-setting assistance, and dockable inkjet<br />

marking for maximum system flexibility and performance.<br />

CHARGER Bed-Type Contour Tape Layers achieve up to 25 degree<br />

contours while delivering 50 m/min. (2000 ipm) lay-up rate. The machines<br />

feature MAG Cincinnati’s newest generation tape head which is the market’s<br />

most productive and consistent at compacting layers of carbon/epoxy<br />

tape.<br />

CHARGER Flat Tape Layers are excellent for high productivity lay-up<br />

of large laminates that are then cut into smaller pieces and drape formed.<br />

These machines feature programmable compaction force and optional<br />

vacuum lay-up/cutting tables and ultrasonic laminate cutting enabling<br />

superior quality and performance.<br />

New tape head accommodates fast loading via open sided supply reel<br />

and is capable of laying wrinkle-free 300 mm (12 in.) tape on contours<br />

.<br />

High mold clearance design provides superior conformance and compaction<br />

on ramps and joggles<br />

Segmented shoe allows tape laying with minimum use of roller for less<br />

risk of contamination