Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Buildings<br />

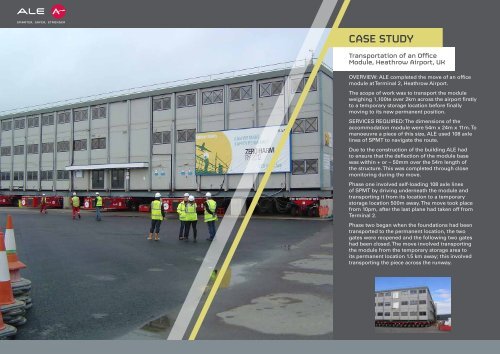

CASE STUDY<br />

Transportation of an Office<br />

Module, Heathrow Airport, UK<br />

OVERVIEW: ALE completed the move of an office<br />

module at Terminal 2, Heathrow Airport.<br />

The scope of work was to transport the module<br />

weighing 1,100te over 2km across the airport firstly<br />

to a temporary storage location before finally<br />

moving to its new permanent position.<br />

SERVICES REQUIRED: The dimensions of the<br />

accommodation module were 54m x 24m x 11m. To<br />

manoeuvre a piece of this size, ALE used 108 axle<br />

lines of SPMT to navigate the route.<br />

Due to the construction of the building ALE had<br />

to ensure that the deflection of the module base<br />

was within + or – 50mm over the 54m length of<br />

the structure. This was completed through close<br />

monitoring during the move.<br />

Phase one involved self-loading 108 axle lines<br />

of SPMT by driving underneath the module and<br />

transporting it from its location to a temporary<br />

storage location 500m away. The move took place<br />

from 10pm, after the last plane had taken off from<br />

Terminal 2.<br />

Phase two began when the foundations had been<br />

transported to the permanent location, the two<br />

gates were reopened and the following two gates<br />

had been closed. The move involved transporting<br />

the module from the temporary storage area to<br />

its permanent location 1.5 km away; this involved<br />

transporting the piece across the runway.<br />

CASE STUDY<br />

Installation of the Arena<br />

Corinthians roof, Brazil<br />

OVERVIEW: ALE completed the lowering<br />

of the roof structure at the Arena<br />

Corinthians, Brazil.<br />

SERVICES REQUIRED: The first stage of<br />

the project saw ALE install and utilise two<br />

strand jacks, of 70t capacity, side by side<br />

to create a tensioning system.<br />

This system allowed the cable section<br />

to be manufactured and installed. ALE<br />

were then required to use ten jacks,<br />

ranging from 300t – 500t capacity, to<br />

lower the north and south sides of the<br />

stadium to complete the installation.<br />

The interim towers were then able to<br />

be removed.<br />

Together, we are Smarter, Safer, Stronger<br />

15