HSE Annual Report 2010 (English) - WINTERSHALL

HSE Annual Report 2010 (English) - WINTERSHALL

HSE Annual Report 2010 (English) - WINTERSHALL

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

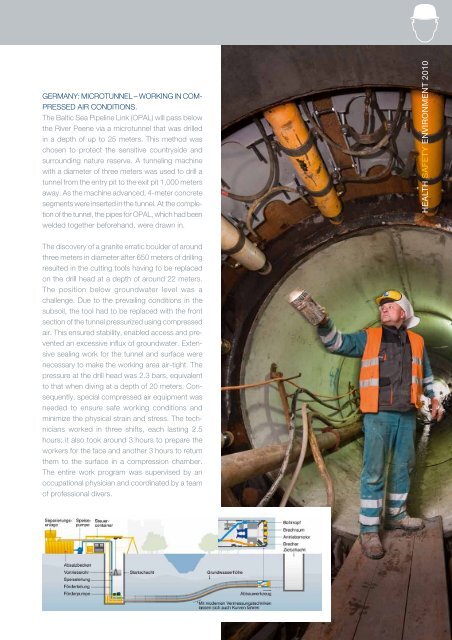

GERMANY: MICROTUNNEL – WORKING IN COM-<br />

PRESSED AIR CONDITIONS.<br />

The Baltic Sea Pipeline Link (OPAL) will pass below<br />

the River Peene via a microtunnel that was drilled<br />

in a depth of up to 25 meters. This method was<br />

chosen to protect the sensitive countryside and<br />

surrounding nature reserve. A tunneling machine<br />

with a diameter of three meters was used to drill a<br />

tunnel from the entry pit to the exit pit 1,000 meters<br />

away. As the machine advanced, 4-meter concrete<br />

segments were inserted in the tunnel. At the completion<br />

of the tunnel, the pipes for OPAL, which had been<br />

welded together beforehand, were drawn in.<br />

The discovery of a granite erratic boulder of around<br />

three meters in diameter after 650 meters of drilling<br />

resulted in the cutting tools having to be replaced<br />

on the drill head at a depth of around 22 meters.<br />

The position below groundwater level was a<br />

challenge. Due to the prevailing conditions in the<br />

subsoil, the tool had to be replaced with the front<br />

section of the tunnel pressurized using compressed<br />

air. This ensured stability, enabled access and prevented<br />

an excessive influx of groundwater. Extensive<br />

sealing work for the tunnel and surface were<br />

necessary to make the working area air-tight. The<br />

pressure at the drill head was 2.3 bars, equivalent<br />

to that when diving at a depth of 20 meters. Consequently,<br />

special compressed air equipment was<br />

needed to ensure safe working conditions and<br />

minimize the physical strain and stress. The technicians<br />

worked in three shifts, each lasting 2.5<br />

hours; it also took around 3 hours to prepare the<br />

workers for the face and another 3 hours to return<br />

them to the surface in a compression chamber.<br />

The entire work program was supervised by an<br />

occupational physician and coordinated by a team<br />

of professional divers.<br />

HEALTH SAFETY ENVIRONMENT <strong>2010</strong>