koff - LEPA

koff - LEPA

koff - LEPA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Adsorption in biosensors<br />

1. Adsorption from an infinitely large volume<br />

1.1 Thermodynamic aspects<br />

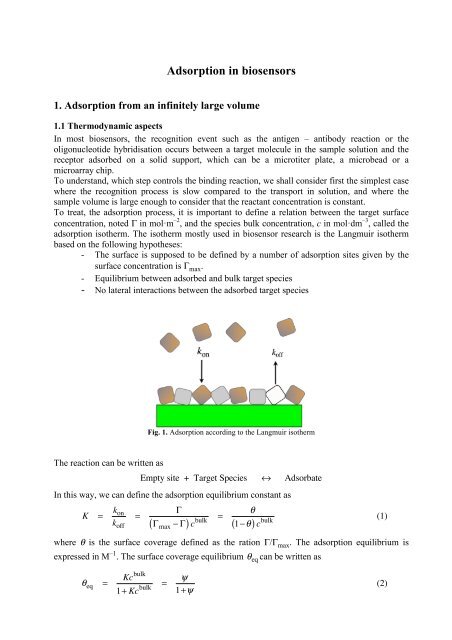

In most biosensors, the recognition event such as the antigen – antibody reaction or the<br />

oligonucleotide hybridisation occurs between a target molecule in the sample solution and the<br />

receptor adsorbed on a solid support, which can be a microtiter plate, a microbead or a<br />

microarray chip.<br />

To understand, which step controls the binding reaction, we shall consider first the simplest case<br />

where the recognition process is slow compared to the transport in solution, and where the<br />

sample volume is large enough to consider that the reactant concentration is constant.<br />

To treat, the adsorption process, it is important to define a relation between the target surface<br />

concentration, noted Γ in mol·m –2 , and the species bulk concentration, c in mol·dm –3 , called the<br />

adsorption isotherm. The isotherm mostly used in biosensor research is the Langmuir isotherm<br />

based on the following hypotheses:<br />

- The surface is supposed to be defined by a number of adsorption sites given by the<br />

surface concentration is Γ max .<br />

- Equilibrium between adsorbed and bulk target species<br />

- No lateral interactions between the adsorbed target species<br />

The reaction can be written as<br />

Fig. 1. Adsorption according to the Langmuir isotherm<br />

Empty site + Target Species ! Adsorbate<br />

In this way, we can define the adsorption equilibrium constant as<br />

K =<br />

kon <strong>koff</strong> =<br />

!<br />

( ! max " ! ) c bulk<br />

=<br />

!<br />

( 1"! ) c<br />

bulk (1)<br />

where θ is the surface coverage defined as the ration Γ/Γ max . The adsorption equilibrium is<br />

expressed in M –1 . The surface coverage equilibrium ! eq can be written as<br />

! eq =<br />

Kc bulk<br />

1+ Kc bulk<br />

=<br />

"<br />

1+"<br />

(2)

The dimensionless parameter ψ is useful to define the adsorption process. If ψ is much smaller<br />

than unity, then we have an adsorption from a dilute solution where the surface coverage is small<br />

and directly proportional to the bulk concentration; we then speak of the linearized Langmuir<br />

isotherm. If ψ is much greater than unity, then the coverage tends to a full monolayer. When ψ<br />

is equal to unity, the equilibrium coverage is half of the full coverage. In the case of biosensing,<br />

we deal generally with dilute solutions and therefore the equilibrium surface concentration is<br />

directly proportional to the bulk concentration.<br />

! eq = ! max Kc bulk (3)<br />

Exercise : For all the calculations, we shall take K=10 9 M –1 , k on =10 6 M –1 ·s –1 , a bulk analyte<br />

concentration of 0.1 pM unless specified otherwise, and ! max " 10 #9 mol·m #2 .<br />

Calculate the area of an adsorption site, the equilibrium surface coverage and ψ .<br />

1.2 Kinetic aspects<br />

The rate law for a binding reaction is just given by the difference between the adsorption process<br />

considered as a second order reaction between the reactant and a free site and the desorption<br />

process simply considered as a first order reaction, and we can write<br />

d!<br />

dt<br />

= k on c bulk (1!!) ! k off! (4)<br />

This differential equation can be re-arranged as<br />

d!<br />

!<br />

"<br />

dt +! k onc bulk + k off<br />

and the solution is then given by<br />

! =<br />

k on c bulk<br />

k on c bulk + k off<br />

#<br />

$ = konc bulk (5)<br />

1! exp ! konc bulk " " ( + k<br />

#<br />

off )t $ $<br />

#&<br />

% %' =<br />

where τ is the time constant for the adsorption defined as<br />

! =<br />

1<br />

k on c bulk + k off<br />

=<br />

t d<br />

1+"<br />

"<br />

"# 1! exp [ !t /# ] $<br />

1+"<br />

% (6)<br />

where td is the desorption time ( td = 1/ <strong>koff</strong> ) . This equation clearly shows that the adsorption<br />

kinetics from dilute solutions is controlled by the desorption time.<br />

The adsorption kinetics is illustrated schematically in Figure 2 for different values of ψ<br />

Fig. 2. Time dependence of the surface coverage<br />

(7)<br />

2

Figures 3 & 4 illustrate the dependence of τ on k on and k off .<br />

log ( / s )<br />

log ( / s )<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

-1<br />

-2<br />

k off = 10 –4<br />

k off = 10 –3<br />

k off = 10 –2<br />

k off = 10 –1<br />

k on = 10 5<br />

-15 -10 -5 0<br />

log (c /M)<br />

Fig. 3. Influence of desorption time <strong>koff</strong> in s –1 .<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

-1<br />

-2<br />

k off = 10 –4<br />

k on = 10 6 , 10 5 , 10 4 , 10 3<br />

-15 -10 -5 0<br />

log (c /M)<br />

Fig. 4. Influence of adsorption time kon in M –1 ·s –1 .<br />

At low concentrations, the adsorption time constant is dominated by the desorption rate whilst it<br />

is dominated by the adsorption rate at high concentrations. The transition point on Figures 3 & 4<br />

corresponds to a concentration of K –1 .<br />

We can also define the adsorption time t a = 1/ k onc bulk<br />

( ) such that<br />

! !1 = t a !1 + td !1 (8)<br />

At low bulk concentrations ( !

! = ! eq<br />

t<br />

t d<br />

Exercise : Calculate t a , t d , and τ. Please comment. Plot Γ(t)/Γ eq .<br />

To give some orders of magnitude, Table 1 gives some kinetic values for some classical systems.<br />

k on / M –1 ·s –1 k off / s –1<br />

IgE 10 6 10 –3<br />

IgG4 10 6 10 –2<br />

Avidin-Biotin 10 8 10 –7<br />

ss-DNA 6·10 4 5·10 –5<br />

Exercise : Please comment on the different values<br />

1.3 Adsorption measurement<br />

To monitor the adsorption of target species onto a substrate, one can distinguish label-free<br />

techniques and techniques relying on a chemical labelling step.<br />

Label free techniques include wire conductivity measurements, capacitance measurements,<br />

quartz microbalance measurements, resonators and surface plasmon resonance measurements.<br />

Chemical labelling is used for immunoassays and protein arrays using often a secondary<br />

antibody labelled with an enzyme. Enzyme activity is then monitored by addition of a substrate.<br />

In the case of DNA, the complementary oligo sequence is itself labelled often with a<br />

fluorophore.<br />

Label-free techniques are very useful to measure the kinetics of binding. For example, a flow<br />

system combined to SPR can be used to measure a sensorgram. The measurement is done in two<br />

steps. First, a buffer solution is passed on the detector, and at time t=0, a solution of target<br />

species is injected, the adsorption is then monitored. At a given time, the flowing solution is<br />

switched to the eluent and the desorption is monitored as shown below.<br />

Adsorption<br />

Desorption<br />

Exercise : Please explain the physical principles of a label-free technique (min 1 A4 page).<br />

Derive the equation and draw a sensorgram for the system used above, namely K=10 9 M –1 ,<br />

k on =10 6 M –1 ·s –1 , a bulk analyte concentration of 0.1 pM.<br />

Time<br />

(11)<br />

4

2. Adsorption from a finite volume<br />

2.1 Thermodynamic aspects<br />

In microsystems, the surface to volume ratio can be very large and the bulk concentration can<br />

decrease when the target molecules adsorb. At equilibrium, the bulk concentration and therefore<br />

the equilibrium surface coverage will be different than for large systems having a small S/V ratio.<br />

t = 0 c 0<br />

Adsorption<br />

Equilibrium c eq < c 0<br />

Fig. 5. Adsorption in a microchannel<br />

Another way to increase even further the surface to volume ratio is to fill the channel with<br />

magnetic beads coated by antibodies. In this case, the area corresponds to the total bead area, and<br />

the volume corresponds to the void volume between the beads.<br />

Let’s consider the injection of target molecules in a microchannel, as illustrated in Figure 5. The<br />

number of molecules injected is n in = c inV , where V is the volume of the solution. These<br />

molecules distribute themselves between the walls and the bulk, and if we consider a linearized<br />

Langmuir isotherm, we have:<br />

µ<br />

nin = nwall + nsolution = ! eqA<br />

+ ceqV = K! maxceqA + ceqV (12)<br />

µ<br />

where ! eq is the equilibrium surface concentration in the microchannel, which is related to the<br />

sample concentration by<br />

µ<br />

! eq<br />

=<br />

" K! maxV %<br />

#<br />

$ V + K! maxA &<br />

' cin =<br />

with ! a dimensionless geometric factor, given by<br />

! =<br />

V<br />

AK! max<br />

! eq<br />

1+ K! max A /V = ! ! eq<br />

1+!<br />

We can see that when the volume is large, we recover eq.(3). We can also define a wall<br />

collection efficiency as<br />

! = n wall<br />

n in<br />

= A! eq<br />

µ<br />

Vcin =<br />

K! maxA<br />

V + K! maxA =<br />

1<br />

1+"<br />

We can see that α tends to unity for large surfaces and to zero for large volumes.<br />

(13)<br />

(14)<br />

(15)<br />

5

Exercise: Calculate α and ! for a microchannel 1cm long x100µm wide x 50µm deep, and for<br />

a microtiter plate V = 100µL, A = 1 cm 2 .<br />

50!m<br />

1cm<br />

Example : IgG-Antigen<br />

100!m<br />

K=10 9 M –1<br />

kon=10 6 M –1 ·s –1<br />

100 L = 1cm<br />

V = 50nL<br />

2<br />

2.2 Comparison between a microtiter plate and a microchannel<br />

c bulk = 0.1 pM<br />

A = 3mm 2<br />

Exercise: Please fill the following table Total using well volume the = 300numerical L values listed above:<br />

D=10 –10 m 2 ·s –1<br />

!= 0.01667<br />

Microtiter well Microchannel<br />

A market of more than 20 billion $...<br />

" = 0.9836<br />

Volume ! = 100 "m<br />

100μL<br />

# max = 10 –9 mol·m –2<br />

Initial number of antigens in solution<br />

Surface area 100 mm 2<br />

Maximum antibody sites<br />

Adsorbed antigens<br />

(Maximum)<br />

Enzyme Linked ImmunoSorbent Assay<br />

ELISA<br />

100 L = 1cm 2<br />

Total well volume<br />

DiagnoSwiss Immunochip<br />

Surface = blocking 300 L<br />

Y Y Y Y<br />

# eq $ 10 –6<br />

With one fill, we have only 0.0001% of a<br />

monolayer for a 0.1pM solution<br />

Y Y Y<br />

Y<br />

Y<br />

Y<br />

Y Y Y<br />

Capture antibody adsorption<br />

Wash<br />

Wash<br />

Antigen adsorption<br />

Wash<br />

Counter antibody adsorption<br />

Addition of substrate<br />

Detection<br />

2.3 Kinetic aspects<br />

To estimate the kinetics of adsorption in a microsystem, we can write eq.(4) as<br />

dn wall<br />

n s dt<br />

"<br />

= kon #<br />

$<br />

n in ! n wall<br />

V<br />

%<br />

&<br />

' ns ! n " wall %<br />

#<br />

$<br />

&<br />

' ! k "<br />

off<br />

#<br />

$<br />

n s<br />

n wall<br />

n s<br />

%<br />

&<br />

'<br />

Y Y Y<br />

Y<br />

Y<br />

Y Y Y Y<br />

6<br />

Y<br />

Y Y Y<br />

A market of more than 20<br />

where n s is the total number of sites available on the walls of the microsystem. Implicitly, we<br />

assume that the bulk concentration is homogeneous, i.e. we neglect any mass transport<br />

contribution. By neglecting the second order term, we can re-write this differential equation as<br />

dt + kon nin + n !<br />

s<br />

"<br />

# V<br />

dn wall<br />

The solution of eq.(17) is<br />

n wall =<br />

( )<br />

k onn inn s<br />

( )<br />

V kon nin + n !<br />

s<br />

"<br />

# V<br />

$<br />

+ <strong>koff</strong> %<br />

& nwall = konninns V<br />

( )<br />

1' exp '<br />

$<br />

+ <strong>koff</strong> %<br />

&<br />

k ( ( ! on nin + ns * *<br />

"<br />

#<br />

) * ) V<br />

$<br />

+ <strong>koff</strong> %<br />

& t<br />

+ +<br />

--<br />

, , -<br />

We can re-arrange this equation introducing the geometric factor ! to read<br />

n wall =<br />

( )<br />

nin 1+! ( 1+ Kcin ) 1! exp ! kon nin + n ( ( "<br />

s<br />

* *<br />

#<br />

$<br />

) * ) V<br />

%<br />

+ <strong>koff</strong> &<br />

' t<br />

+ +<br />

--<br />

, , -<br />

The adsorption time constant in a microsystem τ µ can be compared to that of a planar surface in<br />

a large volume as when n in is much greater than n s the two expressions converge.<br />

(16)<br />

(17)<br />

(18)<br />

(19)

! µ =<br />

1<br />

( )<br />

V<br />

k on n in + n s<br />

+ k off<br />

=<br />

1<br />

kon ( cin + (A /V)! max ) + <strong>koff</strong> If we still define ψ as equal to Kc in , then when ψ

3. Adsorption on a planar substrate with semi infinite linear diffusion<br />

3.1 General equations<br />

When the rate of adsorption is fast compared to the time scale of diffusion, the kinetics of the<br />

binding may depend on the rate of arrival of the target species to the surface.<br />

To know in which case we operate, it is useful to define a diffusion time as t diff = ! 2 / D , where δ<br />

is the diffusion layer thickness and D the diffusion coefficient. The diffusion layer thickness<br />

varies with time in unstirred solutions, but can be fixed by controlling the hydrodynamics e.g.<br />

flow cells or the geometry e.g. microbeads (steady-state diffusion).<br />

To be able to treat kinetic and mass transport, we shall use the two-layer model, where we define<br />

a volumic surface concentration c surf that differs from the bulk value c bulk such that the diffusion<br />

flux is driven by the gradient (c surf – c bulk )/δ . Indeed, a diffusion flux results from a gradient of<br />

concentration.<br />

By rewriting eq.(4) in terms of the surface concentration Γ and a volumic concentration at the<br />

surface c surf , we have<br />

d!(t)<br />

dt<br />

= konc surf ( ! max " !(t) ) " <strong>koff</strong>!(t) (22)<br />

Two layer model<br />

!<br />

c<br />

z<br />

surf<br />

Adsorbed layer<br />

Surface layer<br />

Bulk<br />

c bulk<br />

Fig.6. Two-layer model with the adsorbed and the surface layers.<br />

The diffusion equation is given by Fick’s second law, which for a linear geometry reads<br />

!c(x,t)<br />

!t<br />

= D ! 2 c(x,t)<br />

! x 2 (23)<br />

where D is the diffusion coefficient (m 2 ·s –1 ). The variation of the surface concentration of the<br />

target species with time is equal to the flux of arrival at the surface:<br />

d!(t)<br />

dt<br />

= D !c(x,t) " %<br />

#<br />

$<br />

! x &<br />

'<br />

x=0<br />

= ( J(t) (24)<br />

8

Unfortunately, these equations cannot be solved analytically in the general case, but specific<br />

solutions can be obtained for example assuming that the diffusion process is steady-state.<br />

3.2 Steady-state approximation for kinetic-diffusion control at short times<br />

Here, we consider the simple case based on neglecting the presence of occupied sites, i.e.<br />

!

!(t) =<br />

konc bulk "<br />

%<br />

$ ! '<br />

max<br />

$<br />

' t<br />

$<br />

2t<br />

1+ k '<br />

# on! max<br />

D &<br />

=<br />

" t % 1<br />

! eq<br />

#<br />

$ td &<br />

'<br />

1+ kon! max<br />

Figure 7 shows a surface concentration-time plot showing the influence of the diffusion in stirred<br />

and unstirred solutions.<br />

Exercise : Please plot Γ(t)/Γ eq using D = 10 –10 m 2 ·s –1 and δ = 100µm. Please also calculate the<br />

Damköhler number.<br />

Γ /Γ eq<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0.0<br />

0<br />

Kinetic control<br />

Kinetic-Steady state diffusion<br />

Kinetic-Time dependent<br />

diffusion layer thickness<br />

200<br />

400<br />

Fig. 7. Influence of the diffusion on the adsorption. ( K=10 9 M –1 , kon=10 6 M –1 ·s –1 , c bulk = 0.1 pM,<br />

t /s<br />

600<br />

2t<br />

D<br />

800<br />

1000<br />

D=10 –10 m 2 ·s –1 , δ = 100 µm and ! max " 10 #9 mol·m #2 ). θ

3.3 Steady-state approximation for kinetic-diffusion control in dilute solutions<br />

( ) ,<br />

When the surface concentration is proportional to the volumic surface concentration !

Γ /Γ eq<br />

1.0<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

0.0<br />

0<br />

2000<br />

4000<br />

Kinetic-Steady state diffusion<br />

Diffusion control<br />

Kinetic-Time dependent<br />

diffusion layer thickness<br />

t /s<br />

6000<br />

8000<br />

10000<br />

Fig. 8. Comparison between stirred and unstirred diffusion controlled reactions . ( K=10 9 M –1 ,<br />

kon=10 6 M –1 ·s –1 , c bulk = 0.1 pM, D=10 –10 m 2 ·s –1 , δ = 100 µm and ! max " 10 #9 mol·m #2 ).<br />

This figure shows that the perturbation theory gives a rather good approximation to the exact<br />

solution eq.(38).<br />

3.4 Steady-state approximation for kinetic-diffusion control - General case<br />

Eq.(26) can be more generally written as<br />

d!(t)<br />

dt<br />

= konc surf ! max ( 1"! ) " <strong>koff</strong>! max! = " J = D<br />

or in terms of surface coverage<br />

d!(t)<br />

dt<br />

= konc surf ( 1!! ) ! <strong>koff</strong>! =<br />

D<br />

!" max<br />

( ) (40)<br />

! cbulk " c surf<br />

c bulk ! c surf ( ) (41)<br />

from which we can as before obtain an expression for the surface concentration<br />

c surf<br />

( )<br />

( )<br />

= cbulk + Da ! / K<br />

1+ Da 1!!<br />

The differential equation (41) now reads<br />

or<br />

d!(t)<br />

dt<br />

=<br />

( )<br />

konc bulk ( + Da<strong>koff</strong> ! ) ( 1!! )<br />

( )<br />

1+ Da 1!!<br />

" 1+ Da 1!! %<br />

$<br />

'd! =<br />

# ! !" ( ! +1)<br />

&<br />

dt<br />

td ( )<br />

! <strong>koff</strong>! = koncbulk !! konc bulk + <strong>koff</strong> 1+ Da 1!!<br />

( )<br />

We can integrate this expression explicitly assuming no initial coverage to get<br />

Da! ! 1+ Da " % " " " +1%<br />

%<br />

#<br />

$ " +1&<br />

' ln 1!!<br />

#<br />

$<br />

#<br />

$ " &<br />

'<br />

&<br />

'<br />

( )<br />

t " +1<br />

=<br />

td (42)<br />

(43)<br />

(44)<br />

12

We can either plot the time as a function of the surface coverage or see different limiting cases to<br />

recover the previous approximations.<br />

Γ /Γ eq<br />

1.0<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

0.0<br />

0<br />

500<br />

1000<br />

1500<br />

t /s<br />

2000<br />

ψ =0.1<br />

ψ =1<br />

ψ =10<br />

Figure 9. Comparison between kinetic control under ideal stirring (full line) and with some<br />

diffusion influence according to eq.(44) (dotted line). Da = 1, t d =1000s.<br />

We define a diffusion time as t diff = ! 2 / D , where δ is the diffusion layer thickness and D the<br />

diffusion coefficient.<br />

Exercise: If δ = 100 µm and D = 10 –10 m 2 ·s –1 , calculate t diff and compare with t a and t d . Compare<br />

this general solution with the two approximations, namely at short times and for dilute solutions.<br />

2500<br />

3000<br />

13

4. Adsorption-diffusion in microsystems<br />

4.1 Steady-state approximation<br />

Let us consider a microchannel of height 2h.<br />

2h<br />

l<br />

L<br />

By symmetry, the diffusion layer thickness is h as the top molecules diffuse to the top plate and<br />

the bottom ones to the bottom plates.<br />

We can therefore write the diffusion equation as in eq.(26) as<br />

d!(t)<br />

dt<br />

= konc surf ! max = " J = D<br />

! cbulk " c surf ( ) (45)<br />

To take in to account the depletion in the center of the channel upon adsorption as in equation<br />

(16) reproduced below<br />

dn wall<br />

n sdt<br />

"<br />

= kon #<br />

$<br />

n in ! n wall<br />

V<br />

and the diffusion equation reads<br />

d!(t)<br />

dt = dnwall Adt = kon "<br />

#<br />

$<br />

n surf<br />

V<br />

%<br />

&<br />

' ns ! n " wall %<br />

#<br />

$<br />

&<br />

' ! k "<br />

off<br />

#<br />

$<br />

n s<br />

%<br />

&<br />

' ! max = D "<br />

! #<br />

$<br />

As in equation (27), we can express nsurf as<br />

nsurf = nin ! nwall kon " max!<br />

+1<br />

D<br />

We can now solve the differential equation<br />

dn wall<br />

dt<br />

= Ak on ! max<br />

V<br />

#<br />

$<br />

%<br />

The solution of this equation is<br />

n wall<br />

n s<br />

%<br />

&<br />

'<br />

n in ( n wall ( n surf<br />

V<br />

%<br />

&<br />

'<br />

(46)<br />

(47)<br />

= n in ! n wall<br />

Da +1 (48)<br />

n in " n wall<br />

Da +1<br />

&<br />

'<br />

( == 1<br />

( " t % +<br />

nwall = nin * 1! exp !<br />

#<br />

$ !td ( Da +1)<br />

&<br />

' -<br />

) *<br />

, -<br />

!t d<br />

#<br />

$<br />

%<br />

n in " n wall<br />

Da +1<br />

When Da>>1, we are diffusion controlled with a fast kinetic, we have<br />

( " t % +<br />

nwall = nin * 1! exp !<br />

#<br />

$ !tdDa &<br />

' -<br />

)<br />

,<br />

&<br />

'<br />

(<br />

(49)<br />

(50)<br />

(51)<br />

14

and when the mass transport is fast, we recover nearly eq.(21)<br />

nwall = nin 1! exp ! t<br />

( "<br />

*<br />

#<br />

$<br />

)<br />

!t d<br />

% +<br />

&<br />

' -<br />

,<br />

Exercise : Calculate the number of antigens adsorbed in the same microchannel as above after 30<br />

s and compared to the number one would reach at equilibrium. Please comment.<br />

4.2 Comparison between a microtiter plate and a microchannel<br />

Discuss the differences between a microtiter plate and a microchannel.<br />

Please fill the following table using the numerical values listed above taking into account the<br />

diffusion:<br />

Volume 100μL<br />

Initial number of antigens in solution<br />

Adsorbed antigens<br />

(Maximum)<br />

Adsorbed antigens<br />

After 3 min<br />

Adsorbed antigens<br />

After 15 min<br />

Adsorbed antigens<br />

After 10 s<br />

Adsorbed antigens<br />

After 30 s<br />

Microtiter well Microchannel<br />

XXXXX<br />

XXXXX<br />

XXXXX<br />

XXXXX<br />

(52)<br />

15

5. Coating a microchannel<br />

5.1 Iterative stop-flow with adsorption equilibrium<br />

One way to coat a microchannel is the stop-flow method that consists in filling the channel<br />

quickly and to allow the adsorption to take place. This process is then repeated n-times until the<br />

surface concentration is high enough to allow a detection using, for example, a sandwich assay.<br />

During the iterative process, the total number of molecules present after the nth fill of the<br />

microchannel channel is equal to what was adsorb on the wall at the (n-1) fill plus the number of<br />

molecules injected during the nth fill<br />

n tot,N = n wall, N –1 + n in (53)<br />

In this way, we can write for the successive iterations.<br />

First fill:<br />

Second fill:<br />

n tot,1 = n in (54)<br />

n wall, 1 = !n in (55)<br />

ntot,2 = nwall, 1 + nin = ( 1+ ! )nin (56)<br />

µ<br />

ntot,2 = nwall,2 + nsolution = ! eq,2A<br />

+ ceqV = K! maxceqA + ceqV (57)<br />

µ<br />

! eq,2<br />

=<br />

" K! max %<br />

#<br />

$ V + K! maxA &<br />

' ntot,2 µ<br />

nwall,2 = ! eq,2A<br />

=<br />

" K! maxA %<br />

#<br />

$ V + K! maxA &<br />

' ntot,2 (58)<br />

= ! 1+ ! ( )nin (59)<br />

Then, at the n-th fill we have<br />

ntot,n = nwall, n!1 + nin = 1+ ! + ! 2 +... + ! n–1<br />

( )nin (60)<br />

and<br />

nwall,n = ! + ! 2 +... + ! n–1<br />

( ) · nin (61)<br />

Considering the properties of geometric series<br />

n wall,N<br />

n in<br />

N –1<br />

!<br />

i=0<br />

= ! 1"! N<br />

= = ! ! i<br />

( )<br />

1"!<br />

As illustrated in Figure 10, we have an additive filling for the values of α close to unity.<br />

(62)<br />

16

n wall / n in<br />

15<br />

10<br />

5<br />

0<br />

0<br />

5<br />

! = 0.99<br />

10<br />

N<br />

Fig. 10. Iterative filling<br />

! = 0.9<br />

15<br />

! = 0.8<br />

! = 0.7<br />

The advantage of the stop-flow method is to guarantee a homogeneous coating of the wall.<br />

Exercise: With previous parameters, calculate how many fills are required to coat a<br />

microchannel with 100’000 antigens and estimate the time required, the sample volume<br />

consumption and the number of analyte molecules wasted.<br />

5.2 Iterative stop-flow with kinetic control<br />

To estimate the kinetics of adsorption in a microsystem, we can write<br />

dn wall<br />

n s dt<br />

( )<br />

V<br />

" nin ! nwall ! n0 % "<br />

= kon #<br />

$<br />

&<br />

'<br />

#<br />

$<br />

n s ! n wall<br />

n s<br />

%<br />

&<br />

' ! k "<br />

off<br />

#<br />

$<br />

where n s is the total number of sites available on the walls of the microsystem, and n0 the<br />

number of molecules adsorbed from the previous step. Implicitly, we assume that the bulk<br />

concentration is constant, i.e. we neglect any mass transport contribution. We can re-write this<br />

differential equation as<br />

dt + kon nin + ns + n !<br />

0<br />

"<br />

# V<br />

dn wall<br />

which gives that<br />

( )<br />

nwall = n0 exp ! k ( " on nin + ns + n0 *<br />

#<br />

$<br />

) V<br />

n wall<br />

n s<br />

$<br />

+ <strong>koff</strong> %<br />

& nwall = kon nin + n0 V<br />

( )<br />

( )n s<br />

kon nin + n0 +<br />

V k " on nin + ns + n0 #<br />

$ V<br />

( )<br />

%<br />

+ <strong>koff</strong> &<br />

' t<br />

+<br />

-<br />

,<br />

20<br />

%<br />

&<br />

'<br />

( )n s<br />

( )<br />

1! exp !<br />

%<br />

+ <strong>koff</strong> &<br />

'<br />

k ( ( " on nin + ns + n0 * *<br />

#<br />

$<br />

) * ) V<br />

We can re-arrange this equation introducing the geometric factor ! to read<br />

%<br />

+ <strong>koff</strong> &<br />

' t<br />

+ +<br />

--<br />

, , -<br />

(63)<br />

(64)<br />

(65)<br />

17

( )<br />

nwall = n0 exp ! k ( " on nin + ns + n0 *<br />

#<br />

$<br />

) V<br />

nin + n0 +<br />

1+! + K! cin + c0 %<br />

+ <strong>koff</strong> &<br />

' t<br />

+<br />

-<br />

,<br />

( ) 1! exp ! k ( ( " on ( nin + ns + n0 )<br />

* *<br />

#<br />

$ V<br />

) *<br />

)<br />

%<br />

+ <strong>koff</strong> &<br />

' t<br />

+ +<br />

--<br />

, , -<br />

The adsorption time constant in a microsystem τ µ can be compared to that of a planar surface in<br />

a large volume as when n in is much greater than n s the two expressions converge.<br />

! µ =<br />

1<br />

( )<br />

V<br />

k on n in + n s + n 0<br />

+ k off<br />

=<br />

t d<br />

( ) =<br />

1+! !1 + K c in + c 0<br />

If we still define ψ as equal to Kc in , then when ψ

progressively along the channel. If the binding kinetics is slow, the coating will be more<br />

homogeneous but it is important not to flow to fast, not too waste too many target species.<br />

As developed in Annexe 2, under pure diffusion control the diffusion layer thickness in a flow<br />

channel varies with the flow rate according to<br />

! =<br />

∫<br />

l<br />

3<br />

0<br />

3a 2 Dx<br />

dx<br />

!<br />

0<br />

l<br />

∫ dx<br />

=<br />

∫<br />

l<br />

3<br />

0<br />

0.759Dhx<br />

dx<br />

< v ><br />

l<br />

∫ dx<br />

0<br />

=<br />

3<br />

4<br />

0.759Dh<br />

< v ><br />

l<br />

3 l 4/3<br />

The flux of the target species to the wall of a microchannel of length l, of width L, of half height<br />

h where the average liquid velocity is is expressed by<br />

J = 0.8131 c b LD 2/3 l 2/3 < v > 1/3 h !1/3 (73)<br />

Please fill the following table and comment<br />

Linear speed<br />

cm/s<br />

0.01<br />

0.1<br />

1<br />

10<br />

Flow rate<br />

nL/min<br />

δ/μm<br />

nadsorbed<br />

during 1 min<br />

Which flow rate is required to obtain a homogeneous coating along the channel?<br />

(72)<br />

nin<br />

during 1 min<br />

Compared how long it would take to immobilize 100’000 target species under pure kinetic<br />

control and pure diffusion control.<br />

5.4 How to fill a microchannel?<br />

What is the best way to coat a microchannel, with continuous flow or by iterative filling?<br />

19

6. Adsorption-diffusion on a spherical substrate<br />

Nowadays, most immunoassays take place on magnetic beads as illustrated in Figure 11.<br />

Fig. 11. Immunoassay on a magnetic bead<br />

An interesting property of spherical diffusion is to provide a finite diffusion layer thickness. This<br />

property is used in electrochemistry with microelectrodes that can generate steady-state currents<br />

in the absence of any hydrodynamics.<br />

The diffusion layer thickness is equal to the radius R of the substrate.<br />

Exercise : Please demonstrate<br />

For ψ >1, we can use eq.(29), which shows that the surface concentration increases linearly with<br />

time<br />

!(t) =<br />

konc bulk ! max<br />

1+ kon ! maxR "<br />

%<br />

$<br />

'<br />

$<br />

'<br />

t =<br />

#<br />

$<br />

D &<br />

'<br />

" ! eq % t<br />

#<br />

$ 1+ Da&<br />

'<br />

The smaller the beads, the less important the diffusion. It is then only controlled by the kinetics.<br />

For ψ

7. ELISA assay (from www.interferonsource.com)<br />

“Enzyme Linked Immuno-Sorbent Assay (ELISA) is a powerful technique for detection and<br />

quantitation of biological substances such as proteins, peptides, antibodies, and hormones. By<br />

combining the specificity of antibodies with the sensitivity of simple enzyme assay, ELISA can<br />

provide a quick and useful measurement of the concentration of an unknown antigen or<br />

antibody. Currently, there are three major types of ELISA assays commonly used by researchers.<br />

They are: indirect ELISA, typically used for screening antibodies; sandwich ELISA (or antigen<br />

capture), for analysis of antigen present; and competitive ELISA, for antigen specificity”.<br />

Figure 14. Elisa scheme http://www.interferonsource.com/New_InterferonSource/ELISA/ELISA_Description.html,<br />

TetraMethylBenzidine for oxidation by HRP<br />

“The "sandwich" technique is so called because the antigen being assayed is held between two<br />

different antibodies. In this method:<br />

1. Plate is coated with a capture antibody.<br />

2. Sample is then added, and antigen present binds to capture antibody.<br />

3. The detecting antibody is then added and binds to a different region (epitope) of the<br />

antigen.<br />

4. Enzyme linked secondary antibody is added and binds to the detecting antibody.<br />

5. The substrate is then added and the reaction between the substrate and the enzyme<br />

product can be monitored optically or electrochemically.<br />

6. The signal generated is directly proportional to the amount of antibody bound antigen.<br />

Optimizing an ELISA assay requires the careful selection of antibodies and enzyme-substrate<br />

reporting system. Once optimized, sandwich ELISA technique is fast and accurate. If a purified<br />

antigen standard is available, this method can be used to detect the presence and to determine<br />

the quantity of antigen in an unknown sample. The sensitivity of the sandwich ELISA is<br />

dependent on 3 factors:<br />

a) The number of molecules of the first antibody that are bound to the solid phase,<br />

namely, the microtiter plate.<br />

b) The avidity of the antibodies (both capture and detection) for the antigen<br />

c) The specific activity of the detection antibody that is in part dependent on the number<br />

and type of labelled moieties it contains. It is important to note that while an ELISA assay is a<br />

useful tool to detect the presence and the quantity of an antigen in the sample, it does not<br />

21

provide information concerning the biological activity of the sample. ELISAs are not generally<br />

used to discriminate active or non-active forms of a protein. It may also detect degraded proteins<br />

that have intact epitopes”.<br />

8. Protein array (from Arrait.com)<br />

“Antibody, Antigen, Peptide and other Protein Microarrays Custom Made to Order. Antibody<br />

microarrays to Cancer, Apoptosis, Growth Factors, Cytokines, Receptors and More... Users can<br />

to assay thousands of specific proteins with the ArrayIt Protein Microarrays. A wide variety of<br />

proteins representing a range of biological functions are detectable. ArrayIt microarrays allow<br />

users to measure differences in protein abundance using a two-color fluorescent labeling<br />

technique that can be provided with the microarrays. “Sandwich” detection schemes can also be<br />

implemented, please discuss your application goals with us. Detection is typically fluorescentbased<br />

using microarray scanners, but microarrays for other detection platforms can be<br />

provided. The protocols are simple, and the detection limits are extremely high.<br />

Figure 15. Protein array scheme<br />

http://www.arrayit.com/Products/Microarrays/<br />

Figure 15. Two color antibody microarray. Compare two biological samples to measure the absolute and relative<br />

differences in protein expression. This procedure is fluorescence-based and compatible with all current microarray<br />

scanners. Extracted proteins are directly labelled (kit provided) and analysed. The covalently immobilized<br />

antibodies capture fluorescently labelled antigens during the reaction step. Normal and cancerous cells can be<br />

compared. The raw data provide a measure of proteins from samples A & B.<br />

22

9. Redox detection in a microchannel<br />

Most immunoassays use an optical detection method based either on colorimetry, fluorescence<br />

or nowadays more and more chemiluminescence. In ELISA assays, an enzyme reaction takes<br />

place that produce often by cleavage an optical probe.<br />

Fig 16 : Gravicell from DiagnoSwiss SA<br />

The Michaelis-Menten equation for an enzyme reaction is rarely expressed in its explicit form<br />

that gives the product concentration as a function of time<br />

–[P] + KM ln [S ! 0] – [P] $<br />

#<br />

" [S<br />

&<br />

0] %<br />

= ' vmt (76)<br />

At short times, we can linearize this equation<br />

–[P] ! K M<br />

[P]<br />

[S 0 ] = ! v m t<br />

to obtain<br />

vmt [P]=<br />

1+ KM / [S0 ]<br />

(78)<br />

In the case of excess substrate concentration, this equation reduces to<br />

[P]=v mt (79)<br />

In the case of immune-assays with electrochemical detection, the enzyme reaction produces a<br />

redox active probe. In the example below, alkali phosphatase is used to cleave paraaminophenolphosphate<br />

(PAPP) to produce para-aminophenol (PAP) that can be oxidized to<br />

quinone-imine. By amperometry, the current is directly proportional to the PAP concentration<br />

(77)<br />

23

NH2<br />

O<br />

PO 3 2-<br />

ALP,<br />

H2O<br />

pH = 9<br />

NH 2<br />

OH<br />

PAPP AP<br />

+ HPO 4 2-<br />

NH 2<br />

OH<br />

2e -<br />

2H +<br />

NH<br />

O<br />

AP QI<br />

I [A]<br />

8.0E-09<br />

7.0E-09<br />

6.0E-09<br />

5.0E-09<br />

4.0E-09<br />

3.0E-09<br />

2.0E-09<br />

1.0E-09<br />

2 pM<br />

1 pM<br />

0.0E+00<br />

0 pM<br />

0<br />

-1.0E-09<br />

200 400 600 800 1000 1200 1400 1600<br />

Time [s]<br />

Fig 17 : Amperometric detection with PAPP, and PAP oxidation<br />

Ag Concentration<br />

In the case of an oxidation of microdisc electrode, the current is equal to 4nFDcr, where n is the<br />

number of electrons exchanged, F is the Faraday constant, D the diffusion coefficient of the<br />

redox probe, c its concentration and r the radius of the microdisc electrode.<br />

Exercise : Assume a Michaelis-Menten rate law, and calculate the number of PAP molecules<br />

produced as a function of time. Calculate the current one would get on a 25 µm Ø gold disc<br />

microelectrodes. How many electrodes can one fit in the microchannel?<br />

In the literature, we can find k2= 50 s –1<br />

10 pM<br />

24

Annexe 1: ψ

c(x, s) = cbulk<br />

s<br />

!<br />

c bulk<br />

# 1<br />

+<br />

$<br />

% K" max<br />

s &<br />

D '<br />

(<br />

1<br />

sD exp!<br />

In this way, the transform of the concentration at the surface is<br />

c(0, s) = cbulk<br />

s<br />

Knowing the following inverse transform<br />

we have<br />

with<br />

or<br />

!<br />

{ } =<br />

L exp(u 2 t)erfc(u t )<br />

c bulk<br />

# D &<br />

s + s<br />

$<br />

% K" max '<br />

(<br />

1<br />

s s + u<br />

c surf (t) = c bulk 1! exp(a 2 "<br />

#<br />

Dt)erfc(a Dt ) $<br />

%<br />

a =<br />

1<br />

K! max<br />

!(t) = ! eq 1" exp(a 2 #<br />

$<br />

Dt)erfc(a Dt ) %<br />

&<br />

s<br />

D x<br />

A1.9<br />

A1.10<br />

( ) A1.11<br />

A1.12<br />

A1.13<br />

A1.14<br />

It is important to realise that the term in brackets depends only on the adimensional term u =<br />

a 2 Dt as shown below, which in terms depends only on the physical parameters K, Γ max and D,<br />

but not on the bulk concentration. The latter affects only Γ eq .<br />

Fig.8. Illustration of equation Error! Reference source not found.<br />

The transform of the flux using eq.(A1.4) is<br />

"<br />

J (s) = ! D<br />

#<br />

$<br />

!c(x, s)<br />

! x<br />

%<br />

&<br />

'<br />

x=0<br />

=<br />

c D<br />

( a D + s)<br />

A1.15<br />

26

which gives<br />

J(t) = c D 1<br />

!t ! a D expa2 "<br />

Dt %<br />

$<br />

erfc(a Dt ) '<br />

#<br />

&<br />

This expression of the flux can be compared to the Cottrell equation in chronoamperometry<br />

JCottrell(t) = c D 1 ! $<br />

#<br />

" !t<br />

&<br />

%<br />

A1.16<br />

A1.17<br />

We can therefore see that for small values of a D , i.e. large K values or for a large specific<br />

surface area providing a large Γ max or even for small molecules with a small diffusion<br />

coefficient, the Cottrell equation is a good approximation.<br />

Exercise: Derive the equivalent of the Cottrell equation by the perturbation method of a steadystate<br />

flux.<br />

27

Annexe 2: Laminar flow. The Grätz problem<br />

We shall consider here a solution flowing parallel to two plane onto which molecules are<br />

adsorbed on a section of length l as shown in Figure 13. The problem is analogous to the current<br />

obtained in a band electrode in a flow channel.<br />

The equation of flux conservation is given by<br />

!c<br />

!t<br />

Fig. 13. Adsorption in a flow channel<br />

= " divJ = D# 2 c " v·gradc A2.1<br />

In steady state, for a 2D system where the x axis is parallel to the electrode and the y axis<br />

perpendicular to it, we have only<br />

v x<br />

!c<br />

!x + v !c<br />

y<br />

!y = D !2c !y 2 + !2c !x 2<br />

" %<br />

$ '<br />

# &<br />

( D !2c !y 2<br />

A2.2<br />

by neglecting the longitudinal diffusion. The continuity equation for an incompressible fluid is<br />

classically given by<br />

!vx !x + !vy !y<br />

= div(!v) = 0 A2.3<br />

We can solve this equation by doing a series development on y, to obtain<br />

and<br />

with<br />

vx = vx (y = 0) + y !v " x %<br />

#<br />

$<br />

!y &<br />

vy = vy(y = 0) + y !v " y %<br />

#<br />

$<br />

!y &<br />

= 1 2 y2 !<br />

"<br />

!y #<br />

$<br />

!v y<br />

!y<br />

= ( 1 2 y2 ! "<br />

!x #<br />

$<br />

%<br />

&<br />

'<br />

y=0<br />

!v x<br />

!y<br />

%<br />

&<br />

' y=0<br />

+... = y!(x) A2.4<br />

"<br />

' +<br />

y=0<br />

1 2 y2 !2vy !y 2 $<br />

#<br />

%<br />

'<br />

&<br />

+... = ( 1 2 y2 ! "<br />

!y #<br />

$<br />

y=0<br />

!v x<br />

!x<br />

+...<br />

%<br />

&<br />

' y=0<br />

' +... = (<br />

y=0<br />

1 2 y2 ! '(x) +...<br />

+...<br />

A2.5<br />

28

and since<br />

!(x) =<br />

"<br />

#<br />

$<br />

!v y<br />

!y<br />

assuming that<br />

%<br />

&<br />

'<br />

y=0<br />

"<br />

#<br />

$<br />

!v x<br />

!y<br />

%<br />

&<br />

' y=0<br />

= ( !v " x %<br />

#<br />

$<br />

!x &<br />

'<br />

y=0<br />

A2.6<br />

= ( ( y! '(x) ) = 0 A2.7<br />

y=0<br />

v x (y = 0) = v y (y = 0) = 0 A2.8<br />

The flux conservation equation (1.90) becomes<br />

y!(x) !c<br />

!x " y2 ! '(x) !c<br />

2 !y = D !2c !y 2<br />

If the flow is parallel to the wall such that v y is zero, then equation (1.98) reduces to<br />

y!(x) !c<br />

!x = D !2 c<br />

!y 2<br />

A2.9<br />

A2.10<br />

For a Poiseuille flow profile between two planes located at –h and h, the velocity profile is<br />

given by<br />

"<br />

$<br />

#<br />

v x = v max 1!<br />

2<br />

Y<br />

h 2<br />

%<br />

'<br />

&<br />

= 3 < v ><br />

2<br />

2<br />

Y<br />

1!<br />

h 2<br />

" %<br />

$ '<br />

# &<br />

with Y = y ! h , and then β(x) is constant and equal to 3/h.<br />

Equation (1.99) can then be written<br />

D !2 c<br />

!y 2<br />

= 3 < v ><br />

h<br />

Fig. 14. Diffusion layer thickness in flow channels<br />

y !c<br />

!x = 2vmax y<br />

h<br />

!c<br />

!x<br />

A2.11<br />

A2.12<br />

29

Diffusion layer thickness: Approximate solution<br />

To solve equation (1.99), we can consider the thickness of the diffusion layer δ (x) as illustrated<br />

above, and linearize the gradients and write<br />

y! !c<br />

!x<br />

!c dy<br />

= y!<br />

!y dx<br />

#c dy<br />

" y!<br />

#y dx<br />

#c d"<br />

= "!<br />

" dx<br />

with y = ! (x) and !c = c b " c( x = 0).<br />

Similarly, we have<br />

D !2 c<br />

!y 2<br />

" D ! #c<br />

!y #y<br />

= D #c<br />

! 2<br />

With these simplifications, eq.(1.99) reduces to<br />

! d"<br />

dx<br />

= D<br />

" 2<br />

that we can integrate to have<br />

= !#c d"<br />

dx<br />

A2.13<br />

A2.14<br />

A2.15<br />

! 3 = 3Dx<br />

" A2.16<br />

The limiting current on the band electrode is then for the case illustrated in figure 13<br />

I = nFDLc b l dx<br />

0 ! (x)<br />

! = nFDLc b l<br />

0<br />

dx<br />

3<br />

By substituting the value of β equal to 3/h.<br />

or<br />

3Dx<br />

"<br />

= 3 –1/3 nFc b LD 2/3 " 1/3 l 2/3<br />

! A2.17<br />

I = nFc b LD 2/3 l 2/3 < v > 1/3 h !1/3 A2.18<br />

I =<br />

! 2$<br />

"<br />

#<br />

3%<br />

&<br />

1/3<br />

nFc b L vmaxD 2 l 2 !<br />

#<br />

"<br />

h<br />

$<br />

&<br />

%<br />

1/3<br />

!<br />

#<br />

"<br />

= 0.8735nFc b L v maxD 2 l 2<br />

We can write this equation as a function of the volumetric flow rate FV given by<br />

h<br />

$<br />

&<br />

%<br />

1/3<br />

A2.19<br />

F V = 2 < v > hd A2.20<br />

and obtain an equation.<br />

"<br />

$<br />

#<br />

I = 2 !1/3 nFc b L D2 l 2 F V<br />

h 2 d<br />

%<br />

'<br />

&<br />

1/3<br />

"<br />

$<br />

#<br />

= 0.7937 nFc b L D2 l 2 F V<br />

Diffusion layer thickness: Exact solution<br />

We can solve analytically eq.(1.99), by using a similarity variable and write<br />

! y $<br />

c(x, y) = F<br />

"<br />

#<br />

! (x) %<br />

&<br />

The boundary conditions are<br />

h 2 d<br />

%<br />

'<br />

&<br />

1/3<br />

A2.21<br />

= F ( ! ) A2.22<br />

30

or<br />

c(0, y) = c(x, !) = c<br />

c(x, 0) = 0<br />

! y $<br />

c(0, y) = F<br />

"<br />

#<br />

! (0) %<br />

&<br />

c(x, 0) = F( 0)<br />

= 0<br />

The partial derivatives are then<br />

!c<br />

!x<br />

!c<br />

!y<br />

! 2 c<br />

!y 2<br />

!! dF<br />

=<br />

!x d!<br />

!! dF<br />

=<br />

!y d!<br />

=<br />

! " !! dF %<br />

!y #<br />

$<br />

!y d! &<br />

'<br />

= F( ')<br />

= c<br />

y<br />

= "<br />

" 2<br />

# d" &<br />

$<br />

%<br />

dx '<br />

( dF<br />

d!<br />

1 dF<br />

=<br />

" d!<br />

1 !<br />

=<br />

" !y<br />

" dF %<br />

#<br />

$<br />

d! &<br />

'<br />

! d" dF<br />

= "<br />

" dx d!<br />

The two variables differential equation (1.99) becomes<br />

d 2 F<br />

d! 2<br />

! $<br />

#<br />

" %<br />

!<br />

& +!2 "# 2<br />

#<br />

"<br />

D<br />

d# $<br />

dx<br />

&<br />

%<br />

dF<br />

d!<br />

1 !! d " dF %<br />

=<br />

" !y d! #<br />

$<br />

d! &<br />

' =<br />

1<br />

" 2<br />

d 2 F<br />

d! 2<br />

" %<br />

$ '<br />

# &<br />

A2.23<br />

A2.24<br />

A2.25<br />

A2.26<br />

A2.27<br />

= 0 A2.28<br />

The term in brackets must be constant with respect to x and we can write<br />

!" 2 ! d" $<br />

#<br />

" D dx<br />

&<br />

%<br />

= a2 A2.29<br />

We should therefore solve the following equation<br />

d 2 F<br />

d! 2<br />

! $<br />

# &<br />

" %<br />

+ a2 ! 2 dF<br />

d!<br />

A solution of this equation is<br />

since<br />

and<br />

= 0 A2.30<br />

F(!) = c1 exp ! a2<br />

3 z3<br />

" %<br />

$ '<br />

# &<br />

dz + c !<br />

( 0<br />

2<br />

A2.31<br />

F '(!) = c1 exp ! a2<br />

3 !3<br />

" %<br />

$ '<br />

# &<br />

F ''(!) = ! c1a 2 ! 2 exp ! a2<br />

3 !3<br />

" %<br />

$ '<br />

# &<br />

A2.32<br />

A2.33<br />

The integration constants of equation (1.120) must satisfy the boundary conditions (1.113), such<br />

that<br />

31

and<br />

c 2 = 0 A2.34<br />

c1 = c / exp ! a2<br />

3 z3<br />

" %<br />

$ '<br />

# &<br />

dz<br />

(<br />

) A2.35<br />

0<br />

Equation (1.120) becomes<br />

F(!) = c<br />

(<br />

(<br />

!<br />

0<br />

)<br />

0<br />

exp ! a2 "<br />

$<br />

#<br />

exp ! a2 "<br />

$<br />

#<br />

3 z3<br />

3 z3<br />

%<br />

'<br />

&<br />

dz<br />

%<br />

'<br />

&<br />

dz<br />

The normalising integral is finite and equal to<br />

exp ! a2<br />

3 z3<br />

" %<br />

$ '<br />

# &<br />

dz<br />

(<br />

) =<br />

0<br />

2 3<br />

9<br />

5/6<br />

a 2/3 * 2 " %<br />

#<br />

$<br />

3&<br />

'<br />

The concentration profiles are therefore given by<br />

! y $<br />

c(x, y) = F<br />

"<br />

#<br />

! (x) %<br />

&<br />

= F(") =<br />

To calculate the thickness of the diffusion layer, we can write<br />

and<br />

" !c%<br />

#<br />

$<br />

!y&<br />

'<br />

y=0<br />

! dF $<br />

"<br />

#<br />

d! %<br />

& !=0<br />

= !! " dF %<br />

!y #<br />

$<br />

d! &<br />

'<br />

!=0<br />

=<br />

3 1/6 a 2/3 ' 2 ! $<br />

"<br />

#<br />

3%<br />

& c b<br />

2<br />

= 1 " dF %<br />

" #<br />

$<br />

d! &<br />

'<br />

!=0<br />

This equation allows us to calculate a= 0.87116.<br />

By integration of eq.(1.118), we have<br />

! =<br />

∫<br />

l<br />

3<br />

0<br />

3a 2 Dx<br />

dx<br />

!<br />

0<br />

l<br />

∫ dx<br />

=<br />

A2.36<br />

A2.37<br />

3 1/6 a 2/3 c' 2 ! $<br />

"<br />

#<br />

3%<br />

&<br />

exp (<br />

2<br />

a2<br />

3 z3<br />

! $<br />

# &<br />

" %<br />

dz<br />

"<br />

) A2.38<br />

0<br />

= (c<br />

"<br />

= cb<br />

"<br />

A2.39<br />

= 0.8131 a 2/3 c b = c b A2.40<br />

∫<br />

l<br />

3<br />

0<br />

0.759Dhx<br />

dx<br />

< v ><br />

l<br />

∫ dx<br />

0<br />

=<br />

3<br />

4<br />

0.759Dh<br />

< v ><br />

l<br />

3 l 4/3<br />

The limiting current on the band electrode is then for the case illustrated in figure 13<br />

I = nFDLc b l dx<br />

0 ! (x)<br />

! = nFDLc b l<br />

!<br />

0<br />

dx<br />

3<br />

3a 2 Dx<br />

"<br />

= 3 –1/3 a "2/3 nFc b LD 2/3 " 1/3 l 2/3<br />

A2.41<br />

32

By substituting the value of β equal to 3/h.<br />

A2.42<br />

I = a !2/3 nFc b LD 2/3 l 2/3 < v > 1/3 h !1/3 = 0.8131nFc b LD 2/3 l 2/3 < v > 1/3 h !1/3 A2.43<br />

We can write this equation as a function of the volumetric flow rate FV given by eq.(1.109) and<br />

obtain an equation similar to equation (7.50) from the book “ Analytical & Physical<br />

electrochemistry”.<br />

"<br />

$<br />

#<br />

I = 2 !1/3 a !2/3 nFc b L D2 l 2 F V<br />

h 2 d<br />

As a function of the maximum velocity, we have<br />

"<br />

#<br />

$<br />

I = a !2/3 nFc b LD 2/3 l 2/3 2v max<br />

"<br />

$<br />

#<br />

= 1.0744nFc b L v maxD 2 l 2<br />

h<br />

3<br />

%<br />

'<br />

&<br />

%<br />

'<br />

&<br />

1/3<br />

1/3<br />

%<br />

&<br />

'<br />

"<br />

$<br />

#<br />

= 0.6454 nFc b L D2 l 2 F V<br />

1/3<br />

h !1/3 =<br />

" 2%<br />

#<br />

$<br />

3&<br />

'<br />

h 2 d<br />

%<br />

'<br />

&<br />

1/3<br />

1/3<br />

a !2/3 nFc b L vmaxD 2 l 2 "<br />

$<br />

#<br />

h<br />

%<br />

'<br />

&<br />

A2.44<br />

1/3<br />

A2.45<br />

33