Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Cottonwood Holsteins Ltd<br />

Laingspring Dairy Ltd<br />

“The bottom line is that a robot is not magic, not the<br />

end all and be all,” he emphasizes. “It is a milk harvesting<br />

tool. Period! There must be a whole package of<br />

farm management to make money. The robotic system<br />

helps achieve that.”<br />

“...a robot is not magic,<br />

not the end all and be all”<br />

Other Herd Management Notes<br />

Cows are quiet, calm, enjoying a low stress environment<br />

where they are not herded to the holding area.<br />

According to Brent, they are at the max for two units.<br />

“There is no time for down time, but we are doing well<br />

at that level. More than 130 cows with two units would<br />

be difficult.” Milking frequency average is 2.5 and milking<br />

time is over 90% of the robots’ daily time. Idle time<br />

is 2 to 4%.<br />

“In a robotic milking set-up, I think there should be<br />

more comfort stalls than cows – about 2 to 3%. The cow<br />

looking for an open stall should not have to wander up<br />

and down the alley to find an empty stall.”<br />

Over-all health has improved. Disease costs are way<br />

down, about half of previous. Foot and leg health has<br />

greatly improved in the new facilities. The Bovi-Booster<br />

in the robot together with the installation of rubber<br />

mats in all alleys is the biggest factor for improved foot<br />

and leg health.<br />

A brother is the local veterinarian, who has used innovative<br />

procedures including DNA testing and successfully<br />

setting broken leg bones and other major<br />

surgical interventions.<br />

Interesting Stories<br />

In order to begin construction of the barn beginning<br />

in March when the frost was still deep in the ground,<br />

large trucks could drive on the frozen soil but could not<br />

pour concrete. So they purchased three hoppers of a<br />

Super-B of coal to spread along the footing’s layout.<br />

Straw was spread over top and set on fire. The coal<br />

burned for days, thawing the frost. The soil was hot, allowing<br />

for pouring concrete and construction in warm<br />

conditions while trucks could continue to drive on solid,<br />

frozen soil. The builders loved it.<br />

Brent has produced and sold small hay bales to the<br />

horse trade including export to Florida and Texas – one<br />

year 32 semi-truck loads. Horse owners in the southern<br />

US buy Canadian hay because of the blister beetle<br />

in their local hay that affects horses.<br />

“When my grandfather started shipping milk in 1916,<br />

the cans were hauled by horse and wagon to Giroux six<br />

miles away by 7:30 am, and then loaded on the train for<br />

transportation to the milk plant in Winnipeg. His original<br />

contract was for 160lb or two cans daily.”<br />

When Ray and Bertha took over the farm in 1980, they<br />

were milking 40 cows in a tie stall barn. By 2002 they<br />

milked 110 cows in a 113 stall tie stall barn and grew to<br />

160 as mentioned earlier. At that time, swapping cows<br />

in and out alone took an hour twice a day.<br />

Future<br />

“Our four to five year projection is to expand to four<br />

robots and maximize production,” says Tyrone.<br />

Ted points out, “The new Manitoba QPP [quota purchase<br />

policy – for buying quota], could slow down our<br />

plans if we have any infractions or our SCC or IBC<br />

counts exceed the various limits. Any single inhibitor<br />

infraction means no quota purchase opportunity for<br />

12 months. We must be diligent in all aspects of milk<br />

management.”<br />

Ray concludes, “The facility has met our expectations<br />

to date. It is significantly better in all respects to the<br />

old barn. And this is only the first two years. Our goal is<br />

300kg of quota to ultimately fill the barn. Also we have<br />

reached 300 animal units that require a farm manure<br />

management plan – not a major issue along-side CQM<br />

and the ProAction initiatives of Dairy Farmers of Canada.”<br />

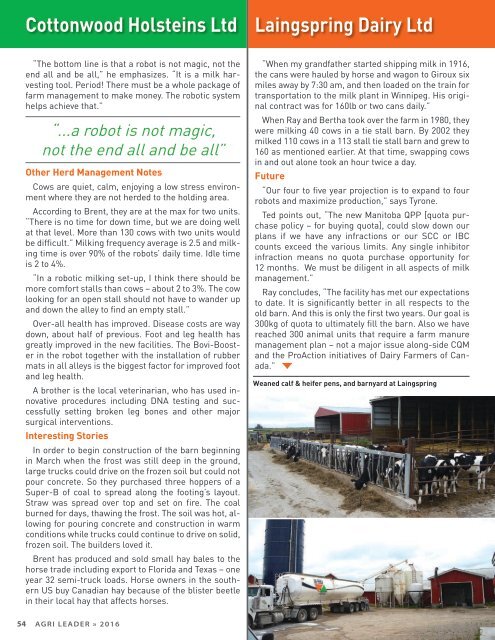

Weaned calf & heifer pens, and barnyard at Laingspring<br />

54 AGRI LEADER » 2016