In-House Coating versus Job Coating Service - PLATIT

In-House Coating versus Job Coating Service - PLATIT

In-House Coating versus Job Coating Service - PLATIT

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

cutting edges on their own? Wett, since<br />

job coaters cannot know the surface<br />

consistency of various objects, usuatly<br />

they micro-btast a[[ toots to avoid bad<br />

coating adhesion. This can negative[y<br />

affect the functional efficiency of finishing<br />

precision toots, which need sharp<br />

cutting edges. The performance of toots<br />

often depends on the speciat configuration<br />

of cuttjng edges, die geometries or<br />

contact surfaces, and the [ike. 0f course,<br />

Si\4Es do not like to give away their sma[[<br />

and big secrets. But their competitors<br />

often make audits at the job coaters. At<br />

in-house coating, the SiVEs can take care<br />

of their own toots and surety about their<br />

optimaI pretreatment to 100 per cent.<br />

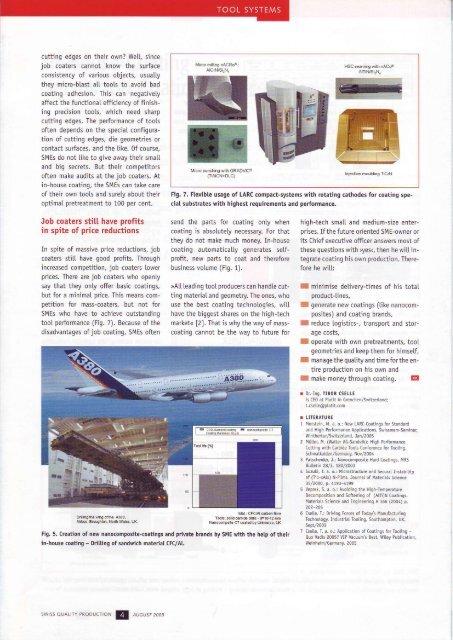

Fig. 7. Ftexible usage of LARC compact-systems with rotating cathodes for coating special<br />

substrates with highest requirements and performance.<br />

<strong>Job</strong> coaters sti[[ have profits<br />

in spite of price reductions<br />

send the parts for coating onty when<br />

coating is absotutely necessary. For that<br />

they do not rnake much money. <strong>In</strong>-house<br />

<strong>In</strong> spite of massive price reductions, job coatjng automaticatty generates setf-<br />

coaters sti[ have good profits. Through profit, new parts to coal and therefore<br />

increased competition, job coaters lower<br />

prices. There are job coaters who openty<br />

business volume (Fig. 1).<br />

say that they onty offer basic coatings, >A[[ leading tool producers can hand[e cut-<br />

but for a mjnimal price. This means comting materiaI and geometry. The ones, who<br />

petition for mass-coaters, but not for use the best coating technotogies, witl<br />

Sf4Es who have to achieve outstanding have the biggest shares on the high-tech<br />

tool performance (Fig. 7). Because of the<br />

disadvantages of job coating, SMEs often<br />

market< [2]. That is why the way of masscoating<br />

cannot be the way to future for<br />

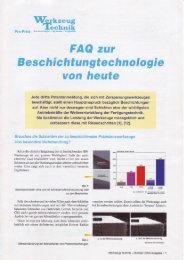

o lnhq ih€ slE orrh. A3ao,<br />

arrbur, Broughlü, Nonh walos, uK,<br />

Mat.: CFC/AI .atbm ibrc<br />

T6lr:solldcalbrß ddlb - rF1{}12 hh<br />

N.nocompsfi. C7 coar€d by unrmerco, lK<br />

Fig. 5, Creation of new nanocomposite-coatings and private brands by SME with the hetp of their<br />

in-house coating - Drilting of sandwi.h materiat CFC/AL<br />

sw rs oJA-r,y DRoDLcrror.r<br />

@<br />

oi,c,-,s,<br />

:oo.<br />

Micro punching<br />

widr GRADVIC@<br />

ctiAtcN+DLc)<br />

HSc{eamins wlth nACCP<br />

lnjectjon mouldins TicrN<br />

high-tech small and medium-size enterprises.<br />

If the future oriented 5ME-owner or<br />

its Chief executive officer answers most of<br />

these questions with )yes