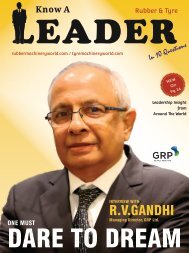

Interview With A Tyre Leader_PK Mohamed_Apollo Tyres

Mohamed is a soft-spoken and an accomplished tyre technologist with 5 decades of experience in the field of Tyre Technology and Manufacturing. When you read this passionate interview of his journey from a college lecturer to a well-known tyre technologist, you will observe struggles, challenges, achievements, dedication and loyalty; and importance of continuous education - a complete package of learning and leadership wisdom for new generation of aspiring professionals in tyre industry.

Mohamed is a soft-spoken and an accomplished tyre technologist with 5 decades of experience in the field of Tyre Technology and Manufacturing. When you read this passionate interview of his journey from a college lecturer to a well-known tyre technologist, you will observe struggles, challenges, achievements, dedication and loyalty; and importance of continuous education - a complete package of learning and leadership wisdom for new generation of aspiring professionals in tyre industry.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

| LEADER - INTERVIEW |<br />

24<br />

PW: How do you envision tyre building<br />

shaping up in the next 10 years? As a<br />

technologist, what are your expectations<br />

from a machinery manufacturer/supplier<br />

to achieve this vision?<br />

<strong>PK</strong>M: As we all know, the tyre building<br />

machine is one piece of equipment which is<br />

used by the tyre engineer to convert tyre<br />

layout into actual green tyre. This is a very<br />

critical process. The tyre technologist<br />

expects that this process to happen with<br />

bare minimum movements of components<br />

placed in the respective position of tyres. If<br />

changes happen as against his expectation,<br />

the performance of the tyre will have a<br />

very adverse impact. Even though tyre<br />

building equipment manufacturers have<br />

done enough development in the areas<br />

of cycle time reduction, application of<br />

component, its accuracy and<br />

repeatability, there are several areas<br />

which need attention to improve the<br />

uniformity, cycle time and accuracy of<br />

component placement. The cycle time of<br />

carcass drum is 80 to 90% more than<br />

shaping and B&T drums which<br />

determines the overall productivity of<br />

“There are several areas (in<br />

<strong>Tyre</strong> Building Machinery)<br />

which need attention to<br />

improve the uniformity,<br />

cycle time and accuracy of<br />

component placement.”<br />

Inside <strong>Apollo</strong> Chennai Plant<br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016