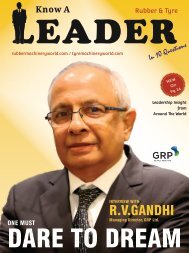

Interview With A Tyre Leader_PK Mohamed_Apollo Tyres

Mohamed is a soft-spoken and an accomplished tyre technologist with 5 decades of experience in the field of Tyre Technology and Manufacturing. When you read this passionate interview of his journey from a college lecturer to a well-known tyre technologist, you will observe struggles, challenges, achievements, dedication and loyalty; and importance of continuous education - a complete package of learning and leadership wisdom for new generation of aspiring professionals in tyre industry.

Mohamed is a soft-spoken and an accomplished tyre technologist with 5 decades of experience in the field of Tyre Technology and Manufacturing. When you read this passionate interview of his journey from a college lecturer to a well-known tyre technologist, you will observe struggles, challenges, achievements, dedication and loyalty; and importance of continuous education - a complete package of learning and leadership wisdom for new generation of aspiring professionals in tyre industry.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

| LEADER - INTERVIEW |<br />

30<br />

PW: <strong>Tyre</strong> design is a fascinating topic<br />

though few people really understand<br />

the differences in design between<br />

brands. How has the design of tyres<br />

really changed during as you witnessed<br />

it? What were the key factors driving this<br />

change?<br />

<strong>PK</strong>M: <strong>Tyre</strong> technology is an amalgamation<br />

of science and engineering. It is dominated<br />

by physics, chemistry, mechanical and<br />

chemical engineering. <strong>Tyre</strong> is a product<br />

which is a unique combination of steel and<br />

rubber. Steel is responsible to withstand all<br />

stresses experienced by the tyre and rubber<br />

is responsible for taking care of its strain.<br />

Such an intelligent sharing of stresses and<br />

strain is rarely seen in any other product<br />

other than a tyre. So it is a challenge for<br />

the tyre engineer to design a carcass of a<br />

tyre with minimal strain on material when<br />

the same is stressed by inflation, vehicle<br />

load or traction loads. This challenge<br />

further increases when it comes to the tread<br />

design. Tread is responsible not only for<br />

providing adequate traction, mileage, and<br />

water drainage but also need to cater to<br />

other performance requirement of rolling<br />

resistance and noise. It is noticed that,<br />

several new concepts such as Natural<br />

Inflated Profile (NIP) and Tension Controlled<br />

Optimized Theory (TCOT), have been tried<br />

by several companies but the tyre<br />

technologist is yet not very successful in<br />

creating a carcass which can withstand<br />

under inflated condition and provide the<br />

same performance. This still remains as a<br />

challenge. In the case of tread, several<br />

developments have taken place to enhance<br />

water drainage & traction improvement,<br />

reduction in foot print pressure & noise and<br />

improvement in aesthetics and aggressive<br />

looks. While the pattern design methodology<br />

followed by many companies generally<br />

follow same guidelines, significant<br />

deviations are seen recently to meet the new<br />

found challenges in meeting label values in<br />

RR, traction and noise. In depth<br />

understanding is required to make<br />

significant alterations in tried and tested<br />

“<strong>Tyre</strong> technology is an<br />

amalgamation of science and<br />

engineering. It is dominated by<br />

physics, chemistry, mechanical<br />

and chemical engineering. <strong>Tyre</strong><br />

is a product which is a unique<br />

combination of steel and<br />

rubber.”<br />

Know A <strong>Leader</strong> - Rubber & <strong>Tyre</strong> Machinery World | JAN 2016