2016_catalog_web

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

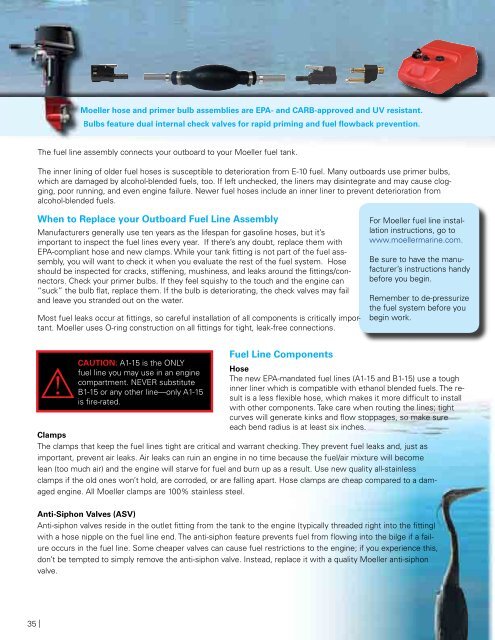

Moeller hose and primer bulb assemblies are EPA- and CARB-approved and UV resistant.<br />

Bulbs feature dual internal check valves for rapid priming and fuel flowback prevention.<br />

The fuel line assembly connects your outboard to your Moeller fuel tank.<br />

The inner lining of older fuel hoses is susceptible to deterioration from E-10 fuel. Many outboards use primer bulbs,<br />

which are damaged by alcohol-blended fuels, too. If left unchecked, the liners may disintegrate and may cause clogging,<br />

poor running, and even engine failure. Newer fuel hoses include an inner liner to prevent deterioration from<br />

alcohol-blended fuels.<br />

When to Replace your Outboard Fuel Line Assembly<br />

Manufacturers generally use ten years as the lifespan for gasoline hoses, but it’s<br />

important to inspect the fuel lines every year. If there’s any doubt, replace them with<br />

EPA-compliant hose and new clamps. While your tank fitting is not part of the fuel asssembly,<br />

you will want to check it when you evaluate the rest of the fuel system. Hose<br />

should be inspected for cracks, stiffening, mushiness, and leaks around the fittings/connectors.<br />

Check your primer bulbs. If they feel squishy to the touch and the engine can<br />

“suck” the bulb flat, replace them. If the bulb is deteriorating, the check valves may fail<br />

and leave you stranded out on the water.<br />

Most fuel leaks occur at fittings, so careful installation of all components is critically important.<br />

Moeller uses O-ring construction on all fittings for tight, leak-free connections.<br />

For Moeller fuel line installation<br />

instructions, go to<br />

www.moellermarine.com.<br />

Be sure to have the manufacturer’s<br />

instructions handy<br />

before you begin.<br />

Remember to de-pressurize<br />

the fuel system before you<br />

begin work.<br />

⚠<br />

CAUTION: A1-15 is the ONLY<br />

fuel line you may use in an engine<br />

compartment. NEVER substitute<br />

B1-15 or any other line—only A1-15<br />

is fire-rated.<br />

Fuel Line Components<br />

Hose<br />

The new EPA-mandated fuel lines (A1-15 and B1-15) use a tough<br />

inner liner which is compatible with ethanol blended fuels. The result<br />

is a less flexible hose, which makes it more difficult to install<br />

with other components. Take care when routing the lines; tight<br />

curves will generate kinks and flow stoppages, so make sure<br />

each bend radius is at least six inches.<br />

Clamps<br />

The clamps that keep the fuel lines tight are critical and warrant checking. They prevent fuel leaks and, just as<br />

important, prevent air leaks. Air leaks can ruin an engine in no time because the fuel/air mixture will become<br />

lean (too much air) and the engine will starve for fuel and burn up as a result. Use new quality all-stainless<br />

clamps if the old ones won’t hold, are corroded, or are falling apart. Hose clamps are cheap compared to a damaged<br />

engine. All Moeller clamps are 100% stainless steel.<br />

Anti-Siphon Valves (ASV)<br />

Anti-siphon valves reside in the outlet fitting from the tank to the engine (typically threaded right into the fitting)<br />

with a hose nipple on the fuel line end. The anti-siphon feature prevents fuel from flowing into the bilge if a failure<br />

occurs in the fuel line. Some cheaper valves can cause fuel restrictions to the engine; if you experience this,<br />

don’t be tempted to simply remove the anti-siphon valve. Instead, replace it with a quality Moeller anti-siphon<br />

valve.<br />

35 |