Level transmitter LT 100

Level transmitter LT 100

Level transmitter LT 100

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

© KROHNE 09/2001 7.02363.21.00<br />

GR/PRINTO<br />

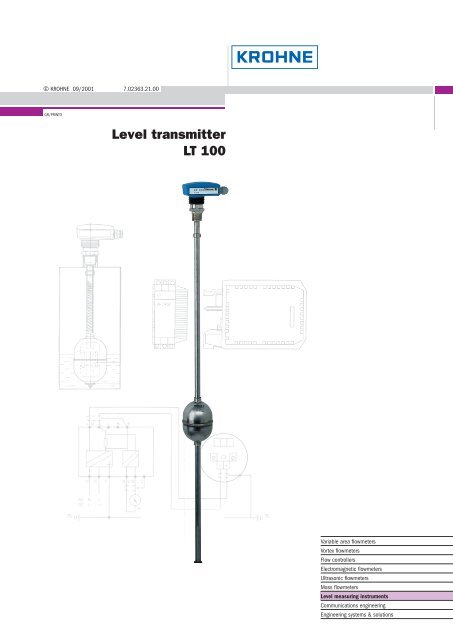

<strong>Level</strong> <strong>transmitter</strong><br />

<strong>LT</strong> <strong>100</strong><br />

Status: 10/99<br />

Variable area flowmeters<br />

Vortex flowmeters<br />

Flow controllers<br />

Electromagnetic flowmeters<br />

Ultrasonic flowmeters<br />

Mass flowmeters<br />

<strong>Level</strong> measuring instruments<br />

Communications engineering<br />

Engineering systems & solutions

<strong>Level</strong> <strong>transmitter</strong><br />

<strong>LT</strong> <strong>100</strong><br />

For long-distance transmission of liquid<br />

level data<br />

Operating principle<br />

Housing<br />

The device operates on the float principle.<br />

A float guided on a non-magnetic tube<br />

follows the level of the liquid surface, thereby<br />

actuating the reed switches located inside<br />

the tube by means of a built-in magnet<br />

system. The reed switches shunt over parts<br />

of a resistor string. The magnet system<br />

operates the reed switches according to the<br />

position of the float and thus causes the<br />

resistance of the resistor string to change as<br />

a function of the liquid level. The float travel<br />

distance can be limited by stops fitted to<br />

the guide tube. The signal conditioner produces<br />

an output signal from 4 – 20 mA.<br />

Gasket<br />

Threaded connection<br />

Upper end stop<br />

Guide tube<br />

Resistor string with<br />

reed switches<br />

Float<br />

Magnet system<br />

Lower end stop<br />

128

<strong>LT</strong> <strong>100</strong><br />

Application range<br />

Simple and<br />

rugged design for<br />

pressures up to<br />

40 bar/580 psig and<br />

temperatures<br />

up to 130°C/266°F)<br />

Wetted parts of<br />

stainless steel;<br />

for aggressive<br />

products coated<br />

with PVC, PP,<br />

PVDF, PTFE<br />

Long-distance<br />

data transmission<br />

up to 2000 m<br />

Guide tube<br />

length<br />

0.3 – 6 m<br />

Interface<br />

detection also<br />

possible<br />

The <strong>LT</strong> <strong>100</strong> is designed for liquid level measurement in storage or<br />

process tanks.<br />

The products must not be adhesive or of high viscosity.<br />

The min. density is 0.4 kg/l or 25 lb/ft 3<br />

Optional: Interface level between two immiscible liquids.<br />

The difference in density between both liquids needs to be min.<strong>100</strong> g/l.<br />

Typical liquids are:<br />

● Water and aqueous liquids<br />

● Acids/alkalis<br />

● Organic and inorganic solvents<br />

All wetted parts can be coated with plastic for use in aggressive media.<br />

Product<br />

Overview<br />

Continuous, non-contact Switches<br />

Ultrasonic Radar Ultrasonic Buoyancy Capacitance<br />

Continuous, contact<br />

Ultrasonic Buoyancy TDR<br />

Vibration<br />

<strong>LT</strong> <strong>100</strong> 129

<strong>LT</strong> <strong>100</strong><br />

Responsibility for suitability and intended use of our instruments rests solely with the purchaser.<br />

Technical data<br />

Measuring conditions<br />

Product<br />

Liquids<br />

Temperature<br />

–40 … +130°C (–40 … 266°F)<br />

Density<br />

≥ 0.4 kg/l (≥ 25 lb/ft)<br />

Operating pressure<br />

≤ 40 bar (≤ 580 psig)<br />

Ambient temperature<br />

Polycarbonate housing<br />

–30 … +60°C (–22 … +140°F)<br />

Aluminium housing<br />

–40 … +60°C (–40 … +140°F)<br />

Overall length<br />

0.3 – 6 m (1 – 20 ft)<br />

Measuring accuracy<br />

Standard ±10 mm (±0.4’’)<br />

Option ± 5 mm (±0.2’’)<br />

Important: note specified float operating data, see table “Float Selection”<br />

Materials<br />

Housing<br />

Standard<br />

Option<br />

Gaskets<br />

Connection<br />

Housing cover<br />

Polycarbonate<br />

Cast aluminium with epoxy finish<br />

Nitriles<br />

Buna-N<br />

Screw connection Stainless steel 316 L (1.4435, 1.4404)<br />

Flange<br />

Standard Stainless steel 316 L (1.4435, 1.4404)<br />

Option<br />

Stainless steel, coated (PVC, PP, PVDF, PTFE)<br />

Guide tube<br />

Standard Stainless steel 316 L (1.4435, 1.4404)<br />

Option<br />

Stainless steel, coated (PVC, PP, PVDF, PTFE)<br />

Float<br />

See table “Float Selection”<br />

Connection<br />

Screw connection<br />

G1’’, 1’’ NPT<br />

Flanges DN 50, PN 10<br />

DN <strong>100</strong>, PN 40<br />

2’’ ANSI, 150 lb<br />

4’’ ANSI, 300 lb<br />

Other connections on request<br />

Protection category IP 66<br />

Terminals (max. wire cross-section) 1.5 mm 2 (AWG 14)<br />

Cable entry<br />

Polycarbonate housing<br />

PG 13.5 (polyamide)<br />

Aluminium housing<br />

PG 13.5, option PG 16 (nickel-plated brass)<br />

Current output<br />

4 – 20 mA<br />

Electromagnetic compatibility (EMC) to EN 50081-1, EN 50082-2<br />

130 <strong>LT</strong> <strong>100</strong>

<strong>LT</strong> <strong>100</strong><br />

Float selection<br />

Select float as a function of the pressure, temperature and density of the liquid.<br />

In addition, the required degree of corrosion resistance must be considered.<br />

Shape Dimensions Material Min. density Max. Max.<br />

in mm (inches) kg/l (lb/ft 3 ) operating product<br />

L ≤ 4 (≤ 13.12 ft)/ pressure temperature<br />

L > 4 (> 13.12 ft) in bar (psig)* in °C (°F)<br />

Ball dia. 142 x 157 x 1.0 Stainless steel 316 Ti 0.55 / 0.6 35 (507) – 40 … +130<br />

(5.59 x 6.18 x 0.04) (1.4571) (34.34) / (37.46) (– 40 … +266)<br />

dia. 142 x 157 x 0.7 Stainless steel 316 Ti 0.4 / 0.5 20 (290) – 40 … +130<br />

(5.59 x 6.18 x 0.027) (1.4571) (24.97) / (31.21) (– 40 … +266)<br />

Cylinder dia. 90 x 140 Stainless steel 316 L 0.8 / 0.9 40 (580) – 40 … +130<br />

(3.54 x 5.51) (1.4435, 1.4404) (49.94) / (56.19) (– 40 … +266)<br />

dia. 64 x 140 Stainless steel 316 Ti 0.9 / – 25 (362) – 40 … +130<br />

(2.52 x 5.51) (1.4571) (56.19) / – (– 40 … +266)<br />

dia. 90 x <strong>100</strong> PVC 0.7 / – 4 (58) – 10 … + 60<br />

(3.54 x 3.94) (43.70) / (43.07) (– 14 … +140)<br />

dia. 90 x <strong>100</strong> PP 0.55 / 0.55 4 (58) – 20 … +110<br />

(3.54 x 3.94) (34.34) / (34.34) (– 44 … +230)<br />

dia. 90 x <strong>100</strong> PVDF 0.9 / 0.9 4 (58) – 40 … +130<br />

(3.54 x 3.94) (56.19) / (56.19) (– 40 … +266)<br />

dia. 90 x 125 Hard glass** 0.8 / 0.8 4 (58) – 40 … +130<br />

(3.54 x 4.92) (49.94) / (49.94) (– 40 … +266)<br />

L = length guide tube<br />

** The specified operating pressure applies to 20°C/68°F only!<br />

** Hard glass float used for PTFE instrument version.<br />

Float test pressure = 1.3 times the max. allowable operating pressure.<br />

Data transmission system and electrical connections<br />

All types supply directly a current of 4 – 20 mA via the built-in converter.<br />

The signal conditioner PROFSI, with or without galvanically isolated output, is available for the intrinsically safe version.<br />

With the C 90 digital indicator the liquid level can be displayed on a 4-character LED display.<br />

Device designation …ER (ER/BRX) …ER (EExi)<br />

Overall length<br />

Standard ≤ 4000 mm (≤ 13 ft) ≤ 4000 mm (≤ 13 ft)<br />

Option ≤ 6000 mm (≤ 20 ft) ≤ 6000 mm (≤ 20 ft)<br />

Measuring error<br />

Standard ± 10 mm (≤ 0.4’’) ± 10 mm (≤ 0.4’’)<br />

Option ± 5 mm (≤ 0.2’’) ± 5 mm (≤ 0.2’’)<br />

Ambient temperature –20 … +70°C (–4 ... +158°F) –20 … +70°C (–4 ... +158°F)<br />

(higher temperatures on request)<br />

Current output 4 – 20 mA 4 – 20 mA<br />

Power supply 14 – 36 V DC with reverse-polarity protection 14 – 30 V DC<br />

Max. load<br />

(U-12 V) / 20 mA, max. 500 Ω<br />

(U-12 V) / 20 mA, max. 500 Ω<br />

Process temperature –20 … +135°C –20 … +135°C<br />

(–4 ... +275°F) (–4 ... +275°F)<br />

others supplied on request<br />

others supplied on request<br />

Electromagnetic compatibility (EMC) EN 50081-1, EN 50082-2<br />

Self-inductance – negligible<br />

Self-capacitance – negligible<br />

Product<br />

Overview<br />

Vibration<br />

Continuous, non-contact Switches<br />

Ultrasonic Radar Ultrasonic Buoyancy Capacitance<br />

Continuous, contact<br />

Ultrasonic Buoyancy TDR<br />

<strong>LT</strong> <strong>100</strong> 131

<strong>LT</strong> <strong>100</strong><br />

Signal conditioner PROFSI<br />

Dimensions in mm (inches)<br />

Power supply<br />

Standard<br />

Option<br />

Power consumption<br />

230 V AC, (±10%), 50 Hz<br />

24, 48, 115 V AC, 50 Hz,<br />

24 V DC (±10%)<br />

AC = 4 VA; DC = 3 W<br />

Protection category<br />

(EN 60529/lEC 529) IP 20 (equivalent to NEMA 1)<br />

Ambient temperature –20 … +60°C (–4 … +140°F)<br />

Current output 4 – 20 mA<br />

Load<br />

≤ 850 Ω<br />

Linearity < 0.1%<br />

Housing<br />

Attachment<br />

Snap-on mounting on 35 mm, standard rail to DIN 46 277<br />

Screw mounting Dimensions to DIN 43 604<br />

Connection<br />

Self-opening binding posts<br />

Max. cross-section 2 x 2.5 mm 2<br />

Material<br />

Polyamide<br />

Electromagnetic<br />

compatibility (EMC) to EN 50081-1, EN 50082-2<br />

Ex<br />

PROFSI<br />

35.5 (1.40“) 110 (4.33“)<br />

75 (2.95“)<br />

Digital indicator C 90<br />

Dimensions in mm (inches)<br />

Power supply<br />

Standard<br />

230 V AC (±10% ), 50/60 Hz<br />

Option<br />

115 V AC (±10% ), 50/60 Hz<br />

Power consumption 6 VA<br />

Protection category IP 63<br />

(EN 60529/IEC 529)<br />

Ambient temperature –20 … +70°C (–4 … 158°F)<br />

Current output 4 – 20 mA<br />

Load<br />

15 Ω<br />

Display Digital (–9999 – +9999)<br />

4-digit with LED<br />

Height of digits 14 mm<br />

Housing material Makrolon<br />

Electromagnetic<br />

compatibility (EMC) to EN 50081-1, EN 50082-2<br />

43 (1.69”)<br />

90 (3.54”)<br />

min. clearance when mounting several<br />

digital indicators in one panel<br />

23 (0.91”)<br />

43 (1.69”)<br />

≥ 10<br />

(≥ 0.4”)<br />

44 (1.73”)<br />

≥ 20<br />

102 (4.02”)<br />

≥ 40<br />

(≥ 1.57”)<br />

91 (3.58”)<br />

48 (1.89”)<br />

7,5 (0.3”)<br />

(≥ 0.79”)<br />

132 <strong>LT</strong> <strong>100</strong>

<strong>LT</strong> <strong>100</strong><br />

Dimensions and weights<br />

The weights refer to devices with <strong>100</strong>0 mm guide tube and DN 50 flange.<br />

The flange DN <strong>100</strong> weighs an additional 0.7 kg.<br />

Every additional <strong>100</strong> mm or 4’’ tube length:<br />

≤ 4000 mm (≤ 13.12 ft) = 0.06 kg (0.13 lb)<br />

> 4000 mm (> 13.12 ft) = 0.16 kg (0.36 lb)<br />

Additional weight for: connection “04” = 5.4 kg (12.1 lb)<br />

cast aluminium housing = 0.7 kg (1.6 lb)<br />

Weights of devices with ANSI flanges equivalent to those with<br />

the same DIN nominal size, with the following variations:<br />

2’’ Class 150 lb/RF “07” –0.8 kg (–1.8 lb)<br />

4’’ Class 150 lb/RF “08” –0.5 kg (–1.1 lb)<br />

2’’ Class 300 lb/RF “09” +0.2 kg (+0.5 lb)<br />

4’’ Class 300 lb/RF “10” +3.7 kg (+5.9 lb)<br />

Product<br />

Overview<br />

Vibration<br />

Dimensions in mm (inches)<br />

<strong>LT</strong> <strong>100</strong><br />

Polycarbonate<br />

housing<br />

<strong>LT</strong> <strong>100</strong><br />

Aluminium<br />

housing<br />

Aluminium housing with<br />

coated version<br />

<strong>LT</strong> <strong>100</strong>/R – PVC/03/PC<br />

<strong>LT</strong> <strong>100</strong>/R – PP/03/PC<br />

<strong>LT</strong> <strong>100</strong>/R – PVD/03/PC<br />

4.6 kg<br />

(10.3 lb)<br />

Standard version<br />

<strong>LT</strong> <strong>100</strong>/R – /01/PC<br />

1.8 kg<br />

(4.0 lb)<br />

* L > 4000 mm<br />

* or > 13.12 ft<br />

Coated version<br />

<strong>LT</strong> <strong>100</strong>/R – PTFE/03/PC<br />

5.9 kg<br />

(13.2 lb)<br />

Flange version<br />

<strong>LT</strong> <strong>100</strong>/R – /03/PC<br />

4.1 kg<br />

(9.2 lb)<br />

* L > 4000 mm<br />

* or > 13.12 ft<br />

Version with<br />

aluminium housing<br />

<strong>LT</strong> <strong>100</strong>/R – /01/AL<br />

2.5 kg<br />

(5.6 lb)<br />

Continuous, non-contact Switches<br />

Ultrasonic Radar Ultrasonic Buoyancy Capacitance<br />

Flange version with<br />

aluminium housing<br />

<strong>LT</strong> <strong>100</strong>/R – /03/AL<br />

4.8 kg<br />

(10.8 lb)<br />

* L > 4000 mm<br />

* or > 13.12 ft<br />

Aluminium housing<br />

with coated version<br />

<strong>LT</strong> <strong>100</strong>/R – PVC/03/AL<br />

<strong>LT</strong> <strong>100</strong>/R – PP/03/AL<br />

<strong>LT</strong> <strong>100</strong>/R – PVDF/03/AL<br />

5.3 kg<br />

(11.9 lb)<br />

* L > 4000 mm<br />

* or > 13.12 ft<br />

Aluminium housing<br />

with coated version<br />

<strong>LT</strong> <strong>100</strong>/R – PTFE/03/AL<br />

6.6 kg<br />

(14.8 lb)<br />

Continuous, contact<br />

Ultrasonic Buoyancy TDR<br />

* L > 4000 mm<br />

* or > 13.12 ft<br />

* L > 4000 mm<br />

* or > 13.12 ft<br />

<strong>LT</strong> <strong>100</strong> 133

<strong>LT</strong> <strong>100</strong><br />

Electrical connection<br />

ER (BRX)<br />

<strong>LT</strong> <strong>100</strong><br />

Approvals<br />

Application<br />

Intrinsically safe hazardous-duty version for use in Zone 1<br />

(EEx ia IIC T6)<br />

Flameproof enclosure (EEx d IIC T6) for use in Zone 1<br />

Signal conditioner PROFSI (EEx ia IIC) for use in Zone 1<br />

Instrument version<br />

<strong>LT</strong> <strong>100</strong>/.. /ER(EExi)<br />

<strong>LT</strong> <strong>100</strong>/.. /ER(BRX)<br />

Certification mark<br />

L.C.I.E.-No. 92.C 6123X<br />

L.C.I.E.-No. 87.B 6099X<br />

L.C.I.E.-No. 91.C 6066X<br />

Product<br />

Overview<br />

Continuous, contact<br />

Ultrasonic Buoyancy TDR<br />

Continuous, non-contact Switches<br />

Ultrasonic Radar Ultrasonic Buoyancy Capacitance<br />

Vibration<br />

Type code<br />

Instrument<br />

<strong>LT</strong> <strong>100</strong> <strong>Level</strong> <strong>transmitter</strong><br />

Materials<br />

R Stainless steel 316 L (1.4435, 1.4404)<br />

R-PVC Stainless steel 316 L (1.4435, 1.4404), PVC coated<br />

R-PP Stainless steel 316 L (1.4435, 1.4404), PP coated<br />

R- PVDF Stainless steel 316 L (1.4435, 1.4404), PVDF coated<br />

R-PTFE Stainless steel 316 L (1.4435, 1.4404), PTFE coated<br />

Connection*<br />

01 G1A 06 DN <strong>100</strong>, PN 40<br />

02 NPT 1" 07 ANSI 2", 150 lb RF<br />

03 DN 50, PN 16 08 ANSI 4", 150 lb RF<br />

04 DN <strong>100</strong>, PN 16 09 ANSI 2", 300 lb RF<br />

05 DN 50, PN 40 10 ANSI 4", 300 lb RF<br />

Housing version<br />

PC Polycarbonate<br />

AL Di-cast aluminium<br />

Application range<br />

N Normal range<br />

BRX Long-distance data transmission system Zone 1, EEx d IIC T6 (explosion-proof)<br />

EExi Long-distance data transmission system Zone 1, EEx ia IIC T6 (intrinsically safe)<br />

TS Interface detection<br />

<strong>LT</strong> <strong>100</strong><br />

*When ordering, please specify overall length.<br />

<strong>LT</strong> <strong>100</strong> 135

Notes