InTrac® Series – versatile retractable housings: When process ...

InTrac® Series – versatile retractable housings: When process ...

InTrac® Series – versatile retractable housings: When process ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

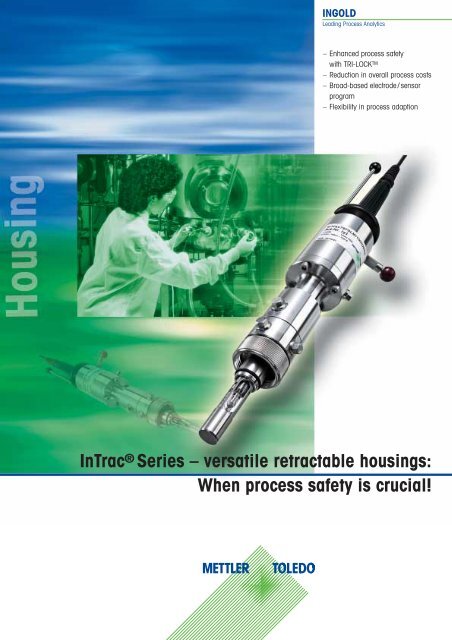

INGOLD<br />

Leading Process Analytics<br />

<strong>–</strong> Enhanced <strong>process</strong> safety<br />

with TRI-LOCK TM<br />

<strong>–</strong> Reduction in overall <strong>process</strong> costs<br />

<strong>–</strong> Broad-based electrode / sensor<br />

program<br />

<strong>–</strong> Flexibility in <strong>process</strong> adaption<br />

InTrac ® <strong>Series</strong> <strong>–</strong> <strong>versatile</strong> <strong>retractable</strong> <strong>housings</strong>:<br />

<strong>When</strong> <strong>process</strong> safety is crucial!

Safe and reliable.<br />

Chemical <strong>process</strong>es:<br />

Greater safety even under<br />

demanding conditions.<br />

Pharmaceutical <strong>process</strong>es:<br />

Double flushing chamber for<br />

a higher degree of sterility.<br />

Food and beverage industry:<br />

Hygienic <strong>process</strong> adaption.<br />

InTrac <strong>retractable</strong> <strong>housings</strong><br />

The new InTrac <strong>retractable</strong> <strong>housings</strong> from METTLER TOLEDO<br />

fulfill the highest demands on <strong>process</strong> safety and reliability<br />

even in harsh applications.<br />

Operational safety<br />

through TRI-LOCK TM .<br />

Reduced overall<br />

<strong>process</strong> costs.<br />

Broad-based electrode and<br />

sensor compatibility.<br />

Flexibility of<br />

<strong>process</strong> adaption.<br />

The TRI-LOCK TM safety system from METTLER TOLEDO prevents any release of <strong>process</strong><br />

media via the housing. Without the presence of a sensor, the housing cannot<br />

be inserted into the <strong>process</strong>. Also it makes it impossible to remove the electrode<br />

from the housing when in the measuring position. An optional alignment system<br />

indicates the actual position of the housing at all times, even in automated systems.<br />

The InTrac family of <strong>retractable</strong> <strong>housings</strong> helps to substantially reduce the operating<br />

costs of a measuring point, by allowing well-planned automatic cleaning and<br />

calibration of the electrodes which will increase their average operational life significantly.<br />

Consequently, the performance characteristics of the individual electrodes<br />

can be exploited to the full, and plant productivity optimized at the same time.<br />

A wide variety of different types of electrodes and sensors can be used in conjunction<br />

with the InTrac family of <strong>retractable</strong> <strong>housings</strong>, whether in the measurement<br />

of pH / redox, dissolved oxygen, CO2, conductivity, or turbidity. Appropriate models<br />

are also available for specific applications in the chemical and pharmaceutical<br />

industries or for food and beverage <strong>process</strong>es.<br />

METTLER TOLEDO offers a variety of different <strong>process</strong> adaptions, ranging from the<br />

tried and tested INGOLD sockets, or flange fixtures, to special hygienic connection<br />

systems. The <strong>retractable</strong> <strong>housings</strong> are available both in steel and in polymer<br />

versions to suit individual <strong>process</strong> requirements. Immersion depths are variable,<br />

and can be suited to the design and configuration of vessels and pipes.

InTrac 776 e <strong>retractable</strong> <strong>housings</strong><br />

InTrac 776 e: the tough one.<br />

InTrac 776 e <strong>retractable</strong> <strong>housings</strong> are designed for applications in the<br />

chemical industry in <strong>process</strong>es involving the use of pH / redox electrodes with<br />

liquid electrolyte reference systems, e.g. InPro 2000 or 465 <strong>Series</strong>. In the built-in<br />

flushing chamber, the electrode can be cleaned and, if necessary, also be<br />

recalibrated, both procedures without any interruption of the ongoing <strong>process</strong>.<br />

Also the intermittent use of these electrodes leads to an increase in their operational<br />

life and reduces the overall costs of the measuring point.<br />

Main specifications<br />

InTrac 776 e<br />

Operation Manual or pneumatic<br />

Immersion depths 70, 100 or 200 mm<br />

Electrode types Liquid-filled electrodes (InPro 2000 or 465 <strong>Series</strong>)<br />

Wetted O-rings Viton ®-FDA, EPDM-FDA or Kalrez ®-FDA<br />

Process-wetted parts DIN 1.4404 / AISI 316L, HA-C22, titanium,<br />

PP, PVDF, PEEK<br />

Specific features TRI-LOCK TM , sensor detector, position indicators,<br />

(optional, pneumatic or inductive version)<br />

Certificates / approvals CE: •<br />

PED*: •<br />

ATEX (94/9/EC): •<br />

MaxCert TM : • * PED = pressure equipment directive, 97/23/EC<br />

InTrac 776 e<br />

(with pneumatic position indicators)<br />

MaxCert from METTLER TOLEDO<br />

covering the following certificates /<br />

approvals included in delivery:<br />

<strong>–</strong> Material certificate<br />

according to 3.1B<br />

<strong>–</strong> Confirmation of FDA conformity<br />

of wetted parts according<br />

to EN 10 204-2.1<br />

<strong>–</strong> Additional relevant certificates<br />

(depending upon type of housing)<br />

TRI-LOCK from METTLER TOLEDO<br />

provides the following<br />

elements of safety:<br />

<strong>–</strong> Safe sealing of <strong>process</strong> medium<br />

<strong>–</strong> No motion of housing without<br />

sensor / electrode in place<br />

<strong>–</strong> No removal of sensor / electrode<br />

possible while housing in<br />

measuring position (immersed)<br />

<strong>–</strong> No unintentional release of<br />

<strong>process</strong> media possible<br />

High flexibility in<br />

<strong>process</strong> adaptions<br />

METTLER TOLEDO<br />

offers a wide<br />

selection of <strong>process</strong><br />

adaptions in various materials and<br />

sizes, such as<br />

<strong>–</strong> DN 25 for INGOLD weld-in sockets<br />

<strong>–</strong> Flanges (DIN and ANSI)<br />

<strong>–</strong> NPT threads<br />

<strong>–</strong> TriClamp<br />

<strong>–</strong> Tuchenhagen Varivent<br />

InTrac 776 e<br />

(pneumatic type, made of PP)

InTrac 777 e<br />

(pneumatic version, made of PVDF)<br />

InTrac 777 e / 797 e / 798 e <strong>retractable</strong> <strong>housings</strong><br />

InTrac 777e / 797e / 798 e versatility at a glance.<br />

The InTrac 777 e / 797 e <strong>retractable</strong> <strong>housings</strong> have been specifically designed<br />

for use with 12 mm electrodes and sensors for the measurement of pH / redox,<br />

dissolved oxygen, CO2 and conductivity in industrial <strong>process</strong>es. InTrac 777 e with<br />

a single flushing chamber is suitable for employment in the chemical industry.<br />

InTrac797 e with double chambers is the preferred choice for sterile <strong>process</strong>es in<br />

the pharmaceutical industry. The InTrac 798 e with the hygienic design (EHEDG) is<br />

the optimal housing for the food & beverage industries. Special models<br />

(InTrac 779 e / 799 e) are also available for InPro 8100 / 8200 turbidity sensors.<br />

Main specifications<br />

InTrac 797 e<br />

(manual version)<br />

Use in Ex-classified<br />

zones<br />

The InTrac 776 e / 777e / 797e<br />

<strong>retractable</strong> <strong>housings</strong> (steel<br />

versions) are intrinsically safe for<br />

operation in Ex-classified zones<br />

according to guideline<br />

ATEX 94/9/EC.<br />

InTrac 777 e and InTrac 797 e InTrac 798 e<br />

Operation Manual or pneumatic Manual or pneumatic<br />

Immersion InTrac 777 e / 779 e: 70, 100 or 200 mm 50 or 100 mm<br />

depths InTrac 797 e / 799 e: 100 mm<br />

Electrodes / sensors pH: Gel or solid polymer electrolyte models, ø 12 mm All 120 mm electrodes / sensors<br />

CO 2: InPro 5000 (InTrac 797 e) with Pg 13.5 thread and 12 mm<br />

Dissolved oxygen: InPro 6800 / InPro 6900 diameter (except turbidity sensors)<br />

Conductivity: InPro 7001 (not with InTrac 797 e)<br />

Turbidity: InPro 8100 / InPro 8200<br />

Wetted O-rings Viton ®-FDA, EPDM-FDA or Kalrez ®-FDA / USP VI EPDM-FDA<br />

Process-wetted InTrac 77X e: DIN 1.4404 / AISI 316L, HA-C22, titanium, DIN 1.4404<br />

parts PP, PVDF, PEEK<br />

InTrac 79X e: DIN 1.4404 / AISI 316L<br />

Flexible <strong>process</strong> adapation 776 e 777 e / 779 e 797 e / 799 e<br />

DN 25: • • • •<br />

Flanges (DIN, ANSI): • •<br />

NPT thread: • •<br />

TriClamp: • • • •<br />

Tuchenhagen Varivent: • • • •<br />

Neumo DN50: •<br />

Specific features TRI-LOCK TM , sensor detector, position indicators, Hygenic design, uniform<br />

(optional, pneumatic or inductive version) sensor length 120 mm<br />

Certificates / approvals CE: • •<br />

PED*: •<br />

ATEX (94/9/EC): •<br />

MaxCert TM : •<br />

Sterile test: • (for InTrac 797 e / 799 e)<br />

EHEDG: on request •<br />

3A: on request •<br />

* PED = pressure equipment directive, 97/23/EC<br />

InTrac 798 e<br />

(pneumatic version)

InTrac <strong>retractable</strong> <strong>housings</strong> in the measurement loop<br />

Automatic control with EasyClean.<br />

The new <strong>retractable</strong> <strong>housings</strong> combined with the EasyClean automatic cleaning and calibration system<br />

form unique measuring systems. These systems accomodate specific maintenance objectives aimed<br />

at optimizing <strong>process</strong> safety as well as maintenance costs <strong>–</strong> even in the most demanding applications.<br />

Examples of a complete measurement loop<br />

Field of application Retractable Parameter Electrodes / Transmitter Cleaning &<br />

housing Sensors Calibration<br />

System<br />

InTrac 776 e pH/Redox Liquid electrolyte pH2100 e<br />

Chemical industry electrodes pH2500<br />

(CPI) InTrac 777 e pH/Redox Gel and solid pH2220 X<br />

polymer electrolyte M700<br />

electrodes<br />

O2 InPro 6800 O24100 e EC150<br />

Conductivity InPro 7001-VP Cond 7100 e EC200<br />

InTrac 779 e Turbidity InPro 8100 Trb8300 EC300<br />

InPro 8200 EC300 EX<br />

InTrac 797 e pH InPro 3100 pH2100 e EC350<br />

Pharmaceutical InTrac 798 e InPro 3200 pH2500<br />

industry InPro 3300 M700<br />

O2 InPro 6800 O24100 e<br />

Food and Beverage InPro 6900<br />

Industry CO2 InPro 5000 CO25100 e<br />

InTrac 799 e Turbidity InPro 8100 Trb8300<br />

InPro 8200<br />

Typical system configuration for demanding applications<br />

~<br />

Transmitter<br />

”Emergency”<br />

button<br />

~<br />

Control unit Valve assembly<br />

Warning<br />

light<br />

Air<br />

H2O Remote control<br />

Buffers and<br />

cleaning solution<br />

5000 ml

Anti-blowout lip provides a positive stop<br />

while retracting the sensor to prevent<br />

accidental blowout.<br />

InTrac ® 787 <strong>retractable</strong> housing<br />

for in-line pH/ORP and O2 measurements.<br />

Safety chain rated to 180 kg (400 lbs.)<br />

for ease-of-use and maximum protection.<br />

INGOLD<br />

Leading Process Analytics<br />

The Mettler-Toledo InTrac 787<br />

<strong>retractable</strong> housing is designed for<br />

continuous in-line measurements in<br />

industrial <strong>process</strong>es including chemical,<br />

pulp & paper applications.<br />

The hot-tap design allows the sensor<br />

to be removed from a <strong>process</strong> line,<br />

tank, or vessel without interrupting the<br />

flow or draining the container when<br />

retracted through a ball valve.<br />

All Mettler-Toledo 12 x 120 mm sensors<br />

with detachable cables may be used<br />

with the InTrac 787. Integrated flushing<br />

ports allow an in-line rinsing of the electrode<br />

without removing it from the <strong>process</strong>.<br />

The ball valve provides a safe,<br />

tight <strong>process</strong> seal.<br />

For increased installation flexibility, there<br />

are two versions available with variable<br />

insertion length from 0 to 100 mm, and<br />

0 to 300 mm.<br />

Key safety advantages include<br />

<strong>–</strong> Safe <strong>process</strong> sealing due to a ball valve<br />

<strong>–</strong> Integrated anti-blowout lip prevents<br />

accidental blowout<br />

<strong>–</strong> Safety chain rated to 1.7 kN (400 lbs.)<br />

working load limit<br />

<strong>–</strong> Double o-ring <strong>process</strong> seals<br />

provide redundant protection<br />

against <strong>process</strong> leakage<br />

<strong>–</strong> Flushing ports for cleaning without<br />

interrupting the <strong>process</strong><br />

<strong>–</strong> Two different sensor insertion<br />

depths (100/300 mm 4/12")<br />

<strong>–</strong> All wetted parts 3.1B certified

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

InTrac ® 787 <strong>retractable</strong> housing<br />

InTrac ® 787 <strong>retractable</strong> housing.<br />

ISO<br />

9001<br />

certified<br />

102/300 mm<br />

551/ 754 mm<br />

1 Quick release latch<br />

2 SS chain<br />

3 Dual o-ring seal<br />

4 Wiper ring<br />

5 Electrode holder<br />

6 Cage for electrode<br />

protection<br />

7 Anti blow out lip<br />

ISO<br />

14001<br />

certified<br />

Management System<br />

certified according to<br />

ISO 9001 / ISO 14001<br />

The InTrac 787 has been specially designed to meet your application requirements by offering two versions<br />

for the <strong>process</strong> insertion tube. The standard housing was designed to fit any of our detachable cable<br />

120 mm sensors and features a sensor cage for added protection against sensor breakage and optional<br />

flushing ports for increased cleanability.<br />

Specifications<br />

Dimensions see dimensional drawing<br />

Maximum pressure* 9 bar (130 psi)<br />

Maximum temperature* 140 °C ( 266 °F)<br />

Insertion length variable 0 to 100 (300) mm / 0” to 4 (12)"<br />

Wetted parts Housing 316L Stainless Steel (3.1B)<br />

O-rings Viton ®<br />

Ball valve Ball 316 (1.4401)<br />

Housing CF-8M (1.4408)<br />

Sealing PTFE<br />

Ball valve DN40, 1.5" NPT full port<br />

* See electrode specification<br />

Ordering information<br />

InTrac 787 including: complete housing with ball valve, electrode holder (120 mm) with protection cage and flushing ports.<br />

Description Order Number<br />

InTrac 787/100 mm (4") 52 402 401<br />

InTrac 787/300 mm (12") 52 402 402<br />

Flange C40 PN16 1 1 /2" NPT 52 402 404<br />

Flange ANSI 150/6 1 1 /2" NPT 52 402 405<br />

See appropriate data sheets for sensor and cable specifications and ordering information.<br />

Spare parts and options<br />

Immersion tube complete for 100 mm (4")version, incl. 3.1B 52 402 389<br />

Immersion tube complete for 300 mm (12") version, incl. 3.1B 52 402 390<br />

Ball valve / DN40-1"NPT / 3.1B 52 402 422<br />

Double nipple 1" NPT / 3.1B 52 402 421<br />

Serto for flushing ports 787 / D6 mm 52 402 465<br />

Serto for flushing ports 787 / D6,35 mm 52 402 466<br />

Swagelok for flushing port 787 / 6 mm 52 402 467<br />

Swagelok for flushing port 787 / 6,35 mm 52 402 468<br />

O-ring set (5) InTrac787 Viton cpl. 52 402 403<br />

O-ring set (5) 120 mm electrode holder / Vi 52 402 463<br />

Flushing chamber InTrac787 incl. nipples 52 402 464<br />

Electrode holder 120 mm cpl. 52 402 469<br />

Chain cpl. 52 402 470<br />

Cable fitting cpl. 52 402 471<br />

InPro ® , InTrac ® , and Xerolyt ® are registered trademarks of Mettler-Toledo, Inc.<br />

Viton ® is a registered trademark of E.I. DuPont de Nemours and Co.<br />

INTERNET<br />

http://www.mtpro.com<br />

Mettler-Toledo GmbH, Process Analytics<br />

Industrie Nord, CH-8902 Urdorf<br />

Phone + 41 44 729 62 11, Fax +41 44 729 66 36<br />

Subject to technical changes.<br />

© Mettler-Toledo GmbH 01/06.<br />

Printed in Switzerland. 52 402 505<br />

Sales and service:

InTrac 785 Retractable Housing<br />

Easy Sensor Access<br />

In Harsh Chemical Applications<br />

Flexibility in<br />

maintenance intervals<br />

Gain access to the sensor without interrupting<br />

the <strong>process</strong>. Simple retraction and<br />

<strong>process</strong> sealing via ball valve allows easy<br />

maintenance.<br />

Wide range of<br />

installation options<br />

Adjustable insertion length up to 220 mm<br />

(8.66") allows simple installation in a<br />

variety of applications. The unique design<br />

provides further versatility by accepting<br />

any pH, DO and Turbidity measurements.<br />

Different <strong>process</strong> connections are available<br />

to have multiple installation options.<br />

Increased production<br />

uptime<br />

The durable design ensures reliable operation<br />

in the most aggressive applications.<br />

The housing is available in stainless steel<br />

Hastelloy or titanium with Viton ® or<br />

Kalrez ® sealing.<br />

High operational safety<br />

A ball valve is the industry proven solution<br />

to separate the <strong>process</strong> from the environment.<br />

The InTrac 785 has been engineered<br />

with an integral anti-blowout tip for<br />

maximum safety. The ball valve of the<br />

InTrac 785 safely isolates the sensor from<br />

the <strong>process</strong> for safe, continuous operation.<br />

InTrac 785 <strong>–</strong> The reliable and easy<br />

to use <strong>retractable</strong> housing for harsh<br />

environments<br />

The InTrac 785 <strong>retractable</strong> housing is the easy way of<br />

getting access to the sensor without <strong>process</strong> interruption.<br />

<strong>When</strong>ever maintenance on the sensor is<br />

required, a simple retraction of the sensor and closing<br />

the ball valve allows fast sensor operation.<br />

The housing is specially designed for harsh chemical<br />

applications and is available in different materials<br />

for medium wetted parts (1.4435 / 316L, Hastelloy,<br />

titanium). This ensures reliable operation even in<br />

demanding chemical and pulp and paper applications.<br />

The InTrac 785 allows a wide range of installation<br />

possibilities, thanks to the long insertion length (useradjustable<br />

with an adjusting collar) and a wide variety<br />

of <strong>process</strong> connections. If the ball valve is already<br />

present or a factory standard needs to be used, this<br />

housing is also available without ball valve and<br />

<strong>process</strong> connection.

Technical data<br />

InTrac 785<br />

Designation InTrac 785<br />

Design pressure 16 bar / 232 psi<br />

Functional pressure 6 bar / 87 psi<br />

Process temperature 130 °C / 266 °F<br />

Insertion length Up to 220 mm / 8.66 inches (adjustable)<br />

Process connections 1" M NPT, 1 1 ⁄4" M NPT, flange ANSI A150-1.5, flange DIN DN50 PN16,<br />

without ball valve and <strong>process</strong> connection<br />

Medium wetted parts 1.4435 / 316L / C22 / titanium, ball valve always made of 1.4408<br />

O-ring material Viton ® or Kalrez ®<br />

Ball valve 1" NPT full port, 1.4408<br />

(also C22 and Ti versions equipped with ball valve made of 1.4408)<br />

Flushing chamber Optionally available<br />

Protective cage Yes<br />

Safety feature Anti-blowout tip: provides a positive stop while retracting the sensor to prevent<br />

accidental blowout<br />

Suitable sensors pH: all 12 mm design with 425 mm length<br />

Turbidity: all with 409 mm length<br />

Oxygen: all with 420 mm length<br />

Get on-line support<br />

via www.mt.com/pro<br />

Visit our website at any time for fast and competent information.<br />

The very latest, updated product and support documentation is available<br />

in many different languages.<br />

Visit our website for fast and competent information.<br />

Sales and service:<br />

■ Support center with easy<br />

and free download<br />

■ For on-line access click on<br />

<strong>–</strong> Contact us<br />

<strong>–</strong> Request more information<br />

<strong>–</strong> Get a quote<br />

www.mt.com/pro<br />

ISO<br />

9001<br />

certified<br />

ISO<br />

14001<br />

certified<br />

Management System<br />

certified according to<br />

ISO 9001 / ISO 14001<br />

216 mm/8.50"<br />

220 mm/8.66"<br />

674 mm/26.53"<br />

Visit for more information<br />

Mettler-Toledo AG<br />

Process Analytics<br />

CH - 8902 Urdorf, Switzerland<br />

Phone +41 44 729 62 11<br />

Fax +41 44 729 66 36<br />

Subject to technical changes.<br />

© 01/ 2008 Mettler-Toledo AG<br />

Printed in Switzerland. 52 403 860<br />

757 mm/29.80"<br />

■ Country-specific information<br />

■ Search functionality<br />

■ Find and download product<br />

and application documents

Housings<br />

156<br />

Retractable Housings<br />

Sensor Access Without Process Interruption<br />

Mettler-Toledo Ingold International<br />

InTrac 776e<br />

For Liquid-Filled pH-Electrodes<br />

USP<br />

Class VI<br />

Process Entry: Top-entry, Side-entry, Pipe-entry (see Figure 1 pg. 142)<br />

The <strong>retractable</strong> InTrac 776e <strong>housings</strong> are designed for applications in <strong>process</strong>es<br />

which utilize pH/ORP sensors that have a liquid electrolyte reference system such<br />

as the InPro 2000 and INGOLD 465 series electrodes.<br />

The housing has a built-in flushing chamber in which the electrode can be cleaned<br />

and calibrated if necessary, both accomplished without interruption of the <strong>process</strong>.<br />

This enhanced housing incorporates the TRI-LOCK safety system which increases<br />

<strong>process</strong> safety and reliability even in harsh applications.<br />

Specifications<br />

Operation Manual or pneumatic<br />

Ambient temperature Polypropylene: 0 to 70°C (32 to 158°F)<br />

Stainless steel: <strong>–</strong>10 to 70°C (14 to 158°F)<br />

Functional pressure range Manual: 0 to 5 bar (0 to 73 psig)<br />

Pneumatic: 0 to 8 bar (0 to 116 psig)<br />

Max. permissible pressure Polypropylene (PP): 6 bar/20°C (87 psig at 68°F)<br />

PVDF, PEEK: 6 bar/20°C (87 psig at 68°F)<br />

316L stainless steel: 6 bar/130°C (87 psig at 266°F)<br />

Hastelloy ® /Ti: 6 bar/130°C (87 psig at 266°F)<br />

Insertion lengths 70 mm, 100 mm, 200 mm (2.76", 3.94", 7.87")<br />

Wetted parts 316L stainless steel, Hastelloy-C22, titanium,<br />

PP, PVDF, PEEK<br />

Wetted O-rings Viton ® -FDA, EPDM-FDA, Kalrez ® -FDA-USP Class VI<br />

Housing length 70/100 mm: 545 mm (21.8") in <strong>process</strong><br />

710 mm (28") retracted from<br />

<strong>process</strong><br />

200 mm: 645 mm (25.4") in <strong>process</strong><br />

1110 mm (43.7") retracted from<br />

<strong>process</strong><br />

Pneumatic conditions 4 to 8 bar (58 to 116 psig)<br />

Flushing connections 2 to 6 bar (29 to 87 psig)<br />

(water, steam)<br />

Position monitoring (options) Pneumatic check (3/2 way valve), G 1 8"<br />

Inductive check, non-Ex, M12�1<br />

Inductive check, Ex, M12�1<br />

Certificates Declaration of conformity CE; Pressure Equipment<br />

Directive guidelines (PED) 97/23/EC;<br />

Certificate of conformity according to EN10204-2.1;<br />

Material certificate according to 3.1;<br />

ATEX: II 1/2 GD IIC T6/T5/T4/T3;<br />

FM: IS Cl. I,II,III, Div1, GR ABCDEFG/T6; MaxCert<br />

Sensor Fit Guide (for Liquid-Filled pH Glass Electrodes)<br />

Sensor Length Insertion Length<br />

70 mm 100 mm 200 mm<br />

250 mm • • <strong>–</strong><br />

450 mm <strong>–</strong> <strong>–</strong> •

Ordering Information<br />

InTrac 776e for Liquid-Filled pH/ORP Sensors Process Connect Insertion Length Wetted Parts Order Number<br />

InTrac 776e-M with Viton ® DN25 70 mm SS 52 403 220<br />

InTrac 776e-M with Viton ® DN25 100 mm SS 52 403 221<br />

InTrac 776e-M with Viton ® DN25 200 mm SS 52 403 222<br />

InTrac 776e-P with Viton ® DN25 70 mm SS 52 403 223<br />

InTrac 776e-P with Viton ® DN25 100 mm SS 52 403 224<br />

InTrac 776e-P with Viton ® DN25 200 mm SS 52 403 225<br />

InTrac 776e-M with Viton ® DN25 70 mm PVDF 52 403 226<br />

InTrac 776e-M with Viton ® DN25 100 mm PVDF 52 403 227<br />

InTrac 776e-P with Viton ® DN25 70 mm PVDF 52 403 228<br />

InTrac 776e-P with Viton ® DN25 100 mm PVDF 52 403 229<br />

InTrac 776e-R with Viton ® DN25 100 mm SS 52 403 230<br />

InTrac 776e-I with Viton ® DN25 100 mm SS 52 403 231<br />

InTrac 776e-M with Kalrez ® DN25 70 mm SS 52 403 232<br />

For the housing configuration of the InTrac 776e, InTrac 777e, and InTrac 779e, please use the product configurator below.<br />

Product configurator (InFit 776e, InTrac 777e, and InTrac 779e)<br />

Flushing chamber<br />

7 Single flushing chamber<br />

Electrode/sensor type<br />

6 pH electrodes with liquid electrolyte<br />

7 pH electrodes with gel/polymer electrolyte and sensors with Pg13.5 thread<br />

9 Turbidity sensors<br />

Operation mode<br />

M Manual operation<br />

P Pneumatic operation<br />

R Pneumatic operation with pneumatic position indication<br />

I Pneumatic operation with inductive position indication, non-Ex<br />

X Pneumatic operation with inductive position indication, Ex<br />

Insertion length (H)<br />

0 7 0 H = 70 mm<br />

1 0 0 H = 100 mm<br />

2 0 0 H = 200 mm<br />

Material (wetted parts)<br />

4 4 0 4 DIN 1.4404/AISI 316L (stainless steel)<br />

C 2 2 − DIN 2.4602/Alloy C22<br />

T i − − Titanium<br />

P P − − Polypropylene<br />

P V D F Polyvinylidene fluoride<br />

P E E K Polyetherether ketone<br />

Process connection<br />

D 0 0 INGOLD DN25 weld-in socket<br />

D 0 2 Flange DN32 PN16 (SS version only)<br />

D 0 3 Flange DN40 PN16<br />

D 0 4 Flange DN50-PN16<br />

A 0 2 ANSI Flange A150-1 1 2"<br />

A 0 3 ANSI Flange A150-2"<br />

A 0 4 ANSI Flange A150-3"<br />

N 0 1 NPT 1"<br />

N 0 2 NPT 1 1 4"<br />

N 0 3 NPT 1 1 2"<br />

T 0 1 Tri-Clamp flange 1 1 2", straight<br />

T 0 2 Tri-Clamp flange 2", straight<br />

V 0 1 Varivent flange DN50, straight<br />

O-ring material<br />

V i FKM Viton ® FDA<br />

E P EPDM FDA<br />

K a FFKM Kalrez ® 6230 FDA/USP Class VI<br />

Body material<br />

A PP conducting<br />

S DIN 1.4404/316L<br />

Flushing connections<br />

0 Without<br />

1 Serto ss<br />

2 PVC<br />

3 PVDF<br />

4 Gyrolok ss<br />

5 Swagelok ® ss<br />

Special<br />

0 Standard<br />

1 Special<br />

InTrac 7 / / / / /<br />

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30<br />

Biopharm<br />

Chemical<br />

Food & Bev.<br />

InTrac 77Xe<br />

Hastelloy ® i and titanium<br />

<strong>housings</strong> have cap nuts<br />

made of stainless steel.<br />

Varivent and Tri-Clamp<br />

flanges are available<br />

in stainless steel only.<br />

Feature Overview<br />

<strong>–</strong> Multiple <strong>process</strong> connections<br />

available<br />

<strong>–</strong> For use with liquid filled<br />

pH or ORP electrodes<br />

<strong>–</strong> Advanced TRI-LOCK<br />

safety system<br />

<strong>–</strong> Removes sensor without<br />

interruption of the <strong>process</strong><br />

Other Highlights<br />

<strong>–</strong> MaxCert covers<br />

necessary certifications<br />

<strong>–</strong> Increased operational<br />

safety and reliability<br />

<strong>–</strong> Several materials of<br />

construction available<br />

<strong>–</strong> Pressurized chamber<br />

to ensure positive<br />

electrolyte flow<br />

Mettler-Toledo Ingold International<br />

157

Housings<br />

158<br />

Retractable Housings<br />

Sensor Access Without Process Interruption<br />

Mettler-Toledo Ingold International<br />

InTrac 777e/779e<br />

The Reliable Allrounder<br />

USP<br />

Class VI<br />

Feature Overview<br />

<strong>–</strong> Multiple <strong>process</strong> connections<br />

available<br />

<strong>–</strong> For use with 12 mm INGOLD sensors<br />

<strong>–</strong> Advanced TRI-LOCK safety system<br />

<strong>–</strong> Removes sensor without interruption<br />

of the <strong>process</strong><br />

Other Highlights<br />

<strong>–</strong> MaxCert covers necessary<br />

certifications<br />

<strong>–</strong> Increased operational safety<br />

and reliability<br />

<strong>–</strong> Several materials of constructions<br />

available<br />

<strong>–</strong> Patented safety immersion tube<br />

Process Entry: Top-entry, Side-entry, Pipe-entry (see Figure 1 pg. 142)<br />

The <strong>retractable</strong> InTrac 777e/779e <strong>housings</strong> are specifically designed for applications<br />

in <strong>process</strong>es which utilize 12 mm pH, ORP, dissolved oxygen, CO2,<br />

conductivity, and turbidity (InTrac 779e) sensors. The housing has a flushing<br />

chamber in which the electrode can be cleaned and calibrated if necessary, both<br />

accomplished without interruption of the <strong>process</strong>. This enhanced housing incorporates<br />

the TRI-LOCK safety system which increases <strong>process</strong> safety and reliability<br />

even in harsh applications. Multiple <strong>process</strong> connections and materials of<br />

construction make the InTrac 777e/779e an excellent choice for use in either the<br />

chemical, biopharmaceutical or food and beverage industries.<br />

Specifications<br />

Operation Manual or pneumatic<br />

Ambient temperature Polypropylene: 0 to 70°C (32 to 158°F)<br />

Stainless steel: <strong>–</strong>10 to 70°C (14 to 158°F)<br />

Functional pressure range Manual: 0 to 5 bar (0 to 73 psig)<br />

Pneumatic: 0 to 8 bar (0 to 116 psig)<br />

Max. permissible pressure Polypropylene (PP): 6 bar/20°C (87 psig at 68°F)<br />

PVDF, PEEK: 6 bar/20°C (87 psig at 68°F)<br />

316L stainless steel: 6 bar/130°C (87 psig at 266°F)<br />

Hastelloy ® /Ti: 6 bar/130°C (87 psig at 266°F)<br />

Insertion lengths 70 mm, 100 mm, 200 mm (2.76", 3.94", 7.87")<br />

Wetted parts 316L stainless steel, Hastelloy-C22, titanium,<br />

PP, PVDF, PEEK<br />

Wetted O-rings Viton ® -FDA, EPDM-FDA, Kalrez ® -FDA and USP Class VI<br />

Housing length 70/100 mm: 360 mm (14.2") in <strong>process</strong><br />

515 mm (20.3") retracted from<br />

<strong>process</strong><br />

200 mm: 460 mm (18.1") in <strong>process</strong><br />

915 mm (36") retracted from<br />

<strong>process</strong><br />

Pneumatic conditions 4 to 8 bar (58 to 116 psig)<br />

Flushing connections 2 to 6 bar (29 to 87 psig)<br />

(water, steam)<br />

Position monitoring (options) Pneumatic check (3/2 way valve), G 1 8"<br />

Inductive check, non-Ex, M12�1<br />

Inductive check, Ex, M12�1<br />

Certificates Declaration of conformity CE; Pressure Equipment<br />

Directive guidelines (PED) 97/23/EC;<br />

Certificate of conformity according to EN10204-2.1;<br />

Material certificate according to 3.1;<br />

ATEX: II 1/2 GD IIC T6/T5/T4/T3;<br />

FM: IS Cl. I,II,III, Div1, GR ABCDEFG/T6; MaxCert

Ordering Information<br />

InTrac 777e and InTrac 779e Process Connect Insertion Length Wetted Parts Order Number<br />

InTrac 777e-M with Viton ® DN25 70 mm SS 52 403 205<br />

InTrac 777e-M with Viton ® DN25 100 mm SS 52 403 206<br />

InTrac 777e-M with Viton ® DN25 200 mm SS 52 403 207<br />

InTrac 777e-P with Viton ® DN25 70 mm SS 52 403 208<br />

InTrac 777e-P with Viton ® DN25 100 mm SS 52 403 209<br />

InTrac 777e-P with Viton ® DN25 200 mm SS 52 403 210<br />

InTrac 777e-M with Viton ® DN25 70 mm PVDF 52 403 211<br />

InTrac 777e-M with Viton ® DN25 100 mm PVDF 52 403 212<br />

InTrac 777e-P with Viton ® DN25 70 mm PVDF 52 403 213<br />

InTrac 777e-P with Viton ® DN25 100 mm PVDF 52 403 214<br />

InTrac 777e-R with Viton ® DN25 100 mm SS 52 403 215<br />

InTrac 777e-I with Viton ® DN25 100 mm SS 52 403 216<br />

InTrac 777e-M with Viton ® NPT 1" 70 mm SS 52 403 217<br />

InTrac 777e-M with Viton ® NPT 1" 100 mm SS 52 403 218<br />

InTrac 777e-M with Viton ® NPT 1" 200 mm SS 52 403 219<br />

InTrac 779e-M with Viton ® DN25 70 mm SS 52 403 236<br />

If the housing configuration required is not included in the order number list above, please use the product configurator found on page 157.<br />

Accessories for InTrac 7XXe Housings Order Number<br />

Pt100-764/5 m (16.4 ft) 10 1003 104IG<br />

Pt1000-764/5 m (16.4 ft) 10 1003 116IG<br />

3/2-way valve set (2 pcs), pneumatic 52 403 023<br />

Inductive check-back, Non-Ex (2 pcs.) 52 403 024<br />

Inductive check-back, Ex (2 pcs.) 52 403 025<br />

O-ring set Viton ®-FDA (InTrac 7XXe) 52 403 172<br />

O-ring set Kalrez ®-FDA-USP Class VI (InTrac 7XXe) 52 403 173<br />

O-ring set EPDM-FDA (InTrac 7XXe) 52 403 174<br />

InFit 777e/InFit 779e Sensor Fit Guide<br />

Sensor Length Insertion Length<br />

70 mm 100 mm 200 mm<br />

205 mm (Turbidity) • 1 • 1 <strong>–</strong><br />

220 mm (O2/CO2) • • <strong>–</strong><br />

225 mm (pH/ORP) • • <strong>–</strong><br />

407 mm (Turbidity) <strong>–</strong> <strong>–</strong> • 1<br />

420 mm (O2/CO2) <strong>–</strong> <strong>–</strong> •<br />

425 mm (pH/ORP) <strong>–</strong> <strong>–</strong> •<br />

1 InTrac 779e only<br />

Pos. 1 Pos. 2 Pos. 3 Pos. 4 Pos. 5 Pos. 1 Pos. 2 Pos. 3 Pos. 4<br />

Immersion tube H100/H200<br />

The patented design of the immersion tube H100/H200 guarantees in any<br />

position, safe containment of the <strong>process</strong> medium during sensor insertion and<br />

retraction procedures. The patented immersion tube comes as standard with<br />

all <strong>housings</strong> with insertion length of 100 mm and 200 mm.<br />

Biopharm<br />

Chemical<br />

Food & Bev.<br />

Wastewater<br />

Pos. 5<br />

Immersion tube H70<br />

Housings with an insertion length of 70 mm do not offer this feature.<br />

An insertion length of 70 mm might be required, where the pipe diameter does<br />

not allow an 100 mm insertion.<br />

Mettler-Toledo Ingold International<br />

159

Housings<br />

160<br />

Retractable Housings<br />

Sensor Access Without Process Interruption<br />

Mettler-Toledo Ingold International<br />

InTrac 796<br />

For Sterile Conditions With Liquid-Filled pH-Electrodes<br />

USP<br />

Class VI<br />

Feature Overview<br />

<strong>–</strong> The InTrac 796 housing is designed to<br />

meet the specific application requirements<br />

of biotechnology <strong>process</strong>es<br />

<strong>–</strong> Retraction and reinsertion of the electrode<br />

under sterile conditions permit<br />

electrode servicing during <strong>process</strong><br />

<strong>–</strong> Sterilizable double flushing chamber<br />

lock effectively prevents any external<br />

contamination<br />

The InTrac 796 <strong>retractable</strong> <strong>housings</strong> have been designed to meet the most stringent<br />

hygienic requirements found in the biotech, pharmaceutical, and food industries.<br />

A special double flushing chamber assures complete sterilization of the upper and<br />

lower sections of sensor and insertion shaft, allowing the sensors to be removed<br />

and replaced under a completely controlled sterile environment. The InTrac 796 is<br />

designed for use with INGOLD liquid-filled pH electrodes and is ideally suited for<br />

side-mounted bioreactor applications.<br />

Specifications<br />

Operation Manual or pneumatic<br />

Ambient temperature Immersion tube: 0 to 130°C (32 to 266°F)<br />

steam sterilizable<br />

Headpart: 0 to 80°C (32 to 176°F)<br />

Functional pressure range 3 to 8 bar (43.5 to 116 psig)<br />

Max. permissible pressure 0 to 6 bar (0 to 87 psig)<br />

Insertion lengths 75 mm (2.95")<br />

Wetted parts 316L stainless steel, DIN 1.4435 with<br />

3.1 material certificate<br />

Wetted O-rings Viton ® -FDA-USP Class VI<br />

Housing length 527 mm (20.8") in <strong>process</strong><br />

575 mm (22.6") retracted from <strong>process</strong><br />

Certificates Declaration of conformity CE;<br />

Material certificate according to 3.1<br />

Suggested Sensors<br />

pH DO CO2 Conductivity Turbidity<br />

465 N/A N/A N/A N/A<br />

InPro 2000<br />

Sensor Fit Guide<br />

Sensor Length Insertion Length<br />

75 mm<br />

250 mm •<br />

Process Entry: Top-entry, Side-entry, Pipe-entry (see Figure 1 pg. 142)

Ordering Information<br />

InTrac 796 Process Connect Bore Size Insertion Length Wetted Parts Order Number<br />

InTrac 796M/75 DN25 25 mm 75 mm SS 00 796 3002<br />

InTrac 796P/75 DN25 25 mm 75 mm SS 00 796 3010<br />

OPTIONS: Ra finish, electro-polish, non-reactive materials, O-rings, <strong>process</strong> connection, other Custom<br />

i<br />

Function of the double<br />

flushing chamber lock<br />

In the double flushing<br />

chamber design (see Figs. 1.1 and<br />

1.2), the measuring tip of the retracted<br />

electrode can be cleaned (or serviced if<br />

necessary), then sterilized with steam.<br />

In contrast to single-chamber designs,<br />

the double flushing chamber configuration<br />

ensures that after sterilization the<br />

lower rinsing chamber adjacent to the<br />

<strong>process</strong> medium always remains sterile<br />

when the electrode is inserted. Sterility<br />

is assured because the upper portion of<br />

the <strong>retractable</strong> shaft remains sterile as<br />

it passes into the lower chamber during<br />

sensor insertion.<br />

Figure 1.1 “IN” Position<br />

Lower rinsing chamber<br />

Figure 1.2 “OUT” Position<br />

Upper rinsing chamber<br />

Biopharm<br />

Food & Bev.<br />

Mettler-Toledo Ingold International<br />

161

Housings<br />

162<br />

Retractable Housings<br />

Sensor Access Without Process Interruption<br />

Mettler-Toledo Ingold International<br />

InTrac 797e/799e<br />

<strong>When</strong> Sterile Conditions Are Required<br />

USP<br />

Class VI<br />

Feature Overview<br />

<strong>–</strong> Multiple <strong>process</strong> connections<br />

available<br />

<strong>–</strong> For use with 12 mm INGOLD sensors<br />

<strong>–</strong> Double flushing chamber<br />

<strong>–</strong> Removes sensor without interruption<br />

of the <strong>process</strong><br />

Other Highlights<br />

<strong>–</strong> Twin-chamber lock effectively<br />

prevents any external contamination<br />

<strong>–</strong> Increased operational safety<br />

and reliability<br />

<strong>–</strong> Advanced TRI-LOCK safety system<br />

Process Entry: Top-entry, Side-entry, Pipe-entry (see Figure 1 pg. 142)<br />

The <strong>retractable</strong> InTrac 797e/799e <strong>housings</strong> are specifically designed for applications<br />

in <strong>process</strong>es which utilize 12 mm pH, ORP, dissolved oxygen, CO2,<br />

conductivity, and turbidity (InTrac 799e) sensors. This sterilizable housing has<br />

a double flushing chamber which was designed to meet the highest demands of<br />

the pharmaceutical and food and beverage industries where sterile conditions are<br />

required. The double flushing chamber allows complete sterilization of the upper<br />

and lower sections of a sensor and insertion shaft allowing the electrode/sensor to<br />

be removed and replaced under a completely sterile environment.<br />

Specifications<br />

Operation Manual or pneumatic<br />

Ambient temperature Stainless steel: <strong>–</strong>10 to 70°C (14 to 158°F)<br />

Functional pressure range Manual: 0 to 5 bar (0 to 73 psig)<br />

Pneumatic: 0 to 8 bar (0 to 116 psig)<br />

Max. permissible pressure 316L stainless steel: 6 bar/130°C (87 psig at 266°F)<br />

Insertion lengths 100 mm (3.94")<br />

Wetted parts 316L stainless steel<br />

Wetted O-rings Viton ® -FDA, EPDM-FDA, Kalrez ® -FDA-USP Class VI<br />

Housing length 100 mm: 460 mm (18.1") in <strong>process</strong><br />

715 mm (28.2") retracted from<br />

<strong>process</strong><br />

Pneumatic conditions 4 to 8 bar (58 to 116 psig)<br />

Flushing connections 2 to 6 bar (29 to 87 psig)<br />

(water, steam)<br />

Position monitoring (options) Pneumatic check (3/2 way valve), G 1 8"<br />

Inductive check, non-Ex, M12�1<br />

Inductive check, Ex, M12�1<br />

Certificates Declaration of conformity CE; Pressure Equipment<br />

Directive guidelines (PED) 97/23/EC;<br />

Certificate of conformity according to EN10204-2.1;<br />

Material certificate according to 3.1;<br />

ATEX: II 1/2 GD IIC T6/T5/T4/T3;<br />

FM: IS Cl. I,II,III, Div1, GR ABCDEFG/T6; MaxCert<br />

InTrac 797e/InTrac 799e Sensor Fit Guide<br />

Sensor Length Insertion Length<br />

100 mm �12 mm Sensor/Electrode<br />

297 mm • 1 Turbidity<br />

320 mm • 2 O2, CO2<br />

325 mm • 2 pH/ORP<br />

1 InTrac 799e only<br />

2 InTrac 797e only

Ordering Information<br />

InTrac 797e and InTrac 799e Process Connect Insertion Length Wetted Parts Order Number<br />

InTrac 797e-M with Viton ® DN25 100 mm SS 52 403 233<br />

InTrac 797e-P with Viton ® DN25 100 mm SS 52 403 235<br />

InTrac 797e-M with Viton ® and 768 adapter DN25 200 mm SS 52 403 234<br />

InTrac 799e-M with Viton ® DN25 100 mm SS 52 403 237<br />

Accessories for InTrac 7XXe Housings Order Number<br />

Pt100-764/5 m (16.4 ft) 10 1003 104IG<br />

Pt1000-764/5 m (16.4 ft) 10 1003 116IG<br />

3/2-way valve set (2 pcs), pneumatic 52 403 023<br />

Inductive check-back, Non-Ex (2 pcs.) 52 403 024<br />

Inductive check-back, Ex (2 pcs.) 52 403 025<br />

O-ring set Viton ®-FDA (InTrac 7XXe) 52 403 172<br />

O-ring set Kalrez ®-FDA-USP Class VI (InTrac 7XXe) 52 403 173<br />

O-ring set EPDM-FDA (InTrac 7XX e) 52 403 174<br />

If the housing configuration required is not included in the order number list above, please use the product configurator below.<br />

Product configurator (InTrac 797e, InTrac 799e)<br />

Flushing chamber<br />

9 Double flushing chamber<br />

Electrode/sensor type<br />

7 pH electrodes with gel/polymer electrolyte and sensors with Pg13.5 thread<br />

9 Turbidity sensors<br />

Operation mode<br />

M Manual operation<br />

P Pneumatic operation<br />

R Pneumatic operation with pneumatic position indication<br />

I Pneumatic operation with inductive position indication, non-Ex<br />

X Pneumatic operation with inductive position indication, Ex<br />

Insertion length (H)<br />

1 0 0 H = 100 mm<br />

Material (wetted parts)<br />

4 4 0 4 DIN 1.4404/AISI 316L (stainless steel)<br />

Process connection<br />

D 0 0 INGOLD DN25 weld-in socket<br />

T 0 1 Tri-Clamp flange 1 1 2", straight<br />

T 0 2 Tri-Clamp flange 2", straight<br />

V 0 1 Varivent flange DN50, straight<br />

O-ring material<br />

V i FKM Viton ® -FDA<br />

E P EPDM-FDA<br />

K a FFKM Kalrez ® 6230-FDA/USP Class VI<br />

Body material<br />

A PP conducting<br />

S DIN 1.4404/316L<br />

Flushing connections<br />

0 Without<br />

1 Serto ss<br />

4 Gyrolok ss<br />

5 Swagelok ® ss<br />

Special<br />

0 Standard<br />

1 Special<br />

InTrac 7 / / / / /<br />

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30<br />

Biopharm<br />

Food & Bev.<br />

Mettler-Toledo Ingold International<br />

163

Housings<br />

164<br />

Retractable Housings<br />

Sensor Access Without Process Interruption<br />

Mettler-Toledo Ingold International<br />

InTrac 798e<br />

The Hygienic Solution<br />

Feature Overview<br />

<strong>–</strong> Standard 120 mm sensors fit<br />

all <strong>housings</strong>: more cost effective<br />

<strong>–</strong> Unique self-contained design<br />

with no external moving parts:<br />

very safe operation<br />

<strong>–</strong> EHEDG compliance<br />

Other Highlights<br />

<strong>–</strong> 3.1 certificate included<br />

<strong>–</strong> Optimized drain placement assures<br />

no residual remains after cleaning<br />

<strong>–</strong> Powerful non-jamming mechanism<br />

works well in viscous or fibrous environments<br />

®<br />

Originally designed as a companion product to protect the InPro 3300 ISFET<br />

pH electrode from caustic CIP conditions, the unique benefits of the InTrac 798e<br />

housing can also be used with all 120 mm sensors. The InTrac 798e is<br />

completely self-contained and has none of the external moving parts commonly<br />

associated with <strong>retractable</strong> <strong>housings</strong>. Regardless of the insertion depth selected,<br />

less costly 120 mm sensors are needed to operate the InTrac 798e, which<br />

reduces overall operating expenses and inventory requirements.<br />

Absolute cleanability is possible because the flushing chamber drain and O-ring<br />

have been optimally positioned to assure all CIP solutions are completely drained<br />

from the chamber prior to the sensor being re-inserted into your <strong>process</strong>.<br />

Specifications<br />

Wetted parts Stainless 316L<br />

Surface finish N5/N5 (Ra16/Ra16)<br />

(O-ring groove/Other)<br />

O-ring EPDM-FDA<br />

Sensor fitting Pg13.5<br />

Temperature range 0<strong>–</strong>140°C/32<strong>–</strong>284°F<br />

Pressure rating 0<strong>–</strong>16 bar (0<strong>–</strong>232 psi)<br />

(Sensor dependent)<br />

Process Entry: Top-entry, Side-entry, Pipe-entry (see Figure 1 pg. 142)<br />

Suggested Sensors<br />

pH/DO/CO2/Conductivity<br />

All 120 mm sensors with Pg13.5 and 12 mm diameter (except turbidity sensors)<br />

Sensor Fit Guide<br />

Sensor Length Insertion Length<br />

50 mm 100 mm<br />

120 mm • •<br />

A unique design allows the InTrac 798e housing to use 120 mm sensors regardless of the<br />

housing length.

Ordering Information<br />

InTrac 798e Process Connect Bore Size Insertion Length Wetted Parts Order Number<br />

InTrac 798e Manual DN25 25 mm 100 mm SS 52 402 764<br />

InTrac 798e Pneumatic DN25 25 mm 100 mm SS 52 402 766<br />

InTrac 798e Manual NEU050 25 mm 100 mm SS 52 402 768<br />

InTrac 798e Manual NEU050 25 mm 50 mm SS 52 402 769<br />

InTrac 798e Pneumatic NEU050 25 mm 100 mm SS 52 402 770<br />

InTrac 798e Pneumatic NEU050 25 mm 50 mm SS 52 402 771<br />

InTrac 798e Manual TC/2" 25 mm 100 mm SS 52 402 772<br />

InTrac 798e Manual TC/2" 25 mm 50 mm SS 52 402 773<br />

InTrac 798e Pneumatic TC/2" 25 mm 100 mm SS 52 402 774<br />

InTrac 798e Pneumatic TC/2" 25 mm 50 mm SS 52 402 775<br />

InTrac 798e Manual VAR050 25 mm 100 mm SS 52 402 776<br />

InTrac 798e Manual VAR050 25 mm 50 mm SS 52 402 777<br />

InTrac 798e Pneumatic VAR050 25 mm 100 mm SS 52 402 778<br />

InTrac 798e Pneumatic VAR050 25 mm 50 mm SS 52 402 779<br />

OPTIONS: Ra finish, electro-polish, non-reactive materials, O-rings, <strong>process</strong> connection, other Custom<br />

InTrac 798e Options Order Number<br />

Pt100-764/5 m (16.4 ft) 10 100 3104IG<br />

Pt1000-764/5 m (16.4 ft) 10 100 3116IG<br />

Inductive position indicators non-Ex (2) 52 402 398<br />

Pneumatic position indicators (2) 52 401 324<br />

InTrac 798e Spare Parts Order Number<br />

Twist lock tube 798e complete 52 403 560<br />

Sealing set 798e P 52 403 557<br />

Sealing set 798e M 52 403 558<br />

Safety system 798e complete 52 403 559<br />

InPro 3300 inside the InTrac 798e<br />

Biopharm<br />

Food & Bev.<br />

Mettler-Toledo Ingold International<br />

165

Housings<br />

166<br />

Retractable Housings<br />

Sensor Access Without Process Interruption<br />

Mettler-Toledo Ingold International<br />

InTrac 787<br />

For Harsh Applications<br />

InTrac 787 is a rugged, <strong>retractable</strong> housing for the most demanding industrial<br />

applications. Ease-of-use and safety are the key features of this well-designed,<br />

“bullet-proof” <strong>process</strong> connection system. Sensor maintenance and replacement<br />

becomes a fast and easy task using the InTrac 787, and can be done without<br />

any interruption to your <strong>process</strong>. Redundant safety features prevent the retracted<br />

sensor and tubing from becoming a flying projectile, even under extreme conditions.<br />

Once retracted, the InTrac 787’s integral ball valve completely seals off<br />

your <strong>process</strong>, preventing loss of medium or contamination. The design allows for<br />

direct mounting to <strong>process</strong> lines, tanks, and other standard <strong>process</strong>ing hardware.<br />

This housing offers variable insertion lengths, up to 300 mm (12").<br />

Specifications<br />

Wetted parts Stainless 316L<br />

Surface finish N6/N5 (Ra32/Ra16)<br />

(O-ring groove/Other)<br />

O-ring Viton ® -FDA<br />

Sensor fitting InTrac 787: Pg13.5<br />

Temperature range Up to 130°C/266°F<br />

Pressure rating 9 bar (130 psi)<br />

(Sensor dependent)<br />

Process Entry: Top-entry, Side-entry, Pipe-entry (see Figure 1 pg. 142)<br />

Suggested Sensors<br />

pH DO CO2 Conductivity Turbidity<br />

InPro 3030 InPro 6050 N/A InPro 7001 InPro 8050<br />

InPro 3100 InPro 6800 (12 mm) InPro 7108 InPro 8100<br />

InPro 3250 InPro 6900 InPro 8200<br />

InPro 4010<br />

InPro 4250<br />

InPro 4800<br />

DPA<br />

DPAS<br />

DXK<br />

Feature Overview<br />

<strong>–</strong> Mechanical linkage ensures<br />

safe operation<br />

<strong>–</strong> Anti-blowout lip prevents<br />

accidental blowout<br />

<strong>–</strong> Safety chain rated to 400 lbs<br />

working load<br />

<strong>–</strong> Variable insertion length:<br />

0 to 300 mm (0" to 12")<br />

<strong>–</strong> Full port 1.5" ball valve (1000 WOG<br />

required)<br />

Other Highlights<br />

<strong>–</strong> NEMA 4X cord grip<br />

<strong>–</strong> Flushing port connections<br />

permit sensor cleaning<br />

<strong>–</strong> Double O-ring <strong>process</strong> seals<br />

provide redundant protection against<br />

<strong>process</strong> leakage<br />

<strong>–</strong> Self-wiping <strong>retractable</strong> tube reduces<br />

O-ring wear

Ordering Information<br />

InTrac 787 Process Connect Bore Size Insertion Length Wetted Parts Order Number<br />

InTrac 787/100 mm (4") NPT/1.5" 1.5" 0<strong>–</strong>100 mm/0"<strong>–</strong>4" SS 52 402 401<br />

InTrac 787/300 mm (12") NPT/1.5" 1.5" 0<strong>–</strong>300 mm/0"<strong>–</strong>12" SS 52 402 402<br />

O-ring kit N/A N/A N/A Viton ®-FDA 52 402 403<br />

1<br />

2<br />

102/300 mm<br />

4"/12"<br />

1 Cage for electrode protection<br />

2 Anti-blowout lip<br />

3 Electrode holder<br />

4 Flushing connection<br />

5 Wiper ring<br />

6 Dual 0-ring seal<br />

7 SS chain<br />

8 Quick release latch<br />

Safety chain rated to 400 lbs. for ease-of-use and<br />

maximum protection.<br />

3<br />

1 1 ⁄ 2<br />

ca. 440/638 mm<br />

ca. 17"/25"<br />

Anti-blowout lip provides a positive stop while retracting<br />

the sensor to prevent accidental blowout.<br />

4<br />

5<br />

6<br />

7<br />

8<br />

Chemical<br />

Wastewater<br />

Mettler-Toledo Ingold International<br />

167