User Report: Macpi Bonding Technology Visit to ... - Macpi Group

User Report: Macpi Bonding Technology Visit to ... - Macpi Group

User Report: Macpi Bonding Technology Visit to ... - Macpi Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Recently, JSN visited big-scale swimwear maker, Fook<br />

Wah Kun Kee Knitting Fty. Ltd. and big-scale underwear<br />

maker, Zhongshan Anqi Garment Fac<strong>to</strong>ry both in South<br />

China thanks <strong>to</strong> cooperation by <strong>Macpi</strong> (<strong>Group</strong>)(HK) Limited.<br />

In this reporting trip, JSN was accompanied by Mr.<br />

Teddy Leung, sales manager and Ms. Racy Xie, cus<strong>to</strong>mer<br />

relations manager from <strong>Macpi</strong> (<strong>Group</strong>)(HK) Limited. In<br />

addition, JSN interviewed Mr. Armando Raccagni, managing<br />

direc<strong>to</strong>r of <strong>Macpi</strong> (<strong>Group</strong>)(HK) about the recent<br />

sales situation of his company’s bonding machines, future<br />

prospects, etc. at DTC 2009 in Dongguan.<br />

Fook Wah Kun Kee Knitting Fac<strong>to</strong>ry<br />

Specialist of Swimwear<br />

JSN recently visited Gongmin Fac<strong>to</strong>ry belonging <strong>to</strong><br />

Fook Wah Kun Kee Knitting Fac<strong>to</strong>ry, a specialist of<br />

swimwear manufacture. This fac<strong>to</strong>ry has installed<br />

24 J. S. N. International, April 2009<br />

<strong>User</strong> <strong>Report</strong>: <strong>Macpi</strong> <strong>Bonding</strong> <strong>Technology</strong><br />

<strong>Visit</strong> <strong>to</strong> Energetic Swimwear/Underwear Makers<br />

Developing New Products with <strong>Macpi</strong> <strong>Bonding</strong><br />

Machines in South China<br />

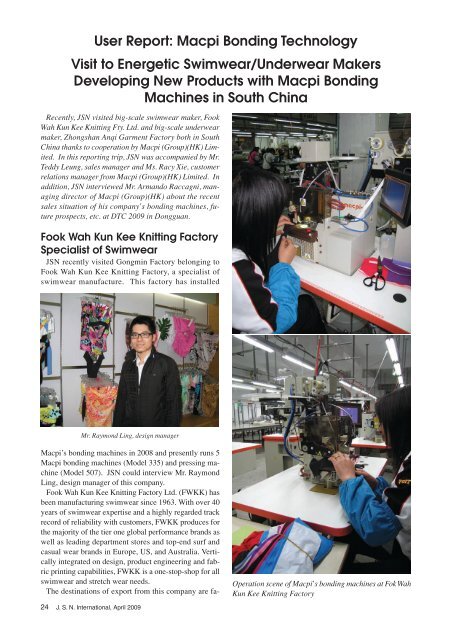

Mr. Raymond Ling, design manager<br />

<strong>Macpi</strong>’s bonding machines in 2008 and presently runs 5<br />

<strong>Macpi</strong> bonding machines (Model 335) and pressing machine<br />

(Model 507). JSN could interview Mr. Raymond<br />

Ling, design manager of this company.<br />

Fook Wah Kun Kee Knitting Fac<strong>to</strong>ry Ltd. (FWKK) has<br />

been manufacturing swimwear since 1963. With over 40<br />

years of swimwear expertise and a highly regarded track<br />

record of reliability with cus<strong>to</strong>mers, FWKK produces for<br />

the majority of the tier one global performance brands as<br />

well as leading department s<strong>to</strong>res and <strong>to</strong>p-end surf and<br />

casual wear brands in Europe, US, and Australia. Vertically<br />

integrated on design, product engineering and fabric<br />

printing capabilities, FWKK is a one-s<strong>to</strong>p-shop for all<br />

swimwear and stretch wear needs.<br />

The destinations of export from this company are fa-<br />

Operation scene of <strong>Macpi</strong>’s bonding machines at Fok Wah<br />

Kun Kee Knitting Fac<strong>to</strong>ry

Mr. Armando Raccagni, managing direc<strong>to</strong>r of <strong>Macpi</strong> (<strong>Group</strong>)(HK)<br />

and Mr. Raymond Ling, design manager of Fook Wah Kun Kee<br />

Knitting Fty. Ltd. at <strong>Macpi</strong>’s showroom for bonding technology in<br />

Hong Kong<br />

Mr. Teddy Leung, sales manager and Ms. Racy Xie, cus<strong>to</strong>mer relations<br />

manager from <strong>Macpi</strong> (<strong>Group</strong>)(HK) Limited and Mr. Raymond<br />

Ling, design manager of Fook Wah Kun Kee Knitting Fty. Ltd. at<br />

its fac<strong>to</strong>ry in South China<br />

mous swimwear brands in Europe and Australia. This<br />

company’s Gongmin Fac<strong>to</strong>ry has a workforce of about<br />

5,000 employees who manufacture 14 million pieces of<br />

swimwear yearly. This company’s advantages lie in the<br />

design planning by 25 staffers and merchandizing by more<br />

than 100 staffers besides the manufacturing capabilities.<br />

This company also attaches importance <strong>to</strong> printing of the<br />

fabrics for swimwear.<br />

Their Standpoint on <strong>Bonding</strong><br />

FWKK sees bonding as a unique value-added design<br />

attribute for swimwear. However, they are still at the early<br />

stages of studying the full potential of bonding application<br />

on swimwear; through its study they are trying <strong>to</strong><br />

understand the potentialities and limitations of this technology.<br />

As a swimwear manufacturer, FWKK is most concerned<br />

with the durability of the bond upon exposure <strong>to</strong> harsh<br />

environments such as chlorinated pool water, sea water,<br />

over-elongation, and sun tan lotion. With the right bonding<br />

tape and the right bonding machinery such as the<br />

<strong>Macpi</strong> machines, FWKK hopes <strong>to</strong> achieve a consistent<br />

Come <strong>to</strong> Touch<br />

the Future<br />

We will be waiting for you<br />

World World of of Textile Textile Producing Producing<br />

Halle 7<br />

Stand D029 -D021<br />

World of Textile Producing<br />

www.macpi.com<br />

wwww.<br />

w.macpi.comm<br />

Integrated Solutions for Garment Industry<br />

Halle 8<br />

Stand D045 -C040<br />

World of Textile Producing<br />

www.imaitaly.iit<br />

Köln 21/24 - 04 -09<br />

Test<br />

Drive<br />

Circle # 15 on Reader Service Card<br />

J. S. N. International, April 2009 25

ond application time and time again.<br />

FMKK is excited about the innovation behind this<br />

technology, and they are pleased with the after sales<br />

services that <strong>Macpi</strong> has provided in helping them<br />

achieve their goals.<br />

As a company that invests in new innovation, FWKK<br />

is looking for partners like <strong>Macpi</strong> that can work with<br />

them <strong>to</strong> find the right solution.<br />

Future plans on bonding:<br />

This company intends <strong>to</strong> continue studying new ways<br />

<strong>to</strong> apply bonding <strong>to</strong> swimwear. Machine applied bonding<br />

has the potential <strong>to</strong> save a tremendous amount of<br />

time per garment when compared <strong>to</strong> manual applied<br />

bonding. It also has the potential of ensuring greater<br />

consistency and quality assurance.<br />

<strong>Visit</strong> <strong>to</strong> Zhongshan Anqi Garment<br />

Fac<strong>to</strong>ry<br />

Manufacture of Original Brand<br />

Items Occupies 85% of<br />

All Products<br />

Underwear Production Utilizing <strong>Macpi</strong><br />

<strong>Bonding</strong> <strong>Technology</strong><br />

Will Expand <strong>to</strong> 30% within 2 Years the<br />

Ratio of High Value Added Item,<br />

Seamless Underwear<br />

JSN recently visited a <strong>Macpi</strong> bonding machine user,<br />

Zhongshan Anqi Garment Fac<strong>to</strong>ry. This company uses<br />

<strong>Macpi</strong> 335 bonding machine and 507 pressing machine.<br />

JSN could make an interview with Mr. Liang Shen<br />

Quan, company president and Mr. Mark Chan, fac<strong>to</strong>ry<br />

manager and Mr. Arvin. This company has 3 affiliated<br />

fac<strong>to</strong>ries in Guangdong Province, China. This company<br />

has been constructing a new office shown here<br />

(as an image pho<strong>to</strong>).<br />

Zhongshan Anqi Garment Fac<strong>to</strong>ry is a private company<br />

with ten years of his<strong>to</strong>ry. Covering an area of<br />

20,000 square meters, the company has over 1000<br />

employees and under it there is one T-shirts fac<strong>to</strong>ry<br />

and one socks fac<strong>to</strong>ry. This company manufactures<br />

200,000 pieces of men’s and ladies’ underwear daily.<br />

Of the <strong>to</strong>tal output of this company at present, 95% is<br />

occupied by sewing underwear, and 5% by seamless<br />

underwear (men’s briefs and ladies’ shorts) which is a<br />

high value added item based on bonding technology.<br />

Manufacture of the seamless underwear is said <strong>to</strong> be<br />

expanded <strong>to</strong> 30% within 2 years, i.e., <strong>to</strong> 10,000 pieces<br />

or more in daily production (from the current 5,000<br />

pieces). For achieving this goal, this company is scheduled<br />

<strong>to</strong> install 40 <strong>to</strong> 50 bonding machines. Also in<br />

near future, seamless sports outerwear will be added<br />

<strong>to</strong> the production items. As a reason why this company<br />

has adopted <strong>Macpi</strong> bonding machines, they said,<br />

26 J. S. N. International, April 2009<br />

Mr. Liang Shen Quan, company president of Zhongshan Anqi Garment<br />

Fac<strong>to</strong>ry<br />

<strong>Visit</strong> <strong>to</strong> Zhongshan Anqi Garment Fac<strong>to</strong>ry – the scenes of showroom

This company has been constructing a new office shown here (as<br />

an image pho<strong>to</strong>).<br />

At the office: (from left) Mr. Arvin, Mr. Liang Shen Quan, company<br />

president and Mr. Mark Chan, fac<strong>to</strong>ry manager and Ms. Racy Xie,<br />

cus<strong>to</strong>mer relations manager from <strong>Macpi</strong> (<strong>Group</strong>)(HK) Limited<br />

“Those machines are easy <strong>to</strong> operate, so work can be<br />

efficiently carried out. In addition, high-quality finishing<br />

is ensured.”<br />

The company has been working hard over these years.<br />

Zhongshan Anqi Garment Fac<strong>to</strong>ry develops the market<br />

with quality and brand. This company manufactures<br />

and sells 4 original brand items; Roober, Gioven-<br />

Kelvin, Emilio and G5001. The original brand<br />

launched first is “Roober.” It was in 1996. The production<br />

ratio of the original brand items in this company<br />

is as high as 85%. The remaining 15% comes<br />

in<strong>to</strong> the category of OEM. Thanks <strong>to</strong> the years of effort,<br />

the company has developed over 50 regional agents<br />

in more than 20 cities and have opened 300 or more<br />

boutiques in China. Besides, this company’s own<br />

marketing offices have been set up in Macau, Hong<br />

Kong, Singapore and France.<br />

Their products include underwear, T-shirts, socks and<br />

man’s sportswear. According <strong>to</strong> different packages and<br />

raw materials, the products are sorted <strong>to</strong> high, middle<br />

and low levels.<br />

Anqi products are currently sold in large wholesale<br />

markets, shopping malls and business streets. In addition,<br />

they are exported <strong>to</strong> the East Europe (Poland),<br />

Southeast Asia, Middle East (Iran), Africa (South Africa)<br />

and many other countries and regions.<br />

Mr. Liang Shen Quan, president said, “We are always<br />

developing original items by utilizing new technology,<br />

which are different from the existing items.<br />

Therefore, the underwear based on <strong>Macpi</strong> bonding<br />

technology is a very important project item for our<br />

company in the future.”<br />

<strong>Macpi</strong> <strong>Bonding</strong> <strong>Technology</strong><br />

Covers All Fabrics Including<br />

Lingerie, Swimwear, Sportswear<br />

Interview with Mr. Armando<br />

Raccagni, Managing Direc<strong>to</strong>r of<br />

<strong>Macpi</strong> <strong>Group</strong> (HK) Limited<br />

Mr. Armando Raccagni, managing direc<strong>to</strong>r of <strong>Macpi</strong> <strong>Group</strong> (HK)<br />

Limited<br />

At DTC 2009 held in Dongguan, China at the end of<br />

this March, JSN interviewed Mr. Armando Raccagni,<br />

managing direc<strong>to</strong>r of <strong>Macpi</strong> <strong>Group</strong> (HK) Limited about<br />

the present business situation of his company’s bonding<br />

technology.<br />

Presently, <strong>Macpi</strong> is actively investing a substantial<br />

amount of money in R&D. This company has delivered<br />

a <strong>to</strong>tal of 1,500 bonding machines in the world market as<br />

of 2008. In China, 100 companies are using more than<br />

500 <strong>Macpi</strong> bonding machines in <strong>to</strong>tal. These users are<br />

fac<strong>to</strong>ries manufacturing lingerie, swimwear, sportswear,<br />

outerwear, etc. <strong>Macpi</strong> considers its users as business part-<br />

J. S. N. International, April 2009 27

ners and is developing merchandise while adopting the<br />

users’ opinions as much as possible. <strong>Macpi</strong> not only sells<br />

its machines <strong>to</strong> the cus<strong>to</strong>mers, but also informs the theory<br />

and know-how on bonding technology so as <strong>to</strong> be helpful<br />

for the users <strong>to</strong> improve their business.<br />

The most important element presently in bonding<br />

technology is glue. New glue products have been developed<br />

one after another, and dedicated makers are<br />

manufacturing and selling various kinds of films. Furthermore,<br />

as the melting point of glue is falling, it has<br />

become possible <strong>to</strong> manufacture clothes by use of<br />

bonding on all fabrics.<br />

In this situation, <strong>Macpi</strong> is further focusing on the development<br />

of new products. For example, product design<br />

is under constant improvement for facilitating machine<br />

work and temperature control has been becoming<br />

easier. <strong>Macpi</strong> bonding machine is capable of bonding<br />

any fabric by using various films (glues) and always<br />

intended <strong>to</strong> be a bonding machine which matches<br />

contemporary needs. In addition, because <strong>Macpi</strong> machines<br />

have been developed under the concept of environmental<br />

friendliness, namely energy saving, power<br />

consumption during machine work can be minimized.<br />

As a hopeful market, <strong>Macpi</strong> is now highly interested<br />

in sportswear. In the field of sportswear, <strong>Macpi</strong> is devoted<br />

<strong>to</strong> the dissemination of bonding technology in<br />

the manufacture of outerwear for ski. This February,<br />

28 J. S. N. International, April 2009<br />

<strong>Macpi</strong> marketed 3 kinds of bonding machines for outerwear.<br />

These new items are now exhibited and demonstrated<br />

at the showroom in Hong Kong. The users<br />

are invited periodically <strong>to</strong> this showroom so that they<br />

can experience bonding technology actually with the<br />

materials brought in by themselves.<br />

Contact:<br />

Fook Wah Kun Kee Knitting Fty. Ltd.<br />

Flat B, 9/Fl., Po Yip Building<br />

62-70, Texaco Rd., Tsuen Wan,<br />

Hong Kong<br />

Tel: +852 2612 7225<br />

Fax: +852 2413 6055<br />

Zhongshan Anqi Garment Fac<strong>to</strong>ry<br />

Zijing Road, Jucheng Avenue, Xiaolan Town, Zhongshan<br />

City, Guangdong Province, China<br />

Tel: +86-760-22100180<br />

Fax: +86-760-22108967<br />

<strong>Macpi</strong> <strong>Group</strong> (HK) Limited<br />

8/F, LMK Development Estate, 10-16 Kwai Ting Road<br />

Kwai Chung, N.T., Hong Kong<br />

Tel: +852 2423 6801/02<br />

Fax: +852 2900 7633