You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CASE STUDY<br />

Installation of the Carl-Urich<br />

Bridge, Germany<br />

Bridge Launching<br />

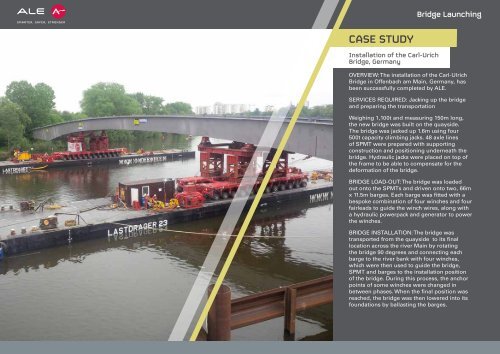

OVERVIEW: The installation of the Carl-Ulrich<br />

Bridge in Offenbach am Main, Germany, has<br />

been successfully completed by ALE.<br />

SERVICES REQUIRED: Jacking up the bridge<br />

and preparing the transportation<br />

Weighing 1,100t and measuring 150m long,<br />

the new bridge was built on the quayside.<br />

The bridge was jacked up 1.6m using four<br />

500t capacity climbing jacks. 48 axle lines<br />

of SPMT were prepared with supporting<br />

construction and positioning underneath the<br />

bridge. Hydraulic jacks were placed on top of<br />

the frame to be able to compensate for the<br />

deformation of the bridge.<br />

BRIDGE LOAD-OUT: The bridge was loaded<br />

out onto the SPMTs and driven onto two, 66m<br />

x 11.5m barges. Each barge was fitted with a<br />

bespoke combination of four winches and four<br />

fairleads to guide the winch wires, along with<br />

a hydraulic powerpack and generator to power<br />

the winches.<br />

BRIDGE INSTALLATION: The bridge was<br />

transported from the quayside to its final<br />

location across the river Main by rotating<br />

the bridge 90 degrees and connecting each<br />

barge to the river bank with four winches,<br />

which were then used to guide the bridge,<br />

SPMT and barges to the installation position<br />

of the bridge. During this process, the anchor<br />

points of some winches were changed in<br />

between phases. When the final position was<br />

reached, the bridge was then lowered into its<br />

foundations by ballasting the barges.<br />

BRIDGE JACKING<br />

CASE STUDY<br />

Rail bridge<br />

replacement, UK<br />

OVERVIEW: ALE replaced a 500t railway bridge<br />

in Liverpool as part of a track upgrade.<br />

SERVICES REQUIRED: The bridge decks which<br />

were adjoined to Liverpool Sandhills station<br />

were removed using twenty eight axles of<br />

SPMT. ALE integrated sixteen 100t capacity<br />

climbing jacks into the transport arrangement,<br />

to ensure height requirements over the<br />

abutment wall.<br />

To complete the project the old and<br />

replacement bridge decks were required to<br />

be manoeuvred around the station platform<br />

and beneath a temporary walkway bridge.<br />

ALE used various configurations of SPMT to<br />

achieve the limited space manoeuvres, ALE<br />

also had to ensure that no loading was applied<br />

to the large section of pavement that needed to<br />

be crossed, this was achieved by transporting<br />

them across bridging mats. The decks were<br />

then offloaded to high level trestles where they<br />

would then be jacked down for demolition.<br />

The 270t replacement bridge decks which were<br />

previously jacked up to installation height in<br />

preparation were removed from the trestles<br />

using sixteen axles of SPMT complete with<br />

high level trailer steelwork.<br />

Together, we are Smarter, Safer, Stronger<br />

21